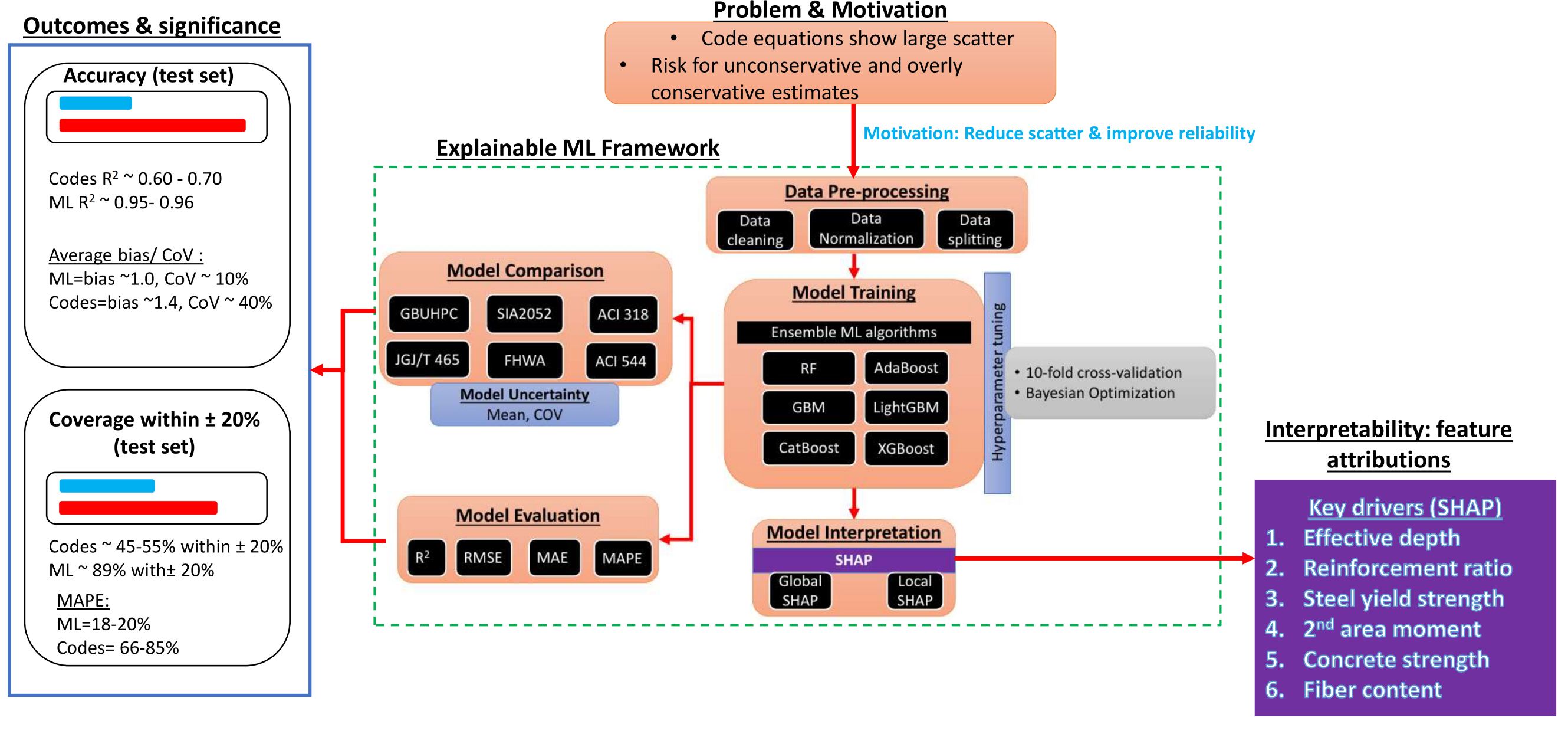

Existing code equations for predicting the bending capacity of ultra high performance fiber reinforced concrete (UHPFRC) beams often show large scatter, with coefficients of variation (CoV) exceeding 30 to 60 %, leading to both overly conservative and unconservative estimates. This study develops a novel and explainable machine learning (ML) framework for accurate bending capacity prediction, representing the first systematic benchmarking of advanced ensemble ML methods against international and national design codes. An updated database of 264 experimental UHPFRC beam tests was compiled from the literature and partitioned into training (70%), validation (15%), and testing (15%) subsets. Six ensemble algorithms were optimized using Bayesian hyperparameter tuning with 10 fold cross validation, namely Random Forest (RF), Gradient Boosting Machine (GBM), Light Gradient Boosting Machine (LightGBM), Adaptive Boosting (AdaBoost), Categorical Boosting (CatBoost), and Extreme Gradient Boosting (XGBoost). The best performing models, CatBoost and XGBoost, achieved excellent predictive accuracy on unseen test data (R2 ≈ 0.96 to 0.97, RMSE ≈ 15 to 18 kN·m, CoV ≈ 10%) with essentially no systematic bias. These results clearly outperform code equations (R2 ≈ 0.60–0.70, CoV ≈ 28–64%, and biases up to 40 %). Interpretability analysis using Shapley Additive Explanations (SHAP) confirmed that effective depth and reinforcement ratio are the dominant predictors of bending strength, followed by steel yield strength and section properties, while UHPC compressive strength and fiber parameters had relatively minor influence within the dataset range. The novelty of this study lies in presenting an integrated and interpretable ML framework that not only achieves superior predictive performance but also provides mechanistic insight into UHPFRC beam behavior. The proposed approach offers a reliable data driven complement to current design codes and has potential for practical adoption in structural engineering design and code development.

- Open Access

- Article

Intelligent Data Driven Ensemble Approaches for Bending Strength Prediction of Ultra-High Performance Concrete Beams

- Kennedy Silewu 1, *,

- Charles Kahanji 1,

- Lenganji Simwanda 2,

- Miroslav Sykora 2

Author Information

Received: 03 Aug 2025 | Revised: 29 Aug 2025 | Accepted: 03 Sep 2025 | Published: 09 Sep 2025

Abstract

Graphical Abstract

Keywords

UHPFRC beams | bending capacity | explainable AI | machine learning | ensemble models

References

- 1.

Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and numerical study on mechanical properties of ultra high per- formance concrete (uhpc). Constr. Build. Mater. 2017, 156, 402–411. https://doi.org/10.1016/j.conbuildmat.2017.08.170.

- 2.

Simwanda, L.; Babafemi, A.J.; Koker, N.D.; et al. Bayesian calibration and reliability analysis of ultra high-performance fibre reinforced concrete beams exposed to fire. Struct. Saf. 2023, 103, 102352. https://doi.org/10.1016/j.strusafe.2023.102352.

- 3.

Li, J.; Wu, Z.; Shi, C.; et al. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296. https://doi.org/10.1016/j.conbuildmat.2020.119296.

- 4.

Chu, H.; Zhang, Y.; Wang, F.; et al. Effect of graphene oxide on mechanical properties and durability of ultra-high- performance concrete prepared from recycled sand. Nanomaterials 2020, 10, 1718. https://doi.org/10.3390/nano10091718.

- 5.

Wang, D.; Shi, C.; Wu, Z.; et al. A review on ultra high performance concrete: Part ii. hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. https://doi.org/10.1016/j.conbuildmat.2015.08.095.

- 6.

Kahanji, C.; Ali, F.; Nadjai, A., Structural performance of ultra-high-performance fiber-reinforced concrete beams. Struct. Concr. 2017, 18, 249–258. https://doi.org/10.1002/suco.201600006.

- 7.

Meade, T.M.; Graybeal, B.A. Flexural response of lightly reinforced ultra-high performance concrete beams. In Proceedings of the 3rd International fib Congress and Exhibition Incorporating the PCI Annual Convention and Bridge Conference: Think Globally, Build Locally,Washington, DC, USA, 29 May–2 June 2010.

- 8.

Ullah, R.; Yuan, Q.; Ahmad, J.; et al. Ultra-high-performance concrete (uhpc): A state-of-the-art review. Materials 2022, 15 4131. https://doi.org/10.3390/ma15124131.

- 9.

Feng, J.; Shao, X.; Qiu, M.; et al. Reliability evaluation of flexural capacity design provision for uhpc beams reinforced with steel rebars/prestressing tendons. Eng. Struct. 2024, 300, 117160. https://doi.org/10.1016/j.engstruct.2023.117160.

- 10.

Carpinteri, A.; Corrado, M.; Mancini, G.; et al. Size-scale effects on plastic rotational capacity of reinforced concrete beams. ACI Struct. J. 2009, 106. https://doi.org/10.14359/51663190.

- 11.

Carpinteri, A.; Corrado, M. Nonlinear fracture mechanics investigation on the ductility of reinforced concrete beams. Rev. Ibracon Estruturas Mater. 2010, 3, 137–148. https://doi.org/10.1590/S1983-41952010000200002.

- 12.

Skarzyski, Ł.; Tejchman, J. Experimental investigations of fracture process using dic in plain and reinforced concrete beams under bending. Strain 2013, 49, 521–543. https://doi.org/10.1111/str.12064.

- 13.

Recupero, A.; Granata, M. Bending–shear interaction domains for externally prestressed concrete girders. Adv. Civ. Eng. 2013, 1–13. https://doi.org/10.1155/2013/580646.

- 14.

Zhurtov, A.; Khezhev, T.; Kokoev, M. An investigation of the stress-strain state of two-layer armocement structures on the power and temperature effects during a fire. Mater. Sci. Forum 2018, 931, 219–225. https://doi.org/10.4028/www.scientific.net/MSF.931.219.

- 15.

Zhou, H.; Li, Z.; Guo, E.; et al. Test study on size effect of flexural capacity of rc cantilever beams. Adv. Mater. Res. 2012, 446–449, 3160–3164. https://doi.org/10.4028/www.scientific.net/AMR.446-449.3160.

- 16.

Amin, M.N.; Iqbal, M.; Khan, K.; et al. Ensemble tree-based approach towards flexural strength prediction of frp reinforced concrete beams. Polymers 2022, 14, 1303. https://doi.org/10.3390/polym14071303.

- 17.

Wang, X.; Ma, X.; Chen, S. Uncertainty-aware fuzzy knowledge embedding method for generalized structural performance prediction. Comput.-Aided Civ. Infrastruct. Eng. 2025. https://doi.org/10.1111/mice.13457.

- 18.

Waqas, H.; Bahrami, A.; Sahil, M.; et al. Performance prediction of hybrid bamboo-reinforced concrete beams using gene expression programming for sustainable construction. Materials 2023, 16 6788. https://doi.org/10.3390/ma16206788.

- 19.

Chen, S.; Wang, J.Y. Flexural behaviour of rebar-reinforced ultra-high-performance concrete beams. Mag. Concr. Res. 2018, 70, 215–227. https://doi.org/10.1680/jmacr.17.00283.

- 20.

Huang, J.; He, Z.; Khan, M.B.E.; et al. Flexural behaviour and evaluation of ultra-high-performance fibre reinforced concrete beams cured at room temperature. Sci. Rep. 2021, 11, 19069. https://doi.org/10.1038/s41598-021-98502-x.

- 21.

Yang, I.H.; Joh, C.; Kim, B.S. Structural behavior of ultra high performance concrete beams subjected to bending. Eng. Struct. 2010, 32, 3478–3487. https://doi.org/10.1016/j.engstruct.2010.07.017.

- 22.

El-Helou, R.; Graybeal, B. Flexural behavior and design of ultrahigh-performance concrete beams. J. Struct. Eng. 2022, 148, 04022013. https://doi.org/10.1061/(asce)st.1943-541x.0003246.

- 23.

Feng, Z.; Ke, L. Flexural and cracking behaviors of reinforced uhpc beams with various reinforcement ratios and fiber contents. Eng. Struct. 2021, 245, 113266. https://doi.org/10.1016/j.engstruct.2021.113266.

- 24.

Fan, D.; Yu, R.; Shui, Z.; et al. A new design approach of steel fibre reinforced ultra-high performance concrete composites: Experiments and modeling, Cem. Concr. Compos. 2020, 110, 103597. https://doi.org/10.1016/j.cemconcomp.2020.103597

- 25.

Fan, D.; Yu, R.; Fu, S.; et al. Precise design and characteristics prediction of ultra-high performance concrete (uhpc) based on artificial intelligence techniques. Cem. Concr. Compos. 2021, 122, 104171.

- 26.

Fan, D.; Zhu, J.; Fan, M.; et al. Intelligent design and manufacturing of ultra-high performance concrete (uhpc)–a review. Constr. Build. Mater. 2023, 385 131495.

- 27.

Nguyen, H.; Vu, T.; Vo, T.; et al. Efficient machine learning models for prediction of concrete strengths. Constr. Build. Mater. 2021, 266 120950. https://doi.org/10.1016/j.conbuildmat.2020.120950.

- 28.

Feng, D.; Wang, W.; Mangalathu, S.; et al. Implementing ensemble learning methods to predict the shear strength of rc deep beams with/without web reinforcements. Eng. Struct. 2021, 235 111979. https://doi.org/10.1016/j.engstruct.2021.111979.

- 29.

Simwanda, L.; Sykora, M. Prediction of moment capacity of ultra-high-performance con-crete beams using explainable extreme gradient boosting ma-chine learning model. In Proceedings of the CEACM S4ML 2024 Conference, Prague, Czech Republic, 19–21 June 2024.

- 30.

Ye, M.; Li, L.; Yoo, D.-Y.; et al. Prediction of shear strength in uhpc beams using machine learning-based models and shap interpretation. Constr. Build. Mater. 2023, 408, 133752. https://doi.org/10.1016/j.conbuildmat.2023.133752.

- 31.

Mahmoud, A.A.; El-Sayed, A.A.; Aboraya, A.M.; et al. Synergizing machine learning and experimental analysis to predict post- heating compressive strength in waste concrete. Struct. Concr. 2025, 26, 2916–2950. https://doi.org/10.1002/suco.202400211.

- 32.

Zeyad, A.M.; Mahmoud, A.A.; El-Sayed, A.A.; et al. Compressive strength of nano concrete materials under elevated temperatures using machine learning. Sci. Rep. 2024, 14, 24246. https://doi.org/10.1038/s41598-024-73713-0.

- 33.

Solhmirzaei, R.; Salehi, H.; Kodur, V. Predicting flexural capacity of ultrahigh-performance concrete beams: Machine learning–based approach. J. Struct. Eng. 2022, 148, 1–13. https://doi.org/10.1061/(asce)st.1943-541x.0003320.

- 34.

Qin, S.; Li, J.; Song, R.; et al. Flexural capacity prediction of reinforced uhpc beams using an interpretable machine learning model. Struct. Eng. Int. 2024, 1–12.

- 35.

Qian, Y.; Sufian, M.; Hakamy, A.; et al. Application of machine learning algorithms to evaluate the influence of various parameters on the flexural strength of ultra-high-performance concrete. Front. Mater. 2023, 9, 1114510. https://doi.org/10.3389/fmats.2022.1114510.

- 36.

Ergen, F.; Katlav, M. Machine and deep learning-based prediction of flexural moment capacity of ultra-high performance concrete beams with/out steel fiber. Asian J. Civ. Eng. 2024, 25, 4541–4562. https://doi.org/10.1007/s42107-024-01064-2.

- 37.

Thai, H. Machine learning for structural engineering: A state-of-the-art review. Structures 2022, 38, 448–449.

- 38.

Amezquita-Sanchez, J.; Valtierra-Rodriguez, M.; Adeli, H. Machine learning applications in structural engineering. Stud. Syst. Decis. Control 2024, 547, 47–76. https://doi.org/10.1007/978-3-031-65976-83.

- 39.

Bunje, K.; Fehling, E., About shear force and punching shear resistance of structural elements of ultra high performance concrete. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 401–411.

- 40.

Strwald, S. Versuche zum Biegetragverhalten von UHPC mit kombinierter Bewehrung; Fachgebiet Massivbau, Fachbere- ich Bauingenieurwesen, Universitt Kassel: Kassel, Germany, 2011.

- 41.

Yang, I.H.; Joh, C.; Kim, B.S. Flexural strength of large-scale ultra high performance concrete prestressed t-beams. Can. J. Civ. Eng. 2011, 38, 1185–1195. https://doi.org/10.1139/l11-078.

- 42.

Bertram, G.; Hegger, J. Zum Verbund- und Querkrafttragverhalten von Spannbetonträgern aus Ultra-Hochfestem Beton; Technical Report; Lehrstuhl und Institut fr Massivbau, RWTH Aachen University: Aachen, Germany, 2012.

- 43.

Randl, N.; Simon, C.; Mészöly, T. Experimental investigations on UHP(FR)C beams with high strength reinforcement. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fibre-Reinforced Concrete (UHPFRC 2013), Marseille, France, 1–3 October 2013.

- 44.

Hussein, L.; Amleh, L., Shear behavior of uhpfrc beams without stirrups, In Proceedings of the 10th fib International PhD Symposium in Civil Engineering, Laval, QC, Canada, 21–23 July 2014; pp. 437–442.

- 45.

Baby, F.; Marchand, P.; Toutlemonde, F. Shear behavior of ultrahigh performance fiber-reinforced concrete beams. i: Experimental investigation. J. Struct. Eng. 2014, 140, 4013111. https://doi.org/10.1061/(ASCE)ST.1943-541X.0000907.

- 46.

Randl, N.; Mszly, T. The effect of fibres in UHPFRC beams with longitudinal steel reinforcement. In Proceedings of the Fibre-Reinforced Concrete: From Design to Structural Applications (FRC 2014: ACI-fib International Workshop Proceedings), Montreal, QC, Canada, 24–25 July 2014.

- 47.

Yoo, D.Y.; Yoon, Y.S. Structural performance of ultra-high-performance concrete beams with different steel fibers. Eng. Struct. 2015, 102, 409–423.

- 48.

Lim, T.; Hong, S. Shear tests for ultra-high performance fiber reinforced concrete (UHPFRC) beams with shear reinforcement. In Proceedings of the Fibre-Reinforced Concrete: From Design to Structural Applications (FRC 2014: ACI-fib International Workshop Proceedings), Montreal, QC, Canada, 24–25 July 2014.

- 49.

Li, Y.; Guertin-Normoyle, C.; Algassem, O.; et al. Effect of ultra-high performance fibre reinforced concrete and high-strength steel on the flexural behaviour of reinforced concrete beams. In Proceedings of the AFGC-ACI-fib-RILEM Int. Symposium on Ultra-High Performance Fibre-Reinforced Concrete (UHPFRC 2017), Montpellier, France, 2–4 October 2017.

- 50.

Yoo, D.Y.; Banthia, N.; Yoon, Y.S. Experimental and numerical study on flexural behavior of ultra-high-performance fiber- reinforced concrete beams with low reinforcement ratios. Can. J. Civ. Eng. 2017, 44, 18–28. https://doi.org/10.1139/cjce-2015-0384.

- 51.

Pansuk, W.; Nguyen, T.N.; Sato, Y.; et al. Shear capacity of high performance fiber reinforced concrete i-beams. Constr. Build. Mater. 2017, 157, 182–193. https://doi.org/10.1016/j.conbuildmat.2017.09.057.

- 52.

Giesler, A.J.; McGinnis, M.J.; Weldon, B.D. Flexural behavior and analysis of prestressed ultra-high-performance concrete beams made from locally available materials. PCI J. 2018, 63, 66–80. https://doi.org/10.15554/pcij63.6-02.

- 53.

Hasgul, U.; Turker, K.; Birol, T.; et al. Flexural behavior of ultra-high-performance fiber reinforced concrete beams with low and high reinforcement ratios. Struct. Concr. 2018, 19, 1577–1590. https://doi.org/10.1002/suco.201700089.

- 54.

Kodur, V.; Solhmirzaei, R.; Agrawal, A.; et al. Analysis of flexural and shear resistance of ultra high performance fiber rein- forced concrete beams without stirrups. Eng. Struct. 2018, 174, 873–884. https://doi.org/10.1016/j.engstruct.2018.08.010.

- 55.

Qi, J.; Wang, J.; Ma, Z.J. Flexural response of high-strength steel-ultra-high-performance fiber reinforced concrete beams based on a mesoscale constitutive model: Experiment and theory. Struct. Concr. 2018, 19, 719–734. https://doi.org/10.1002/suco.201700043.

- 56.

Shafieifar, M.; Farzad, M.; Azizinamini, A. A comparison of existing analytical methods to predict the flexural ca- pacity of ultra high performance concrete (uhpc) beams. Constr. Build. Mater. 2018, 172, 10–18. https://doi.org/10.1016/j.conbuildmat.2018.03.229.

- 57.

Yang, I.H.; Joh, C.; Kim, K.C. A comparative experimental study on the flexural behavior of high-strength fiber- reinforced concrete and high-strength concrete beams. Adv. Mater. Sci. Eng. 2018, 2018, 7390798. https://doi.org/10.1155/2018/7390798.

- 58.

Gomaa, S.; Alnaggar, M. Transitioning from shear to flexural failure of UHPC beams by varying fiber content. Int. Interact. Symp. Ultra-High Perform. Concr. 2019, 2, 9731. https://doi.org/10.21838/uhpc.9731.

- 59.

Pourbaba, M.; Sadaghian, H.; Mirmiran, A. Flexural response of uhpfrc beams reinforced with steel rebars. Adv. Civ. Eng. Mater. 2019, 8, 411–430. https://doi.org/10.1520/ACEM20190129.

- 60.

Pourbaba, M.; Sadaghian, H.; Mirmiran, A. A comparative study of flexural and shear behavior of ultra-high-performance fiber-reinforced concrete beams. Adv. Struct. Eng. 2019, 22, 1727–1738. https://doi.org/10.1177/1369433218823848.

- 61.

Shao, Y.; Billington, S.L. Utilizing full UHPC compressive strength in steel reinforced UHPC beams. In Proceedings of the 2nd International Interactive Symposium on Ultra-High Performance Concrete (2IIS-UHPC), Albany, NY, USA, 2–5 June 2019.

- 62.

Turker, K.; Hasgul, U.; Birol, T.; et al. Hybrid fiber use on flexural behavior of ultra high performance fiber reinforced concrete beams. Compos. Part B Eng. 2019, 229, 111400. https://doi.org/10.1016/j.compstruct.2019.111400.

- 63.

Yavas, A.; Hasgul, U.; Turker, K.; Birol, T. Effective fiber type investigation on the shear behavior of ultrahigh-performance fiber-reinforced concrete beams. Adv. Struct. Eng. 2019, 22, 1591–1605.

- 64.

Hasgul, U.; Yavas, A.; Birol, T.; Turker, K. Steel Fiber Use as Shear Reinforcement on I-Shaped UHP-FRC Beams. Appl. Sci. 2019, 9, 5526.

- 65.

Liu, C.; Zhang, Y.; Yao, Y.; Huang, Y. Calculation method for flexural capacity of high strain-hardening ultra-high performance concrete T-beams. Struct. Concr. 2019, 20, 405–419.

- 66.

Qiu, M.; Shao, X.; Zhu, Y.; Zhan, J.; Yan, B.; Wang, Y. Experimental investigation on flexural cracking behavior of ultrahigh performance concrete beams. Struct. Concr. 2020, 21, 2134–2153.

- 67.

Sturm, A.B.; Visintin, P.; Oehlers, D.J. Blending fibres to enhance the flexural properties of UHPFRC beams. Constr. Build. Mater. 2020, 244, 118328.

- 68.

Yang, I.H.; Park, J.; Bui, T.Q.; et al. An Experimental Study on the Ductility and Flexural Toughness of Ultrahigh- Performance Concrete Beams Subjected to Bending. Materials 2020, 13, 2225.

- 69.

Qiu, M.; Shao, X.; Wille, K.; Yan, B.; Wu, J. Experimental Investigation on Flexural Behavior of Reinforced Ultra High Performance Concrete Low-Profile T-Beams. Int. J. Concr. Struct. Mater. 2020, 14, 5.

- 70.

Bae, B.I.; Lee, M.S.; Choi, C.S.; Jung, H.S.; Choi, H.K. Evaluation of the ultimate strength of the ultra-high-performance fiber-reinforced concrete beams. Appl. Sci. 2021, 11, 2951.

- 71.

Khan, M.I.; Fares, G.; Abbas, Y.M.; et al. Behavior of non-shear-strengthened uhpc beams under flexural loading: Influence of reinforcement percentage. Appl. Sci. 2021, 11, 11168.

- 72.

Metje, K.; Leutbecher, T. Experimental investigations on the shear bearing behavior of prestressed ultra-high performance fiber-reinforced concrete beams with compact cross-section. Struct. Concr. 2021, 22, 3746–3762.

- 73.

Yavas, A.; Ince, M. Effect of reinforcement ratio on flexural behavior of I-shaped UHPFRC beams. Structures 2021, 34, 4457–4465.

- 74.

Zhu, L.; Li, T.; Wang, Y.; et al. Experimental and numerical study on T-Shaped UHPFRC beams with high-strength reinforcement. Struct. Concr. 2021, 22, 3630–3645.

- 75.

Bae, B.I.; Choi, H.K. Experimental Study on the Flexural Behavior of Lap-Spliced Ultra-High-Performance Fiber- Reinforced Concrete Beams. Polymers 2022, 14, 2138.

- 76.

Huß, M.; Waldenhofer, R.; Freytag, B.; et al. Zusammenwirken von Faser-und Betonstahlbewehrung bei biege- beanspruchten UHPC-Bauteilen. Beton Stahlbetonbau 2022, 117, 699–710.

- 77.

Shao, Y.; Billington, S.L. Impact of UHPC Tensile Behavior on Steel Reinforced UHPC Flexural Behavior. J. Struct. Eng. 2022, 148, 04021244.

- 78.

Sawicki, B.; Brhwiler, E.; Denari, E. Inverse Analysis of R-UHPFRC Beams to Determine the Flexural Response under Service Loading and at Ultimate Resistance. J. Struct. Eng. 2022, 148, 04021260.

- 79.

de Lima, P.B.; Krahl, P.A.; Silva, F.A.; et al. A modeling strategy for the flexural performance prediction of UHPC beams accounting for variability of properties. Compos. Struct. 2023, 322, 117374.

- 80.

Breiman, L.; Friedman, J.; Olshen, R.; et al. Classification and Regression Trees; Wadsworth International Group: Belmont, CA, USA, 1984.

- 81.

Iglewicz, B.; Hoaglin, D. How to Detect and Handle Outliers; ASQC Quality Press: Milwaukee, WI, USA, 1993.

- 82.

Huber, P. Robust Estimation of a Location Parameter. Ann. Math. Stat. 1964, 35, 73–101.

- 83.

EN 1990:2002; Eurocode 0: Basis of Structural Design. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- 84.

CEN/TC 250/SC 2; Background Document to FprEN 1992-1-1:2023—Eurocode 2: Design of Concrete Structures, Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. European Committee for Standardization (CEN): Brussels, Belgium,2023.

- 85.

Feng, J.; Shao, X.; Qiu, M.; et al. Reliability evaluation of flexural capacity design provision for UHPC beams reinforced with steel rebars/prestressing tendons. Eng. Struct. 2024, 300, 117160. https://doi.org/10.1016/j.engstruct.2023.117160.

- 86.

Chinese Standard JGJ/T 465- 2019: Standard for Design of Steel Fiber Reinforced Concrete Structures; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China. 2019.

- 87.

Swiss Standard (SIA 2052); MCS-EPFL Recommendation: Ultra-High Performance Fibre Reinforced Cement-Based Composites (UHPFRC)—Construction Material, Dimensioning and Application. Swiss Society of Engineers and Architects (SIA): Zrich, Switzerland, 2016.

- 88.

American Concrete Institute. Building Code Requirements for Structural Concrete and Commentary; ACI 318-19; American Concrete Institute: Indianapolis, ID, USA, 2019.

- 89.

ACI Committee 544. Design Considerations for Steel Fiber Reinforced Concrete; Guide to Design with Fiber-Reinforced Concrete (Technical Report); American Concrete Institute: Farmington Hills, MI, USA, 2018.

- 90.

Aaleti, S.; Petersen, B.; Sritharan, S. Design Guide for Precast UHPC Waffle Deck Panel System, Including Connections; Final Report; Federal Highway Administration, U.S. Department of Transportation: Washington, DC, USA; 2013.

- 91.

Simwanda, L.; De Koker, N.; Viljoen, C. Structural reliability of ultra high-performance fibre reinforced concrete beams in flexure. Eng. Struct. 2021, 244, 112767.

- 92.

Ye, M.; Li, L.; Jin, W.; et al. Interpretable ensemble machine learning models for predicting the shear capacity of UHPC joints. Eng. Struct. 2024, 315, 118443.

- 93.

Madirisha, M.M.; Simw, A.L.; Mtei, R.P. Predicting the hydrogen storage capacity of alumina pillared interlayer clays using interpretable ensemble machine learning. Int. J. Hydrogen Energy 2025, 120, 354–364.

- 94.

David, A.B.; Olalusi, O.B.; Awoyera, P.O.; et al. Suitability of Mechanics-Based and Optimized Machine Learning-Based Models in the Shear Strength Prediction of Slender Beams without Stirrups. Buildings 2024, 14, 3946.

- 95.

Kyriakides, G.; Margaritis, K.G. Hands- On Ensemble Learning with Python: Build Highly Optimized Ensemble Machine Learning Models Using Scikit-Learn and Keras; Packt Publishing Ltd.: Birmingham, UK, 2019.

- 96.

Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. Adv. Neural Inf. Process. Syst. 2017, 30.

- 97.

Wakjira, T.G.; Alam, M.S. Peak and ultimate stress-strain model of confined ultra-high-performance concrete (UHPC) using hybrid machine learning model with conditional tabular generative adversarial network. Appl. Soft Comput. 2024, 154, 111353.

- 98.

Cao, Y.; Su, F.; Antwi-Afari, M.F.; et al. Enhancing mix proportion design of low carbon concrete for shield segment using a combination of Bayesian optimization-NGBoost and NSGA-III algorithm. J. Clean. Prod. 2024, 465, 142746.

- 99.

Genc¸, B.; Tunc¸, H. Optimal training and test sets design for machine learning. Turk. J. Electr. Eng. Comput. Sci. 2019, 27, 1534–1545.

- 100.

Akiba, T.; Sano, S.; Yanase, T.; et al. Optuna: A next-generation hyperparameter optimization framework. In Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Anchorage, AK, USA, 4–8 August 2019; pp. 2623–2631.

- 101.

Dietterich, T.G. Approximate statistical tests for comparing supervised classification learning algorithms. Neural Comput. 1998, 10, 1895–1923.

- 102.

Xiong, F.; Yang, W.; Zhang, Y.; et al. Study on the electromagnetic field aligning steel fibres in UHPC reinforced beams. Cem. Concr. Compos. 2023, 143, 105251.

- 103.

Liu, Y.; Xie, J.; Yan, J. Flexural and fracture performance of UHPC exposed to low-temperature environment. Constr. Build. Mater. 2023, 373, 130865.

- 104.

Guo, Y.; Wang, J. Experimental study on UHPC beams without web reinforcement under four-point bending: shear behaviour and size effect. Constr. Build. Mater. 2023, 409, 133802.

- 105.

Yan, W.; Zhang, R.; Subedi, S.; et al. Experimental investigation on flexural performance of UHPC beams reinforced with steel-FRP bars. Arch. Civ. Mech. Eng. 2024, 24, 132.

- 106.

Du, L.; Wu, D.; Wang, J.; et al. Experimental Study on Flexural Behavior of Retard-Bonded Prestressed UHPC Beams with Different Reinforcement Ratios. Buildings 2025, 15, 887.

- 107.

Tian, X.; Fang, Z.; Liu, S.; et al. Monotonic flexural behaviour of steel-fibre reinforced UHPC beams at sub-zero temperatures. Cem. Concr. Compos. 2024, 150, 105550.

- 108.

Wang, Z.; Liang, X.; Wan, S.; et al. Flexural behaviour and damage evolution of steel-reinforced UHPC beams at low temperatures. Eng. Fail. Anal. 2025, 181, 109925.

- 109.

Yang, J.; Yan, K.; Doh, J.; et al. Experimental study on shear performance of UHPC beams at elevated temperatures. Eng. Struct. 2023, 291, 116304.

- 110.

Jin, L.; Xie, C.; Yu, W.; et al. Shear failures and bearing capacity analysis of UHPC beams at low temperatures: Experiment and formulation. Eng. Struct. 2025, 330, 119903.

- 111.

Ge, W.; Chen, Z.; Zhang, Z.; et al. Shear behavior of externally prestressed UHPC beams without stirrups. Case Stud. Constr. Mater. 2023, 18, e01766.

This work is licensed under a Creative Commons Attribution 4.0 International License.