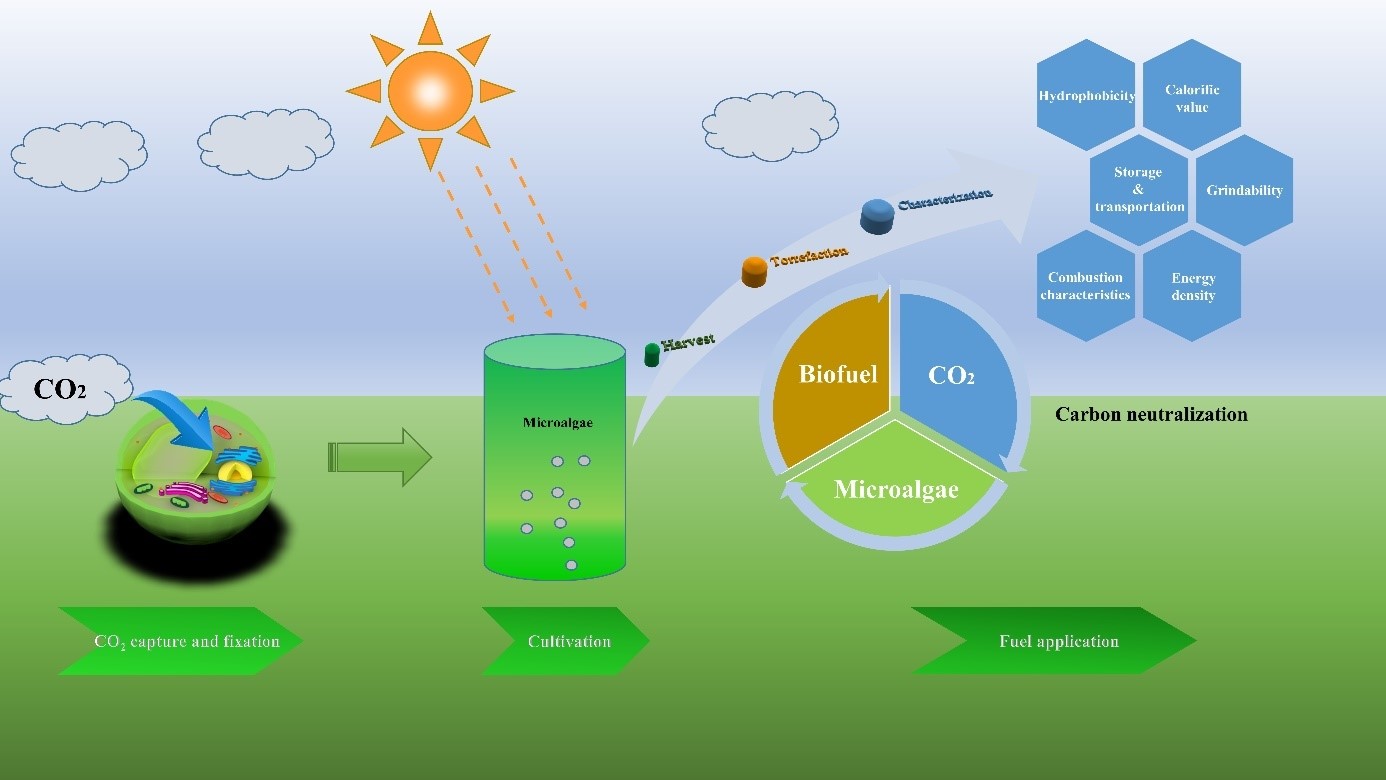

In the past decades, a series of phenomena such as global warming, glacier melting, sea level rise, and haze weather caused by the greenhouse effect have been reported, which seriously threaten the future of humans. To address this challenge, several countries have initiated interventions to prevent climate change, such as carbon neutralization. Given the current economic, social development and environmental protection requirements, microalgal carbon fixation appears to be a suitable approach to achieve carbon net zero emission while also promoting microalgal biofuel production. This promotes the realization of energy structure transformation and optimization of carbon neutralization. This article provides a comprehensive and state-of-the-art review of research progress on microalgal carbon capture and solid biofuel production via the torrefaction process, with focus on the efficiency and capacity of microalgal carbon fixation, as well as the principle and application of microalgal torrefaction. The detailed review includes the practical value and development prospect of microalgal torrefied biochar, fuel performance conversion, and mechanism in the torrefaction process. Furthermore, the environmental impact of microalgal carbon fixation and torrefaction process are discussed to evaluate the overall environmental benefits of microalgal utilization via life cycle assessment (LCA) method. The technical difficulties of microalgal carbon fixation and torrefaction process are also discussed. This review paper is beneficial to guide the scheme demonstration and specific implementation of microalgal carbon neutralization and thus lead to the efficient establishment of microalgal carbon reduction, biomass accumulation, and biofuel production techniques.

- Open Access

- Review

Life Cycle Assessment of Microalgal Carbon Fixation and Torrefaction for Carbon Neutralization: A State-of-the-Art Review

- Congyu Zhang *,

- Jin Fang,

- Yong Zhan,

- Xin Wang,

- Tao Chen,

- Kuifeng Hao,

- Jiaqi Ma,

- Yuting Wang

Author Information

Received: 23 May 2024 | Revised: 12 Aug 2024 | Accepted: 05 Sep 2024 | Published: 10 Sep 2024

Abstract

Graphical Abstract

Keywords

life cycle assessment | microalgal carbon fixation | microalgal torrefaction | integrative analysis | carbon neutralization

References

- 1.Sathya, A.B.; Thirunavukkarasu, A.; Nithya, R.; et al. Microalgal biofuel production: Potential challenges and prospective research. Fuel 2023, 332, 126199.

- 2.Kong, F.; Torres, I.; Warakanont, J.; et al. Lipid catabolism in microalgae. New Phytol. 2018, 218, 1340–1348.

- 3.Wang, Y.; Yang, S.; Liu, J.; et al. Realization process of microalgal biorefinery: The optional approach toward carbon net-zero emission. Sci. Total Environ. 2023, 901, 165546.

- 4.Peter, A.P.; Khoo, K.S.; Chew, K.W.; et al. Microalgae for biofuels, wastewater treatment and environmental monitoring. Environ. Chem. Lett. 2021, 19, 2891–2904.

- 5.Yusoff, I.I.; Rohani, R.; Zaman, N.K.; et al. Comprehensive evaluation of the integrated membrane contactor-microalgae photobioreactor system for simultaneous H2 purification and CO2 treatment from biomass fermented gases. J. Clean. Prod. 2021, 318, 128608.

- 6.Fu, J.; Huang, Y.; Xia, A.; et al. How the sulfur dioxide in the flue gas influence microalgal carbon dioxide fixation: From gas dissolution to cells growth. Renew. Energy 2022, 198, 114–122.

- 7.Tamburic, B.; Evenhuis, C.R.; Crosswell, J.R.; et al. An empirical process model to predict microalgal carbon fixation rates in photobioreactors. Algal Res. 2018, 31, 334–346.

- 8.Zhao, B.; Su, Y. Process effect of microalgal-carbon dioxide fixation and biomass production: A review. Renew. Sustain. Energy Rev. 2014, 31, 121–132.

- 9.de Pablo, J.G.; Lindley, M.; Hiramatsu, K.; et al. Label-free live microalgal starch screening via Raman flow cytometry. Algal Res. 2023, 70, 102993.

- 10.Feng, L.; Wang, Z.; Jia, D.; et al. Functional metabolism pathways of significantly regulated genes in Nannochloropsis oceanica with various nitrogen/phosphorus nutrients for CO2 fixation. Sci. Total Environ. 2023, 883, 163318.

- 11.Yong, Y.G.; Ong, H.C.; Show, P.L.; et al. Torrefaction of microalgal biochar as potential coal fuel and application as bio-adsorbent. Energy Convers. Manag. 2018, 165, 152–162.

- 12.Zhang, C.; Ho, S.-H.; Chen, W.-H.; et al. Oxidative torrefaction performance of microalga Nannochloropsis Oceanica towards an upgraded microalgal solid biofuel. J. Biotechnol. 2021, 338, 81–90.

- 13.Zhang, C.; Li, F.; Ho, S.-H.; et al. Oxidative torrefaction of microalga Nannochloropsis Oceanica activated by potassium carbonate for solid biofuel production. Environ. Res. 2022, 212, 113389.

- 14.Ubando, A.T.; Rivera, D.R.T.; Chen, W.-H.; et al. A comprehensive review of life cycle assessment (LCA) of microalgal and lignocellulosic bioenergy products from thermochemical processes. Bioresour. Technol. 2019, 291, 121837.

- 15.Lin, J.-Y.; Xue, C.; Tan, S.-I.; et al. Pyridoxal kinase PdxY mediated carbon dioxide assimilation to enhance the biomass in Chlamydomonas reinhardtii CC-400. Bioresour. Technol. 2021, 322, 124530.

- 16.Lababpour, A. A dynamic model for the prediction of flue gas carbon dioxide removal by the microalga Chlorella vulgaris in column photobioreactor. Alex. Eng. J. 2018, 57, 3311–3320.

- 17.Zhang, C.; Wang, C.; Cao, G.; et al. Comparison and characterization of property variation of microalgal biomass with non-oxidative and oxidative torrefaction. Fuel 2019, 246, 375–385.

- 18.Lu, Y.; Mu, D.; Xue, Z.; et al. Life cycle assessment of industrial production of microalgal oil from heterotrophic fermentation. Algal Res. 2021, 58, 102404.

- 19.Sun, J.; Yang, L.; Xiao, S.; et al. A promising microalgal wastewater cyclic cultivation technology: Dynamic simulations, economic viability, and environmental suitability. Water Res. 2022, 217, 118411.

- 20.Ma, J.; Yang, L.; Wang, D.; et al. Digitalization in response to carbon neutrality: Mechanisms, effects and prospects. Renew. Sustain. Energy Rev. 2024, 191, 114138.

- 21.Yang, Y.; Tong, L.; Yin, S.; et al. Status and challenges of applications and industry chain technologies of hydrogen in the context of carbon neutrality. J. Clean. Prod. 2022, 376, 134347.

- 22.Gao, H.; Liu, Q.; Yan, C.; et al. Mitigation of greenhouse gas emissions and improved yield by plastic mulching in rice production. Sci. Total Environ. 2023, 880, 162984.

- 23.Dubey, A.; Arora, A. Advancements in carbon capture technologies: A review. J. Clean. Prod. 2022, 373, 133932.

- 24.Zeng, J.; Yang, M. Digital technology and carbon emissions: Evidence from China. J. Clean. Prod. 2023, 430, 139765.

- 25.Liu, Y.; Weng, Z.; Han, B.; et al. Recent studies on the comprehensive application of biochar in multiple environmental fields. J. Clean. Prod. 2023, 421, 138495.

- 26.Goveas, L.C.; Nayak, S.; Vinayagam, R.; et al. Microalgal remediation and valorisation of polluted wastewaters for zero-carbon circular bioeconomy. Bioresour. Technol. 2022, 365, 128169.

- 27.Ruiz-Ruiz, P.; Gómez-Borraz, T.L.; Saldivar, A.; et al. Diluted methane mitigation by a co-culture of alkaliphilic methanotrophs and the microalgae Scenedesmus obtusiusculus towards carbon neutrality. Biochem. Eng. J. 2024, 203, 109211.

- 28.Zhang, J.-T.; Wang, J.-X.; Liu, Y.; et al. Microalgal-bacterial biofilms for wastewater treatment: Operations, performances, mechanisms, and uncertainties. Sci. Total Environ. 2024, 907, 167974.

- 29.da Rosa, G.M.; de Morais, M.G.; Costa, J.A.V. Green alga cultivation with monoethanolamine: Evaluation of CO2 fixation and macromolecule production. Bioresour. Technol. 2018, 261, 206–212.

- 30.Kuo, C.-M.; Jian, J.-F.; Sun, Y.-L.; et al. An efficient Photobioreactors/Raceway circulating system combined with alkaline-CO2 capturing medium for microalgal cultivation. Bioresour. Technol. 2018, 266, 398–406.

- 31.Ketheesan, B.; Nirmalakhandan, N. Feasibility of microalgal cultivation in a pilot-scale airlift-driven raceway reactor. Bioresour. Technol. 2012, 108, 196–202.

- 32.Cheng, J.; Guo, W.; Ameer Ali, K.; et al. Promoting helix pitch and trichome length to improve biomass harvesting efficiency and carbon dioxide fixation rate by Spirulina sp. in 660 m2 raceway ponds under purified carbon dioxide from a coal chemical flue gas. Bioresour. Technol. 2018, 261, 76–85.

- 33.Basu, S.; Sarma Roy, A.; Ghoshal, A.K.; et al. Operational strategies for maximizing CO2 utilization efficiency by the novel microalga Scenedesmus obliquus SA1 cultivated in lab scale photobioreactor. Algal Res. 2015, 12, 249–257.

- 34.Duarte, J.H.; Fanka, L.S.; Costa, J.A.V. Utilization of simulated flue gas containing CO2, SO2, NO and ash for Chlorella fusca cultivation. Bioresour. Technol. 2016, 214, 159–165.

- 35.Lam, M.K.; Lee, K.T. Effect of carbon source towards the growth of Chlorella vulgaris for CO2 bio-mitigation and biodiesel production. Int. J. Greenh. Gas Control 2013, 14, 169–176.

- 36.da Rosa, G.M.; Moraes, L.; Cardias, B.B.; et al. Chemical absorption and CO2 biofixation via the cultivation of Spirulina in semicontinuous mode with nutrient recycle. Bioresour. Technol. 2015, 192, 321–327.

- 37.Kargupta, W.; Ganesh, A.; Mukherji, S. Estimation of carbon dioxide sequestration potential of microalgae grown in a batch photobioreactor. Bioresour. Technol. 2015, 180, 370–375.

- 38.Kumar, A.; Yuan, X.; Sahu, A. K.; et al. A hollow fiber membrane photo-bioreactor for CO2 sequestration from combustion gas coupled with wastewater treatment: A process engineering approach. J. Chem. Technol. Biotechnol. 2010, 85, 387–394.

- 39.Arroyo, C.A.; Contreras, J.L.; Zeifert, B.; et al. CO2 Capture of the Gas Emission, Using a Catalytic Converter and Airlift Bioreactors with the Microalga Scenedesmus dimorphus. Appl. Sci. 2019, 9, 3212.

- 40.Zhao, X.; Zhang, T.; Dang, B.; et al. Microalgae-based constructed wetland system enhances nitrogen removal and reduce carbon emissions: Performance and mechanisms. Sci. Total Environ. 2023, 877, 162883.

- 41.Li, P.; Wang, D.; Hu, Z.; et al. Insight into the potential mechanism of bicarbonate assimilation promoted by mixotrophic in CO2 absorption and microalgae conversion system. Chemosphere 2024, 349, 140903.

- 42.Burlacot, A.; Peltier, G. Energy crosstalk between photosynthesis and the algal CO2-concentrating mechanisms. Trends Plant Sci. 2023, 28, 795–807.

- 43.Yan, Z.; Shen, T.; Li, W.; et al. Contribution of microalgae to carbon sequestration in a natural karst wetland aquatic ecosystem: An in-situ mesocosm study. Sci. Total Environ. 2021, 768, 144387.

- 44.Li, P.; Luo, Y.; Yuan, X. Life cycle and techno-economic assessment of source-separated wastewater-integrated microalgae biofuel production plant: A nutrient organization approach. Bioresour. Technol. 2022, 344, 126230.

- 45.Lucas, B.F.; Brunner, T.A. Attitudes and perceptions towards microalgae as an alternative food: A consumer segmentation in Switzerland. Algal Res. 2024, 78, 103386.

- 46.Chen, S.; Li, X.; Ma, X.; et al. Lighting the way to sustainable development: Physiological response and light control strategy in microalgae-based wastewater treatment under illumination. Sci. Total Environ. 2023, 903, 166298.

- 47.Oliva, G.; Galang, M.G.; Buonerba, A.; et al. Carbon capture and utilization in waste to energy approach by leading-edge algal photo-bioreactors: The influence of the illumination wavelength. Case Stud. Chem. Environ. Eng. 2023, 7, 100348.

- 48.Zhang, C.; Ho, S.-H.; Chen, W.-H.; et al. Torrefaction performance and energy usage of biomass wastes and their correlations with torrefaction severity index. Appl. Energy 2018, 220, 598–604.

- 49.Chen, W.H.; Lin, B.J.; Lin, Y.Y.; et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887.

- 50.Zhang, C.; Zhan, Y.; Chen, W.-H.; et al. Correlations between different fuel property indicators and carbonization degree of oxidatively torrefied microalgal biomass. Energy 2024, 286, 129693.

- 51.Chen, W.-H.; Aniza, R.; Arpia, A.A.; et al. A comparative analysis of biomass torrefaction severity index prediction from machine learning. Appl. Energy 2022, 324, 119689.

- 52.Zhang, C.; Chen, W.-H.; Ho, S.-H.; et al. Comparative advantages analysis of oxidative torrefaction for solid biofuel production and property upgrading. Bioresour. Technol. 2023, 386, 129531.

- 53.Zhang, C.; Yang, W.; Chen, W.-H.; et al. Effect of torrefaction on the structure and reactivity of rice straw as well as life cycle assessment of torrefaction process. Energy 2021, 240, 122470.

- 54.Chen, W.H.; Lin, B.J.; Colin, B.; et al. Hygroscopic transformation of woody biomass torrefaction for carbon storage. Appl. Energy 2018, 231, 768–776.

- 55.Zhang, C.; Chen, W.-H.; Zhang, Y.; et al. Influence of microorganisms on the variation of raw and oxidatively torrefied microalgal biomass properties. Energy 2023, 276, 127612.

- 56.Song, Y.; Chen, Z.; Li, Y.; et al. Regulation of energy properties and thermal behavior of bio-coal from lignocellulosic biomass using torrefaction. Energy 2024, 289, 129949.

- 57.Jiang, Y.; Zhou, G.; Zhang, H.; et al. Coupling effects of heating pelleting and torrefaction on black pellets production from microalga Nannochloropsis Oceanica residues. Fuel 2023, 353, 129007.

- 58.Mei, Y.; Chen, Y.; Zhang, S.; et al. Effect of temperature oscillation on torrefaction and pyrolysis of elm branches. Energy 2023, 271, 127055.

- 59.Ho, S.-H.; Zhang, C.; Tao, F.; et al. Microalgal Torrefaction for Solid Biofuel Production. Trends Biotechnol. 2020, 38, 1023–1033.

- 60.Zhang, C.; Wang, M.; Chen, W.-H.; et al. A comparison of conventional and oxidative torrefaction of microalga Nannochloropsis Oceanica through energy efficiency analysis and life cycle assessment. J. Clean. Prod. 2022, 369, 133236.

- 61.Bates, R.B.; Ghoniem, A.F. Biomass torrefaction: Modeling of volatile and solid product evolution kinetics. Bioresour. Technol. 2012, 124, 460–469.

- 62.Chen, W.H.; Wu, Z.Y.; Chang, J.S. Isothermal and non-isothermal torrefaction characteristics and kinetics of microalga Scenedesmus obliquus CNW-N. Bioresour. Technol. 2014, 155, 245–251.

- 63.Chen, Y.C.; Chen, W.H.; Lin, B.J.; et al. Impact of torrefaction on the composition, structure and reactivity of a microalga residue. Appl. Energy 2016, 181, 110–119.

- 64.Chen, W.H.; Huang, M.Y.; Chang, J.S.; et al. An energy analysis of torrefaction for upgrading microalga residue as a solid fuel. Bioresour. Technolgy 2015, 185, 285–293.

- 65.Chen, W.H.; Huang, M.Y.; Chang, J.S.; et al. Thermal decomposition dynamics and severity of microalgae residues in torrefaction. Bioresour. Technol. 2014, 169, 258–264.

- 66.Chen, W.H.; Huang, M.Y.; Chang, J.S.; et al. Torrefaction operation and optimization of microalga residue for energy densification and utilization. Appl. Energy 2015, 154, 622–630.

- 67.Bach, Q.V.; Chen, W.H.; Lin, S.C.; et al. Wet torrefaction of microalga Chlorella vulgaris ESP-31 with microwave-assisted heating. Energy Convers. Manag. 2016, 141, 163–170.

- 68.Bach, Q.V.; Chen, W.H.; Sheen, H.K.; et al. Gasification kinetics of raw and wet-torrefied microalgae Chlorella vulgaris ESP-31 in carbon dioxide. Bioresour. Technol. 2017, 244, 1393–1399.

- 69.Phusunti, N.; Phetwarotai, W.; Tekasakul, S. Effects of torrefaction on physical properties, chemical composition and reactivity of microalgae. Korean J. Chem. Eng. 2017, 35, 503–510.

- 70.Ho, S.-H.; Zhang, C.; Chen, W.-H.; et al. Characterization of biomass waste torrefaction under conventional and microwave heating. Bioresour. Technol. 2018, 264, 7–16.

- 71.Wu, K.T.; Tsai, C.J.; Chen, C.S.; et al. The characteristics of torrefied microalgae. Appl. Energy 2012, 100, 52–57.

- 72.Moreira, D.; Pires, J.C.M. Atmospheric CO2 capture by algae: Negative carbon dioxide emission path. Bioresour. Technol. 2016, 215, 371–379.

- 73.Raheem, A.; Prinsen, P.; Vuppaladadiyam, A.K.; et al. A review on sustainable microalgae based biofuel and bioenergy production: Recent developments. J. Clean. Prod. 2018, 181, 42–59.

- 74.Song, W.; He, Y.; Huang, R.; et al. Life cycle assessment of deep-eutectic-solvent-assisted hydrothermal disintegration of microalgae for biodiesel and biogas co-production. Appl. Energy 2023, 335, 120758.

- 75.Wu, G.; Tham, P.E.; Chew, K.W.; et al. Net zero emission in circular bioeconomy from microalgae biochar production: A renewed possibility. Bioresour. Technol. 2023, 388, 129748.

- 76.Yu, K.L.; Chen, W.-H.; Sheen, H.-K.; et al. Production of microalgal biochar and reducing sugar using wet torrefaction with microwave-assisted heating and acid hydrolysis pretreatment. Renew. Energy 2020, 156, 349–360.

- 77.Yu, K.L.; Show, P.L.; Ong, H.C.; et al. Microalgae from wastewater treatment to biochar—Feedstock preparation and conversion technologies. Energy Convers. Manag. 2017, 150, 1–13.

- 78.Sadvakasova, A.K.; Kossalbayev, B.D.; Bauenova, M.O.; et al. Microalgae as a key tool in achieving carbon neutrality for bioproduct production. Algal Res. 2023, 72, 103096.

- 79.Min Woon, J.; Shiong Khoo, K.; Akermi, M.; et al. Reviewing biohydrogen production from microalgal cells through fundamental mechanisms, enzymes and factors that engendering new challenges and prospects. Fuel 2023, 346, 128312.

- 80.Zhang, C.; Chen, W.-H.; Ho, S.-H. Economic feasibility analysis and environmental impact assessment for the comparison of conventional and microwave torrefaction of spent coffee grounds. Biomass Bioenergy 2023, 168, 106652.

- 81.Bhar, R.; Tiwari, B.R.; Sarmah, A.K.; et al. A comparative life cycle assessment of different pyrolysis-pretreatment pathways of wood biomass for levoglucosan production. Bioresour. Technol. 2022, 356, 127305.

- 82.Zhu, X.; Labianca, C.; He, M.; et al. Life-cycle assessment of pyrolysis processes for sustainable production of biochar from agro-residues. Bioresour. Technol. 2022, 360, 127601.

- 83.Zhou, H.; Zhang, W.; Li, L.; et al. Environmental impact and optimization of lake dredged-sludge treatment and disposal technologies based on life cycle assessment (LCA) analysis. Sci. Total Environ. 2021, 787, 147703.

- 84.Lee, J.G.; Chae, H.G.; Cho, S.R.; et al. Impact of plastic film mulching on global warming in entire chemical and organic cropping systems: Life cycle assessment. J. Clean. Prod. 2021, 308, 127256.

- 85.Puig-Samper Naranjo, G.; Bolonio, D.; Ortega, M.F.; et al. Comparative life cycle assessment of conventional, electric and hybrid passenger vehicles in Spain. J. Clean. Prod. 2021, 291, 125883.

- 86.Cvetković, S.M.; Radoičić, T.K.; Kijevčanin, M.; et al. Life Cycle Energy Assessment of biohydrogen production via biogas steam reforming: Case study of biogas plant on a farm in Serbia. Int. J. Hydrog. Energy 2021, 46, 14130–14137.

- 87.Hosseinzadeh-Bandbafha, H.; Rafiee, S.; Mohammadi, P.; et al. Exergetic, economic, and environmental life cycle assessment analyses of a heavy-duty tractor diesel engine fueled with diesel–biodiesel-bioethanol blends. Energy Convers. Manag. 2021, 241, 114300.

- 88.Li, R.; Zhang, C.; Chen, W.-H.; et al. Multistage utilization of soybean straw-derived P-doped biochar for aquatic pollutant removal and biofuel usage. Bioresour. Technol. 2023, 387, 129657.

- 89.Liu, G.; Zhang, X.; Liu, H.; et al. Biochar/layered double hydroxides composites as catalysts for treatment of organic wastewater by advanced oxidation processes: A review. Environ. Res. 2023, 234, 116534.

- 90.Quiroz, D.; Greene, J.M.; Quinn, J.C. Regionalized Life-Cycle Water Impacts of Microalgal-Based Biofuels in the United States. Environ. Sci. Technol. 2022, 56, 16400–16409.

- 91.Cao, B.; Zhang, T.; Zhang, W.; et al. Enhanced technology based for sewage sludge deep dewatering: A critical review. Water Res. 2021, 189, 116650.

- 92.Zhang, J.; Zhang, X.; Yang, M.; et al. Transforming lignocellulosic biomass into biofuels enabled by ionic liquid pretreatment. Bioresour. Technol. 2021, 322, 124522.

- 93.Thengane, S.K.; Burek, J.; Kung, K.S.; et al. Life cycle assessment of rice husk torrefaction and prospects for decentralized facilities at rice mills. J. Clean. Prod. 2020, 275, 123177.

- 94.Huang, X.; Bai, S.; Liu, Z.; et al. Fermentation of pigment-extracted microalgal residue using yeast cell-surface display: Direct high-density ethanol production with competitive life cycle impacts. Green Chem. 2020, 22, 153–162.

- 95.Wang, X.; Liu, F.; Li, Y.; et al. Development of a facile and bi-functional superhydrophobic suspension and its applications in superhydrophobic coatings and aerogels in high-efficiency oil–water separation. Green Chem. 2020, 22, 7424–7434.

- 96.Zhang, L.-J.; Qian, L.; Ding, L.-Y.; et al. Ecological and toxicological assessments of anthropogenic contaminants based on environmental metabolomics. Environ. Sci. Ecotechnology 2021, 5, 100081.

- 97.Aresti, L.; Christodoulides, P.; Florides, G.A. An investigation on the environmental impact of various Ground Heat Exchangers configurations. Renew. Energy 2021, 171, 592–605.

- 98.Choi, H.I.; Lee, J.S.; Choi, J.W.; et al. Performance and potential appraisal of various microalgae as direct combustion fuel. Bioresour. Technol. 2019, 273, 341–349.

- 99.Sun, P.; Liu, C.; Li, A.; et al. Using carbon dioxide-added microalgal-bacterial granular sludge for carbon-neutral municipal wastewater treatment under outdoor conditions: Performance, granule characteristics and environmental sustainability. Sci. Total Environ. 2022, 848, 157657.

- 100.Valente, A.; Iribarren, D.; Dufour, J. How do methodological choices affect the carbon footprint of microalgal biodiesel? A harmonised life cycle assessment. J. Clean. Prod. 2019, 207, 560–568.

- 101.Zaimes, G.G.; Khanna, V. Integrating the Role of Thermodynamics in LCA: A Case Study of Microalgal Biofuels. In Encyclopedia of Sustainable Technologies, Abraham, M.A., Ed.; Elsevier: Oxford, 2017; pp. 397–406.

- 102.Liang, D.; Wu, J.; Lu, L.; et al. Coupling with in-situ electrochemical reactive chlorine species generation and two-phase partitioning method for enhanced microalgal biodiesel production. Bioresour. Technol. 2022, 364, 128100.

- 103.Czyrnek-Delêtre, M.M.; Rocca, S.; Agostini, A.; et al. Life cycle assessment of seaweed biomethane, generated from seaweed sourced from integrated multi-trophic aquaculture in temperate oceanic climates. Appl. Energy 2017, 196, 34–50.

- 104.Wang, S.; Lu, W.; Esakkimuthu, S.; et al. Life cycle assessment of carbon-based adsorbent preparation from algal biomass. J. Clean. Prod. 2023, 427, 139269.

How to Cite

Zhang, C.; Fang, J.; Zhan, Y.; Wang, X.; Chen, T.; Hao, K.; Ma, J.; Wang, Y. Life Cycle Assessment of Microalgal Carbon Fixation and Torrefaction for Carbon Neutralization: A State-of-the-Art Review. Green Energy and Fuel Research 2024, 1 (1), 23–38. https://doi.org/10.53941/gefr.2024.100004.

RIS

BibTex

Copyright & License

Copyright (c) 2024 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References