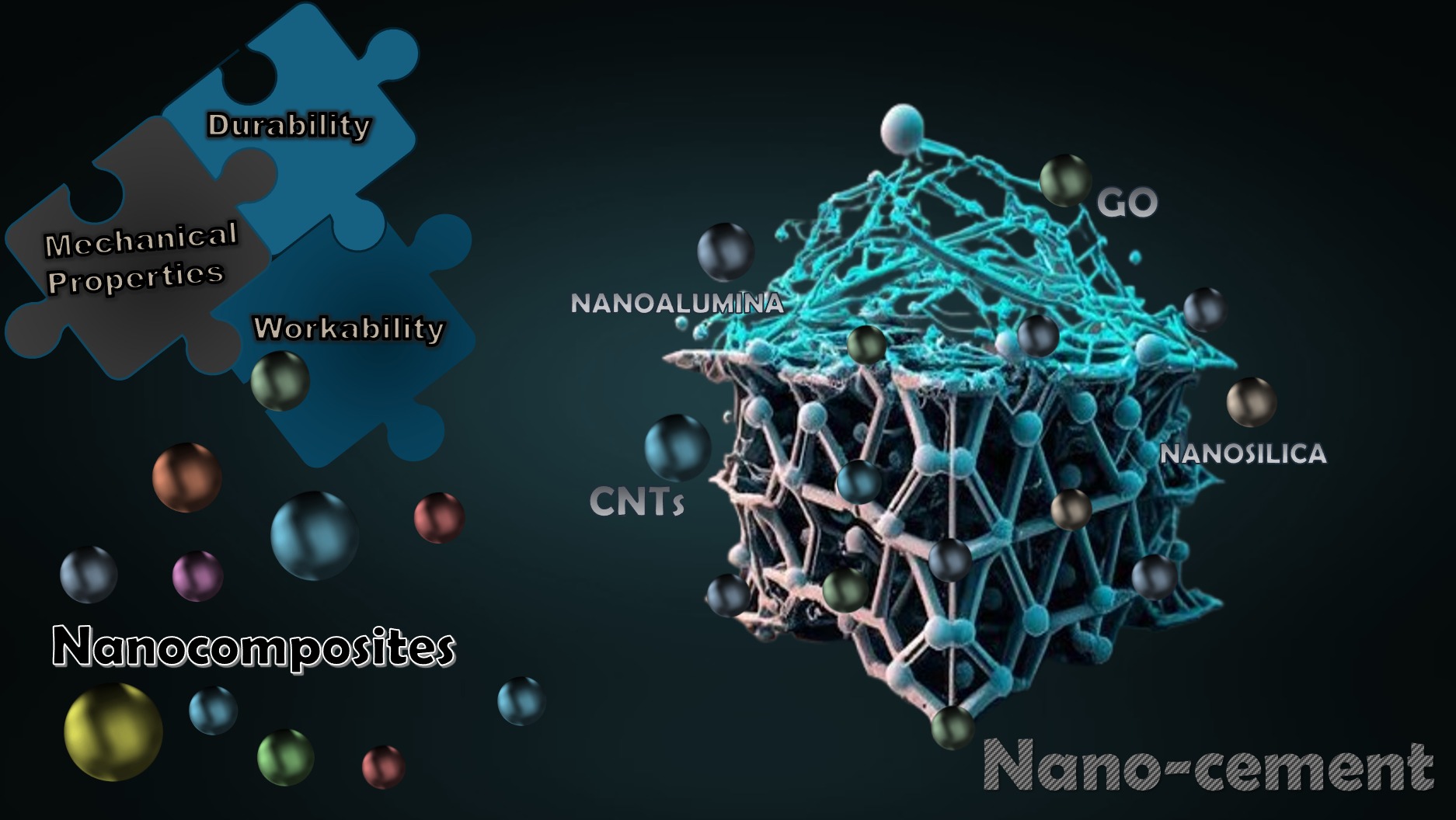

The performance of cement-based materials is affected by physicochemical processes occurring at the nanoscale. As a result, incorporating nanomaterials into civil engineering applications to develop nano-modified cement-based materials has emerged as a promising research area. Significant efforts in nanotechnology have focused on exploring the unique behaviors and properties of materials at the nanoscale. In past decades, numerous research efforts have aimed to boost the properties of materials based on cement, using various nanomaterials while investigating the mechanisms behind nano-reinforcement. This work offers a detailed review of the newer advancements in nano-engineered cementitious materials. It first examines the fundamental properties and dispersion techniques of commonly used nanomaterials, such as nanotubes and graphene, in cementitious systems. Subsequently, it reviews the evolution of such composites in terms of workability, mechanical performance, and durability. Lastly, the study highlights the existing challenges in this research field and offers insights for future developments.

- Open Access

- Review

Comparison of Nanocomposites Groups Performance in Cements: A Review

Author Information

Received: 14 Jul 2025 | Revised: 28 Sep 2025 | Accepted: 28 Sep 2025 | Published: 13 Oct 2025

Abstract

Graphical Abstract

Keywords

cement nanocomposites | carbon based | nano-silica | nano-alumina | nano-clays | durability | workability

References

- 1.

Franco-Luján, V.A.; Montejo-Alvaro, F.; Ramírez-Arellanes, S.; et al. Nanomaterial-Reinforced Portland-Cement-Based Materials: A Review. Nanomaterials 2023, 13, 1383. https://doi.org/10.3390/nano13081383.

- 2.

Liu, C.; Huang, X.; Wu, Y.-Y.; et al. Advance on the Dispersion Treatment of Graphene Oxide and the Graphene Oxide Modified Cement-Based Materials. Nanotechnol. Rev. 2021, 10, 34–49. https://doi.org/10.1515/ntrev-2021-0003.

- 3.

Han, B.; Zhang, L.; Zeng, S.; et al. Nano-Core Effect in Nano-Engineered Cementitious Composites. Compos. Part Appl. Sci. Manuf. 2017, 95, 100–109. https://doi.org/10.1016/j.compositesa.2017.01.008.

- 4.

Paul, S.C.; Van Rooyen, A.S.; Van Zijl, G.P.A.G.; et al. Properties of Cement-Based Composites Using Nanoparticles: A Comprehensive Review. Constr. Build. Mater. 2018, 189, 1019–1034. https://doi.org/10.1016/j.conbuildmat.2018.09.062.

- 5.

Yang, M.; Chen, L.; Lai, J.; et al. Advancing Environmental Sustainability in Construction through Innovative Low-Carbon, High-Performance Cement-Based Composites: A Review. Mater. Today Sustain. 2024, 26, 100712. https://doi.org/10.1016/j.mtsust.2024.100712.

- 6.

Lu, S.; Gong, C.; Yu, J.; et al. Reinforcing Mechanisms Review of the Graphene Oxide on Cement Composites. Nanotechnol. Rev. 2024, 13, 20240120. https://doi.org/10.1515/ntrev-2024-0120.

- 7.

Hou, P.; Shi, J.; Prabakar, S.; et al. Effects of Mixing Sequences of Nanosilica on the Hydration and Hardening Properties of Cement-Based Materials. Constr. Build. Mater. 2020, 263, 120226. https://doi.org/10.1016/j.conbuildmat.2020.120226.

- 8.

Hsissou, R.; Seghiri, R.; Benzekri, Z.; et al. Polymer Composite Materials: A Comprehensive Review. Compos. Struct. 2021, 262, 113640. https://doi.org/10.1016/j.compstruct.2021.113640.

- 9.

Chen, J.; Gao, X. Thermal and Electrical Anisotropy of Polymer Matrix Composite Materials Reinforced with Graphene Nanoplatelets and Aluminum-Based Particles. Diam. Relat. Mater. 2019, 100, 107571. https://doi.org/10.1016/j.diamond.2019.107571.

- 10.

Datsyuk, V.; Trotsenko, S.; Trakakis, G.; et al. Thermal Properties Enhancement of Epoxy Resins by Incorporating Polybenzimidazole Nanofibers Filled with Graphene and Carbon Nanotubes as Reinforcing Material. Polym. Test. 2020, 82, 106317. https://doi.org/10.1016/j.polymertesting.2019.106317.

- 11.

Lin, L.; Ning, H.; Song, S.; et al. Flexible Electrochemical Energy Storage: The Role of Composite Materials. Compos. Sci. Technol. 2020, 192, 108102. https://doi.org/10.1016/j.compscitech.2020.108102.

- 12.

Gao, H.; Wang, J.; Chen, X.; et al. Nanoconfinement Effects on Thermal Properties of Nanoporous Shape-Stabilized Composite PCMs: A Review. Nano Energy 2018, 53, 769–797. https://doi.org/10.1016/j.nanoen.2018.09.007.

- 13.

Rashidi, Y.; Li, L.; Habibnejad Korayem, A. Biopolymer-Assisted Stable Halloysite Nanotubes Dispersion in Alkaline Environment and Their Application in Cementitious Composite. Cem. Concr. Res. 2024, 183, 107574. https://doi.org/10.1016/j.cemconres.2024.107574.

- 14.

Abhilash, P.P.; Nayak, D.K.; Sangoju, B.; et al. Effect of Nano-Silica in Concrete; a Review. Constr. Build. Mater. 2021, 278, 122347. https://doi.org/10.1016/j.conbuildmat.2021.122347.

- 15.

Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; et al. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. https://doi.org/10.3390/ma12213548.

- 16.

Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon Nanotube Reinforced Cementitious Composites: A Comprehensive Review. Constr. Build. Mater. 2022, 315, 125100. https://doi.org/10.1016/j.conbuildmat.2021.125100.

- 17.

Zhao, L.; Guo, X.; Song, L.; et al. An Intensive Review on the Role of Graphene Oxide in Cement-Based Materials. Constr. Build. Mater. 2020, 241, 117939. https://doi.org/10.1016/j.conbuildmat.2019.117939.

- 18.

Bastos, G.; Patiño-Barbeito, F.; Patiño-Cambeiro, F.; et al. Admixtures in Cement-Matrix Composites for Mechanical Reinforcement, Sustainability, and Smart Features. Materials 2016, 9, 972. https://doi.org/10.3390/ma9120972.

- 19.

Chung, D.D.L. Composites Get Smart. Mater. Today 2002, 5, 30–35. https://doi.org/10.1016/S1369-7021(02)05140-4.

- 20.

Njuguna, J.; Vanli, O.A.; Liang, R. A Review of Spectral Methods for Dispersion Characterization of Carbon Nanotubes in Aqueous Suspensions. J. Spectrosc. 2015, 2015, 463156. https://doi.org/10.1155/2015/463156.

- 21.

Zhu, W.; Feng, Q.; Luo, Q.; et al. Effects of PCE on the Dispersion of Cement Particles and Initial Hydration. Materials 2021, 14, 3195. https://doi.org/10.3390/ma14123195.

- 22.

Lin, Y.; Du, H. Graphene Reinforced Cement Composites: A Review. Constr. Build. Mater. 2020, 265, 120312. https://doi.org/10.1016/j.conbuildmat.2020.120312.

- 23.

Dong, S.; Li, L.; Ashour, A.; et al. Self-Assembled 0D/2D Nano Carbon Materials Engineered Smart and Multifunctional Cement-Based Composites. Constr. Build. Mater. 2021, 272, 121632. https://doi.org/10.1016/j.conbuildmat.2020.121632.

- 24.

Alafogianni, P.; Dassios, K.; Farmaki, S.; et al. On the Efficiency of UV–Vis Spectroscopy in Assessing the Dispersion Quality in Sonicated Aqueous Suspensions of Carbon Nanotubes. Colloids Surf. Physicochem. Eng. Asp. 2016, 495, 118–124. https://doi.org/10.1016/j.colsurfa.2016.01.053.

- 25.

Goyal, R.K. Nanomaterials and Nanocomposites: Synthesis, Properties, Characterization Techniques, and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017; p. 350. ISBN 978-1-315-15328-5.

- 26.

Rodriguez-Loya, J.; Lerma, M.; Gardea-Torresdey, J.L. Dynamic Light Scattering and Its Application to Control Nanoparticle Aggregation in Colloidal Systems: A Review. Micromachines 2023, 15, 24. https://doi.org/10.3390/mi15010024.

- 27.

Du, Y.; Yang, J.; Thomas, B.S.; et al. Hybrid Graphene Oxide/Carbon Nanotubes Reinforced Cement Paste: An Investigation on Hybrid Ratio. Constr. Build. Mater. 2020, 261, 119815. https://doi.org/10.1016/j.conbuildmat.2020.119815.

- 28.

Jagadeesh, P. Efficacy of Graphene Oxide-Based Nanomaterials in Customized Cement Mixtures, a Review of Recent Research Trends. Hybrid Adv. 2025, 10, 100428. https://doi.org/10.1016/j.hybadv.2025.100428.

- 29.

Kauling, A.P.; Seefeldt, A.T.; Pisoni, D.P.; et al. The Worldwide Graphene Flake Production. Adv. Mater. 2018, 30, 1803784. https://doi.org/10.1002/adma.201803784.

- 30.

Lu, D.; Zhong, J. Carbon-Based Nanomaterials Engineered Cement Composites: A Review. J. Infrastruct. Preserv. Resil. 2022, 3, 2. https://doi.org/10.1186/s43065-021-00045-y.

- 31.

Bantie, Z.; Tezera, A.; Abera, D.; et al. Nanoclays as Fillers for Performance Enhancement in Building and Construction Industries: State of the Art and Future Trends. In Developments in Clay Science and Construction Techniques, Almusaed, A., Almssad, A., Yitmen, I., Eds.; IntechOpen: London, UK, 2024. ISBN 978-1-83769-607-9.

- 32.

Olafusi, O.S.; Sadiku, E.R.; Snyman, J.; et al. Application of Nanotechnology in Concrete and Supplementary Cementitious Materials: A Review for Sustainable Construction. SN Appl. Sci. 2019, 1, 580. https://doi.org/10.1007/s42452-019-0600-7.

- 33.

Kishore, K.; Pandey, A.; Wagri, N.K.; et al. Technological Challenges in Nanoparticle-Modified Geopolymer Concrete: A Comprehensive Review on Nanomaterial Dispersion, Characterization Techniques and Its Mechanical Properties. Case Stud. Constr. Mater. 2023, 19, e02265. https://doi.org/10.1016/j.cscm.2023.e02265.

- 34.

Yaghobian, M.; Whittleston, G. A Critical Review of Carbon Nanomaterials Applied in Cementitious Composites—A Focus on Mechanical Properties and Dispersion Techniques. Alex. Eng. J. 2022, 61, 3417–3433. https://doi.org/10.1016/j.aej.2021.08.053.

- 35.

Lyashenko, D.A.; Perfilov, V.A.; Nikolaev, M.E.; et al. Modification of Fine Concrete with Carbon Nanotubes. In Proceedings of the 7th International Conference on Construction, Architecture and Technosphere Safety, Sochi, Russia, 8–14 September 2024; Radionov, A.A., Ulrikh, D.V., Timofeeva, S.S., et al., Eds.; Lecture Notes in Civil Engineering; Springer Nature Switzerland: Cham, Switzerland, 2024; Volume 400, pp. 132–142. ISBN 978-3-031-47809-3.

- 36.

Chen, J.; Akono, A.-T. Influence of Multi-Walled Carbon Nanotubes on the Hydration Products of Ordinary Portland Cement Paste. Cem. Concr. Res. 2020, 137, 106197. https://doi.org/10.1016/j.cemconres.2020.106197.

- 37.

Fu, Q.; Zhao, X.; Zhang, Z.; et al. Effects of Nanosilica on Microstructure and Durability of Cement-Based Materials. Powder Technol. 2022, 404, 117447. https://doi.org/10.1016/j.powtec.2022.117447.

- 38.

Jiang, Z.; Atilhan, M.; Ozbulut, O.E. Exploring Optimal Dispersion Process Parameters for Fabrication of Graphene-Reinforced Cement Composites. Constr. Build. Mater. 2023, 372, 130805. https://doi.org/10.1016/j.conbuildmat.2023.130805.

- 39.

Zhong, J.; Sun, W.; Wei, Q.; et al. Efficient and Scalable Synthesis of Highly Aligned and Compact Two-Dimensional Nanosheet Films with Record Performances. Nat. Commun. 2018, 9, 3484. https://doi.org/10.1038/s41467-018-05723-2.

- 40.

Wang, M.; Yao, H.; Wang, R.; et al. Chemically Functionalized Graphene Oxide as the Additive for Cement–Matrix Composite with Enhanced Fluidity and Toughness. Constr. Build. Mater. 2017, 150, 150–156. https://doi.org/10.1016/j.conbuildmat.2017.05.217.

- 41.

Lotya, M.; King, P.J.; Khan, U.; et al. High-Concentration, Surfactant-Stabilized Graphene Dispersions. ACS Nano 2010, 4, 3155–3162. https://doi.org/10.1021/nn1005304.

- 42.

Papanikolaou, I.; de Souza, L.R.; Litina, C.; et al. Investigation of the Dispersion of Multi-Layer Graphene Nanoplatelets in Cement Composites Using Different Superplasticiser Treatments. Constr. Build. Mater. 2021, 293, 123543. https://doi.org/10.1016/j.conbuildmat.2021.123543.

- 43.

Qin, W.; Guodong, Q.; Dafu, Z.; et al. Influence of the Molecular Structure of a Polycarboxylate Superplasticiser on the Dispersion of Graphene Oxide in Cement Pore Solutions and Cement-Based Composites. Constr. Build. Mater. 2021, 272, 121969. https://doi.org/10.1016/j.conbuildmat.2020.121969.

- 44.

Hossain, S.S.; Bae, C.-J.; Roy, P.K. Recent Progress of Wastes Derived Nano-Silica: Synthesis, Properties, and Applications. J. Clean. Prod. 2022, 377, 134418. https://doi.org/10.1016/j.jclepro.2022.134418.

- 45.

Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; et al. Compressive Strength of Geopolymer Concrete Modified with Nano-Silica: Experimental and Modeling Investigations. Case Stud. Constr. Mater. 2022, 16, e01036. https://doi.org/10.1016/j.cscm.2022.e01036.

- 46.

Rashad, A.M. Effect of Nanoparticles on the Properties of Geopolymer Materials. Mag. Concr. Res. 2019, 71, 1283–1301. https://doi.org/10.1680/jmacr.18.00289.

- 47.

Gosiamemang, T.; Heng, J.Y.Y. Sodium Hydroxide Catalysed Silica Sol-Gel Synthesis: Physicochemical Properties of Silica Nanoparticles and Their Post-Grafting Using C8 and C18 Alkyl-Organosilanes. Powder Technol. 2023, 417, 118237. https://doi.org/10.1016/j.powtec.2023.118237.

- 48.

Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; et al. Beneficial Role of Nanosilica in Cement Based Materials—A Review. Constr. Build. Mater. 2013, 47, 1069–1077. https://doi.org/10.1016/j.conbuildmat.2013.05.052.

- 49.

Smirnova, O.M.; Menéndez Pidal De Navascués, I.; Mikhailevskii, V.R.; et al. Sound-Absorbing Composites with Rubber Crumb from Used Tires. Appl. Sci. 2021, 11, 7347. https://doi.org/10.3390/app11167347.

- 50.

Yakovlev, G.; Polyanskikh, I.; Gordina, A.; et al. Influence of Sulphate Attack on Properties of Modified Cement Composites. Appl. Sci. 2021, 11, 8509. https://doi.org/10.3390/app11188509.

- 51.

Ahmad, J.; Burduhos-Nergis, D.D.; Arbili, M.M.; et al. A Review on Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced Concrete. Buildings 2022, 12, 1951. https://doi.org/10.3390/buildings12111951.

- 52.

Maglad, A.M.; Zaid, O.; Arbili, M.M.; et al. A Study on the Properties of Geopolymer Concrete Modified with Nano Graphene Oxide. Buildings 2022, 12, 1066. https://doi.org/10.3390/buildings12081066.

- 53.

Barbhuiya, G.H.; Moiz, M.A.; Hasan, S.D.; et al. Effects of the Nanosilica Addition on Cement Concrete: A Review. Mater. Today Proc. 2020, 32, 560–566. https://doi.org/10.1016/j.matpr.2020.02.143.

- 54.

Iqbal, S.; Pan, G.; Meng, H.; et al. Surfactant-Free Synthesis of Highly Monodispersed in Situ Grown Nano-Silica on Modified Fly Ash and Its Impact on the Properties of Cement Pastes. Constr. Build. Mater. 2024, 425, 136043. https://doi.org/10.1016/j.conbuildmat.2024.136043.

- 55.

Shahrajabian, F.; Behfarnia, K. The Effects of Nano Particles on Freeze and Thaw Resistance of Alkali-Activated Slag Concrete. Constr. Build. Mater. 2018, 176, 172–178. https://doi.org/10.1016/j.conbuildmat.2018.05.033.

- 56.

Sharkawi, A.M.; Abd-Elaty, M.A.; Khalifa, O.H. Synergistic Influence of Micro-Nano Silica Mixture on Durability Performance of Cementious Materials. Constr. Build. Mater. 2018, 164, 579–588. https://doi.org/10.1016/j.conbuildmat.2018.01.013.

- 57.

Erdem, S.; Hanbay, S.; Güler, Z. Micromechanical Damage Analysis and Engineering Performance of Concrete with Colloidal Nano-Silica and Demolished Concrete Aggregates. Constr. Build. Mater. 2018, 171, 634–642. https://doi.org/10.1016/j.conbuildmat.2018.03.197.

- 58.

Kawashima, S.; Wang, K.; Ferron, R.D.; et al. A Review of the Effect of Nanoclays on the Fresh and Hardened Properties of Cement-Based Materials. Cem. Concr. Res. 2021, 147, 106502. https://doi.org/10.1016/j.cemconres.2021.106502.

- 59.

Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; et al. Influence of Nano-TiO2, Nano-Fe2O3, Nanoclay and Nano-CaCO3 on the Properties of Cement/Geopolymer Concrete. Clean. Mater. 2022, 4, 100061. https://doi.org/10.1016/j.clema.2022.100061.

- 60.

Shebl, S.S.; Allie, L.; Morsy, M.S.; et al. Mechanical Behavior of Activated Nano Silicate Filled Cement Binders. J. Mater. Sci. 2009, 44, 1600–1606. https://doi.org/10.1007/s10853-008-3214-9.

- 61.

Gaharwar, A.K.; Cross, L.M.; Peak, C.W.; et al. 2D Nanoclay for Biomedical Applications: Regenerative Medicine, Therapeutic Delivery, and Additive Manufacturing. Adv. Mater. 2019, 31, 1900332. https://doi.org/10.1002/adma.201900332.

- 62.

Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Characteristics of Nanoclay and Calcined Nanoclay-Cement Nanocomposites. Compos. Part B Eng. 2015, 78, 174–184. https://doi.org/10.1016/j.compositesb.2015.03.074.

- 63.

Niu, X.-J.; Li, Q.-B.; Hu, Y.; et al. Properties of Cement-Based Materials Incorporating Nano-Clay and Calcined Nano-Clay: A Review. Constr. Build. Mater. 2021, 284, 122820. https://doi.org/10.1016/j.conbuildmat.2021.122820.

- 64.

Guo, F.; Aryana, S.; Han, Y.; et al. A Review of the Synthesis and Applications of Polymer–Nanoclay Composites. Appl. Sci. 2018, 8, 1696. https://doi.org/10.3390/app8091696.

- 65.

Rahmanpour, A.; Farahpour, M.R.; Shapouri, R.; et al. Synthesis and Characterization of Alumina-Based Nanocomposites of TiO2/Al2O3/Chitosan with Antibacterial Properties Accelarate Healing of Infected Excision Wounds. Colloids Surf. Physicochem. Eng. Asp. 2022, 644, 128839. https://doi.org/10.1016/j.colsurfa.2022.128839.

- 66.

Gholizadeh, Z.; Aliannezhadi, M.; Ghominejad, M.; et al. High Specific Surface Area γ-Al2O3 Nanoparticles Synthesized by Facile and Low-Cost Co-Precipitation Method. Sci. Rep. 2023, 13, 6131. https://doi.org/10.1038/s41598-023-33266-0.

- 67.

Szymanowski, J.; Sadowski, Ł. The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials 2019, 12, 3465. https://doi.org/10.3390/ma12213465.

- 68.

Zhan, B.J.; Xuan, D.X.; Poon, C.S. The Effect of Nanoalumina on Early Hydration and Mechanical Properties of Cement Pastes. Constr. Build. Mater. 2019, 202, 169–176. https://doi.org/10.1016/j.conbuildmat.2019.01.022.

- 69.

Ayub, M.; Othman, M.H.D.; Khan, I.U.; et al. Promoting Sustainable Cleaner Production Paradigms in Palm Oil Fuel Ash as an Eco-Friendly Cementitious Material: A Critical Analysis. J. Clean. Prod. 2021, 295, 126296. https://doi.org/10.1016/j.jclepro.2021.126296.

- 70.

Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of Nanomaterials Based Self-Healing Concrete: An All-Inclusive Insight. J. Build. Eng. 2019, 23, 155–171. https://doi.org/10.1016/j.jobe.2019.01.032.

- 71.

Metaxa, Z.S.; Tolkou, A.K.; Efstathiou, S.; et al. Nanomaterials in Cementitious Composites: An Update. Molecules 2021, 26, 1430. https://doi.org/10.3390/molecules26051430.

- 72.

Xu, K.; Yang, J.; He, H.; et al. Influences of Additives on the Rheological Properties of Cement Composites: A Review of Material Impacts. Materials 2025, 18, 1753. https://doi.org/10.3390/ma18081753.

- 73.

Liu, C.; Chen, F.; Wu, Y.; et al. Research Progress on Individual Effect of Graphene Oxide in Cement-Based Materials and Its Synergistic Effect with Other Nanomaterials. Nanotechnol. Rev. 2021, 10, 1208–1235. https://doi.org/10.1515/ntrev-2021-0080.

- 74.

Xu, Z.; Bai, Z.; Wu, J.; et al. Microstructural Characteristics and Nano-Modification of Interfacial Transition Zone in Concrete: A Review. Nanotechnol. Rev. 2022, 11, 2078–2100. https://doi.org/10.1515/ntrev-2022-0125.

- 75.

Ahmad, J.; Zhou, Z. Properties of Concrete with Addition Carbon Nanotubes: A Review. Constr. Build. Mater. 2023, 393, 132066. https://doi.org/10.1016/j.conbuildmat.2023.132066.

- 76.

Singh, G.; Saini, B. Nanomaterial in Cement Industry: A Brief Review. Innov. Infrastruct. Solut. 2022, 7, 45. https://doi.org/10.1007/s41062-021-00649-z.

- 77.

Kaid, N.; Cyr, M.; Julien, S.; et al. Durability of Concrete Containing a Natural Pozzolan as Defined by a Performance-Based Approach. Constr. Build. Mater. 2009, 23, 3457–3467. https://doi.org/10.1016/j.conbuildmat.2009.08.002.

- 78.

Chintalapudi, K.; Rao Pannem, R.M. Strength Properties of Graphene Oxide Cement Composites. Mater. Today Proc. 2021, 45, 3971–3975. https://doi.org/10.1016/j.matpr.2020.08.369.

- 79.

Heikal, M.; Abdel-Gawwad, H.A.; Ababneh, F.A. Positive Impact Performance of Hybrid Effect of Nano-Clay and Silica Nano-Particles on Composite Cements. Constr. Build. Mater. 2018, 190, 508–516. https://doi.org/10.1016/j.conbuildmat.2018.09.163.

- 80.

Alani, N.Y.; Al-Jumaily, I.A.; Hilal, N. Effect of Nanoclay and Burnt Limestone Powder on Fresh and Hardened Properties of Self-Compacting Concrete. Nanotechnol. Environ. Eng. 2021, 6, 20. https://doi.org/10.1007/s41204-021-00114-3.

- 81.

Alobaidi, Y.M.; Hilal, N.N.; Faraj, R.H. An Experimental Investigation on the Nano-Fly Ash Preparation and Its Effects on the Performance of Self-Compacting Concrete at Normal and Elevated Temperatures. Nanotechnol. Environ. Eng. 2021, 6, 2. https://doi.org/10.1007/s41204-020-00098-6.

- 82.

Amin, M.; Abu El-Hassan, K. Effect of Using Different Types of Nano Materials on Mechanical Properties of High Strength Concrete. Constr. Build. Mater. 2015, 80, 116–124. https://doi.org/10.1016/j.conbuildmat.2014.12.075.

- 83.

Knop, Y.; Peled, A. Setting Behavior of Blended Cement with Limestone: Influence of Particle Size and Content. Mater. Struct. 2016, 49, 439–452. https://doi.org/10.1617/s11527-014-0509-y.

- 84.

Muhd Norhasri, M.S.; Hamidah, M.S.; Mohd Fadzil, A.; et al. Inclusion of Nano Metakaolin as Additive in Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2016, 127, 167–175. https://doi.org/10.1016/j.conbuildmat.2016.09.127.

- 85.

Alharbi, Y.R.; Abadel, A.A.; Mayhoub, O.A.; et al. Effect of Using Available Metakaoline and Nano Materials on the Behavior of Reactive Powder Concrete. Constr. Build. Mater. 2021, 269, 121344. https://doi.org/10.1016/j.conbuildmat.2020.121344.

- 86.

Irshidat, M.R.; Al-Saleh, M.H. Thermal Performance and Fire Resistance of Nanoclay Modified Cementitious Materials. Constr. Build. Mater. 2018, 159, 213–219. https://doi.org/10.1016/j.conbuildmat.2017.10.127.

- 87.

Oh, J.-A.; Zhuge, Y.; Araby, S.; et al. Cement Nanocomposites Containing Montmorillonite Nanosheets Modified with Surfactants of Various Chain Lengths. Cem. Concr. Compos. 2021, 116, 103894. https://doi.org/10.1016/j.cemconcomp.2020.103894.

- 88.

Garces-Vargas, J.F.; Díaz-Cardenas, Y.; Martirena Hernandez, J.F. Evaluation of the Durability of Concrete with the Use of Calcined Clays and Limestone in Salinas, Ecuador. Minerals 2024, 14, 460. https://doi.org/10.3390/min14050460.

- 89.

Xiaoyu, G.; Yingfang, F.; Haiyang, L. The Compressive Behavior of Cement Mortar with the Addition of Nano Metakaolin. Nanomater. Nanotechnol. 2018, 8, 184798041875559. https://doi.org/10.1177/1847980418755599.

- 90.

Hamed, N.; El-Feky, M.S.; Kohail, M.; et al. Effect of Nano-Clay de-Agglomeration on Mechanical Properties of Concrete. Constr. Build. Mater. 2019, 205, 245–256. https://doi.org/10.1016/j.conbuildmat.2019.02.018.

- 91.

Assaedi, H.; Shaikh, F.U.A.; Low, I.M. Effect of Nanoclay on Durability and Mechanical Properties of Flax Fabric Reinforced Geopolymer Composites. J. Asian Ceram. Soc. 2017, 5, 62–70. https://doi.org/10.1016/j.jascer.2017.01.003.

- 92.

Rezania, M.; Panahandeh, M.; Razavi, N.; et al. Experimental Study of the Simultaneous Effect of Nano-Silica and Nano-Carbon Black on Permeability and Mechanical Properties of the Concrete. Theor. Appl. Fract. Mech. 2019, 104, 102391. https://doi.org/10.1016/j.tafmec.2019.102391.

- 93.

Kumar, S.; Kumar, A.; Kujur, J. Influence of Nanosilica on Mechanical and Durability Properties of Concrete. Proc. Inst. Civ. Eng. Struct. Build. 2019, 172, 781–788. https://doi.org/10.1680/jstbu.18.00080.

- 94.

Li, L.G.; Zheng, J.Y.; Ng, P.L.; et al. Cementing Efficiencies and Synergistic Roles of Silica Fume and Nano-Silica in Sulphate and Chloride Resistance of Concrete. Constr. Build. Mater. 2019, 223, 965–975. https://doi.org/10.1016/j.conbuildmat.2019.07.241.

- 95.

Aydın, A.C.; Nasl, V.J.; Kotan, T. The Synergic Influence of Nano-Silica and Carbon Nano Tube on Self-Compacting Concrete. J. Build. Eng. 2018, 20, 467–475. https://doi.org/10.1016/j.jobe.2018.08.013.

- 96.

Chekravarty, D.; Alapati, M.; Sravana, P.; et al. Experimental Investigations on Durability Properties Nano-Silica Based Concrete. Mater. Today Proc. 2022, 51, 2176–2184. https://doi.org/10.1016/j.matpr.2021.11.126.

- 97.

Elkady, H.M.; Yasien, A.M.; Elfeky, M.S.; et al. Assessment of Mechanical Strength of Nano Silica Concrete (NSC) Subjected to Elevated Temperatures. J. Struct. Fire Eng. 2019, 10, 90–109. https://doi.org/10.1108/JSFE-10-2017-0041.

- 98.

Dhairiyasamy, R.; Gabiriel, D.; Varshney, D.; et al. Optimizing Nanomaterial Dosages in Concrete for Structural Applications Using Experimental Design Techniques. Sci. Rep. 2025, 15, 22375. https://doi.org/10.1038/s41598-025-05265-w.

- 99.

Farzadnia, N.; Abang Ali, A.A.; Demirboga, R. Characterization of High Strength Mortars with Nano Alumina at Elevated Temperatures. Cem. Concr. Res. 2013, 54, 43–54. https://doi.org/10.1016/j.cemconres.2013.08.003.

- 100.

Chu, H.; Wang, Q.; Gao, L.; et al. An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study. Materials 2022, 15, 8118. https://doi.org/10.3390/ma15228118.

- 101.

Muzenski, S.; Flores-Vivian, I.; Sobolev, K. Ultra-High Strength Cement-Based Composites Designed with Aluminum Oxide Nano-Fibers. Constr. Build. Mater. 2019, 220, 177–186. https://doi.org/10.1016/j.conbuildmat.2019.05.175.

- 102.

Muzenski, S.; Flores-Vivian, I.; Farahi, B.; et al. Towards Ultrahigh Performance Concrete Produced with Aluminum Oxide Nanofibers and Reduced Quantities of Silica Fume. Nanomaterials 2020, 10, 2291. https://doi.org/10.3390/nano10112291.

- 103.

Shaikh, F.U.A.; Hosan, A. Effect of Nano Alumina on Compressive Strength and Microstructure of High Volume Slag and Slag-Fly Ash Blended Pastes. Front. Mater. 2019, 6, 90. https://doi.org/10.3389/fmats.2019.00090.

- 104.

Guo, Z.; Hou, P.; Xu, Z.; et al. Sulfate Attack Resistance of Tricalcium Silicate Modified with Nano-Silica and Supplementary Cementitious Materials. Constr. Build. Mater. 2022, 321, 126332. https://doi.org/10.1016/j.conbuildmat.2022.126332.

- 105.

Huang, K.; Xie, J.; Wang, R.; et al. Effects of the Combined Usage of Nanomaterials and Steel Fibres on the Workability, Compressive Strength, and Microstructure of Ultra-High Performance Concrete. Nanotechnol. Rev. 2021, 10, 304–317. https://doi.org/10.1515/ntrev-2021-0029.

- 106.

Liu, C.; Su, X.; Wu, Y.; et al. Effect of Nano-Silica as Cementitious Materials-Reducing Admixtures on the Workability, Mechanical Properties and Durability of Concrete. Nanotechnol. Rev. 2021, 10, 1395–1409. https://doi.org/10.1515/ntrev-2021-0097.

- 107.

Huang, J.; Wang, Z.; Li, D.; et al. Effect of Nano-SiO2/PVA Fiber on Sulfate Resistance of Cement Mortar Containing High-Volume Fly Ash. Nanomaterials 2022, 12, 323. https://doi.org/10.3390/nano12030323.

- 108.

Rajput, B.; Pimplikar, S.S. Influence of Nano Silica on Durability Properties of Concrete. Innov. Infrastruct. Solut. 2022, 7, 180. https://doi.org/10.1007/s41062-022-00777-0.

- 109.

Abna, A.; Mazloom, M. Flexural Properties of Fiber Reinforced Concrete Containing Silica Fume and Nano-Silica. Mater. Lett. 2022, 316, 132003. https://doi.org/10.1016/j.matlet.2022.132003.

- 110.

Yang, Z.; Sui, S.; Wang, L.; et al. Improving the Chloride Binding Capacity of Cement Paste by Adding Nano-Al2O3: The Cases of Blended Cement Pastes. Constr. Build. Mater. 2020, 232, 117219. https://doi.org/10.1016/j.conbuildmat.2019.117219.

- 111.

Jalali Mosallam, S.; Pesaran Behbahani, H.; Shahpari, M.; et al. The Effect of Carbon Nanotubes on Mechanical Properties of Structural Lightweight Concrete Using LECA Aggregates. Structures 2022, 35, 1204–1218. https://doi.org/10.1016/j.istruc.2021.09.003.

- 112.

Piao, R.; Cui, Z.; Jeong, J.-W.; et al. Optimal Multi-Walled Carbon Nanotube Dosage for Improving the Mechanical and Thermoelectric Characteristics of Ultra-High-Performance Fiber-Reinforced Concrete. Constr. Build. Mater. 2025, 462, 139927. https://doi.org/10.1016/j.conbuildmat.2025.139927.

- 113.

Ramezani, M.; Kim, Y.H.; Sun, Z.; et al. Influence of Carbon Nanotubes on Properties of Cement Mortars Subjected to Alkali-Silica Reaction. Cem. Concr. Compos. 2022, 131, 104596. https://doi.org/10.1016/j.cemconcomp.2022.104596.

- 114.

Malayali, A.B.; Venkatesh, R.; Seikh, A.H.; et al. Investigation and Performance Analysis of Eco-Friendly Coco Fiber Concrete Hybridized with CNT Blend. Heliyon 2024, 10, e33031. https://doi.org/10.1016/j.heliyon.2024.e33031.

- 115.

Huang, H.; Teng, L.; Gao, X.; et al. Effect of Carbon Nanotube and Graphite Nanoplatelet on Composition, Structure, and Nano-Mechanical Properties of C-S-H in UHPC. Cem. Concr. Res. 2022, 154, 106713. https://doi.org/10.1016/j.cemconres.2022.106713.

- 116.

Han, G.; Dai, S.; Zhang, J.; et al. Study on the Workability and Early Mechanical Properties of Carbon Nanotube-Coated Fly Ash Modified Cement-Based Grouting Materials. Constr. Build. Mater. 2024, 439, 137327. https://doi.org/10.1016/j.conbuildmat.2024.137327.

- 117.

Carriço, A.; Bogas, J.A.; Hawreen, A.; et al. Durability of Multi-Walled Carbon Nanotube Reinforced Concrete. Constr. Build. Mater. 2018, 164, 121–133. https://doi.org/10.1016/j.conbuildmat.2017.12.221.

- 118.

Mansouri Sarvandani, M.; Mahdikhani, M.; Aghabarati, H.; et al. Effect of Functionalized Multi-Walled Carbon Nanotubes on Mechanical Properties and Durability of Cement Mortars. J. Build. Eng. 2021, 41, 102407. https://doi.org/10.1016/j.jobe.2021.102407.

- 119.

Lu, L.; Ouyang, D.; Xu, W. Mechanical Properties and Durability of Ultra High Strength Concrete Incorporating Multi-Walled Carbon Nanotubes. Materials 2016, 9, 419. https://doi.org/10.3390/ma9060419.

- 120.

Chaipanich, A.; Rianyoi, R.; Nochaiya, T. The Effect of Carbon Nanotubes and Silica Fume on Compressive Strength and Flexural Strength of Cement Mortars. Mater. Today Proc. 2017, 4, 6065–6071. https://doi.org/10.1016/j.matpr.2017.06.095.

- 121.

Sajjad, U.; Sheikh, M.N.; Hadi, M.N.S. Experimental Study of the Effect of Graphene on Properties of Ambient-Cured Slag and Fly Ash-Based Geopolymer Paste and Mortar. Constr. Build. Mater. 2021, 313, 125403. https://doi.org/10.1016/j.conbuildmat.2021.125403.

- 122.

Djenaoucine, L.; Argiz, C.; Picazo, Á.; et al. The Corrosion-Inhibitory Influence of Graphene Oxide on Steel Reinforcement Embedded in Concrete Exposed to a 3.5M NaCl Solution. Cem. Concr. Compos. 2025, 155, 105835. https://doi.org/10.1016/j.cemconcomp.2024.105835.

- 123.

Wang, N.; Wang, S.; Tang, L.; et al. Improved Interfacial Bonding Strength and Reliability of Functionalized Graphene Oxide for Cement Reinforcement Applications. Chem. Eur. J. 2020, 26, 6561–6568. https://doi.org/10.1002/chem.201904625.

- 124.

Li, X.; Liu, Y.M.; Li, W.G.; et al. Effects of Graphene Oxide Agglomerates on Workability, Hydration, Microstructure and Compressive Strength of Cement Paste. Constr. Build. Mater. 2017, 145, 402–410. https://doi.org/10.1016/j.conbuildmat.2017.04.058.

- 125.

Long, W.-J.; Zhang, X.; Feng, G.-L.; et al. Investigation on Chloride Binding Capacity and Stability of Friedel’s Salt in Graphene Oxide Reinforced Cement Paste. Cem. Concr. Compos. 2022, 132, 104603. https://doi.org/10.1016/j.cemconcomp.2022.104603.

- 126.

Zhang, N.; She, W.; Du, F.; et al. Experimental Study on Mechanical and Functional Properties of Reduced Graphene Oxide/Cement Composites. Materials 2020, 13, 3015. https://doi.org/10.3390/ma13133015.

- 127.

Wang, Q.; Wang, J.; Lv, C.; et al. Rheological Behavior of Fresh Cement Pastes with a Graphene Oxide Additive. New Carbon Mater. 2016, 31, 574–584. https://doi.org/10.1016/S1872-5805(16)60033-1.

- 128.

Liao, C.; Lin, B.; Li, M.; et al. Synergistic Effects of Graphene Oxide and Fly Ash on Rheology, Mechanical Properties, and Microstructure of Highly-Flowable Cementitious Grouts. J. Build. Eng. 2024, 87, 109038. https://doi.org/10.1016/j.jobe.2024.109038.

- 129.

Fonseka, I.; Mohotti, D.; Wijesooriya, K.; et al. Influence of Graphene Oxide on Abrasion Resistance and Strength of Concrete. Constr. Build. Mater. 2023, 404, 133280. https://doi.org/10.1016/j.conbuildmat.2023.133280.

- 130.

Reddy, P.; Ravi Prasad, D. The Effect of Graphene Oxide-Fly Ash Hybridisation on the Hydration, Microstructure and Mechanical Characteristics of Cement Concrete. Fuller. Nanotub. Carbon Nanostructures 2024, 32, 380–388. https://doi.org/10.1080/1536383X.2023.2287603.

- 131.

Safarkhani, M.; Naderi, M. Enhanced Impermeability of Cementitious Composite by Different Content of Graphene Oxide Nanoparticles. J. Build. Eng. 2023, 72, 106675. https://doi.org/10.1016/j.jobe.2023.106675.

- 132.

Jiang, J.; Qin, J.; Chu, H. Improving Mechanical Properties and Microstructure of Ultra-High-Performance Lightweight Concrete via Graphene Oxide. J. Build. Eng. 2023, 80, 108038. https://doi.org/10.1016/j.jobe.2023.108038.

- 133.

Zhu, L.; Liu, Y.; Yaoji Tang, Y.L. Synthesis of Chitosan Graft Poly (Acrylic Acid-Co-2-Acrylamide-2-Methylpropanesulfonic Acid)/Graphite Oxide Composite Hydrogel and the Study of Its Adsorption. Polym. Polym. Compos. 2022, 30. https://doi.org/10.1177/09673911221086164.

- 134.

Narimani, A.; Kordnejad, F.; Kaur, P.; et al. Synthesis and Preparation of Poly (AM-Co-AMPS)/GO Nanocomposites Hydrogel as a Rheology Modifier and Fluid Loss Controller for Use in Oil Well Cementing. J. Dispers. Sci. Technol. 2023, 44, 1738–1749. https://doi.org/10.1080/01932691.2022.2039687.

- 135.

Dong, B.; Diao, H.; Ren, H.; et al. Chloride-Ion-Triggered Microcapsule for Self-Suppression of Capillary Suction in Cement Paste. Cem. Concr. Compos. 2023, 141, 105144. https://doi.org/10.1016/j.cemconcomp.2023.105144.

- 136.

Xiong, G.; Ren, Y.; Wang, C.; et al. Effect of Power Ultrasound Assisted Mixing on Graphene Oxide in Cement Paste: Dispersion, Microstructure and Mechanical Properties. J. Build. Eng. 2023, 69, 106321. https://doi.org/10.1016/j.jobe.2023.106321.

- 137.

Wang, W.; Zhong, Z.; Kang, X.; et al. Physico-Mechanical Properties and Micromorphological Characteristics of Graphene Oxide Reinforced Geopolymer Foam Concrete. J. Build. Eng. 2023, 72, 106732. https://doi.org/10.1016/j.jobe.2023.106732.

- 138.

Cui, D.; Wei, H.; Zuo, X.; et al. Use of Graphene Oxide to Improve the Durability and Mechanical Properties of Mortar Immersed in Flowing River for Three Years. Nanomaterials 2020, 10, 2385. https://doi.org/10.3390/nano10122385.

- 139.

Yuan, X.; Dai, M.; Gao, Y.; et al. Pore Morphology Based on Graphene Oxide Modified Steel Fibre Concrete for Freeze–Thaw Resistance. Constr. Build. Mater. 2023, 409, 133877. https://doi.org/10.1016/j.conbuildmat.2023.133877.

- 140.

Zhang, R.; Long, Z.; Long, G.; et al. Mechanism of Graphene Oxide Concrete Macro-Micro Properties Evolution under Large Temperature Difference Freeze-Thaw Action. Constr. Build. Mater. 2024, 415, 135019. https://doi.org/10.1016/j.conbuildmat.2024.135019.

- 141.

Qiao, W.; Shi, M.; Ban, T.; et al. Using Graphene Oxide to Enhance the Bonding Properties between Carbon Fibers and Cement Matrix to Improve the Mechanical Properties of Cement-Based Composites. Constr. Build. Mater. 2024, 453, 138992. https://doi.org/10.1016/j.conbuildmat.2024.138992.

- 142.

Zhang, J.; Xiao, M.; Feng, Y. A Review on Nanomaterials and Polymers Modified Cementitious Materials with High Performances. J. Build. Eng. 2025, 104, 112331. https://doi.org/10.1016/j.jobe.2025.112331.

- 143.

Yang, Q.; Yang, Q.; Peng, X.; et al. A Review of the Effects of Nanomaterials on the Properties of Concrete. Buildings 2025, 15, 2363. https://doi.org/10.3390/buildings15132363.

- 144.

Kishore, K.; Sheikh, M.N.; Hadi, M.N.S. Doped Multi-Walled Carbon Nanotubes and Nanoclay Based-Geopolymer Concrete: An Overview of Current Knowledge and Future Research Challenges. Cem. Concr. Compos. 2024, 154, 105774. https://doi.org/10.1016/j.cemconcomp.2024.105774.

- 145.

Chousidis, N.; Zeris, C. Carbon Nanotube Reinforcement for Cementitious Composites: Advancing Thermal Stability, Mechanical Strength and Durability in Fire-Resistant Concrete. J. Build. Eng. 2025, 111, 113587. https://doi.org/10.1016/j.jobe.2025.113587.

- 146.

Barbhuiya, S.; Das, B.B.; Adak, D. A Comprehensive Review on Integrating Sustainable Practices and Circular Economy Principles in Concrete Industry. J. Environ. Manag. 2024, 370, 122702. https://doi.org/10.1016/j.jenvman.2024.122702.

- 147.

Shen, W.; Liu, Y.; Yan, B.; et al. Cement Industry of China: Driving Force, Environment Impact and Sustainable Development. Renew. Sustain. Energy Rev. 2017, 75, 618–628. https://doi.org/10.1016/j.rser.2016.11.033.

- 148.

Liu, C.; He, X.; Deng, X.; et al. Application of Nanomaterials in Ultra-High Performance Concrete: A Review. Nanotechnol. Rev. 2020, 9, 1427–1444. https://doi.org/10.1515/ntrev-2020-0107.

- 149.

Khan, S.A.; Amjad, H.; Ahmad, F.; et al. A Scientometric Review Summarizing the Impact of Nanomaterials on the Fresh, Hardened, and Durability Properties of Cement-Based Materials. Adv. Civ. Eng. 2024, 2024, 8639483. https://doi.org/10.1155/adce/8639483.

- 150.

Hachhach, M.; Bayou, S.; El Kasmi, A.; et al. Towards Sustainable Scaling-Up of Nanomaterials Fabrication: Current Situation, Challenges, and Future Perspectives. Eng 2025, 6, 149. https://doi.org/10.3390/eng6070149.

- 151.

Fan, L.; Wu, C.; Zheng, J.; et al. Cement-Based Nanocomposites: The Synergic Effect of Graphene Oxide and Cellulose Nanofibers on Microstructural Features and Mechanical Performance. Diam. Relat. Mater. 2025, 158, 112609. https://doi.org/10.1016/j.diamond.2025.112609.

- 152.

Guo, E.; Zhang, W.; Lai, J.; et al. Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification. Buildings 2025, 15, 1234. https://doi.org/10.3390/buildings15081234.

- 153.

Spencer, P.; Li, H.; Hocknull, S.; et al. Exploring Mineral–Organic Interactions for Eco-Friendly Concrete Alternatives: A Radical Concept. RSC Sustain. 2025, 3, 2064–2078. https://doi.org/10.1039/D4SU00696H.

This work is licensed under a Creative Commons Attribution 4.0 International License.