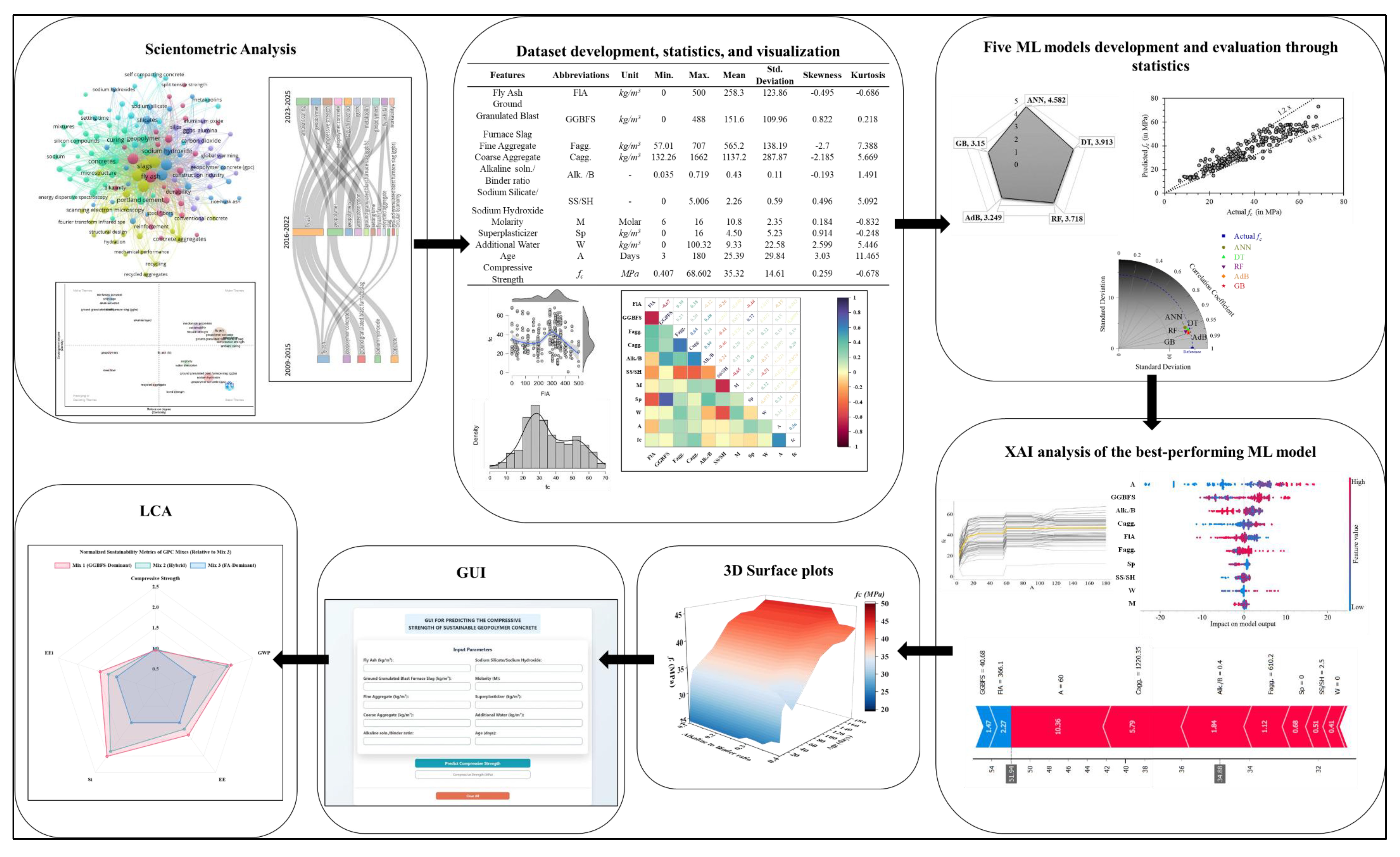

This study proposes a novel, unified framework integrating scientometric analysis, machine learning (ML), explainable artificial intelligence (XAI), and cradle-to-gate life cycle assessment (LCA) to evaluate and predict the performance of slag-fly ash-based geopolymer concrete (SFGPC). A scientometric review of 441 publications (2009–2025) guided the systematic assembly of a dataset comprising 363 SFGPC mixes. Five ML models were trained to predict compressive strength (fc), with Gradient Boosting (GB) achieving the highest accuracy, yielding R2 = 0.954, RMSE = 3.15 MPa, MAE = 1.81 MPa during training, and R2 = 0.95, RMSE = 3.128 MPa, MAE = 2.41 MPa during testing. Multi-layered XAI analysis identified age, slag content, and alkaline-to-binder ratio as the most influential parameters and revealed governing nonlinear interactions. Sustainability assessment showed that the fly ash-dominant mix exhibited the lowest global warming potential (156 kg CO2-eq/m3), the most favourable sustainability index, and the smallest residual emissions after a 25% carbon offset. A user-oriented graphical user interface (GUI) was developed for real-time strength prediction. The novelty of this work lies in introducing an explainable, data-driven, and sustainability-integrated decision-support system for designing transparent and low-carbon geopolymer concretes.

- Open Access

- Article

Explainable Predictive Modelling of Sustainable Slag–Fly Ash Based Geopolymer Concrete with Life Cycle and Carbon-Neutrality Assessment

Author Information

Received: 11 Nov 2025 | Revised: 07 Jan 2026 | Accepted: 09 Jan 2026 | Published: 20 Jan 2026

Abstract

Graphical Abstract

Keywords

geopolymer concrete | scientometric | machine learning | explainable artificial intelligence | life cycle assessment | sustainability

References

- 1.

Ansari, S.S.; Shariq, M.; Mohammad, Z.; et al. Effect of elevated temperature on the structural performance of reinforced high volume fly ash concrete. Structures 2023, 57, 105168. https://doi.org/10.1016/j.istruc.2023.105168.

- 2.

Zhang, B.; Feng, Y.; Zhou, X.; et al Dynamic mechanical behaviour and life cycle assessment of rubberised solid waste-based geopolymer concrete. J. Clean. Prod. 2025, 501, 145247. https://doi.org/10.1016/j.jclepro.2025.145247.

- 3.

Guo, S.; Hu, J.; Dai, Q. A critical review on the performance of portland cement concrete with recycled organic components. J. Clean. Prod. 2018, 188, 92–112. https://doi.org/10.1016/j.jclepro.2018.03.244.

- 4.

de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. https://doi.org/10.1016/j.jclepro.2020.123558.

- 5.

Ansari, S.S.; Ibrahim, S.M.; Hasan, S.D.; et al. Effect of perforated fly ash cenospheres and nano-silica on the thermo-structural behaviour of sustainable concrete. Structures 2025, 80, 109800. https://doi.org/10.1016/j.istruc.2025.109800.

- 6.

Juenger, M.C.G.; Winnefeld, F.; Provis, J.L.; et al. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. https://doi.org/10.1016/j.cemconres.2010.11.012.

- 7.

Degefu, D.M.; Liao, Z.; Berardi, U.; et al. Geopolymer concrete for net-zero buildings: Correlating paste chemistry with monolith hygrothermal performance. Resour. Conserv. Recycl. 2023, 189, 106743. https://doi.org/10.1016/j.resconrec.2022.106743.

- 8.

Wang, D.; Noguchi, T.; Nanao, M.; et al. Parametric investigation and scale testing on accelerated CO2 sequestration of cement-based materials by utilizing industrial waste heat. J. Clean. Prod. 2024, 475, 143716. https://doi.org/10.1016/j.jclepro.2024.143716.

- 9.

Dong, W.; Li, W.; Tao, Z. A comprehensive review on performance of cementitious and geopolymeric concretes with recycled waste glass as powder, sand or cullet. Resour. Conserv. Recycl. 2021, 172, 105664. https://doi.org/10.1016/j.resconrec.2021.105664.

- 10.

Martínez, A.; Miller, S.A. A review of drivers for implementing geopolymers in construction: Codes and constructability. Resour. Conserv. Recycl. 2023, 199, 107238. https://doi.org/10.1016/j.resconrec.2023.107238.

- 11.

Wang, Y.; Liu, H.; Nie, Z.; et al. Experimental investigation into the influence of calcium aluminate cement on the micro- and macro-mechanical properties of the interfacial transition zone in geopolymer concrete. Dev. Built Environ. 2025, 21, 100618. https://doi.org/10.1016/j.dibe.2025.100618.

- 12.

Umer, M.; Ahmad, J.; Mukhtar, H. Innovative valorization of biomass waste-derived sodium silicate for geopolymer concrete synthesis: Sustainability assessment and circular economy potential. J. Clean. Prod. 2024, 452, 142181. https://doi.org/10.1016/j.jclepro.2024.142181.

- 13.

Wang, M.-R.; Jia, D.-C.; He, P.-G.; et al. Microstructural and mechanical characterization of fly ash cenosphere/metakaolin-based geopolymeric composites. Ceram. Int. 2011, 37, 1661–1666. https://doi.org/10.1016/j.ceramint.2011.02.010.

- 14.

Zhang, P.; Gao, Z.; Wang, J.; et al. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. https://doi.org/10.1016/j.jclepro.2020.122389.

- 15.

Valente, M.; Sambucci, M.; Chougan, M.; et al. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber. J. Clean. Prod. 2022, 333, 130013. https://doi.org/10.1016/j.jclepro.2021.130013.

- 16.

Silewu, K.; Kahanji, C.; Simwanda, L.; et al. Intelligent Data Driven Ensemble Approaches for Bending Strength Prediction of Ultra-High Performance Concrete Beams. Bull. Comput. Intell. 2025, 1, 31–52. https://doi.org/10.53941/bci.2025.100003.

- 17.

Benzaamia, A.; Ghrici, M.; Rbouh, R.; et al. Prediction of Chloride Resistance Level in Concrete Using Optimized Tree-Based Machine Learning Models. Bull. Comput. Intell. 2025, 1, 104–117. https://doi.org/10.53941/bci.2025.100007.

- 18.

Asteris, P.G.; Skentou, A.D.; Bardhan, A.; et al. Predicting concrete compressive strength using hybrid ensembling of surrogate machine learning models. Cem. Concr. Res. 2021, 145, 106449. https://doi.org/10.1016/j.cemconres.2021.106449.

- 19.

Le, T.-T.; Skentou, A.D.; Mamou, A.; et al. Correlating the Unconfined Compressive Strength of Rock with the Compressional Wave Velocity Effective Porosity and Schmidt Hammer Rebound Number Using Artificial Neural Networks. Rock. Mech. Rock. Eng. 2022, 55, 6805–6840. https://doi.org/10.1007/s00603-022-02992-8.

- 20.

Asteris, P.G.; Lemonis, M.E.; Nguyen, T.-A.; et al. Soft computing-based estimation of ultimate axial load of rectangular concrete-filled steel tubes. Steel Compos. Struct. 2021, 39, 471–491.

- 21.

Mahmood, W.; Mohammed, A.S.; Asteris, P.G.; et al. Modeling Flexural and Compressive Strengths Behaviour of Cement-Grouted Sands Modified with Water Reducer Polymer. Appl. Sci. 2022, 12, 1016. https://doi.org/10.3390/app12031016.

- 22.

Shamim Ansari, S.; Muhammad Ibrahim, S.; Danish Hasan, S. Conventional and Ensemble Machine Learning Models to Predict the Compressive Strength of Fly Ash Based Geopolymer Concrete. Mater. Today Proc. 2023, in press. https://doi.org/10.1016/j.matpr.2023.04.393.

- 23.

Ansari, S.S.; Ibrahim, S.M.; Hasan, S.D. Interpretable Machine-Learning Models to Predict the Flexural Strength of Fiber-Reinforced SCM-Blended Concrete Composites. J. Struct. Des. Constr. Pract. 2025, 30. https://doi.org/10.1061/JSDCCC.SCENG-1496.

- 24.

Baqer, B.T.; Mohammed, A.S. Evaluating the compressive strength of fly ash-slag-based geopolymer concrete: Impact of hydraulic, silica, alumina, and lime moduli, and sodium silicate using various predictive models. Innov. Infrastruct. Solut. 2025, 10, 191. https://doi.org/10.1007/s41062-025-01973-4.

- 25.

Paruthi, S.; Khan, A.H.; Isleem, H.F.; et al. Influence of silica fume and alccofine on the mechanical performance of GGBS-based geopolymer concrete under varying curing temperatures. J. Struct. Integrity Maint. 2025, 10, 2447661. https://doi.org/10.1080/24705314.2024.2447661.

- 26.

Ahmed, H.U.; Mostafa, R.R.; Mohammed, A.; et al. Support vector regression (SVR) and grey wolf optimization (GWO) to predict the compressive strength of GGBFS-based geopolymer concrete. Neural Comput. Appl. 2023, 35, 2909–2926. https://doi.org/10.1007/s00521-022-07724-1.

- 27.

Ibrahim, S.M.; Ansari, S.S.; Hasan, S.D. Towards white box modeling of compressive strength of sustainable ternary cement concrete using explainable artificial intelligence (XAI). Appl. Soft Comput. 2023, 149, 110997. https://doi.org/10.1016/j.asoc.2023.110997.

- 28.

Ansari, S.S.; Ibrahim, S.M.; Hasan, S.D.; et al. Experiments and predictive modelling on sustainable cementitious mortar with perforated fly ash cenospheres and effectively dispersed nano silica. Mater. Today Commun. 2025, 47, 113020. https://doi.org/10.1016/j.mtcomm.2025.113020.

- 29.

Bianco, I.; Ap Dafydd Tomos, B.; Vinai, R. Analysis of the environmental impacts of alkali-activated concrete produced with waste glass-derived silicate activator—A LCA study. J. Clean. Prod. 2021, 316, 128383. https://doi.org/10.1016/j.jclepro.2021.128383.

- 30.

Ma, X.; Hu, H.; Luo, Y.; et al. A carbon footprint assessment for usage of recycled aggregate and supplementary cementitious materials for sustainable concrete: A life-cycle perspective in China. J. Clean. Prod. 2025, 490, 144772. https://doi.org/10.1016/j.jclepro.2025.144772.

- 31.

Martínez, A.; Miller, S.A. Life cycle assessment and production cost of geopolymer concrete: A meta-analysis. Resour. Conserv. Recycl. 2025, 215, 108018. https://doi.org/10.1016/j.resconrec.2024.108018.

- 32.

Nguyen, M.H.; Mai, H.-V.T.; Trinh, S.H.; et al. A comparative assessment of tree-based predictive models to estimate geopolymer concrete compressive strength. Neural Comput. Appl. 2023, 35, 6569–6588. https://doi.org/10.1007/s00521-022-08042-2.

- 33.

Ahmed, H.U.; Mohammed, A.A.; Mohammed, A. Soft computing models to predict the compressive strength of GGBS/FA- geopolymer concrete. PLoS ONE 2022, 17, e0265846. https://doi.org/10.1371/journal.pone.0265846.

- 34.

Kina, C.; Tanyildizi, H.; Turk, K. Forecasting the compressive strength of GGBFS-based geopolymer concrete via ensemble predictive models. Constr. Build. Mater. 2023, 405, 133299. https://doi.org/10.1016/j.conbuildmat.2023.133299.

- 35.

Shahmansouri, A.A.; Yazdani, M.; Ghanbari, S.; et al. Artificial neural network model to predict the compressive strength of eco-friendly geopolymer concrete incorporating silica fume and natural zeolite. J. Clean. Prod. 2021, 279, 123697. https://doi.org/10.1016/j.jclepro.2020.123697.

- 36.

Jin, J.; Wu, T.; Zhang, Z.; et al. Application of optimization-based estimation analysis for predicting the compressive strength of eco-friendly modified geopolymer concrete. Struct. Concr. 2022, 25, 1489. https://doi.org/10.1002/suco.202201051.

- 37.

Onyelowe, K.C.; Ebid, A.M.; Awoyera, P.; et al. Prediction and validation of mechanical properties of self-compacting geopolymer concrete using combined machine learning methods a comparative and suitability assessment of the best analysis. Sci. Rep. 2025, 15, 6361. https://doi.org/10.1038/s41598-025-90468-4.

- 38.

Bypour, M.; Yekrangnia, M.; Kioumarsi, M. Machine learning-driven optimization for predicting compressive strength in fly ash geopolymer concrete. Clean. Eng. Technol. 2025, 25, 100899. https://doi.org/10.1016/j.clet.2025.100899.

- 39.

Diksha, S.; Dev, N.; Goyal, P.K. Utilizing an enhanced machine learning approach for geopolymer concrete analysis. Nondestruct. Test. Eval. 2025, 40, 904–931. https://doi.org/10.1080/10589759.2024.2334434.

- 40.

Yang, H.; Li, H.; Jiang, J. Predictive modeling of compressive strength of geopolymer concrete before and after high temperature applying machine learning algorithms. Struct. Concr. 2025, 26, 1699–1732. https://doi.org/10.1002/suco.202400552.

- 41.

Chhetri Sapkota, S.; Dahal, D.; Yadav, A.; et al. Analyzing the Behavior of Geopolymer Concrete with Different Novel Machine-Learning Algorithms. J. Struct. Des. Constr. Pract. 2025, 30. https://doi.org/10.1061/JSDCCC.SCENG-1724.

- 42.

Wang, X.; Zhang, H.; Yin, L.; et al. Frost resistance of steel fiber geopolymer concrete studied via the machine learning method. Structures 2025, 73, 108444. https://doi.org/10.1016/j.istruc.2025.108444.

- 43.

Ulloa, N.; Morales León, M.A.; Silva Palmay, L.F.; et al. Evaluating the compressive strength of industrial wastes-based geopolymer concrete with machine learning models. Constr. Build. Mater. 2025, 472, 140891. https://doi.org/10.1016/j.conbuildmat.2025.140891.

- 44.

Nguyen, H.A.T.; Pham, D.H.; Le, A.T.; et al. Transfer learning framework for modelling the compressive strength of ultra-high performance geopolymer concrete. Constr. Build. Mater. 2025, 459, 139746. https://doi.org/10.1016/j.conbuildmat.2024.139746.

- 45.

Hassan, A.; Saleh, R.A.A.; Al-Sameai, H.; et al. Novel hybrid machine learning framework for high-fidelity prediction of fly ash-based geopolymer concrete strength. Compos. Struct. 2026, 378, 119906. https://doi.org/10.1016/j.compstruct.2025.119906.

- 46.

Abdellatief, M.; Hassan, Y.M.; Elnabwy, M.T.; et al. Investigation of machine learning models in predicting compressive strength for ultra-high-performance geopolymer concrete: A comparative study. Constr. Build. Mater. 2024, 436, 136884. https://doi.org/10.1016/j.conbuildmat.2024.136884.

- 47.

Ling, Y.; Wang, K.; Wang, X.; et al. Prediction of engineering properties of fly ash-based geopolymer using artificial neural networks. Neural Comput. Appl. 2021, 33, 85–105. https://doi.org/10.1007/s00521-019-04662-3.

- 48.

Toufigh, V.; Jafari, A. Developing a comprehensive prediction model for compressive strength of fly ash-based geopolymer concrete (FAGC). Constr. Build. Mater. 2021, 277, 122241. https://doi.org/10.1016/j.conbuildmat.2021.122241.

- 49.

Ravikumar, S.; Agrahari, A.; Singh, S.N. Mapping the intellectual structure of scientometrics: A co-word analysis of the journal Scientometrics (2005–2010). Scientometrics 2015, 102, 929–955. https://doi.org/10.1007/s11192-014-1402-8.

- 50.

Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Inf. Informetr. 2017, 11, 959–975. https://doi.org/10.1016/j.joi.2017.08.007.

- 51.

Mustakim, S.M.; Das, S.K.; Mishra, J.; et al. Improvement in Fresh, Mechanical and Microstructural Properties of Fly Ash- Blast Furnace Slag Based Geopolymer Concrete by Addition of Nano and Micro Silica. Silicon 2021, 13, 2415–2428. https://doi.org/10.1007/s12633-020-00593-0.

- 52.

Bellum, R.R.; Nerella, R.; Madduru, S.R.C.; et al. Mix Design and Mechanical Properties of Fly Ash and GGBFS-Synthesized Alkali-Activated Concrete (AAC). Infrastructures 2019, 4, 20. https://doi.org/10.3390/infrastructures4020020.

- 53.

Suresh, G.V.; Karthikeyan, J. Performance enhancement of green concrete. Proc. Inst. Civ. Eng. Eng. Sustain. 2018, 171, 191–203. https://doi.org/10.1680/jensu.15.00066.

- 54.

Pasupathy, K.; Berndt, M.; Castel, A.; et al. Carbonation of a blended slag-fly ash geopolymer concrete in field conditions after 8 years. Constr. Build. Mater. 2016, 125, 661–669. https://doi.org/10.1016/j.conbuildmat.2016.08.078.

- 55.

Deb, P.S.; Nath, P.; Sarker, P.K. Drying Shrinkage of Slag Blended Fly Ash Geopolymer Concrete Cured at Room Temperature. Procedia Eng. 2015, 125, 594–600. https://doi.org/10.1016/j.proeng.2015.11.066.

- 56.

Khan, M.S.H.; Castel, A.; Akbarnezhad, A.; et al. Utilisation of steel furnace slag coarse aggregate in a low calcium fly ash geopolymer concrete. Cem. Concr. Res. 2016, 89, 220–229. https://doi.org/10.1016/j.cemconres.2016.09.001.

- 57.

Bellum, R.R.; Muniraj, K.; Madduru, S.R.C. Exploration of mechanical and durability characteristics of fly ash-GGBFS based green geopolymer concrete. Discov. Appl. Sci. 2020, 2, 919. https://doi.org/10.1007/s42452-020-2720-5.

- 58.

Gopalakrishnan, R.; Chinnaraju, K. Durability Characteristics of Slag/Fly Ash Based Alumina Silicate Concrete at Ambient Temperature. Silicon 2021, 13, 3619–3628. https://doi.org/10.1007/s12633-020-00889-1.

- 59.

Bellum, R.R.; Muniraj, K.; Indukuri, C.S.R.; et al. Investigation on Performance Enhancement of Fly ash-GGBFS Based Graphene Geopolymer Concrete. J. Build. Eng. 2020, 32, 101659. https://doi.org/10.1016/j.jobe.2020.101659.

- 60.

Mathew, G.; Issac, B.M. Effect of molarity of sodium hydroxide on the aluminosilicate content in laterite aggregate of laterised geopolymer concrete. J. Build. Eng. 2020, 32, 101486. https://doi.org/10.1016/j.jobe.2020.101486.

- 61.

Bellum, R.R.; Muniraj, K.; Madduru, S.R.C. Characteristic Evaluation of Geopolymer Concrete for the Development of Road Network: Sustainable Infrastructure. Innov. Infrastruct. Solut. 2020, 5, 91. https://doi.org/10.1007/s41062-020-00344-5.

- 62.

Abbass, M.; Singh, D.; Singh, G. Properties of hybrid geopolymer concrete prepared using rice husk ash, fly ash and GGBS with coconut fiber. Mater. Today Proc. 2021, 45, 4964–4970. https://doi.org/10.1016/j.matpr.2021.01.390.

- 63.

Abdul Sani, M.F.A.; Muhamad, R.; Mo, K.H. Effect of Ground Granulated Blast Furnace Slag as Partial Replacement in Fly Ash-Based Geopolymer Concrete. In Proceedings of the 3rd National Conference on Wind & Earthquake Engineering and International Seminar On Sustainable Construction Engineering, Kuala Lumpur, Malaysia, 12–13 July 2019.

- 64.

Verma, M.; Dev, N. Effect of ground granulated blast furnace slag and fly ash ratio and the curing conditions on the mechanical properties of geopolymer concrete. Struct. Concr. 2022, 23, 2015–2029. https://doi.org/10.1002/suco.202000536.

- 65.

Das, S.K.; Shrivastava, S. Siliceous fly ash and blast furnace slag based geopolymer concrete under ambient temperature curing condition. Struct. Concr. 2021, 22, E341–E351. https://doi.org/10.1002/suco.201900201.

- 66.

Prusty, J.K.; Pradhan, B. Multi-response optimization using Taguchi-Grey relational analysis for composition of fly ash-ground granulated blast furnace slag based geopolymer concrete. Constr. Build. Mater. 2020, 241, 118049. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2020.118049.

- 67.

Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. https://doi.org/10.1016/j.ceramint.2017.07.221.

- 68.

Dave, S.V.; Bhogayata, A. The strength oriented mix design for geopolymer concrete using Taguchi method and Indian concrete mix design code. Constr. Build. Mater. 2020, 262, 120853. https://doi.org/10.1016/j.conbuildmat.2020.120853.

- 69.

Hajimohammadi, A.; Ngo, T.; Vongsvivut, J. Interfacial chemistry of a fly ash geopolymer and aggregates. J. Clean. Prod. 2019, 231, 980–989. https://doi.org/10.1016/j.jclepro.2019.05.249.

- 70.

Phoo-ngernkham, T.; Maegawa, A.; Mishima, N.; et al. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA–GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2015.05.001.

- 71.

Weil, M.; Dombrowski, K.; Buchwald, A. Life-cycle analysis of geopolymers. In Geopolymers; Elsevier: Amsterdam, The Netherlands, 2009; pp. 194–210. https://doi.org/10.1533/9781845696382.2.194.

- 72.

Weil, M.; Buchwald, A.; Dombrowski-Daube, K. How to Assess the Environmental Sustainability of Geopolymers? A Live Cycle Perspective; Trans Tech Publications Ltd.: Baech, Switzerland, 2010; pp. 186–191. https://doi.org/10.4028/www.scientific.net/AST.69.186.

- 73.

Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. https://doi.org/10.1016/j.cemconres.2011.03.016.

- 74.

Shivaprasad, K.N.; Yang, H.-M.; Singh, J.K. A path to carbon neutrality in construction: An overview of recent progress in recycled cement usage. J. CO2 Util. 2024, 83, 102816. https://doi.org/10.1016/j.jcou.2024.102816.

This work is licensed under a Creative Commons Attribution 4.0 International License.