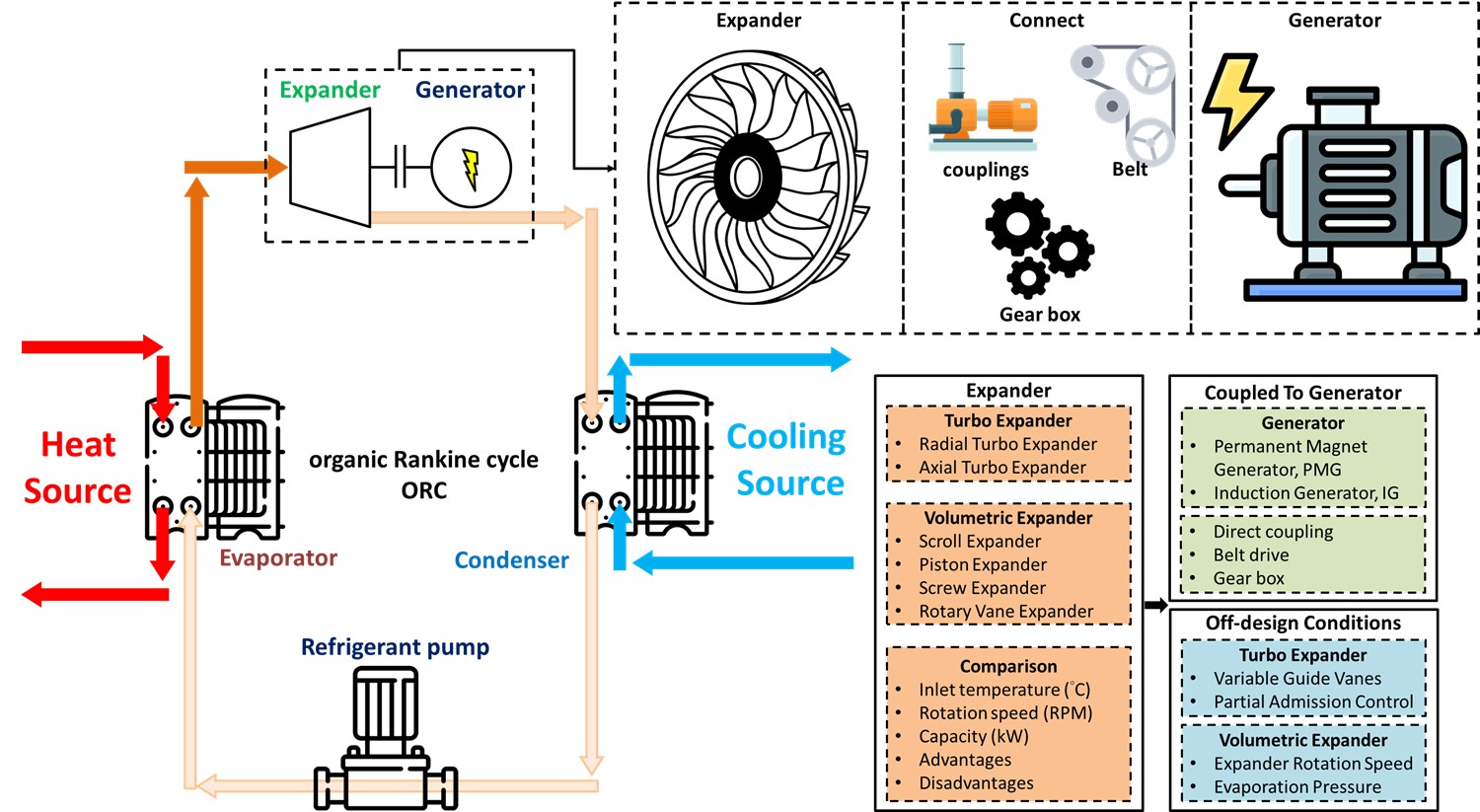

The present study provides a systematic review of expander technologies used in organic Rankine cycle (ORC) systems, examining their operational principles, performance characteristics, and application domains. Expanders can be broadly categorized into turbo and volumetric types, each exhibiting distinct operational advantages. Turbo expanders exhibit high isentropic efficiency and are well suited to high-temperature, high-mass-flow conditions. Their performance strongly depends on blade geometry and operating conditions, which can be optimized through computational fluid dynamics, meanline design, and advanced features such as variable guide vanes and partial admission. Volumetric expanders—including scroll, vane, and screw expanders—are commonly adopted in small- to medium-scale systems because of their simplicity, low cost, and ability to handle two-phase fluids. Scroll expanders are most effective at power outputs below 6 kW, whereas screw expanders provide a wider operational speed range and higher adaptability. Vane expanders, while compact, suffer from efficiency limitations due to internal leakage. All volumetric expanders face technical challenges related to sealing effectiveness, frictional losses, material selection, and thermal stresses. Turbo expanders, which require high manufacturing precision, are more frequently analyzed via simulations than experiments. This review consolidates current advancements, identifies unresolved technical barriers, and outlines strategies for performance enhancement. The insights presented herein are expected to inform expander selection, support system-level design (including control strategies for variable heat sources and mechanical expander–generator coupling), and guide future research, ultimately facilitating the deployment of ORC systems in sustainable and low-grade heat recovery applications.

- Open Access

- Review

Volumetric and Turbine Expander Technologies in Organic Rankine Cycle Systems: A Systematic Review

- Jui-Ching Hsieh *,

- Hsien-Ta Tsai,

- Yeh-Tung Chen,

- Cai-Ling Chen,

- Cheng-Fu Lin

Author Information

Received: 02 Jul 2025 | Revised: 11 Aug 2025 | Accepted: 04 Sep 2025 | Published: 16 Sep 2025

Abstract

Graphical Abstract

Keywords

organic Rankine cycle (ORC) | expander | isentropic efficiency | volumetric efficiency | low-grade heat | variable heat source

References

- 1.Twidell, J. Renewable Energy Resources; Routledge: London, UK, 2021.

- 2.Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; et al. Low-grade heat conversion into power using organic Rankine cycles—A review of various applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979.

- 3.Wieland, C.; Dawo, F.; Schifflechner, C.; et al. Market report on Organic Rankine Cycle power systems: Recent developments and outlook. In Proceedings of the 6th International Seminar on ORC Power Systems, Virtual, 11–13 October 2021.

- 4.Tartière, T.; Astolfi, M. A world overview of the organic Rankine cycle market. Energy Procedia 2017, 129, 2–9.

- 5.Quoilin, S.; Van Den Broek, M.; Declaye, S.; et al. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186.

- 6.Liu, B.T.; Chien, K.H.; Wang, C.C. Effect of working fluids on organic Rankine cycle for waste heat recovery. Energy 2004, 29, 1207–1217.

- 7.White, M.; Sayma, A.I. Improving the economy-of-scale of small organic rankine cycle systems through appropriate working fluid selection. Appl. Energy 2016, 183, 1227–1239.

- 8.Bianchi, M.; Branchini, L.; De Pascale, A.; et al. Performance and total warming impact assessment of pure fluids and mixtures replacing HFCs in micro-ORC energy systems. Appl. Therm. Eng. 2022, 203, 117888.

- 9.Qiu, K.; Thomas, M.; Douglas, M. Investigation of a scroll expander driven by compressed air and its potential applications to ORC. Appl. Therm. Eng. 2018, 135, 109–115.

- 10.Feng, X.; Shi, F.; Qiao, G.; et al. Integrating Organic Rankine Cycle with Thermoelectric Generator in Various Applications Utilizing Low-Grade Energy: A Review; Sustainable Energy Technologies and Assessments; Elsevier: Amsterdam, The Netherlands, 2024.

- 11.Wu, T.; Wei, X.; Meng, X.; et al. Experimental study of operating load variation for organic Rankine cycle system based on radial inflow turbine. Appl. Therm. Eng. 2020, 166, 114641.

- 12.Imran, M.; Usman, M.; Park, B.S.; et al. Volumetric expanders for low grade heat and waste heat recovery applications. Renew. Sustain. Energy Rev. 2016, 57, 1090–1109.

- 13.Zheng, Y.; Hu, D.; Cao, Y.; et al. Preliminary design and off-design performance analysis of an Organic Rankine Cycle radial-inflow turbine based on mathematic method and CFD method. Appl. Therm. Eng. 2017, 112, 25–37.

- 14.Dixon, S.L.; Eng, B.; Hall, C.A. Fluid Mechanics and Thermodynamics of Turbomachinery, 7th ed.; Elsevier: Amsterdam, The Netherlands, 2014.

- 15.Bao, J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342.

- 16.Sauret, E.; Gu, Y. Three-dimensional off-design numerical analysis of an organic Rankine cycle radial-inflow turbine. Appl. Energy 2014, 135, 202–211.

- 17.Wang, Z.; Xie, B.; Xia, X.; et al. Entropy production analysis of a radial inflow turbine with variable inlet guide vane for ORC application. Energy 2023, 265, 126313.

- 18.Al Jubori, A.; Daabo, A.; Al-Dadah, R.K.; et al. Development of micro-scale axial and radial turbines for low-temperature heat source driven organic Rankine cycle. Energy Convers. Manag. 2016, 130, 141–155.

- 19.Yao, Y.; Fang, S.; Zhu, S.; et al. Optimal design and tip leakage flow characteristics analysis of radial inflow turbine used in organic Rankine and vapor compression refrigeration system. Energy 2024, 301, 131668.

- 20.Dong, B.; Xu, G.; Luo, X.; et al. Analysis of the supercritical organic Rankine cycle and the radial turbine design for high temperature applications. Appl. Therm. Eng. 2017, 123, 1523–1530.

- 21.Kim, D.Y.; Kim, Y.T. Preliminary design and performance analysis of a radial inflow turbine for organic Rankine cycles. Appl. Therm. Eng. 2017, 120, 549–559.

- 22.Du, Y.; Yang, Y.; Hu, D.; et al. Off-design performance comparative analysis between basic and parallel dual-pressure organic Rankine cycles using radial inflow turbines. Appl. Therm. Eng. 2018, 138, 18–34.

- 23.Xia, J.; Wang, J.; Wang, H.; et al. Three-dimensional performance analysis of a radial-inflow turbine for an organic Rankine cycle driven by low grade heat source. Energy Convers. Manag. 2018, 169, 22–33.

- 24.Quan, Y.; Liu, J.; Zhang, C.; et al. Aerodynamic design of an axial impulse turbine for the high-temperature organic Rankine cycle. Appl. Therm. Eng. 2020, 167, 114708.

- 25.Sarmiento, A.L.E.; Camacho, R.G.R.; de Oliveira, W.; et al. Design and off-design performance improvement of a radial-inflow turbine for ORC applications using metamodels and genetic algorithm optimization. Appl. Therm. Eng. 2021, 183, 116197.

- 26.Li, B.; Xie, H.; Sun, L.; et al. Optimization design of radial inflow turbine combined with mean-line model and CFD analysis for geothermal power generation. Energy 2024, 291, 130452.

- 27.Yu, H.; Helland, H.; Yu, X.; et al. Optimal design and operation of an Organic Rankine Cycle (ORC) system driven by solar energy with sensible thermal energy storage. Energy Convers. Manag. 2021, 244, 114494.

- 28.Kupka, D.; Koloničný, J.; Pejchal, J. Development of an axial impulse turbine for a small-scale ORC system. Results Eng. 2025, 25, 103994.

- 29.Al Jubori, A.M.; Al-Dadah, R.; Mahmoud, S. An innovative small-scale two-stage axial turbine for low-temperature organic Rankine cycle. Energy Convers. Manag. 2017, 144, 18–33.

- 30.Witanowski, Ł.; Klonowicz, P.; Lampart, P.; et al. Multi-objective optimization of the ORC axial turbine for a waste heat recovery system working in two modes: Cogeneration and condensation. Energy 2023, 264, 126187.

- 31.Yang, Y.; Huo, Y.; Xia, W.; et al. Construction and preliminary test of a geothermal ORC system using geothermal resource from abandoned oil wells in the Huabei oilfield of China. Energy 2017, 140, 633–645.

- 32.Sun, H.; Qin, J.; Yan, P.; et al. Performance evaluation of a partially admitted axial turbine using R245fa, R123 and their mixtures as working fluid for small-scale organic Rankine cycle. Energy Convers. Manag. 2018, 171, 925–935.

- 33.Al Jubori, A.M.; Al-Dadah, R.K.; Mahmoud, S.; et al. Modelling and parametric analysis of small-scale axial and radial-outflow turbines for Organic Rankine Cycle applications. Appl. Energy 2017, 190, 981–996.

- 34.Peng, N.; Wang, E.; Meng, F. Off-design performance comparison of single-stage axial turbines using CO2 and zeotropic mixture for low-temperature heat source. Energy Convers. Manag. 2020, 213, 112838.

- 35.Sun, H.; Qin, J.; Hung, T.C.; et al. Performance analysis of low speed axial impulse turbine using two type nozzles for small-scale organic Rankine cycle. Energy 2019, 169, 1139–1152.

- 36.Naas, T.T.; Telha, M.; Laib, L.; et al. Performance enhancement of three-stage axial turbine for Clean Organic Rankine Cycle system driven by low-temperature heat source. Clean. Eng. Technol. 2021, 5, 100336.

- 37.Klun, M.; Guzović, Z.; Rašković, P. Innovative small axial multistage turbine with partial admission for bottoming ORC. Energy Rep. 2021, 7, 9069–9093.

- 38.Alshammari, F.; Pesyridis, A.; Elashmawy, M. Turbine optimization potential to improve automotive Rankine cycle performance. Appl. Therm. Eng. 2021, 186, 116559.

- 39.Zengin, İ.; Erdoğan, B.; Benim, A.C. CFD and Taguchi based optimization of air driven single stage partial admission axial turbine blade profiles. Energy 2024, 290, 130333.

- 40.Guan, Y.; Li, W.; Zhu, Y.; et al. Aerodynamic performance and flow characteristics of a compressed air energy storage axial turbine with nozzle governing. J. Energy Storage 2023, 63, 106967.

- 41.Lemort, V.; Quoilin, S.; Cuevas, C.; et al. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle. Appl. Therm. Eng. 2009, 29, 3094–3102.

- 42.Zhu, Y.; Jiang, L.; Jin, V.; et al. Impact of built-in and actual expansion ratio difference of expander on ORC system performance. Appl. Therm. Eng. 2014, 71, 548–558.

- 43.Kim, Y.M.; Shin, D.G.; Kim, C.G. Optimization of design pressure ratio of positive displacement expander for vehicle engine waste heat recovery. Energies 2014, 7, 6105–6117.

- 44.Tassou, S.A.; Qureshi, T.Q. Comparative performance evaluation of positive displacement compressors in variable-speed refrigeration applications. Int. J. Refrig. 1998, 21, 29–41.

- 45.Wang, Z.; Wang, Z.; Wang, J.; et al. Theoretical and experimental study on thermodynamic performance of single screw refrigeration compressor with Multicolumn Envelope Meshing Pair. Appl. Therm. Eng. 2016, 103, 139–149.

- 46.Lecompte, S.; Huisseune, H.; Van Den Broek, M.; et al. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461.

- 47.Qiu, G.; Liu, H.; Riffat, S. Expanders for micro-CHP systems with organic Rankine cycle. Appl. Therm. Eng. 2011, 31, 3301–3307.

- 48.Capata, R.; Pantano, F. Expander design procedures and selection criterion for small rated organic rankine cycle systems. Energy Sci. Eng. 2020, 8, 3380–3414.

- 49.Declaye, S.; Quoilin, S.; Guillaume, L.; et al. Experimental study on an open-drive scroll expander integrated into an ORC (Organic Rankine Cycle) system with R245fa as working fluid. Energy 2013, 55, 173–183.

- 50.Ma, X.; Lv, X.; Li, C.; et al. Accurate modelling of the scroll expander via a mechanism-incorporated data-driven method. Int. J. Refrig. 2023, 155, 32–46.

- 51.Yanagisawa, T.; Shimizu, T.; Fukuta, M.; et al. Study on fundamental performance of scroll expander. Trans. Jpn. Soc. Mech. Eng. Ser. B 1988, 54, 2798–2803.

- 52.Hsieh, J.C.; Chen, Y.H.; Hsieh, Y.C. Experimental study of an organic Rankine cycle with a variable-rotational-speed scroll expander at various heat source temperatures. Energy 2023, 270, 126956.

- 53.Hsieh, J.C.; Hsieh, Y.C.; Chen, Y.H. Effect of superheat degree on the performance of an organic Rankine cycle system that utilizes a wet working fluid. Energy Sci. Eng. 2024, 12, 5019–5030.

- 54.Wu, Z.; Pan, D.; Gao, N.; et al. Experimental testing and numerical simulation of scroll expander in a small scale organic Rankine cycle system. Appl. Therm. Eng. 2015, 87, 529–537.

- 55.Fukuta, M.; Yanagisawa, T.; Kosuda, O.; Ogi, Y. Performance of Scroll Expander for CO₂ Refrigeration Cycle. In Proceedings of the International Compressor Engineering Conference, Purdue University, West Lafayette, IN, USA, 17–20 July 2006; Purdue University Press: West Lafayette, IN, USA, 2006.

- 56.Gao, P.; Jiang, L.; Wang, L.W.; et al. Simulation and experiments on an ORC system with different scroll expanders based on energy and exergy analysis. Appl. Therm. Eng. 2015, 75, 880–888.

- 57.Kosmadakis, G.; Mousmoulis, G.; Manolakos, D.; et al. Development of open-drive scroll expander for an Organic Rankine Cycle (ORC) engine and first test results. Energy Procedia 2017, 129, 371–378.

- 58.Cambi, M.; Tascioni, R.; Cioccolanti, L.; et al. Converting a commercial scroll compressor into an expander: Experimental and analytical performance evaluation. Energy Procedia 2017, 129, 363–370.

- 59.Giuffrida, A. A theoretical study on the performance of a scroll expander in an organic Rankine cycle with hydrofluoroolefins (HFOs) in place of R245fa. Energy 2018, 161, 1172–1180.

- 60.Yang, J.; Sun, Z.; Yu, B.; et al. Modeling and optimization criteria of scroll expander integrated into organic Rankine cycle for comparison of R1233zd (E) as an alternative to R245fa. Appl. Therm. Eng. 2018, 141, 386–393.

- 61.Dumont, O.; Parthoens, A.; Dickes, R.; et al. Experimental investigation and optimal performance assessment of four volumetric expanders (scroll, screw, piston and roots) tested in a small-scale organic Rankine cycle system. Energy 2018, 165, 1119–1127.

- 62.Ziviani, D.; James, N.A.; Accorsi, F.A.; et al. Experimental and numerical analyses of a 5 kWe oil-free open-drive scroll expander for small-scale organic Rankine cycle (ORC) applications. Appl. Energy 2018, 230, 1140–1156.

- 63.Fatigati, F.; Cipollone, R. Experimental and theoretical assessment of the effects of electrical load variation on the operability of a small-scale Organic Rankine Cycle (ORC)-based unit equipped with a hermetic scroll expander. Energy 2024, 311, 133318.

- 64.Hijriawan, M.; Pambudi, N.A.; Wijayanto, D.S.; et al. Experimental analysis of R134a working fluid on Organic Rankine Cycle (ORC) systems with scroll-expander. Eng. Sci. Technol. Int. J. 2022, 29, 101036.

- 65.Wang, Z.; Pan, H.; Xia, X.; et al. Experimental investigation on steady and dynamic performance of organic Rankine cycle with R245fa/R141b under different cooling and expander speed conditions. Energy 2022, 241, 122511.

- 66.Zhang, H.H.; Zhang, Y.F.; Feng, Y.Q.; et al. The parametric analysis on the system behaviors with scroll expanders employed in the ORC system: An experimental comparison. Energy 2023, 268, 126713.

- 67.Feng, Y.Q.; Liang, H.J.; Xu, K.; et al. Experimental study on the performance of a great progress 10 kW organic Rankine cycle for low-grade heat source based on scroll-type expander. Energy 2023, 284, 128627.

- 68.Zhen, K.; Shi, L.; Zhang, Y.; et al. Performance prediction and regression analysis of scroll expander based on response surface methodology. Case Stud. Therm. Eng. 2024, 60, 104766.

- 69.Wronski, J.; Imran, M.; Skovrup, M.J.; et al. Experimental and numerical analysis of a reciprocating piston expander with variable valve timing for small-scale organic Rankine cycle power systems. Appl. Energy 2019, 247, 403–416.

- 70.Oudkerk, J.F.; Lemort, V. Detailed experimental and model-based analysis of a swash-plate piston expander for ORC application. Front. Energy Res. 2020, 8, 107.

- 71.Zheng, N.; Zhao, L.; Wang, X.D.; et al. Experimental verification of a rolling-piston expander that applied for low-temperature Organic Rankine Cycle. Appl. Energy 2013, 112, 1265–1274.

- 72.Han, Y.; Kang, J.; Zhang, G.; et al. Performance evaluation of free piston compressor coupling organic Rankine cycle under different operatinSg conditions. Energy Convers. Manag. 2014, 86, 340–348.

- 73.Chatzopoulou, M.A.; Simpson, M.; Sapin, P.; et al. Off-design optimisation of organic Rankine cycle (ORC) engines with piston expanders for medium-scale combined heat and power applications. Appl. Energy 2019, 238, 1211–1236.

- 74.Bianchi, M.; Branchini, L.; Casari, N.; et al. Experimental analysis of a micro-ORC driven by piston expander for low-grade heat recovery. Appl. Therm. Eng. 2019, 148, 1278–1291.

- 75.Bianchi, M.; Branchini, L.; De Pascale, A.; et al. Application and comparison of semi-empirical models for performance prediction of a kW-size reciprocating piston expander. Appl. Energy 2019, 249, 143–156.

- 76.Bianchi, M.; Branchini, L.; De Pascale, A.; et al. Replacement of R134a with low-GWP fluids in a kW-size reciprocating piston expander: Performance prediction and design optimization. Energy 2020, 206, 118174.

- 77.Han, Y.; Zhang, Y.; Zuo, T.; et al. Experimental study and energy loss analysis of an R245fa organic Rankine cycle prototype system with a radial piston expander. Appl. Therm. Eng. 2020, 169, 114939.

- 78.Gao, J.; Ma, C.; Tian, G.; et al. Numerical investigations of an opposed rotary piston expander for the purpose of the applications to a small-scale Rankine cycle. Appl. Therm. Eng. 2021, 182, 116157.

- 79.Wei, J.; Hua, Q.; Wang, J.; et al. Overview of the Development and Application of the Twin Screw Expander. Energies 2020, 13, 6586.

- 80.Ziviani, D.; Bell, I.; van den Broek, M.; De Paepe, M. Comprehensive Model of a Single-Screw Expander for ORC-Systems. In Proceedings of the International Compressor Engineering Conference, Purdue University, West Lafayette, IN, USA, 14–17 July 2014; Purdue University Press: West Lafayette, IN, USA, 2014.

- 81.Tian, Y.; Wang, Z.; Liu, Z.; et al. Two-phase Flow Characteristics and Leakage in the Shaft Seal of Steam Screw Expanders. Int. J. Refrig. 2025, 172, 214–227.

- 82.Tang, H.; Wu, H.; Wang, X.; et al. Performance study of a twin-screw expander used in a geothermal organic Rankine cycle power generator. Energy 2015, 90, 631–642.

- 83.Lei, B.; Wang, W.; Wu, Y.T.; et al. Development and experimental study on a single screw expander integrated into an Organic Rankine Cycle. Energy 2016, 116, 43–52.

- 84.Giuffrida, A. Improving the semi-empirical modelling of a single-screw expander for small organic Rankine cycles. Appl. Energy 2017, 193, 356–368.

- 85.Xia, G.D.; Zhang, Y.Q.; Wu, Y.T.; et al. Experimental study on the performance of single-screw expander with different inlet vapor dryness. Appl. Therm. Eng. 2015, 87, 34–40.

- 86.Ziviani, D.; Groll, E.A.; Braun, J.E.; et al. Review and update on the geometry modeling of single-screw machines with emphasis on expanders. Int. J. Refrig. 2018, 92, 10–26.

- 87.Bianchi, G.; Kennedy, S.; Zaher, O.; et al. Numerical modeling of a two-phase twin-screw expander for Trilateral Flash Cycle applications. Int. J. Refrig. 2018, 88, 248–259.

- 88.Song, X.; Wu, Y.; Shen, L.; et al. Comparative experimental analysis of the effect of lubricant viscosity on the performance of a single-screw expander with different structures. J. Energy Storage 2022, 52, 104958.

- 89.Yang, K.; Zhang, H.; Song, S.; et al. Performance analysis of the vehicle diesel engine-ORC combined system based on a screw expander. Energies 2014, 7, 3400–3419.

- 90.Zhang, Y.Q.; Wu, Y.T.; Xia, G.D.; et al. Development and experimental study on organic Rankine cycle system with single-screw expander for waste heat recovery from exhaust of diesel engine. Energy 2014, 77, 499–508.

- 91.Hsu, S.W.; Chiang HW, D.; Yen, C.W. Experimental investigation of the performance of a hermetic screw-expander organic Rankine cycle. Energies 2014, 7, 6172–6185.

- 92.Ziviani, D.; Gusev, S.; Lecompte, S.; et al. Characterizing the performance of a single-screw expander in a small-scale organic Rankine cycle for waste heat recovery. Appl. Energy 2016, 181, 155–170.

- 93.Ziviani, D.; Gusev, S.; Lecompte, S.; et al. Optimizing the performance of small-scale organic Rankine cycle that utilizes a single-screw expander. Appl. Energy 2017, 189, 416–432.

- 94.Nikolov, A.; Brümmer, A. Investigating a small oil-flooded twin-screw expander for waste-heat utilisation in organic rankine cycle systems. Energies 2017, 10, 869.

- 95.Eyerer, S.; Dawo, F.; Rieger, F.; et al. Experimental and numerical investigation of direct liquid injection into an ORC twin-screw expander. Energy 2019, 178, 867–878.

- 96.Guo, Z.; Zhang, C.; Wu, Y.; et al. Numerical optimization of intake and exhaust structure and experimental verification on single-screw expander for small-scale ORC applications. Energy 2020, 199, 117478.

- 97.Zhao, Z.; Zhang, J.; Wang, G.; et al. Research and clearance analysis on of steam twin-screw expander employed in indutrial waste heat recovery. Energy 2024, 312, 133439.

- 98.Wang, H.X.; Lei, B.; Wu, Y.T.; et al. Experimental investigation and machine learning applications of a quasi-two-stage single screw expander integrated into an Organic Rankine Cycle. Appl. Therm. Eng. 2025, 268, 125896.

- 99.Vodicka, V.; Novotny, V.; Zeleny, Z.; et al. Theoretical and experimental investigations on the radial and axial leakages within a rotary vane expander. Energy 2019, 189, 116097.

- 100.Naseri, A.; Norris, S.; Subiantoro, A. Experimental investigation of a prototype semi-dry revolving vane expander: Design challenges and performance criteria. Energy 2020, 205, 118063.

- 101.Vodicka, V.; Novotny, V.; Mascuch, J.; et al. Impact of major leakages on characteristics of a rotary vane expander for ORC. Energy Procedia 2017, 129, 387–394.

- 102.Yang, B.; Sun, S.; Peng, X.; Guo, B.; Xing, Z. Modeling and Experimental Investigation on the Internal Leakage in a CO₂ Rotary Vane Expander. In Proceedings of the International Compressor Engineering Conference, Purdue University, West Lafayette, IN, USA, 14–17 July 2008; Purdue University Press: West Lafayette, IN, USA, 2008.

- 103.Naseri, A.; Norris, S.E.; Subiantoro, A. Experimental investigation of leakage in the modified revolving vane expander. J. Fluids Eng. 2021, 143, 071206.

- 104.Mahmoud, A.M.; Sherif, S.A.; Lear, W.E. Frictional and internal leakage losses in rotary-vane two-phase refrigerating expanders. J. Energy Resour. Technol. 2010, 132, 021007.

- 105.Jia, X.; Zhang, B.; Pu, L.; et al. Improved rotary vane expander for trans-critical CO2 cycle by introducing high-pressure gas into the vane slots. Int. J. Refrig. 2011, 34, 732–741.

- 106.Yang, B.; Peng, X.; He, Z.; et al. Experimental investigation on the internal working process of a CO2 rotary vane expander. Appl. Therm. Eng. 2009, 29, 2289–2296.

- 107.Casari, N.; Fadiga, E.; Pinelli, M.; et al. Investigation of flow characteristics in a single screw expander: A numerical approach. Energy 2020, 213, 118730.

- 108.Mascuch, J.; Novotny, V.; Vodicka, V.; et al. Experimental development of a kilowatt-scale biomass fired micro–CHP unit based on ORC with rotary vane expander. Renew. Energy 2020, 147, 2882–2895.

- 109.Naseri, A.; Moradi, R.; Norris, S.; et al. Experimental investigation of a revolving vane expander in a micro-scale organic Rankine cycle system for low-grade waste heat recovery. Energy 2022, 253, 124174.

- 110.Fatigati, F.; Vittorini, D.; Di Bartolomeo, M.; et al. Experimental and theoretical analysis of a micro-cogenerative solar ORC-based unit equipped with a variable speed sliding rotary vane expander. Energy Convers. Manag. X 2023, 20, 100428.

- 111.Vittorini, D.; Antonini, A.; Cipollone, R.; et al. Solar thermal-based orc power plant for micro cogeneration–performance analysis and control strategy. Energy Procedia 2018, 148, 774–781.

- 112.Fu, B.R.; Lee, Y.R.; Hsieh, J.C. Design, construction, and preliminary results of a 250-kW organic Rankine cycle system. Appl. Therm. Eng. 2015, 80, 339–346.

- 113.Chang, J.C.; Hung, T.C.; He, Y.L.; et al. Experimental study on low-temperature organic Rankine cycle utilizing scroll type expander. Appl. Energy 2015, 155, 150–159.

- 114.Jiang, Y.; Feng, Y.; Tian, S.; et al. Experimental and numerical optimization of a scroll expander for small-scale ORC systems using pure and mixture working fluids. Energy 2025, 333, 137333.

How to Cite

Hsieh, J.-C.; Tsai, H.-T.; Chen, Y.-T.; Chen, C.-L.; Lin, C.-F. Volumetric and Turbine Expander Technologies in Organic Rankine Cycle Systems: A Systematic Review. Green Energy and Fuel Research 2025, 2 (3), 197–217. https://doi.org/10.53941/gefr.2025.100015.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References