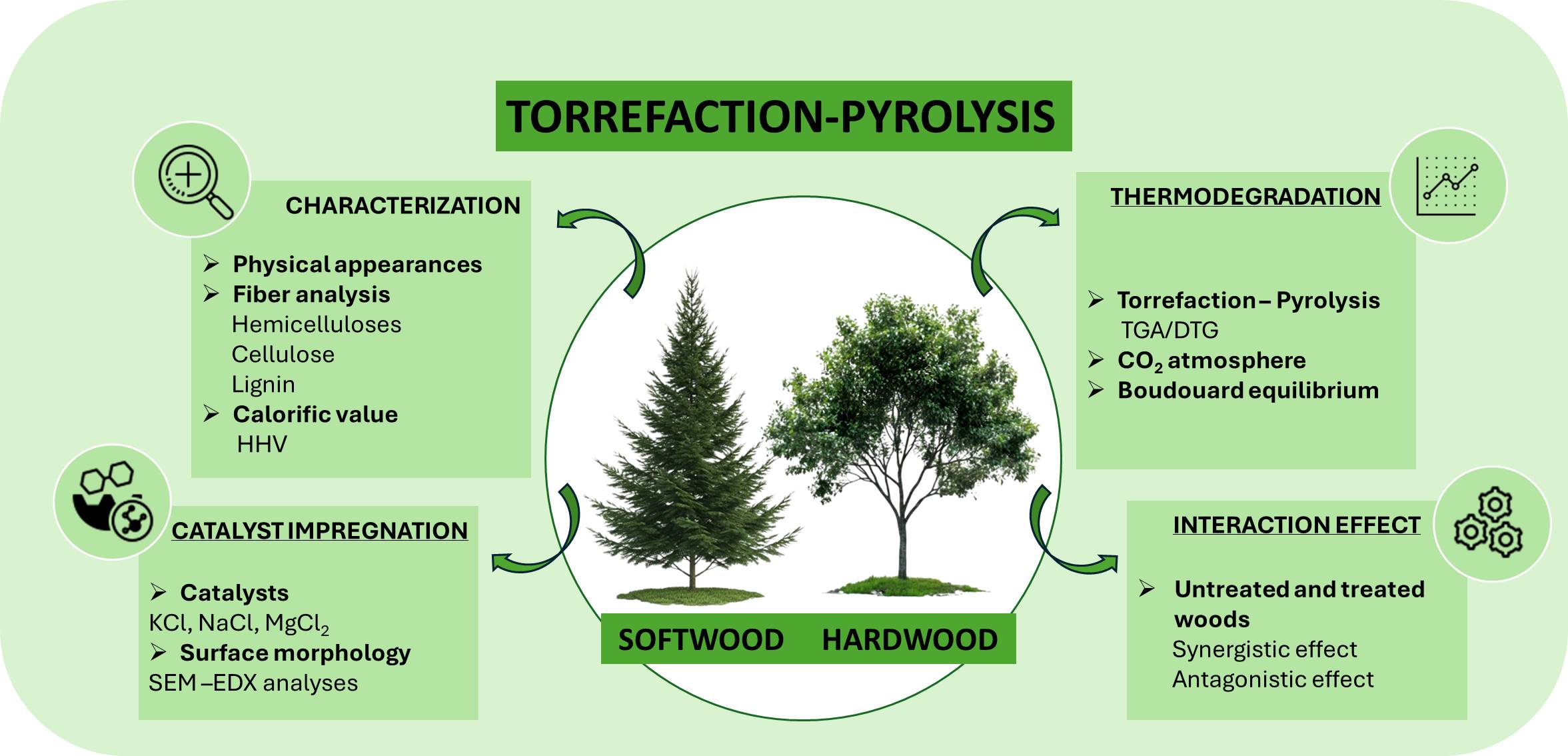

Torrefaction-pyrolysis is the thermal treatment of biomass in an inert atmosphere between 105 °C and 800 °C to break carbon bonds and produce biofuels. The purpose of this study is to examine how woody biomass with different particle sizes (250 µm and 500 μm), wood types (Poplar and Fir), and catalyst types (K, Na, and Mg) responds to catalytic thermochemical conversion in a CO2 environment. Torrefaction-pyrolysis of woody biomass shows the Boudouard equilibrium responds after 780 °C for K and Na-catalysts, except in samples impregnated with Mg-catalyst. When K-catalyst material is present, the C-O-C signal regarding the glycosidic linkages from cellulose and hemicelluloses in Fir is observed to decrease the most. This is related to the fact that Fir (22.43 wt.%) has nearly twice as many hemicelluloses as Poplar (12.18 wt.%), making it less thermally stable and more vulnerable to the prolonged drying required following catalyst impregnation.

- Open Access

- Article

Synergistic and Antagonistic Effects of Catalytic Torrefaction-Pyrolysis of Woody Biomass in a Carbon Dioxide Atmosphere for Biofuel Production

- Elizabeth Wanchisn Smith 1,

- Ria Aniza 2, 3, 4,

- Anelie Petrissans 2, *,

- Rafael Lopes Quirino 1, *,

- Baptiste Colin 2,

- Mathieu Petrissans 2,

- Wei-Hsin Chen 5, 6, 7

Author Information

Received: 01 Apr 2025 | Revised: 27 May 2025 | Accepted: 13 Jun 2025 | Published: 19 Jun 2025

Abstract

Graphical Abstract

Keywords

torrefaction | pyrolysis | catalytic reaction | CO2 carrier gas | Boudouard equilibrium

References

- 1.Nullis, C. WMO Greenhouse Gas Bulletin. More Bad News for the Planet: Greenhouse Gas Levels Hit New Highs. Switzerland: World Meteorological Organization 2022. Available online: https://wmo.int/news/media-centre/more-bad-news-planet-greenhouse-gas-levels-hit-new-highs (accessed on 30 April 2025).

- 2.Aniza, R.; Chen, W.-H.; Pétrissans, A.; et al. A review of biowaste remediation and valorization for environmental sustainability: Artificial intelligence approach. Environ. Pollut. 2023, 324, 121363. https://doi.org/10.1016/j.envpol.2023.121363.

- 3.Vuppaladadiyam, A.K.; Vuppaladadiyam, S.S.V.; Sahoo, A.; et al. Bio-oil and biochar from the pyrolytic conversion of biomass: A current and future perspective on the trade-off between economic, environmental, and technical indicators. Sci. Total Environ. 2023, 857, 159155. https://doi.org/10.1016/j.scitotenv.2022.159155.

- 4.Congyu, Z.; Jin, F.; Yong, Z.; et al. Life Cycle Assessment of Microalgal Carbon Fixation and Torrefaction for Carbon Neutralization: A State-of-the-Art Review. Green Energy Fuel Res. 2024, 1, 23–38. https://doi.org/10.53941/gefr.2024.100004.

- 5.Tubbesing, C.L.; Lara, J.D.; Battles, J.J.; et al. Characterization of the woody biomass feedstock potential resulting from California’s drought. Sci. Rep. 2020, 10, 1096. https://doi.org/10.1038/s41598-020-57904-z.

- 6.Lin, S.L.; Aniza, R.; Lee, Y.Y.; et al. Reduction of traditional pollutants and polychlorinated dibenzo-p-dioxins and dibenzofurans emitted from a diesel engine generator equipped with a catalytic ceramic fiber filter system. Clean Technol. Environ. Policy 2018, 20, 1297–1309. https://doi.org/10.1007/s10098-018-1559-6.

- 7.Lee, Y.Y.; Lin, S.L.; Aniza, R.; et al. Reduction of atmospheric PM2.5 level by restricting the idling operation of buses in a busy station. Aerosol Air Qual. Res. 2017, 17, 2424–2437. https://doi.org/10.4209/aaqr.2017.09.0301.

- 8.Aniza, R.; Chen, W.-H.; Herrera, C.J.A.; et al. Bioenergy and bioexergy analyses with artificial intelligence application on combustion of recycled hardwood and softwood wastes. Renew. Energy 2024, 237, 121885. https://doi.org/10.1016/j.renene.2024.121885.

- 9.Pétrissans, A.; Lin, Y.-Y.; Nguyen, T.N.; et al. Influence of the heating rate on the thermodegradation during the mild pyrolysis of the wood. Wood Mater. Sci. Eng. 2023, 18, 412–421. https://doi.org/10.1080/17480272.2022.2039289.

- 10.Aniza, R.; Petrissans, A.; Petrissans, M. Multifunctional Nanotechnology Application for Wood Properties Enhancement: Adhesive and Coating. In Nanomaterials Additives in Bioadhesives for Wood Composites; Antov, P., Lubis, M.A.R., Lee, S.H., Taghiyari, H.R., Eds.; Springer Nature: Singapore, 2025; pp. 135–149.

- 11.Aniza, R.; Petrissans, A.; Petrissans, M. Life-Cycle Assessment of Nanoparticle in Wood Adhesive and Coating: The State-of-The Art. In Nanomaterials Additives in Bioadhesives for Wood Composites; Antov, P., Lubis, M.A.R., Lee, S.H., Taghiyari, H.R., Eds.; Springer Nature: Singapore, 2025; pp. 231–248.

- 12.Andrade Breves, R.; Ajiola, D.; de Vasconcelos Vieira Lopes, R.; et al. Bio-Based Polyurethane Composites from Macauba Kernel Oil: Part 1, Matrix Synthesis from Glycerol-Based Polyol. J. Compos. Sci. 2024, 8, 363.

- 13.Aniza, R.; Chen, W.-H.; Kwon, E.E.; et al. Lignocellulosic biofuel properties and reactivity analyzed by thermogravimetric analysis (TGA) toward zero carbon scheme: A critical review. Energy Convers. Manag. X 2024, 22, 100538. https://doi.org/10.1016/j.ecmx.2024.100538.

- 14.Chen, W.-H.; Escalante, J.; Xuan, L.L.; et al. Catalytic co-gasification optimization of biomass and polyethylene wastes in oxygen-rich environments. Fuel 2025, 381, 133214. https://doi.org/10.1016/j.fuel.2024.133214.

- 15.McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. https://doi.org/10.1016/S0960-8524(01)00118-3.

- 16.Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. https://doi.org/10.1016/j.pecs.2020.100887.

- 17.Acharya, B.; Dutta, A.; Minaret, J. Review on comparative study of dry and wet torrefaction. Sustain. Energy Technol. Assess. 2015, 12, 26–37. https://doi.org/10.1016/j.seta.2015.08.003.

- 18.Wang, L.; Riva, L.; Skreiberg, Ø.; et al. Effect of Torrefaction on Properties of Pellets Produced from Woody Biomass. Energy Fuels 2020, 34, 15343–15354. https://doi.org/10.1021/acs.energyfuels.0c02671.

- 19.Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Kikas, T. Biomass torrefaction: An overview on process parameters, economic and environmental aspects and recent advancements. Bioresour. Technol. 2020, 301, 122737. https://doi.org/10.1016/j.biortech.2020.122737.

- 20.Amit Kumar, S. Solar Thermal Technologies for Biofuel Production: Recent Advances and Future Prospectus. Green Energy Fuel Res. 2025, 2, 13–25. https://doi.org/10.53941/gefr.2025.100002

- 21.Chen, W.-H. Progress in Green Energy and Fuel for Sustainability. Green Energy Fuel Res. 2024, 1, 13–22. https://doi.org/10.53941/gefr.2024.100003.

- 22.Richa, L.; Colin, B.; Pétrissans, A.; et al. Potassium carbonate impregnation and torrefaction of wood block for thermal properties improvement: Prediction of torrefaction performance using artificial neural network. Appl. Energy 2023, 351, 121894. https://doi.org/10.1016/j.apenergy.2023.121894.

- 23.Nishimura, M.; Iwasaki, S.; Horio, M. The role of potassium carbonate on cellulose pyrolysis. J. Taiwan Inst. Chem. Eng. 2009, 40, 630–637.

- 24.Richa, L.; Colin, B.; Pétrissans, A.; et al. Catalytic and char-promoting effects of potassium on lignocellulosic biomass torrefaction and pyrolysis. Environ. Technol. Innov. 2023, 31, 103193. https://doi.org/10.1016/j.eti.2023.103193.

- 25.Guo, F.; Liu, Y.; Wang, Y.; et al. Pyrolysis kinetics and behavior of potassium-impregnated pine wood in TGA and a fixed-bed reactor. Energy Convers. Manag. 2016, 130, 184–191. https://doi.org/10.1016/j.enconman.2016.10.055.

- 26.Zhao, N.; Li, B.-X. The effect of sodium chloride on the pyrolysis of rice husk. Appl. Energy 2016, 178, 346–352. https://doi.org/10.1016/j.apenergy.2016.06.082.

- 27.Zhu, C.; Huang, K.; Xue, M.; et al. Effect of MgCl2 Loading on the Yield and Performance of Cabbage-Based Biochar. Bioengineering 2023, 10, 836. https://doi.org/10.3390/bioengineering10070836.

- 28.Pradana, Y.S.; Daniyanto; Hartono, M.; Prasakti, L.; et al. Effect of calcium and magnesium catalyst on pyrolysis kinetic of Indonesian sugarcane bagasse for biofuel production. Energy Procedia 2019, 158, 431–439. https://doi.org/10.1016/j.egypro.2019.01.128.

- 29.Müller, T.E.; Leitner, W. CO2 Chemistry. Beilstein J. Org. Chem. 2015, 11, 675–677. https://doi.org/10.3762/bjoc.11.76.

- 30.Nyakuma, B.B.; Wong, S.L.; Faizal, H.M.; et al. Carbon dioxide torrefaction of oil palm empty fruit bunches pellets: Characterisation and optimisation by response surface methodology. Biomass Convers. Biorefinery 2022, 12, 5881–5900. https://doi.org/10.1007/s13399-020-01071-8.

- 31.Cho, D.-W.; Cho, S.-H.; Song, H.; et al. Carbon dioxide assisted sustainability enhancement of pyrolysis of waste biomass: A case study with spent coffee ground. Bioresour. Technol. 2015, 189, 1–6. https://doi.org/10.1016/j.biortech.2015.04.002

- 32.Kim, J.; Lee, J.; Kim, K.-H.; et al. Pyrolysis of wastes generated through saccharification of oak tree by using CO2 as reaction medium. Appl. Therm. Eng. 2017, 110, 335–345. https://doi.org/10.1016/j.applthermaleng.2016.08.200.

- 33.Guizani, C.; Escudero Sanz, F.J.; Salvador, S. Effects of CO2 on biomass fast pyrolysis: Reaction rate, gas yields and char reactive properties. Fuel 2014, 116, 310–320. https://doi.org/10.1016/j.fuel.2013.07.101.

- 34.Chen, D.; Chen, F.; Cen, K.; et al. Upgrading rice husk via oxidative torrefaction: Characterization of solid, liquid, gaseous products and a comparison with non-oxidative torrefaction. Fuel 2020, 275, 117936. https://doi.org/10.1016/j.fuel.2020.117936.

- 35.Dutta, S.; Bhat, N.S. Catalytic Transformation of Biomass-Derived Furfurals to Cyclopentanones and Their Derivatives: A Review. ACS Omega 2021, 6, 35145–35172. https://doi.org/10.1021/acsomega.1c05861.

- 36.Jung, D.; Duman, G.; Zimmermann, M.; et al. Hydrothermal carbonization of fructose—Effect of salts and reactor stirring on the growth and formation of carbon spheres. Biomass Convers. Biorefinery 2023, 13, 6281–6297. https://doi.org/10.1007/s13399-021-01782-6.

- 37.Niu, Q.; Du, X.; Li, K.; et al. Role of catalyst porosity and acidity in nitrogen transformation during catalytic fast pyrolysis of microalgae: Study on extracted protein and model amino acids. Energy Convers. Manag. 2024, 322, 119210. https://doi.org/10.1016/j.enconman.2024.119210.

- 38.Nsibi, C.; Pozzobon, V.; Escudero-Sanz, J.; et al. Catalytic Effects of Potassium Concentration on Steam Gasification of Biofuels Blended from Olive Mill Solid Wastes and Pine Sawdust for a Sustainable Energy of Syngas. Sustainability 2024, 16, 9040.

- 39.Chen, W.-H.; Aniza, R. Specific chemical bioexergy and microwave-assisted torrefaction optimization via statistical and artificial intelligence approaches. Fuel 2023, 333, 126524. https://doi.org/10.1016/j.fuel.2022.126524.

- 40.Md Salim, R.; Asik, J.; Sarjadi, M.S. Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena leucocephala bark. Wood Sci. Technol. 2021, 55, 295–313. https://doi.org/10.1007/s00226-020-01258-2.

- 41.Liu, Y.; Rokni, E.; Yang, R.; et al. Torrefaction of corn straw in oxygen and carbon dioxide containing gases: Mass/energy yields and evolution of gaseous species. Fuel 2021, 285, 119044. https://doi.org/10.1016/j.fuel.2020.119044.

- 42.Shahbeik, H.; Kazemi Shariat Panahi, H.; Dehhaghi, M.; et al. Biomass to biofuels using hydrothermal liquefaction: A comprehensive review. Renew. Sustain. Energy Rev. 2024, 189, 113976. https://doi.org/10.1016/j.rser.2023.113976.

- 43.Basu, P. Chapter 7—Gasification Theory. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Basu, P., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 211–262.

- 44.Eseltine, D.; Thanapal, S.S.; Annamalai, K.; et al. Torrefaction of woody biomass (Juniper and Mesquite) using inert and non-inert gases. Fuel 2013, 113, 379–388

- 45.Uemura, Y.; Saadon, S.; Osman, N.; et al. Torrefaction of oil palm kernel shell in the presence of oxygen and carbon dioxide. Fuel 2015, 144, 171–179. https://doi.org/10.1016/j.fuel.2014.12.050.

- 46.Cho, D.-W.; Lee, J.; Yoon, K.; et al. Pyrolysis of FeCl3-pretreated spent coffee grounds using CO2 as a reaction medium. Energy Convers. Manag. 2016, 127, 437–442. https://doi.org/10.1016/j.enconman.2016.09.036.

- 47.Quan, C.; Zhou, Y.; Gao, N.; et al. Direct CO2 capture from air using char from pyrolysis of digestate solid. Biomass Bioenergy 2023, 175, 106891. https://doi.org/10.1016/j.biombioe.2023.106891.

- 48.Sun, Y.; Dong, B.; Wang, L.; et al. Technology selection for capturing CO2 from wood pyrolysis. Energy Convers. Manag. 2022, 266, 115835. https://doi.org/10.1016/j.enconman.2022.115835.

- 49.Wang, T.; Hsu, C.-L.; Huang, C.-H.; et al. Environmental impact of CO2-expanded fluid extraction technique in microalgae oil acquisition. J. Clean. Prod. 2016, 137, 813–820. https://doi.org/10.1016/j.jclepro.2016.07.179.

- 50.Aho, A.; DeMartini, N.; Pranovich, A.; et al. Pyrolysis of pine and gasification of pine chars—Influence of organically bound metals. Bioresour. Technol. 2013, 128, 22–29. https://doi.org/10.1016/j.biortech.2012.10.093.

- 51.Frost, D.L.; Goroshin, S.; Levine, J.; et al. Critical Conditions for Ignition of Aluminum Particles in Cylindrical Explosive Charges. AIP Conf. Proc. 2006, 845, 972–975. https://doi.org/10.1063/1.2263484.

- 52.Barabulica, I.; Secula, M.S.; Asoltanei, A.M.; et al. Experimental Study on the Reaction of Magnesium in Carbon Dioxide and Nitrogen Atmosphere. ChemEngineering 2024, 8, 41.

- 53.Zhang, S.; Wang, J.; Zhu, S.; et al. Effects of MgCl2 and Mg(NO3)2 loading on catalytic pyrolysis of sawdust for bio-oil and MgO-impregnated biochar production. J. Anal. Appl. Pyrolysis 2020, 152, 104962. https://doi.org/10.1016/j.jaap.2020.104962.

- 54.Aniza, R.; Chen, W.-H.; Lin, Y.-Y.; et al. Independent parallel pyrolysis kinetics of extracted proteins and lipids as well as model carbohydrates in microalgae. Appl. Energy 2021, 300, 117372. https://doi.org/10.1016/j.apenergy.2021.117372.

- 55.Chen, R.; Zhang, S.; Cong, K.; et al. Insight into synergistic effects of biomass-polypropylene co-pyrolysis using representative biomass constituents. Bioresour. Technol. 2020, 307, 123243. https://doi.org/10.1016/j.biortech.2020.123243.

- 56.Menéndez, J.A.; Arenillas, A.; Fidalgo, B.; et al. Microwave heating processes involving carbon materials. Fuel Process. Technol. 2010, 91, 1–8. https://doi.org/10.1016/j.fuproc.2009.08.021.

- 57.Dupont, C.; Boissonnet, G.; Seiler, J.-M.; et al. Study about the kinetic processes of biomass steam gasification. Fuel 2007, 86, 32–40. https://doi.org/10.1016/j.fuel.2006.06.011.

- 58.Kawamoto, H. Review of reactions and molecular mechanisms in cellulose pyrolysis. Curr. Org. Chem. 2016, 20, 2444–2457.

How to Cite

Smith, E. W.; Aniza, R.; Petrissans, A.; Quirino, R. L.; Colin, B.; Petrissans, M.; Chen, W.-H. Synergistic and Antagonistic Effects of Catalytic Torrefaction-Pyrolysis of Woody Biomass in a Carbon Dioxide Atmosphere for Biofuel Production. Green Energy and Fuel Research 2025, 2 (2), 152–173. https://doi.org/10.53941/gefr.2025.100012.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References