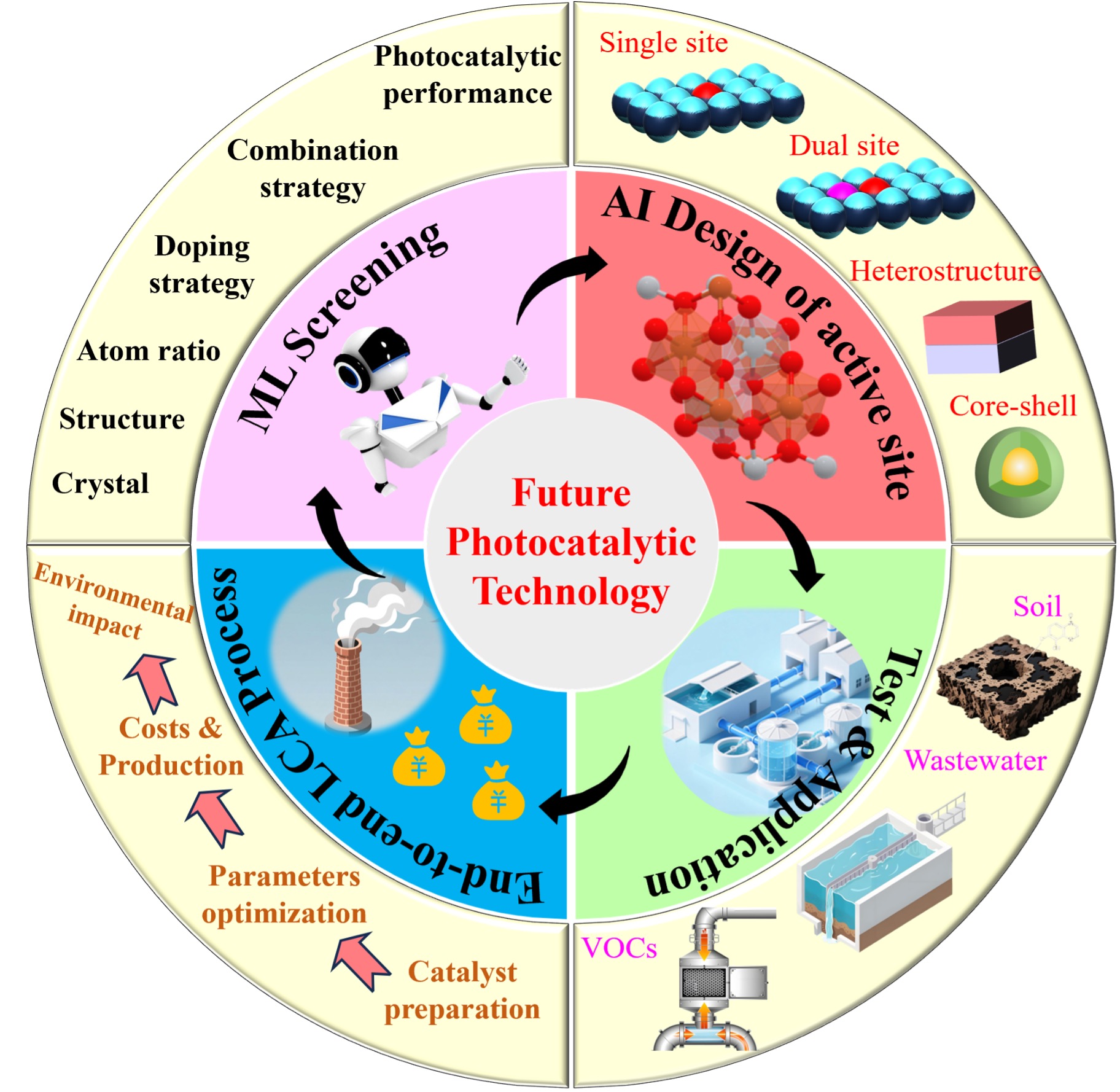

Among various environmental remediation techniques, photocatalytic techniques, which uniquely take advantage of the sunlight, have attracted much attention. However, owing to the poor stability of catalysts, photocatalytic technology is predominantly confined to laboratory research at present, posing challenges for its large-scale application in environmental remediation and resulting in a scarcity of data on its full lifecycle management. This review proposes that machine learning (ML) may serve as a critical link in advancing photocatalytic technology from fundamental research to mature application processes. The data-explosive, scalable development approach facilitated by ML is expected to significantly overcome the limitations of the current trial-and-error method for developing photocatalysts. Integrated with a ML guided full life cycle assessment (LCA) encompassing “material design, process selection, material/energy consumption, pollution disposal, and environmental impact,” this approach can contribute to forming a comprehensive photocatalytic environmental remediation technology system.

- Open Access

- Review

Machine Learning Assists in the Design of Photocatalysts for Environmental Remediation: A Comprehensive Review

- Wei Liu,

- Bingqing Wang,

- Danzeng Yangjin,

- Sihui Zhan *

Author Information

Received: 16 Oct 2025 | Revised: 14 Nov 2025 | Accepted: 17 Nov 2025 | Published: 22 Nov 2025

Abstract

Graphical Abstract

References

- 1.Asghar, H.; Saeed, M.; Mirsafi, F.S.; et al. Zinc Oxide-Graphitic Carbon Nitride Composites: Synthesis, Properties, and Application Scopes in Environmental Remediations. Small 2025, 21, e09637.

- 2.Li, S.; Zhang, T.; Zheng, H.; et al. Efficient photo-Fenton degradation of water pollutants via peracetic acid activation over sulfur vacancies-rich metal sulfides/MXenes. Appl. Cataly. B-Environ. Energy 2025, 366, 125000.

- 3.Lv, M.; Liu, Y.; Wang, M.; et al. Transformative Forces: The Role of Gut Microbiota in Processing Environmental Pollutants. Environ. Sci. Technol. 2025, 59, 15575–15593.

- 4.Gao, X.; Zheng, X.; Wang, X.; et al. Environmental pollutant exposure and adverse neurodevelopmental outcomes: An umbrella review and evidence grading of meta-analyses. J. Hazard. Mater. 2025, 491, 137832.

- 5.Pirvu, F.; Pascu, L.F.; Paun, I.; et al. Sorption of PAHs onto microplastics in Romanian surface waters and sediments: Environmental toxicity and human health risk with emphasis on pediatric exposure. Water Res. 2025, 287, 124483.

- 6.Yu, X.; Tang, L.; Yan, R.; et al. Quantifying PFAS contamination and environmental risk in municipal solid waste landfill refuse: Implications for landfill reuse. Water Res. 2025, 283, 123881.

- 7.Wang, H.; Zhang, S.; Lin, Z.; et al. Occurrence, removal and ecological risk assessment of antibiotics in rural domestic wastewater treatment systems in the Beijing-Tianjin-Hebei region. J. Hazard. Mater. 2025, 495, 139127.

- 8.Cui, P.; Schito, G.; Cui, Q. VOC emissions from asphalt pavement and health risks to construction workers. J. Clean. Prod. 2020, 244, 118757.

- 9.Liu, J.; Qi, W.; Xu, M.; et al. Piezocatalytic Techniques in Environmental Remediation. Angew. Chem. Int. Ed. 2023, 62, e202213927.

- 10.Zadehnazari, A.; Khosropour, A.; Zarei, A.; et al. Viologen-Derived Covalent Organic Frameworks: Advancing PFAS Removal Technology with High Adsorption Capacity. Small 2024, 20, 2405176.

- 11.Xiang, J.; Zhou, Z.; Liu, Z.; et al. Constructing simplified microbial consortia that couple lactic acid and ethanol utilization to highly produce caproic acid from liquor-making wastewater. Water Res. 2025, 284, 123973.

- 12.Dicataldo, G.; Desmond, P.; Al-Maas, M.; et al. Feasibility and application of membrane aerated biofilm reactors for industrial wastewater treatment. Water Res. 2025, 280, 123523.

- 13.Wang, C.; Qi, W.-K.; Zhang, S.-J.; et al. Innovation for continuous aerobic granular sludge process in actual municipal sewage treatment: Self-circulating up-flow fluidized bed process. Water Res. 2024, 260, 121862.

- 14.Wang, S.; Song, W.; Liu, E.; et al. Efficient, facile and recyclable coating strategy to improve heavy metals removal by UF membrane in drinking water purification. Sep. Purif. Technol. 2025, 363, 131995.

- 15.Wang, X.; Guo, S.; Chen, W.; et al. Fe2O3-Kao@g-CN activated peroxymonosulfate remediation of bensulfuron methyl-polluted water and soil: Detoxification, soil properties and crop growth. Chem. Eng. J. 2024, 487, 150745.

- 16.Kasula, M.; Ortbal, S.; Kebede, M.M.; et al. Evaluating Biofiltration Pretreatment and NOM-PFAS Dynamics in PFAS Removal by Nanofiltration Membranes. ACS EST Water 2025, 5, 3628–3642.

- 17.Hou, L.; Hu, K.; Huang, F.; et al. Advances in immobilized microbial technology and its application to wastewater treatment: A review. Bioresour. Technol. 2024, 413, 131518.

- 18.Su, H.; Yin, H.; Wang, R.; et al. Atomic-level coordination structures meet graphitic carbon nitride (g-C3N4) for photocatalysis: Energy conversion and environmental remediation. Appl. Catal. B-Environ. Energy 2024, 348, 123683.

- 19.Wakjira, T.L.; Gemta, A.B.; Kassahun, G.B.; et al. Bismuth-Based Z-Scheme Heterojunction Photocatalysts for Remediation of Contaminated Water. ACS Omega 2024, 9, 8709–8729.

- 20.Wang, W.; Zhang, W.; Deng, C.; et al. Accelerated Photocatalytic Carbon Dioxide Reduction and Water Oxidation under Spatial Synergy. Angew. Chem. Int. Ed. 2024, 63, e202317969.

- 21.Xu, D.; Wang, H.; Zhang, K.; et al. Photocatalytic Waste Polystyrene Plastic Conversion: Reaction Mechanism and Catalyst Design. Environ. Sci. Technol. 2025, 59, 16112–16129.

- 22.Mani, S.S.; Rajendran, S.; Mathew, T.; et al. A review on the recent advances in the design and structure–activity relationship of TiO2-based photocatalysts for solar hydrogen production. Energy Adv. 2024, 3, 1472–1504.

- 23.Tian, T.; Lu, D.; Zhao, B.; et al. Exploring the intrinsic relationship between defects in g-C3N4 and the enhancement of photogenerated carrier dynamics and photocatalytic performance. J. Alloys Compd. 2025, 1010, 178135.

- 24.Zheng, X.; Song, Y.; Gao, Q.; et al. Controllable-Photocorrosion Balance Endows ZnCdS Stable Photocatalytic Hydrogen Evolution. Adv. Funct. Mater. 2025, 35, 2506159.

- 25.Zhang, X.; Bo, C.; Cao, S.; et al. Stability improvement of a Pt/TiO2 photocatalyst during photocatalytic pure water splitting. J. Mater. Chem. A 2022, 10, 24381–24387.

- 26.Masood, H.; Toe, C.Y.; Teoh, W.Y.; et al. Machine Learning for Accelerated Discovery of Solar Photocatalysts. ACS Catal. 2019, 9, 11774–11787.

- 27.Shiekhmohammadi, A.; Alamgholiloo, H.; Asgari, E.; et al. A plasmonic S-scheme Ag/ZrO2/TCN photocatalyst for enhancing interfacial charge transfer: Insights to machine learning models and mechanism for photodegradation. Colloids Surf. A 2025, 717, 136858.

- 28.Wayo, D.D.K.; Goliatt, L.; Ganji, M.D.; et al. DFT and hybrid classical–quantum machine learning integration for photocatalyst discovery and hydrogen production. Rev. Chem. Eng. 2025, 41, 741–774.

- 29.Tunala, S.; Zhai, S.; Wu, F.; et al. Machine learning in photocatalysis: Accelerating design, understanding, and environmental applications. Sci. China Chem. 2025, 68, 3415–3428.

- 30.Li, X.; Maffettone, P.M.; Che, Y.; et al. Combining machine learning and high-throughput experimentation to discover photocatalytically active organic molecules. Chem. Sci. 2021, 12, 10742–10754.

- 31.Mai, H.; Le, T.C.; Chen, D.; et al. Machine Learning for Electrocatalyst and Photocatalyst Design and Discovery. Chem. Rev. 2022, 122, 13478–13515.

- 32.Wang, S.; Mo, P.; Li, D.; et al. Intelligent Algorithms Enable Photocatalyst Design and Performance Prediction. Catalysts 2024, 14, 217.

- 33.Xiao, Y.; Choudhuri, K.; Thanetchaiyakup, A.; et al. Machine-Learning-Assisted Discovery of Mechanosynthesized Lead-Free Metal Halide Perovskites for the Oxidative Photocatalytic Cleavage of Alkenes. Adv. Sci. 2024, 11, 2309714.

- 34.Pang, Y.; Li, P.; Ma, X.; et al. Metal-doped carbon nitride: An all-in-one photocatalyst. EES Catal. 2023, 1, 810–831.

- 35.Wang, L.; Kong, Y.; Fang, Y.; et al. A Ga Doped NiTiO3 Photocatalyst for Overall Water Splitting under Visible Light Illumination. Adv. Funct. Mater. 2022, 32, 2208101.

- 36.Tu, B.; Hao, J.; Wang, F.; et al. Element doping adjusted the built-in electric field at the TiO2/CdS interface to enhance the photocatalytic reduction activity of Cr(VI). Chem. Eng. J. 2023, 456, 141103.

- 37.Ye, L.; Jin, X.; Liu, C.; et al. Thickness-ultrathin and bismuth-rich strategies for BiOBr to enhance photoreduction of CO2 into solar fuels. Appl. Catal. B-Environ. Energy 2016, 187, 281–290.

- 38.Bai, Y.; Wilbraham, L.; Slater, B.J.; et al. Accelerated Discovery of Organic Polymer Photocatalysts for Hydrogen Evolution from Water through the Integration of Experiment and Theory. J. Am. Chem. Soc. 2019, 141, 9063–9071.

- 39.Wang, Y.; Kang, Y.; Zhu, H.; et al. Perovskite Oxynitride Solid Solutions of LaTaON2-CaTaO2N with Greatly Enhanced Photogenerated Charge Separation for Solar-Driven Overall Water Splitting. Adv. Sci. 2021, 8, 2003343.

- 40.Xiao, M.; Wang, Z.; Lyu, M.; et al. Hollow Nanostructures for Photocatalysis: Advantages and Challenges. Adv. Mater. 2019, 31, 1801369.

- 41.Wang, Z.; Gu, Y.; Zheng, L.; et al. Machine Learning Guided Dopant Selection for Metal Oxide-Based Photoelectrochemical Water Splitting: The Case Study of Fe2O3 and CuO. Adv. Mater. 2022, 34, 2106776.

- 42.Nishimura, T.; Kumabe, Y.; Harashima, Y.; et al. Machine-Learning-Driven Photocurrent Prediction in Multielement-Doped Hematite Photoelectrodes. ACS Catal. 2025, 15, 11993–12004.

- 43.Zhang, L.; Chen, G.X.; Wang, Z.L.; et al. Automated machine learning guides discovery of ABO3-type oxides for effective water splitting photocatalysis. Chem. Phys. Lett. 2025, 869, 142034.

- 44.Sohrabi, S.; Rahimi, P.; Khedri, M.; et al. Evaluation of machine learning and molecular dynamics models for photocatalytic water decontamination. Process Saf. Environ. Prot. 2025, 195, 106780.

- 45.Mai, H.; Li, X.; Le, T.C.; et al. Rapid Design of Efficient Mn3O4-Based Photocatalysts by Machine Learning and Density Functional Theory Calculations. Adv. Energy Sustain. Res. 2025, 6, 2400397.

- 46.Wang, H.; You, C. Photocatalytic oxidation of SO2 on TiO2 and the catalyst deactivation: A kinetic study. Chem. Eng. J. 2018, 350, 268–277.

- 47.Haselmann, G.M.; Eder, D. Early-Stage Deactivation of Platinum-Loaded TiO2 Using In Situ Photodeposition during Photocatalytic Hydrogen Evolution. ACS Catal. 2017, 7, 4668–4675.

- 48.Weon, S.; Choi, W. TiO2 Nanotubes with Open Channels as Deactivation-Resistant Photocatalyst for the Degradation of Volatile Organic Compounds. Environ. Sci. Technol. 2016, 50, 2556–2563.

- 49.Allam, O.; Maghsoodi, M.; Jang, S.S.; et al. Unveiling Competitive Adsorption in TiO2 Photocatalysis through Machine-Learning-Accelerated Molecular Dynamics, DFT, and Experimental Methods. ACS Appl. Mater. Interfaces 2024, 16, 36215–36223.

- 50.Wu, C.H.; Wu, C.F.; Shr, J.F.; et al. Parameter settings on preparation of composite photocatalysts for enhancement of adsorption/photocatalysis hybrid capability. Sep. Purif. Technol. 2008, 61, 258–265.

- 51.Fu, X.; Huang, D.; Qin, Y.; et al. Effects of preparation method on the microstructure and photocatalytic performance of ZnSn(OH)6. Appl. Catal. B 2014, 148, 532–542.

- 52.Lin, X.; Du, X.; Wu, S.; et al. Machine learning-assisted dual-atom sites design with interpretable descriptors unifying electrocatalytic reactions. Nat. Commun. 2024, 15, 8169.

- 53.Li, R. Latest progress in hydrogen production from solar water splitting via photocatalysis, photoelectrochemical, and photovoltaic-photoelectrochemical solutions. Chin. J. Catal. 2017, 38, 5–12.

- 54.Wang, Z.; Huang, X.; Wang, X. Recent progresses in the design of BiVO4-based photocatalysts for efficient solar water splitting. Catal. Today 2019, 335, 31–38.

- 55.Yao, T.; An, X.; Han, H.; et al. Photoelectrocatalytic Materials for Solar Water Splitting. Adv. Energy Mater. 2018, 8, 1800210.

- 56.Huang, M.; Wang, S.; Zhu, H. A comprehensive machine learning strategy for designing high-performance photoanode catalysts. J. Mater. Chem. A 2023, 11, 21619–21627.

- 57.Zhang, L.; Zhang, J.; Yu, J.; et al. Charge-transfer dynamics in S-scheme photocatalyst. Nat. Rev. Chem. 2025, 9, 328–342.

- 58.Sudrajat, H.; Nobatova, M. Heterojunction photocatalysts: Where are they headed? RSC Appl. Interfaces 2025, 2, 599–619.

- 59.Wang, Z.; Li, C.; Domen, K. Recent developments in heterogeneous photocatalysts for solar-driven overall water splitting. Chem. Soc. Rev. 2019, 48, 2109–2125.

- 60.Zhou, H.; Sheng, X.; Ding, Z.; et al. Liquid–Liquid–Solid Triphase Interface Microenvironment Mediates Efficient Photocatalysis. ACS Catal. 2022, 12, 13690–13696.

- 61.Pan, S.; Lu, D.; Gan, H.; et al. Long-range hydrophobic force enhanced interfacial photocatalysis for the submerged surface anti-biofouling. Water Res. 2023, 243, 120383.

- 62.Zeng, Z.; Tan, L.; Ye, F.; et al. Carbon nitride with water soluble ability: Enhanced oxygen species interphase mass transfer for homogenous photocatalytic water purification. Appl. Surf. Sci. 2024, 652, 159352.

- 63.Li, L.; Xu, L.; Hu, Z.; et al. Enhanced Mass Transfer of Oxygen through a Gas–Liquid–Solid Interface for Photocatalytic Hydrogen Peroxide Production. Adv. Funct. Mater. 2021, 31, 2106120.

- 64.Zhang, G.; Li, X.; Chen, D.; et al. Internal Electric Field and Adsorption Effect Synergistically Boost Carbon Dioxide Conversion on Cadmium Sulfide@Covalent Triazine Frameworks Core–Shell Photocatalyst. Adv. Funct. Mater. 2023, 33, 2308553.

- 65.Yu, L.; Wang, Q.; Zhuang, C.; et al. Periodic Frustrated Lewis Pairs on Bimetallic Oxide Semiconductors for CO2 Adsorption and Photocatalytic Conversion. ACS Nano 2025, 19, 7239–7252.

- 66.El-Alami, W.; Sousa, D.G.; González, J.D.; et al. TiO2 and F-TiO2 photocatalytic deactivation in gas phase. Chem. Phys. Lett. 2017, 684, 164–170.

- 67.Yu, G.; Wang, N. Gas-Liquid-Solid interface enhanced photocatalytic reaction in a microfluidic reactor for water treatment. Appl. Catal. A 2020, 591, 117410.

- 68.Zhao, Y.; Guo, J.; Yang, B.; et, al. A multilayered Co–Fe MOF/GO 3D evaporator for efficient solar-driven water generation and wastewater purification. J. Mater. Chem. A 2025, 13, 27314–27325.

- 69.Wang, W.; Tian, Z.; Huan, X.; et al. Solar-Driven Interfacial Evaporation: Material Types, Structural Strategies, and Emerging Applications. Langmuir 2025, 41, 24097–24134.

- 70.Song, Y.; Fang, S.; Xu, N.; et al. Solar-driven interfacial evaporation technologies for food, energy and water. Nat. Rev. Clean. Technol. 2025, 1, 55–74.

- 71.Lv, B.; Dong, X.; Xu, Y.; et al. A self-sufficient catalytic nanofiber evaporator for solar-driven efficient water purification through in-situ hydrogen peroxide generation. Chem. Eng. J. 2024, 501, 157611.

- 72.Sheng, X.; Liu, Z.; Zeng, R.; et al. Enhanced Photocatalytic Reaction at Air–Liquid–Solid Joint Interfaces. J. Am. Chem. Soc. 2017, 139, 12402–12405.

- 73.Chen, R.; Li, J.; Wang, H.; et al. Photocatalytic reaction mechanisms at a gas–solid interface for typical air pollutant decomposition. J. Mater. Chem. A 2021, 9, 20184–20210.

- 74.Ma, H.; Wang, X.; Jin, R.; et al. Promote hydroxyl radical and key intermediates formation for deep toluene mineralization via unique electron transfer channel. J. Colloid Interface Sci. 2023, 630, 704–713.

- 75.Li, Y.; Ouyang, S.; Xu, H.; et al. Constructing Solid–Gas-Interfacial Fenton Reaction over Alkalinized-C3N4 Photocatalyst To Achieve Apparent Quantum Yield of 49% at 420 nm. J. Am. Chem. Soc. 2016, 138, 13289–13297.

- 76.Chen, Z.; Zhao, J.; Zhao, J.; et al. Frustrated Lewis pairs photocatalyst for visible light-driven reduction of CO to multi-carbon chemicals. Nanoscale 2019, 11, 20777–20784.

- 77.Xu, C.; Yang, W.; Guo, Q.; et al. Photoinduced decomposition of acetaldehyde on a reduced TiO2(110) surface: Involvement of lattice oxygen. Phys. Chem. Chem. Phys. 2016, 18, 30982–30989.

- 78.Lopez-Besora, J.; Pardal, C.; Isalgue, A.; et al. Exploring the Integration of a Novel Photocatalytic Air Purification Façade Component in Buildings. Buildings 2024, 14, 2481.

- 79.Asadi, S.; Hassan, M.; Nadiri, A.; et al. Artificial intelligence modeling to evaluate field performance of photocatalytic asphalt pavement for ambient air purification. Environ. Sci. Pollut. Res. 2014, 21, 8847–8857.

- 80.Li, W.; Yue, F.; Shi, M.; et al. Thermally assisted photocatalytic industrial flue gas CO2 conversion: 100% selective CO production via synergistic adsorption–conversion in NH2–MXene–MOF hierarchical interfaces. J. Mater. Chem. A 2025, 13, 33233–33244.

- 81.Murgolo, S.; Franz, S.; Arab, H.; et al. Degradation of emerging organic pollutants in wastewater effluents by electrochemical photocatalysis on nanostructured TiO2 meshes. Water Res. 2019, 164, 114920.

- 82.Ding, R.; Yan, W.; Wu, Y.; et, al. Light-excited photoelectrons coupled with bio-photocatalysis enhanced the degradation efficiency of oxytetracycline. Water Res. 2018, 143, 589–598.

- 83.Liu, W.; Dong, Y.; Liu, J.; et al. Halloysite nanotube confined interface engineering enhanced catalytic oxidation of photo-Fenton reaction for aniline aerofloat degradation: Defective heterojunction for electron transfer regulation. Chem. Eng. J. 2023, 451, 138666.

- 84.Liu, R.; Zheng, Z.; Spurgeon, J.; et al. Enhanced photoelectrochemical water-splitting performance of semiconductors by surface passivation layers. Energy Environ. Sci. 2014, 7, 2504–2517.

- 85.Li, J.; Wei, J.; Sun, J.; et al. Building the bimetallic site of Co2Mo3O8/Co9S8 heterojunction via interface electronic reconfiguration to enhance peroxymonosulfate activation for singlet oxygen formation. Chem. Eng. J. 2025, 505, 159739.

- 86.Kuddushi, M.; Deng, X.; Nayak, J.; et al. A Transparent, Tough and Self-Healable Biopolymeric Composites Hydrogel for Open Wound Management. ACS Appl. Bio Mater. 2023, 6, 3810–3822.

- 87.Xu, B.B.; Zhou, M.; Ye, M.; et al. Cooperative Motion in Water–Methanol Clusters Controls the Reaction Rates of Heterogeneous Photocatalytic Reactions. J. Am. Chem. Soc. 2021, 143, 10940–10947.

- 88.Mudhoo, A.; Bhatnagar, A.; Rantalankila, M.; et al. Endosulfan removal through bioremediation, photocatalytic degradation, adsorption and membrane separation processes: A review. Chem. Eng. J. 2019, 360, 912–928.

- 89.Fazey, F.M.; Ryan, P.G. Debris size and buoyancy influence the dispersal distance of stranded litter. Mar. Pollut. Bull. 2016, 110, 371–377.

- 90.Barone, G.D.; Rodríguez-Seijo, A.; Parati, M.; et al. Harnessing photosynthetic microorganisms for enhanced bioremediation of microplastics: A comprehensive review. Environ. Sci. EcoTechnol. 2024, 20, 100407.

- 91.Hu, C.; Tu, S.; Tian, N.; et al. Photocatalysis Enhanced by External Fields. Angew. Chem. Int. Ed. 2021, 60, 16309–16328.

- 92.Li, X.; Wang, W.; Dong, F.; et al. Recent Advances in Noncontact External-Field-Assisted Photocatalysis: From Fundamentals to Applications. ACS Catal. 2021, 11, 4739–4769.

- 93.Zhu, Y.; Wang, H.; Wang, B.; et al. Solar thermoelectric field plus photocatalysis for efficient organic synthesis exemplified by toluene to benzoic acid. Appl. Catal. B-Environ. Energy 2016, 193, 151–159.

- 94.Van Doorslaer, X.; Demeestere, K.; Heynderickx, P.M.; et al. Heterogeneous photocatalysis of moxifloxacin: Identification of degradation products and determination of residual antibacterial activity. Appl. Catal. B-Environ. Energy 2013, 138, 333–341.

- 95.Zhang, Y.; Qi, M.Y.; Tang, Z.R.; et al. Photoredox-Catalyzed Plastic Waste Conversion: Nonselective Degradation versus Selective Synthesis. ACS Catal. 2023, 13, 3575–3590.

- 96.Chen, W.; Li, X.; Wang, F.; et al. Nonepitaxial Gold-Tipped ZnSe Hybrid Nanorods for Efficient Photocatalytic Hydrogen Production. Small 2020, 16, 1902231.

- 97.Wu, S.; Quan, X. Design Principles and Strategies of Photocatalytic H2O2 Production from O2 Reduction. ACS ES&T Eng. 2022, 2, 1068–1079.

- 98.Xia, C.; Yuan, L.; Song, H.; et al. Spatial Specific Janus S-Scheme Photocatalyst with Enhanced H2O2 Production Performance. Small 2023, 19, 2300292.

- 99.Lu, Y.; Dong, Y.; Liu, W.; et, al. Piezo-photocatalytic enhanced microplastic degradation on hetero-interpenetrated Fe1−xS/FeMoO4/ MoS2 by producing H2O2 and self-Fenton action. Chem. Eng. J. 2025, 508, 160935.

- 100.Hu, C.; Huang, H.; Chen, F.; et al. Coupling Piezocatalysis and Photocatalysis in Bi4NbO8X (X = Cl, Br) Polar Single Crystals. Adv. Funct. Mater. 2020, 30, 1908168.

- 101.Wang, R.; Xie, X.; Xu, C.; et al. Bi-piezoelectric effect assisted ZnO nanorods/PVDF-HFP spongy photocatalyst for enhanced performance on degrading organic pollutant. Chem. Eng. J. 2022, 439, 135787.

- 102.Chen, R.; Wang, J.; Zhang, C.; et al. Purification and Value-Added Conversion of NOx under Ambient Conditions with Photo-/Electrocatalysis Technology. Environ. Sci. Technol. 2025, 59, 1013–1033.

- 103.Singh, S.; Kapoor, S.; Singh, J.P. Synergistic Photocatalysis by α-MoO3 Nanostructures and SWCNT Nanocomposites for Efficient Cross-Linking and Oxidative Degradation of Polystyrene Nanoplastics. ACS Appl. Mater. Interfaces 2024, 16, 40914–40926.

- 104.Van Gerven, T.; Mul, G.; Moulijn, J.; et al. A review of intensification of photocatalytic processes. Chem. Eng. Process 2007, 46, 781–789.

- 105.Jiang, H.; Chen, H.; Fu, Y.; et al. SnFe2O4 mediated near-infrared-driven photocatalysis, photothermal sterilization and piezocatalysis. Appl. Surf. Sci. 2023, 611, 155555.

- 106.Lu, D.; Ren, Y.; Yang, Y.; et al. Boosted photocatalytic CO2 reduction by induced electromotive force in rotating magnetic field. Nano Energy 2023, 113, 108578.

- 107.Gong, Y.N.; Zhong, D.C.; Lu, T.B. Porous Supramolecular Crystalline Materials for Photocatalysis. Angew. Chem. Int. Ed. 2025, 64, e202424452.

- 108.Munoz, I.; Rieradevall, J.; Torrades, F.; et al. Environmental assessment of different solar driven advanced oxidation processes. Sol. Energy 2005, 79, 369–375.

- 109.Muñoz, I.; Peral, J.; Ayllón, J.A.; et al. Life cycle assessment of a coupled solar photocatalytic–biological process for wastewater treatment. Water Res. 2006, 40, 3533–3540.

- 110.Dubsok, A.; Khamdahsag, P.; Kittipongvises, S. Life cycle environmental impact assessment of cyanate removal in mine tailings wastewater by nano-TiO2/FeCl3 photocatalysis. J. Clean. Prod. 2022, 366, 132928.

- 111.Foteinis, S.; Borthwick, A.G.; Frontistis, Z.; et al. Environmental sustainability of light-driven processes for wastewater treatment applications. J. Clean. Prod. 2018, 182, 8–15.

- 112.Magdy, M.; Alalm, M.G.; El-Etriby, H.K. Comparative life cycle assessment of five chemical methods for removal of phenol and its transformation products. J. Clean. Prod., 2021, 291, 125923.

- 113.Dominguez, S.; Laso, J.; Margallo, M.; et al. LCA of greywater management within a water circular economy restorative thinking framework. Sci. Total Environ. 2018, 621, 1047–1056.

- 114.Pesqueira, J.F.; Pereira, M.F.R.; Silva, A.M. A life cycle assessment of solar-based treatments (H2O2, TiO2 photocatalysis, circumneutral photo-Fenton) for the removal of organic micropollutants. Sci. Total Environ. 2021, 761, 143258.

- 115.Aboagye, E.; Longo, J.; Conway, M.; et al. Leveraging machine learning algorithms to predict life cycle inventory assessments (LCIA) to facilitate sustainable process design. Comput. Chem. Eng. 2025, 201, 109217.

How to Cite

Liu, W.; Wang, B.; Yangjin, D.; Zhan, S. Machine Learning Assists in the Design of Photocatalysts for Environmental Remediation: A Comprehensive Review. Environmental and Microbial Technology 2026, 1 (1), 2. https://doi.org/10.53941/emt.2026.100002.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References