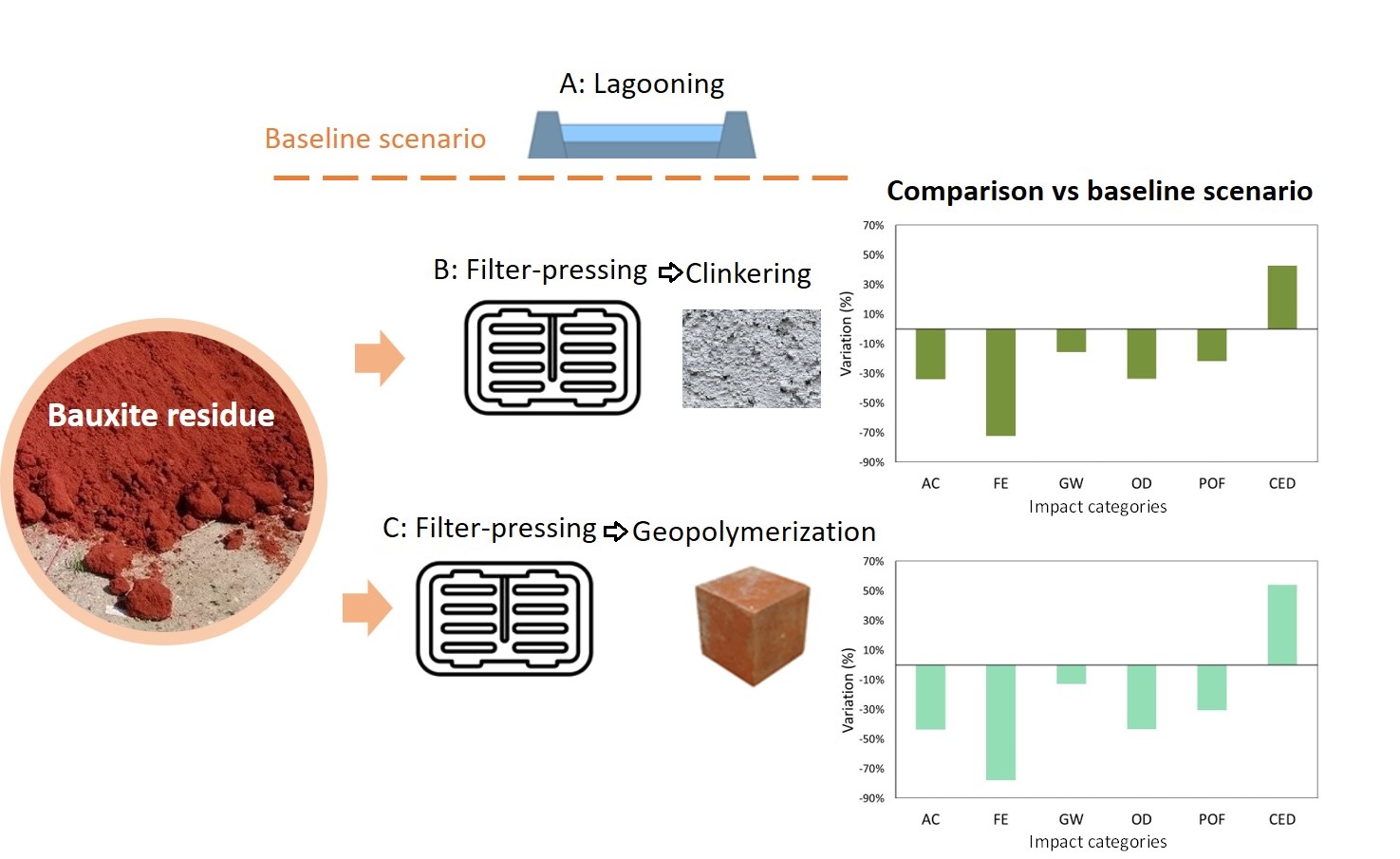

The management of bauxite residue (BR) generated during alumina production, is techno-economically challenging due to its colloidal slurry form, high alkalinity, and elevated concentrations of heavy metals and radionuclides. For every tonne of aluminum produced, 2–3 tonnes of BR are generated, leading to an annual global accumulation of approximately 180 million tonnes. At present, dry disposal (“dry stacking”) has become the most widely adopted management practice, although wet disposal of slurry remains in use in several regions. In this context, the present study assesses the environmental impact and the associated energy consumption of BR management following three different management and valorization practices: the wet disposal of the residue (baseline scenario), the dry disposal followed by the partial use of the dried BR in cement clinkering (current practice of the Greek aluminum industry) and the dry disposal followed by the partial use of the dried BR in a geopolymerization process. Results show that impact categories such as acidification (AC), freshwater eutrophication (FC), ozone depletion (OD), and photochemical ozone formation (POF) decrease by 21.6–77.7% under drying/valorization compared with the baseline. Dry disposal/geopolymer manufacturing presents the lowest possible environmental impact. However, the decrease of the global warming (GW) (by 12.8%), is relatively limited, while CED increases by 54.2% due to geopolymerization. Given the limited number of LCA studies available on bauxite residue management, this study explores key environmental challenges posed by current practices and identifies opportunities for improving sustainability and resource efficiency within the aluminum industry.

- Open Access

- Article

Comparative Life Cycle Assessment of Management and Valorization Practices for Bauxite Residue

- Aikaterini Filippousi 1,

- Michail Samouhos 2,

- Georgios Bartzas 2, *

Author Information

Received: 04 Aug 2025 | Revised: 06 Sep 2025 | Accepted: 09 Sep 2025 | Published: 11 Sep 2025

Abstract

Graphical Abstract

Keywords

red mud | dry disposal | filter pressing | geopolymerization | scenario analysis | contribution analysis

References

- 1.Khairul, M.A.; Zanganeh, J.; Moghtaderi, B. The composition, recycling and utilisation of Bayer red mud. Resour. Conserv. Recycl. 2019, 141, 483–498.

- 2.Sun, C.; Chen, J.; Tian, K.; et al. Geochemical Characteristics and Toxic Elements in Alumina Refining Wastes and Leachates from Management Facilities. Int. J. Environ. Res. Public Health 2019, 16, 1297.

- 3.Döring, J.; Beck, T.; Beyermann, M.; et al. Exposure and radiation protection for work areas with enhanced natural radioactivity. In Proceedings of Naturally Occurring Radioactive Material (NORM V), Seville, Spain, 19–22 March 2007.

- 4.Jovičević-Klug, M.; Souza Filho, I.R.; Springer, H.; et al. Green steel from red mud through climate-neutral hydrogen plasma reduction. Nature 2024, 625, 703–709.

- 5.Archambo, M. New Horizons for Processing and Utilizing Red Mud. Ph.D. Thesis, Michigan Technological University, Houghton, MI, USA, 2021.

- 6.Rai, S.; Bahadure, S.; Chaddha, M.J.; et al. Disposal Practices and Utilization of Red Mud (Bauxite Residue): A Review in Indian Context and Abroad. J. Sustain. Metall. 2019, 6, 1–8.

- 7.CPCB Team. Guidelines for Handling and Management of Red Mud Generated from Alumina Plants; Central Pollution Control Board, Ministry of Environment, Forest and Climate Change: Delhi, India, 2023; p. 122.

- 8.Ruyters, S.; Mertens, J.; Vassilieva, E.; et al. The Red Mud Accident in Ajka (Hungary): Plant Toxicity and Trace Metal Bioavailability in Red Mud Contaminated Soil. Environ. Sci. Technol. 2011, 45, 1616–1622.

- 9.Gelencsér, A.; Kováts, N.; Turóczi, B.; et al. The Red Mud Accident in Ajka (Hungary): Characterization and Potential Health Effects of Fugitive Dust. Environ. Sci. Technol. 2011, 45, 1608–1615.

- 10.Päivärinta-Antikainen, S.; Huovinen, M.; Ojala, S.; et al. Leaching of metals from red mud and toxicity in human cells in vitro. Chemosphere 2023, 332, 138807.

- 11.Tuazon, D.; Corder, G.D. Life cycle assessment of seawater neutralized red mud for treatment of acid mine drainage. Resour. Conserv. Recycl. 2008, 52, 1307–1314.

- 12.Kılcan, C.O.; Georgiades, M.; Rupert, R.J.; et al. Comparative Life Cycle Assessment of Composite Portland Cement Incorporating Bauxite Residue. In Proceedings of the 42nd Annual Cement & Concrete Science Conference, London, UK, 11–12 September 2023.

- 13.Adelfio, L.; Sgarbossa, F.; Leone, R.; et al. Life cycle assessment of red mud-based geopolymer production at industrial scale. In Proceedings of the IFIP WG 5.7 International Conference, APMS 2023, Trondheim, Norway, 17–21 September 2023.

- 14.Occhicone, A.; Vukčević, M.; Bosković, I.; et al. Alkali-activated red mud and construction and demolition waste-based components: Characterization and environmental assessment. Materials 2022, 15, 1617.

- 15.Ma, Y.; Pettersen, J.B. Life cycle assessment of pig iron production from bauxite residue. J. Ind. Ecol. 2023, 27, 1639–1652.

- 16.Joyce, P.J.; Björklund, A. Using life cycle thinking to assess the sustainability benefits of complex valorization pathways for bauxite residue. J. Sustain. Metall. 2019, 5, 69–84.

- 17.ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006; p. 20.

- 18.ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006; p. 46.

- 19.Komnitsas, K.; Bartzas, G.; Paspaliaris, I. Efficiency of limestone and red mud barriers: Laboratory column studies. Miner. Eng. 2004, 17, 183–194.

- 20.Bartzas, G.; Komnitsas, K. Life cycle analysis of pistachio production in Greece. Sci. Total Environ. 2015, 595, 13–24.

- 21.Bartzas, G.; Komnitsas, K. Cradle to gate life-cycle assessment of battery grade nickel sulphate production through high-pressure acid leaching. Sci. Total Environ. 2024, 952, 175902.

- 22.La Rosa, A.; Carvalho, R.; Dias, M.; et al. LCA and LCC Analysis of the Recovering and Reusing Scenario of Metal-Plastic Process Scraps. Mater. Circ. Econ. 2024, 6, 4.

- 23.Balomenos, E. Bauxite residue handling practice and valorisation research in Aluminum of Greece. In Proceedings of the 2th International Bauxite Residue Valorisation and Best Practices Conference, Athens, Greece, 7–10 May 2018.

- 24.Sakaroglou, M.; Anastassakis, G.N. Nickel recovery from electric arc furnace slag by magnetic separation. J. Min. Metall. 2016, 53, 3–15.

- 25.Komnitsas, K.; Yurramendi, L.; Bartzas, G.; et al. Factors affecting co-valorization of fayalitic and ferronickel slags for the production of alkali activated materials. Sci. Total Environ. 2020, 721, 137753.

- 26.Komnitsas, K.; Karmali, V.; Vathi, D.; et al. Factors affecting the properties of slag-based alkali-activated materials. Mater. Proc. 2023, 15, 19.

- 27.Zaharaki, D.; Galetakis, M.; Komnitsas, K. Valorization of construction and demolition (C&D) and industrial wastes through alkali activation. Constr. Build. Mater. 2016, 121, 686–693.

- 28.Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; et al. Implementation of Life Cycle Impact Assessment Methods. In Ecoinvent Report No. 3, v2.0; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007.

- 29.Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; et al. Identifying best existing practice for characterization modeling in life cycle impact assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697.

- 30.Kosai, S.; Yamasue, E. Global warming potential and total material requirement in metal production: Identification of changes in environmental impact through metal substitution. Sci. Total Environ. 2019, 651, 1764–1775.

- 31.DAPEEP. Residual Energy Mix 2020, Renewable Energy Sources, Operator and Guarantees of Origin. Available online: https://www.dapeep.gr/wp-content/uploads/2021/07/20210614_Residual%20Energy%20Mix_20201.pdf?_t=1627024624 (accessed on 12 May 2024).

- 32.Saxe, S.; Kasraian, D. Rethinking environmental LCA life stages for transport infrastructure to facilitate holistic assessment. J. Ind. Ecol. 2020, 24, 1031–1046.

- 33.François, C.; Gondran, N.; Nicolas, J. Spatial and territorial developments for life cycle assessment applied to urban mobility—Case study on Lyon area in France. Int. J. Life Cycle Assess. 2021, 26, 543–560.

- 34.Salas, D.A.; Ramirez, A.D.; Ulloa, N.; et al. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177.

- 35.Li, G.; Liu, J.; Yi, L.; et al. Bauxite Residue (Red Mud) Treatment: Current Situation and Promising Solution. Sci. Total Environ. 2024, 948, 174757.

- 36.Lee, J.H.; Cho, M.; Tal, G.; et al. Do Plug-in Hybrid Adopters Switch to Battery Electric Vehicles (and Vice Versa)? Transp. Res. Part D Transp. Environ. 2023, 119, 103752.

- 37.Di Carlo, E.; Boullemant, A.; Courtney, R. A Field Assessment of Bauxite Residue Rehabilitation Strategies. Sci. Total Environ. 2019, 663, 915–926.

- 38.Yang, Y.; Li, C.; Li, H.; et al. Microwave-Thermal-Assisted Curing Method on Geopolymer Preparation from Panzhihua High-Titanium Slag by Alkali Activation. Constr. Build. Mater. 2023, 400, 132614.

How to Cite

Filippousi, A.; Samouhos, M.; Bartzas, G. Comparative Life Cycle Assessment of Management and Valorization Practices for Bauxite Residue. Earth: Environmental Sustainability 2025, 1 (1), 102–113. https://doi.org/10.53941/eesus.2025.100008.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References