Compacted graphite cast iron (CGI) possesses excellent mechanical properties and is widely used in manufacturing cylinder blocks and heads for high-power internal combustion engines. However, higher tensile strength in CGI corresponds to a greater probability of shrinkage porosity defects occurring during production, resulting in few manufacturers being able to stably produce cylinder heads made of the RuT500 high-strength material grade. To address the shrinkage porosity issue in RuT500 high-strength cylinder heads, this study conducted experimental research focusing on raw material selection and control, the influence of carbon equivalent (CE) on tensile strength and shrinkage porosity, and the optimization of casting feeding design. The results indicate that, based on the specific structural characteristics of this cylinder head and the casting process conditions, cylinder heads with a body tensile strength exceeding 500 MPa and free from shrinkage porosity defects can be successfully produced by selecting high-purity or ultra-high-purity pig iron as the raw material when CE ≤ 4.43 and the riser feeding modulus is 2.2.

- Open Access

- Article

Preparation Process and Optimization of High-Strength Cylinder Head Made from RuT500 Compacted Graphite Iron

- Chunhua He 1,2,

- Yongze Yang 3,

- Dong Qin 4,

- Zhenwen Lian 2,

- Jianyou Huang 1,*,

- Yansheng Che 2,

- Changbo Zhong 4

Author Information

Received: 06 Aug 2025 | Revised: 27 Aug 2025 | Accepted: 10 Sep 2025 | Published: 16 Sep 2025

Abstract

Keywords

compacted graphite iron (CGI) | RuT500 | high-strength | cylinder head | manufacturing process

1.Introduction

As a critical component of an engine, the cylinder head operates under extremely harsh conditions, subject to high temperature, high pressure, and complex mechanical loads. Compacted graphite iron (CGI), due to its balanced combination of properties (such as high strength, good thermal conductivity, and excellent thermal fatigue resistance) positioned between gray iron and ductile iron, has become an ideal material for manufacturing engine cylinder heads [1–5].

However, the primary process challenge in producing cylinder heads using CGI is the susceptibility of castings to shrinkage porosity and cavity defects [6]. This issue is particularly pronounced in high-grade CGI materials. Fundamentally, this stems from the ineffective matching of casting processes (such as gating and risering system design, venting system design) and melting processes (such as molten iron composition control, vermicularization treatment), failing to find the critical balance point. This severely restricts the application of high-grade CGI in the manufacture of high-performance, high-power internal combustion engine cylinder heads.

Currently, public literature specifically addressing RuT500 (internationally designated as GJV500) is relatively scarce. Existing research primarily focuses on material properties and machinability [7–12], with limited studies on its manufacturing process. There is a notable lack of in-depth discussion on key issues encountered during casting, such as shrinkage porosity and shrinkage cavity defects. Nevertheless, to stably obtain CGI cylinder heads free from shrinkage porosity and cavities (hereinafter referred to as high-quality) with a body tensile strength reaching 500 MPa (hereinafter referred to as high-strength), systematic optimization of the casting process, raw material selection, melting process, and indeed the entire production workflow is essential [13].

The author’s company specializes in the production of cylinder blocks and cylinder heads. For products requiring superior material properties, compacted graphite iron (CGI) is exclusively used. The core-making process employs a combination of cold-box and hot-box techniques, utilizing the HSW static pressure molding process. For melting operations, a 10-ton Inductotherm medium-frequency induction furnace is utilized, and production incorporates the Online Controlled Carburization vermicularization process (hereinafter referred to as OCC wire-feeding vermicularization) [14]. Since the cylinder head product requires a body tensile strength on the combustion face of ≥500 MPa (achieving internationally advanced levels), the key challenge for enabling stable production of high-quality, high-strength cylinder heads lies in the precise matching and control of critical parameters within both the casting and melting processes.

Therefore, this paper targets the RuT500 material grade to explore the manufacturing process and optimization strategies for its cylinder heads.

2.Casting Process Design

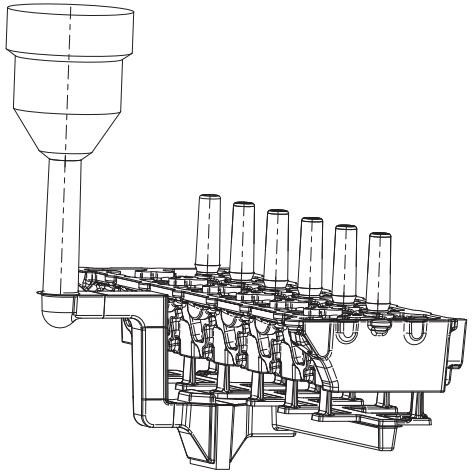

The cylinder head has overall dimensions of 924 mm × 292 mm × 120 mm and is cast in a flask measuring 1450 mm × 1100 mm × 420 mm. Given the extremely demanding material property requirements for this cylinder head (reaching the performance limits of CGI), the process design must prioritize enhanced feeding through the strategic addition of risers.

To improve casting yield and optimize riser placement, a horizontal pouring casting process with one casting per mold was ultimately adopted [15]. Within the mold, the cylinder head combustion face is positioned in the drag (lower mold), and the top face is positioned in the cope (upper mold), as shown in the casting process layout (Figure 1). This arrangement facilitates the placement of exothermic risers at critical hot spots (specifically the fuel injector bore region) for effective feeding.

The gating system employs a bottom-filling design for mold filling, with ingates located on both sides of the fire deck (combustion face) of the cylinder head. The fuel injector bore area constitutes the main hot spot of the entire cylinder head and is situated far from the gating points. The bottom-filling process results in relatively lower iron temperature in this area (as it is filled last), while the riser is positioned at the farthest end of this metal flow path (i.e., near the injector bore). This leads to the lowest molten iron temperature in the riser, making it difficult for a conventional riser to provide effective feeding. Not only can a conventional riser fail to effectively feed the injector bore hot spot, but it may also solidify too quickly itself, causing a “reverse feeding” phenomenon (where the casting feeds the riser instead). Therefore, exothermic risers must be used to effectively solve the feeding problem for this hot spot [16].

The cylinder head requires a body tensile strength of ≥500 MPa on the combustion face. Since critical areas such as the water inlet ports are also located on the combustion face, this region represents the zone with the highest performance demands and relatively unfavorable solidification conditions (experiencing higher metal temperatures and slower cooling during filling). Consequently, evaluating the properties on the combustion face (including the water inlet port area) effectively confirms whether the material properties of the entire casting meet the design requirements. In other words, if the material properties in the combustion face region (particularly including hot spot areas) meet the specification, the entire casting is generally considered to satisfy the performance requirements.

3.Melting Control

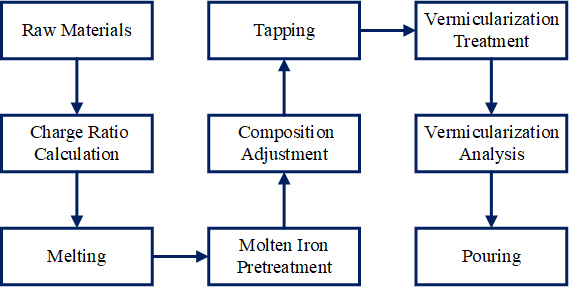

3.1.Melting Process Flow Diagram

Key process control points during melting are detailed in the Process Flow Diagram (shown in Figure 2).

3.2.Raw Material Control Essentials

Pig iron: High-purity or ultra-high-purity premium-grade pig iron is selected [17]. Its advantages include moderate carbon content and low levels of silicon, sulfur, phosphorus, and trace elements, effectively minimizing adverse effects of impurities on the solidification structure and final properties of the cast iron.

Scrap steel: High-cleanliness scrap steel with low alloying elements and impurity content is used. This type of scrap enhances the overall mechanical properties of the cast iron material.

3.3.Vermicularization Treatment Control Essentials

The weight of tapped iron must be precisely controlled within the predetermined range to ensure stability in the quality of the wire-feeding vermicularization treatment. To guarantee consistent vermicularization effects, the slag on the surface of the iron ladle must be completely removed before the wire-feeding process. For the first ladle, the addition parameters of Mg wire (main components: Mg, Si, RE) and inoculating wire (main component: Si) required for vermicularization are comprehensively determined based on the weight of molten iron, treatment temperature, recommended values from the OCC system, and optimized production results [18,19]. The Mg wire addition amount for subsequent ladles is adjusted according to the Mg index detected by the OCC system from the previous ladle, ensuring that the Mg index always remains within the range recommended by the OCC system. The inoculating wire addition is adjusted based on the inoculation index detected by the OCC system. The iron ladle is transferred to the vermicularization wire-feeding station for processing using a forklift. The key to consistently obtaining high-quality vermicular graphite iron material lies in strict control of: the molten iron’s wire-feeding treatment temperature, iron weight, Mg wire addition amount, and its feeding speed.

3.4.Vermicularization Analysis Control Essentials

Upon completion of the wire-feeding vermicularization treatment, the ladle is transferred to the sampling station via forklift for thermal analysis [20,21]. Pouring can only proceed after the thermal analysis results confirm that both the Mg index and the inoculation index meet the technical requirements. If the standards are not met, the ladle of molten iron must be returned to the furnace for re-tapping and re-vermicularization treatment.

4.Material Testing

Following disassembly of the cylinder head, tensile test specimens were extracted from the combustion face region. In accordance with the Chinese National Standard GB/T 228.1—2010 “Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature”, specimens were machined into standard tensile specimens with a diameter of 10 mm and a gauge length of 50 mm.

Tensile testing was conducted on a WDW 3100 electronic universal testing machine (Changchun Chuangyuan Testing Equipment Co., Ltd., Changchun, China) at a crosshead speed of 2 mm/min. Three parallel specimens were tested per group, with the average tensile strength value reported as the final performance result [22].

Metallographic specimens were taken from the tensile specimen exhibiting the strength closest to the group average. After grinding and polishing using a ZMP-2000 intelligent automatic metallographic polishing machine (Shanghai Yanrun Optical Machinery Technology Co., Ltd., Shanghai, China), graphite morphology was observed under an Axio Scope.A1 metallurgical microscope (Carl Zeiss AG, Oberkochen, Baden-Württemberg, Germany). Observations were performed at 100× and 200× magnifications, capturing two micrographs each from five distinct fields of view (upper, middle, lower, left, and right regions) per specimen.

Graphite morphology was classified according to GB/T 26656—2023 “Metallographic Examination of Compacted Graphite Cast Irons” by comparison with standard micrographs, supplemented by analysis using the Axio Imaging intelligent metal microstructure analysis system.

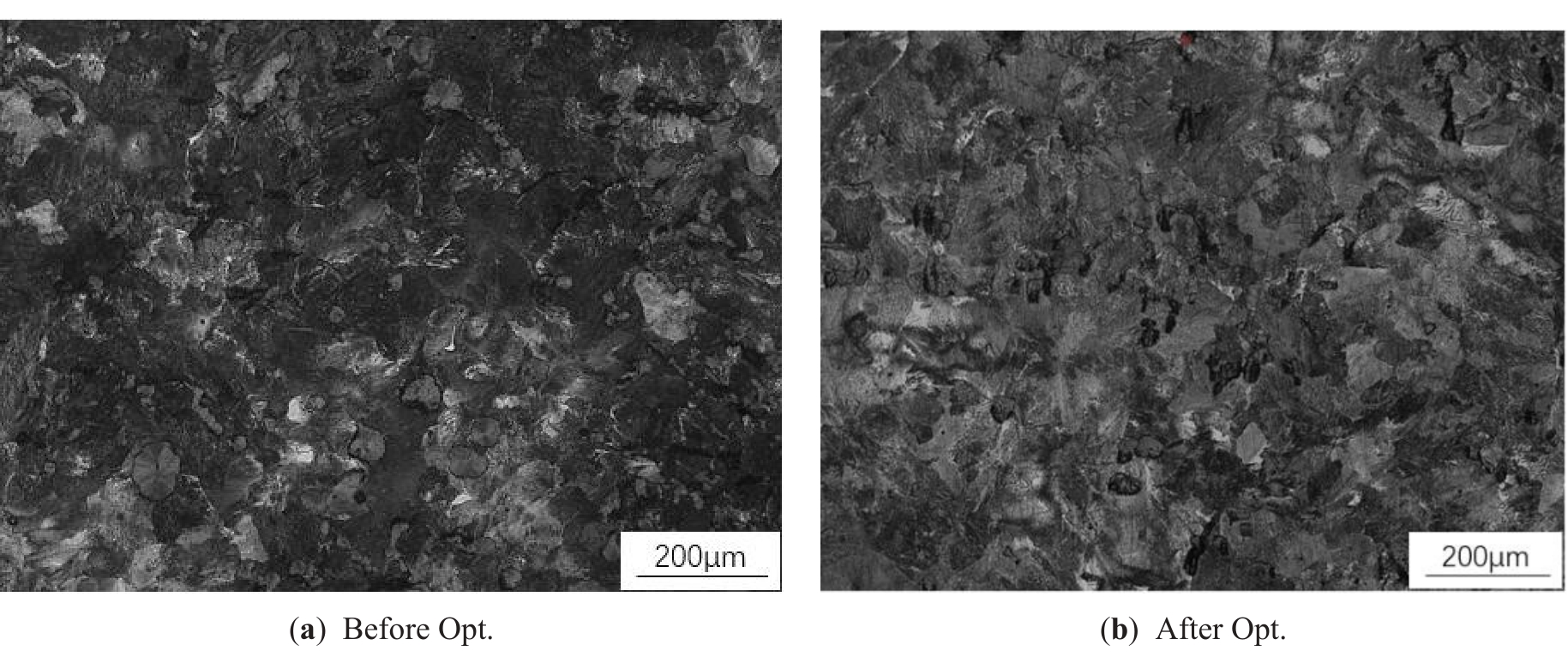

Subsequently, polished specimens were etched with 4% nital solution (nitric acid in ethanol) to reveal the matrix microstructure. Pearlite content was quantitatively rated, with the average rating from multiple fields adopted as the final pearlite content grade for each specimen [23].

5.Pre-Optimization Process Design and Melting Practice

5.1.Experimental Plan

Based on the casting process layout in Figure 1, the feeding modulus of the riser for the cylinder head fuel injector bore was designed as 1.8 (pouring temperature 1490 ℃; 1147 ℃ holding time 300 s). Trials were conducted according to the molten iron composition requirements specified in the melting process, with detailed target compositions listed in Table 1.

Chemical Composition Requirements of Molten Iron Before and After Process Optimization (wt.%).

| Approach | C | Si | Mn | S | Cu | Mo | Sn |

|---|---|---|---|---|---|---|---|

Before Optimization (Before Opt.) | 3.75–3.90 | 1.9–2.2 | 0.4–0.7 | 0.010–0.018 | 0.8–1.0 | 0.1–0.3 | 0.07–0.10 |

After Optimization (After Opt.) | 3.65–3.80 | 1.9–2.1 | 0.4–0.7 | 0.010–0.018 | 0.8–1.0 | 0.1–0.3 | 0.07–0.10 |

5.2.Experimental Results

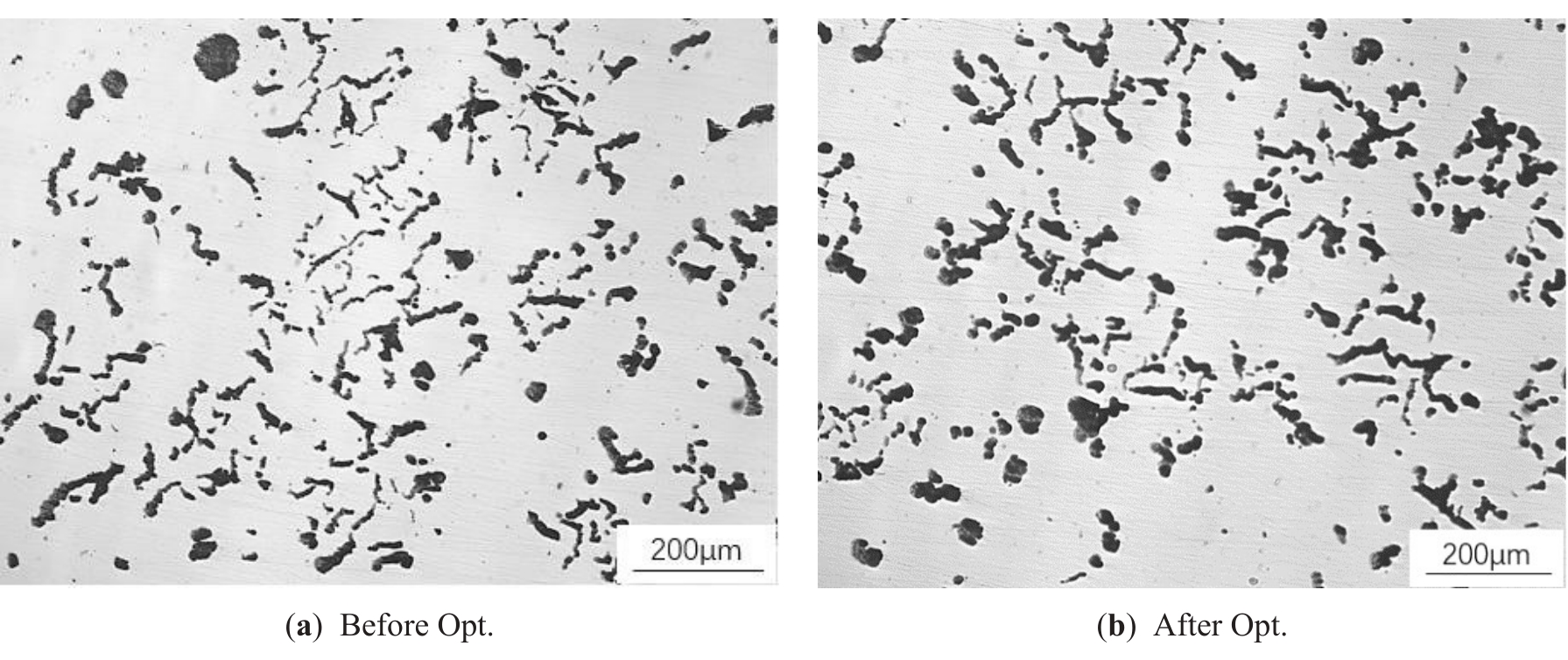

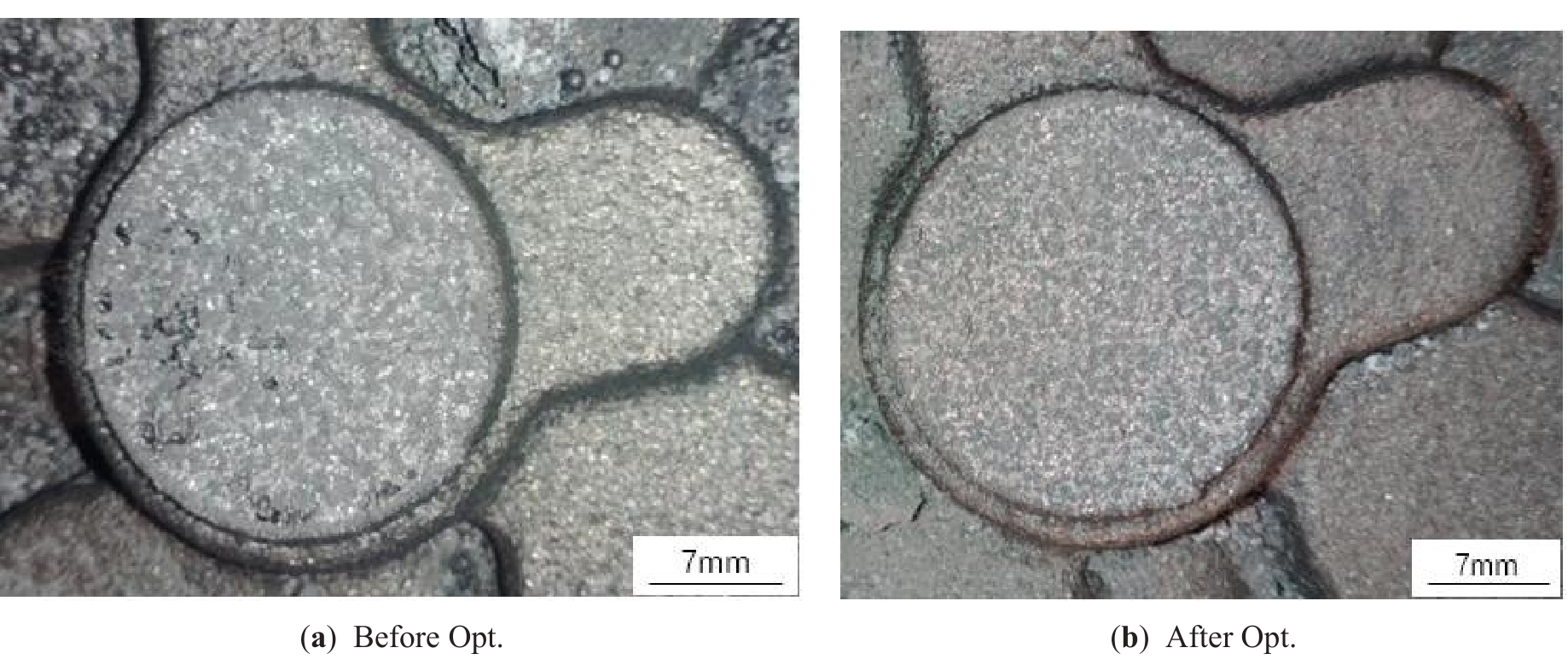

After multiple trial series, experimental data exhibiting consistent vermicularity grades were selected for focused analysis to more accurately identify key control factors for stably producing high-strength (body tensile strength ≥ 500 MPa) and high-quality (shrinkage-defect-free) cylinder heads. This data screening strategy aimed to minimize analytical bias caused by vermicularity fluctuations [24]. Critical process parameters during the optimization and corresponding material property test results are detailed in Table 2; representative microstructures are shown in Figures 3a and 4a.

Key Process Parameters and Material Properties Before and After Optimization.

| Approach | No. | CE/% | Solidification Value | Liquidus Temperature/℃ | Tensile Strength/MPa | Vermicularity/% | Vermicularity Grade | Pearlite Content/% | Casting Quality |

|---|---|---|---|---|---|---|---|---|---|

| Before Opt. | 1 | 4.29 | 50 | 1160 | 538 | 84.2 | 80 | 95 | Shrinkage cavity |

| 2 | 4.35 | 50 | 1153 | 535 | 80.4 | 80 | 95 | Shrinkage cavity | |

| 3 | 4.38 | 50 | 1149 | 525 | 83.6 | 80 | 95 | Shrinkage cavity | |

| 4 | 4.48 | 140 | 1139 | 489 | 81.9 | 80 | 95 | Shrinkage-free | |

| 5 | 4.5 | 140 | 1137 | 470 | 84.7 | 80 | 95 | Shrinkage-free | |

After Opt. | 1 | 4.27 | 50 | 1161 | 545 | 80.5 | 80 | 95 | Shrinkage-free |

| 2 | 4.32 | 50 | 1156 | 532 | 82.5 | 80 | 95 | Shrinkage-free | |

| 3 | 4.34 | 50 | 1153 | 520 | 84.6 | 80 | 95 | Shrinkage-free | |

| 4 | 4.41 | 50 | 1146 | 516 | 81.8 | 80 | 95 | Shrinkage-free | |

| 5 | 4.43 | 50 | 1144 | 511 | 83.7 | 80 | 95 | Shrinkage-free |

5.3.Casting Quality Assessment

(1) Strength Inconsistency: Even with a stabilized vermicularity grade of 80%, the body tensile strength on the combustion face failed to consistently meet the product design requirement (≥500 MPa). Material performance declined significantly when the solidification value (SV) ≥ 140 (A solidification value of 100 represents the eutectic point; a value less than 100 indicates a hypoeutectic composition, and a value greater than 100 indicates a hypereutectic composition. It is a dimensionless quantity.) and the molten iron composition was hyper-eutectic. This indicates an urgent need for further optimization of the current melting process parameter ranges.

(2) Defect-Strength Trade-off: Experimental results demonstrated that cylinder heads achieving a body tensile strength of 500 MPa exhibited a significantly increased risk of shrinkage porosity and cavity defects in the fuel injector bore region [25]. Figure 5a clearly illustrates a typical shrinkage cavity defect near the riser neck adjacent to the fuel injector bore [26].

(3) Hyper-eutectic Benefit: For cylinder heads not attaining 500 MPa body tensile strength, when SV = 140 under hyper-eutectic composition, no shrinkage defects were observed at the injector bore riser neck region despite the identical vermicularity grade. This indicates that hyper-eutectic solidification favors reduced formation of shrinkage porosity and cavity defects.

(4) The CE Conundrum: Achieving hyper-eutectic solidification necessitates increasing the CE. However, elevated CE degrades material properties, making it difficult to satisfy the design requirement for body tensile strength ≥500 MPa.

5.4.Integrated Optimization Pathway

Synthesizing the analysis of material properties and feeding performance, the feasible process route comprises:

(1) Enhance Feeding Capacity: First, increase the feeding capability of the cylinder head risers.

(2) Adjust Iron Composition: Subsequently, appropriately reduce the CE value to shift the molten iron composition into a hypo-eutectic state, thereby improving material properties.

(3) Implement Effective Hot Spot Feeding: Concurrently, employ exothermic risers possessing sufficient feeding modulus to effectively feed critical hot spots.

Through this synergistic process optimization, stable production of high-strength (≥500 MPa) and high-quality (shrinkage-defect-free) cylinder heads can be achieved.

6.Post-Optimization Process Design and Melting Practice

6.1.Experimental Plan

Based on pre-optimization process design schemes, melting ratio parameters, and analysis of trial production results, a two-stage approach was implemented to resolve unstable material properties and shrinkage porosity/cavity defects:

(1) Optimize Casting Design: Increase feeding capacity by enhancing exothermic riser design.

(2) Adjust Melting Parameters: Subsequently reduce the carbon equivalent (CE) to stabilize material properties at the design requirement.

The pre-optimization riser feeding modulus of 1.8 was insufficient. To achieve stable feeding and improve casting yield, the modulus was increased to 2.2 (pouring temperature 1560 °C; 1147 °C holding time 312 s) using exothermic risers. With adequate riser feeding capacity and compliant vermicularity (≥80%), CE reduction improved material properties, enabling consistent attainment of body tensile strength ≥500 MPa. Optimized molten iron composition targets are detailed in Table 1.

6.2.Experimental Results

To enable direct comparison, data matching the vermicularity grades of pre-optimization trials were selected, minimizing analytical bias from vermicularity variations. Key process parameters and material property test results are listed in Table 2; corresponding microstructures are shown in Figures 3b and 4b.

6.3.Casting Quality Assessment

(1) Strength Stability: After CE reduction, body tensile strength on the combustion face consistently achieved values ≥500 MPa at a vermicularity grade of 80.

(2) Defect Elimination: Enhanced riser feeding capability resulted in no occurrence of shrinkage porosity or cavity defects at the fuel injector bore riser neck, as show in Figure 5b. Machining verification confirmed complete resolution of shrinkage defects in this area.

(3) Integrated Performance: Cylinder heads exhibited stable high-strength (≥500 MPa) and defect-free quality.

6.4.Validated Process Mechanism

When riser feeding capacity is sufficient:

(1) CE reduction enables a hypo-eutectic molten iron composition.

(2) Material properties improve controllably.

(3) Stable production of high-strength, high-quality compacted graphite iron (CGI) cylinder heads is achieved.

7.Results Analysis and Discussion

7.1.Experimental Data Screening Strategy

Given the inherent subjectivity in vermicularity assessment, this study prioritized comparative analysis of experimental data sharing identical vermicularity grades to minimize evaluation bias. All subsequent analyses adhered to this controlled vermicularity condition.

7.2.Relationship between CE and Material Properties

Analysis of pre-optimization data (Table 2) established a clear inverse correlation: at consistent vermicularity grades, elevated CE directly caused progressive reduction in body tensile strength.

7.3.Relationship between CE and Casting Defects

Under an identical riser feeding modulus (1.8), pre-optimization data demonstrated:

(1) Reduced CE triggered: Heightened shrinkage tendency; significantly increased shrinkage cavity risk (Mechanism: Diminished eutectic expansion weakened self-feeding capacity).

(2) Increased CE generated: Enhanced self-feeding capacity that reduced shrinkage defects; material property degradation preventing attainment of ≥500 MPa strength requirements.

7.4.Synergistic Optimization of Riser Modulus and CE

Resolving the core conflict—where hypo-eutectic composition improves strength but intensifies shrinkage risk—required coordinated measures:

(1) Substantial enhancement of riser feeding capacity via modulus elevation from 1.8 to 2.2.

(2) Implementation of hypo-eutectic CE composition made feasible by robust feeding assurance.

Post-optimization Outcomes:

(1) Increased modulus (2.2) produced clinically effective feeding performance.

(2) Hypo-eutectic CE consistently delivered body tensile strength ≥500 MPa

(3) The integrated approach successfully enabled stable production of high-strength (≥500 MPa), defect-free cylinder heads

8.Conclusions

Addressing the fundamental conflict between shrinkage defects and high-strength requirements (≥500 MPa) in high-grade RuT500 cylinder head production, this study systematically analyzed and optimized the manufacturing process. Validated conclusions are as follows:

(1) Critical Process Window Confirmation: Using high-purity or ultra-high-purity premium pig iron as raw material, cylinder heads with body tensile strength ≥500 MPa and free from shrinkage defects can be stably produced under the conditions of carbon equivalent (CE) ≤ 4.43 and riser feeding modulus ≥ 2.2.

(2) CE Impact on Material Properties: At consistent vermicularity grades, elevated CE causes a significant reduction in body tensile strength.

(3) CE Influence on Solidification Feeding: Under fixed riser feeding capacity (modulus), increased CE enhances casting self-feeding capacity (primarily through augmented eutectic expansion), thereby reducing shrinkage defect risks.

(4) Synergistic Optimization Strategy: Achieving high-strength targets (≥500 MPa) requires hypo-eutectic compositions (lower CE). To counteract increased shrinkage tendency from reduced CE, feeding capacity must be substantially enhanced (modulus ≥ 2.2), establishing an effective process equilibrium.

Process Integration Principle: Casting process design (e.g., riser system optimization) and melting control (CE, vermicularity) are intrinsically interdependent. Superior casting design enhances fault tolerance and adaptability of melting parameters, significantly improving production controllability for stable manufacturing of high-quality (defect-free), high-strength (≥500 MPa) cylinder heads.

Future Research Directions: Further investigation should deepen the understanding of CGI solidification behavior and microstructure formation mechanisms. Developing advanced production technologies and intelligent control systems will continuously enhance the comprehensive quality and in-service performance of high-strength CGI cylinder heads, providing stronger support for automotive industry innovation.

Author Contributions: J.H.: conceptualization, methodology, software; C.Z.: data curation, writing—original draft preparation; C.H., Y.Y., D.Y., and D.Q.: visualization, investigation; J.H.: supervision; Y.C. and Z.L.: software, validation; C.H.: writing—reviewing and editing. All authors have read and agreed to the published version of the manuscript.

Funding: This project is solely funded by the self-developed funds of the first author's affiliated company and has not received any research funding support from government departments. Special thanks to the 2023 Guangxi University Young and Middle School Teachers’ Basic Research Ability Improvement Project (Project number: 2023KY0360) for this paper.

Institutional Review Board Statement: Not applicable.

Informed Consent Statement: Not applicable.

Data Availability Statement: Not applicable.

Conflicts of Interest: The authors declare no conflict of interest.

References

- 1.

Yang, L. Development and Production Control of High Grade Vermicular Iron for Engine Cylinder Head. In Proceedings of the 2021 China Foundry Week, Shenyang, China, 21–25 October 2021; pp. 178–189.

- 2.

Li, M; Yang, M; Yang, L; Zhao, Z; Experimental Study on Improving Quality Stability of Vermicular Graphite Iron Castings. Mod. Cast Iron 2020, 40, 21–25.

- 3.

Lin, Y; Huang, J; Xie, Z; Wei, J; Development and Application of compacted graphite iron RuT400 for Engines. Chin. Intern. Combust. Engine Eng. 2017, 38, 86–91.

- 4.

Xu, J; Qi, P; Zhou, Y; Yang, S; Dong, Z; Hao, Z; Zhang, Z; Microstructure and Properties of Compacted Graphite Iron and Its Application in Diesel Engines. Foundry Eng. 2023, 47, 24–29.

- 5.

Liu, H; Saksham, D; Shen, M; Chen, K; Wu, V; Wang, L; Industry 4.0 in Metal Forming Industry Towards Automotive Applications: A Review. Int. J. Automot. Manuf. Mater. 2022, 1, 2. https://doi.org/10.53941/ijamm0101002.

- 6.

Huang, J; Xiang, G; Yu, P; Tang, M; Analysis and Countermeasures for Shrinkage Porosity Defects in Isolated Hot Spot Areas of Compacted Graphite Iron Cylinder Heads. Foundry Eng. 2024, 48, 44–49.

- 7.

Daniela, W; de Miranda, A.M; Giuseppe, P; Abrasive Wear Resistance of High-Strength Compacted Graphite Iron under Microabrasion Conditions. Lubricants 2022, 10, 308.

- 8.

Zou, C. Investigations on Fatigue Properties and Damage Mechanisms of Two Compacted Graphite Irons at Different Temperatures. Thesis, Ph.D; , 2020.

- 9.

Fan, X; Zhao, T; Chen, Q; Ye, P; Xu, L; Study on Microstructure and Mechanical Properties of As-cast Synthetic compacted graphite iron. Hot Work. Technol. 2021, 50, 64–67.

- 10.

Li, L; Fang, X; Lai, D; Lin, Y; Ji, Q; Li, S; Study on Cutting Performance of RuT500 by Micro-textured Cutter in Dry Milling. Modul. Mach. Tool Autom. Manuf. Tech. 2023, 41–44. https://doi.org/10.13462/j.cnki.mmtamt.2023.02.010.

- 11.

Li, W; Hou, Y; Ji, Q; Lai, D; Li, S; Lin, Y; Milling Force Study and Parameter Optimization for compacted graphite iron RuT500 with Coated Carbide Cutter. Mach. Tool Hydraul. 2023, 51, 12–16.

- 12.

Yin, C; Dai, C; Li, W; Yu, G; Deng, J; Analysis and Countermeasure of Cracking of the Supercharger Inlet Pipe of a Diesel Engine. Int. J. Automot. Manuf. Mater. 2025, 4, 6. https://doi.org/10.53941/ijamm.2025.100012.

- 13.

Liu, Z. Mass Production Technology of Vermicular Graphite Iron Cylinder Blocks and Heads. Foundry Eng. 2024, 48, 27–31.

- 14.

Qi, P; Xu, J; Ma, X; Wu, Y; Xu, Y; Feeding Wire Technology in Production of Large Vermicular Cast Iron. Foundry Equip. Technol. 2023, 56–59. https://doi.org/10.16666/j.cnki.issn1004-6178.2023.01.017.

- 15.

Du, M; Wang, Y; Zhang, X; Li, J; Wang, Y; Analysis and Prevention of Defects in the Air Passage of Gray Cast Iron Cylinder Head. Shanxi Metall. 2024, 47, 167–169.

- 16.

Zhou, X; Ren, G; Wang, J; Improvement of Casting Process of Vermicular Cast Iron Cylinder Head. Foundry Eng. 2022, 46, 43–45.

- 17.

Wang, Y; Zhang, M; Lv, Q; Xu, J; Qi, P; Cui, B; Process Analysis of RuT500 compacted graphite iron. Foundry Equip. Technol. 2023, 16–18. https://doi.org/10.16666/j.cnki.issn1004-6178.2023.03.005.

- 18.

Ren, G; Qu, M; Liu, B; OCC Production Process of High-Strength Vermicular Graphite Iron Cylinder Head. Modern Vehicle Power 2023, 45–47+51.

- 19.

Yang, L; Han, Z; Li, L; Wu, X; Application Practice of High Grade compacted graphite iron in Cylinder Head. Foundry Eng. 2023, 47, 49–56.

- 20.

Jiang, A; Liu, Z; Liu, Q; Li, N; Xu, Z; Shi, D; Influence of FeSi in Double-chamber Sample Cup on Thermal Analysis Characteristic Values and Vermiculating Rate. Foundry Technol. 2021, 42, 997–1002.

- 21.

Han, Z. Study on Inoculation Thermal Analysis and Effect Evaluation of Compacted Graphite Iron. Thesis, Master’s; , 2023.

- 22.

Lin, Y; Wang, K; Huang, J; Wei, J; Effects of Graphite Morphology and Metallographic Structure on Mechanical Properties of compacted graphite iron. Foundry Technol. 2017, 38, 2582–2585.

- 23.

He, C; Che, Y; Hou, C; Zhong, C; Zhao, M; Chen, X; Shi, F; The Effect of Adding Vanadium on the High Temperature Resistance of Heat Resistant compacted graphite iron. Diesel Engine Des. Manuf. 2023, 4, 47–50.

- 24.

Xu, R; Yang, Z; Li, J; Tao, D; Effect of Vermicular Graphite Rate on High Cycle Fatigue Properties of Vermicular Cast Iron. Hot Work. Technol. 2020, 49, 35–40.

- 25.

Han, Z; Yang, L; Yang, M; Ren, G; Production Control of High Grade Vermicular Graphite Iron Cylinder Head Casting. Mod. Cast Iron 2022, 42, 26–31+35.

- 26.

Wang, H; Cui, Q; Discussion on Shrinkage Porosity and Cavity of Engine Vermicular Graphite Iron Cylinder Head. China Foundry Mach. Technol. 2020, 55, 75–78.

This work is licensed under a Creative Commons Attribution 4.0 International License.