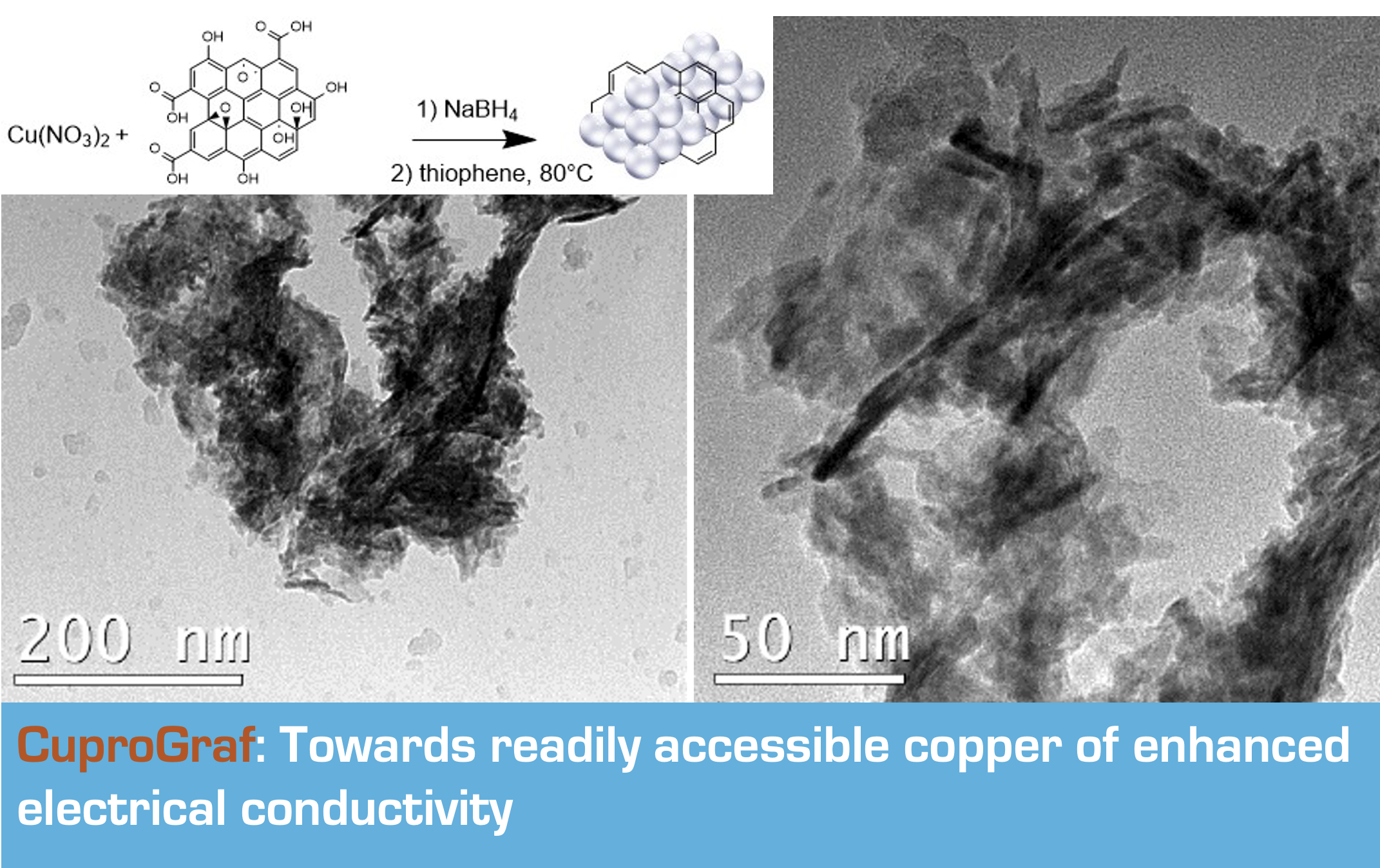

Graphene was encapsulated within the crystal lattice of Cu via the chemical route to molecularly doped metals affording an excellent electrical conductor dubbed herein “CuproGraf”. Metal bars in CuproGraf embedding less than 0.5 wt% graphene obtained by heating followed by hot rolling show nearly 7% lower resistivity when compared to a copper bar obtained from pure Cu powder using the same non-optimized hot rolling procedure. Considering the ease of CuproGraf preparation, and that substantial room for improvement exists by adopting a different CuproGraf powder sintering route to produce bulk wires and foils, the method is promising towards replacement of silver-plated copper wires or similar enhanced conductors wherein higher conductivity than that of copper is required.

- Open Access

- Article

CuproGraf: Towards Readily Accessible Copper of Enhanced Electrical Conductivity

- Matteo Formenti 1,

- Rosaria Ciriminna 2,*,

- Giorgia Lupi 3,

- Carlo Fanciulli 4,

- Cristina Della Pina 1,5,*,

- Riccardo Casati 3,*,

- Mario Pagliaro 2,*

Author Information

Received: 03 Oct 2025 | Revised: 01 Dec 2025 | Accepted: 02 Dec 2025 | Published: 09 Dec 2025

Abstract

Graphical Abstract

References

- 1.

Zhang, W.-J.; Huang, L.; Mi, X.-J.; et al. Researches for higher electrical conductivity copper-based materials. cMat 2024, 1, e13. https://doi.org/10.1002/cmt2.13.

- 2.

Alshehri, H.; Jakubowska, M.; Młożniak, A.; et al. Enhanced electrical conductivity of silver nanoparticles for high frequency electronic applications. ACS Appl. Mater. Interfaces 2012, 4, 7007–7010. https://doi.org/10.1021/am3022569.

- 3.

Tehrani, M. Advanced electrical conductors: An overview and prospects of metal nanocomposite and nanocarbon based conductors. Phys. Status Solidi A 2021, 218, 2000704. https://doi.org/10.1002/pssa.202000704.

- 4.

Cao, M.; Xiong, D.; Yang, L.; et al. Ultrahigh electrical conductivity of graphene embedded in metals. Adv. Funct. Mater. 2019, 29, 1806792. https://doi.org/10.1002/adfm.201806792.

- 5.

Gao, Z.; Zuo, T.; Wang, M.; et al. In-situ graphene enhanced copper wire: A novel electrical material with simultaneously high electrical conductivity and high strength. Carbon 2022, 186, 303–312. https://doi.org/10.1016/j.carbon.2021.10.015.

- 6.

Yao, J.; Kim, C.; Nian, Q.; et al. Copper-graphene composite (CGC) conductors: Synthesis, microstructure, and electrical performance. Small 2024, 20, 2403241. https://doi.org/10.1002/smll.202403241.

- 7.

Almonti, D.; Salvi, D.; Ucciardello, N.; et al. Enhanced wear resistance and thermal dissipation of copper–graphene composite coatings via pulsed electrodeposition for circuit breaker applications. Materials 2024, 17, 6017. https://doi.org/10.3390/ma17236017.

- 8.

Khorram, D.; Elyasi, M.; Mirnia, M.J.; et al. Characterization of copper–graphene nanocomposite block prepared by friction stir additive manufacturing. Prog. Addit. Manuf. 2025, 10, 6805–6824. https://doi.org/10.1007/s40964-025-01008-5.

- 9.

Formenti, M.; Pagliaro, M.; Della Pina, C.; et al. Graphene oxide in palladium nanoparticle (GrafeoPlad): A new class of functional materials. Green Synth. Catal. 2025, 6, 297–301. https://doi.org/10.1016/j.gresc.2024.04.004.

- 10.

Formenti, M.; Casaletto, M.P.; Barone, G.; et al. GrafeoPlad palladium: Insight on structure and activity of a new catalyst series of broad scope. Adv. Sustain. Syst. 2024, 8, 2300643. https://doi.org/10.1002/adsu.202300643.

- 11.

Pagliaro, M.; Pagliaro, M.V.; Caliandro, R.; et al. NiGraf: A new nickel-based molecularly doped metal for enhanced water electrolysis. Mater. Adv. 2024, 5, 2759–2766. https://doi.org/10.1039/d3ma00700f.

- 12.

Formenti, M.; Ciriminna, R.; Della Pina, C.; et al. Reduced NiGraf: An effective hydrogenation catalyst of large applicative potential. Next Mater. 2025, 8, 100751. https://doi.org/10.1016/j.nxmate.2025.100751.

- 13.

Behar-Levy, H.; Avnir, D. Entrapment of organic molecules within metals: Dyes in silver. Chem. Mater. 2002, 14, 1736–1741. https://doi.org/10.1021/cm011558o.

- 14.

Some, S.; Kim, Y.; Yoon, Y.; et al. High-quality reduced graphene oxide by a dual-function chemical reduction and healing process. Sci. Rep. 2013, 3, 1929. https://doi.org/10.1038/srep01929.

- 15.

Stobinski, L.; Lesiak, B.; Malolepszy, A.; et al. Graphene oxide and reduced graphene oxide studied by the XRD, TEM and electron spectroscopy methods. J. Electron Spectrosc. Relat. Phenom. 2014, 195, 145–154. https://doi.org/10.1016/j.elspec.2014.07.003.

- 16.

Wang, Y.-L.; Wang, K.-K.; Wang, Y.-W.; et al. Experiment and simulation for rolling of diamond–Cu composites. Acta Metall. Sin. 2017, 30, 791–800. https://doi.org/10.1007/s40195-017-0561-z.

- 17.

Narula, U.; Tan, C.M.; Tok, E.S. Metal on graphenated metal for VLSI interconnects. Adv. Mater. Interfaces 2018, 5, 1800270. https://doi.org/10.1002/admi.201800270.

- 18.

ASTM B193-20; Standard Test Method for Resistivity of Electrical Conductor Materials. ASTM International: West Conshohocken, PA, USA, 2014. https://doi.org/10.1520/b0193.

- 19.

International Copper Association. Ultra-Conductive Copper Development in China, Final Report. Projects TEK-1064-SJTU and MDP-1268-HA, August 2014–August 2016. Available online: https://internationalcopper.org/wp-content/uploads/2021/08/report-ultra-conductive-copper-development.pdf (accessed on 10 November 2025).

- 20.

Bakoniy, I. Accounting for the resistivity contribution of grain boundaries in metals: Critical analysis of reported experimental and theoretical data for Ni and Cu. Eur. Phys. J. Plus 2021, 136, 410. https://doi.org/10.1140/epjp/s13360-021-01303-4.

- 21.

Cho, Y.C.; Lee, S.; Ajmal, M.; et al. Copper better than silver: Electrical resistivity of the grain-free single-crystal copper wire. Cryst. Growth Des. 2010, 10, 2780–2784. https://doi.org/10.1021/cg1003808.

- 22.

Ajmal, M. Fabrication of the best conductor from single-crystal copper and the contribution of grain boundaries to the Debye temperature. CrystEngComm 2012, 14, 1463–1467. https://doi.org/10.1039/c1ce06026k.

- 23.

Company, L.D. For Aircraft Wire Systems, There Is No Perfect Conductor, Not Even a Silver Plated One, 1 July 2006. Available online: https://lectromec.com/for-aircraft-wire-systems-there-is-no-perfect-conductor-not-even-a-silver-plated-one/ (accessed on 5 December 2025).

- 24.

Ahoba-Sam, C.; Boodhoo, K.V.K.; Olsbye, U.; et al. Tailoring Cu nanoparticle catalyst for methanol synthesis using the spinning disk reactor. Materials 2018, 11, 154. https://doi.org/10.3390/ma11010154.

- 25.

Avnir, D. Molecularly doped metals. Acc. Chem. Res. 2014, 47, 579–592. https://doi.org/10.1021/ar4001982.

This work is licensed under a Creative Commons Attribution 4.0 International License.