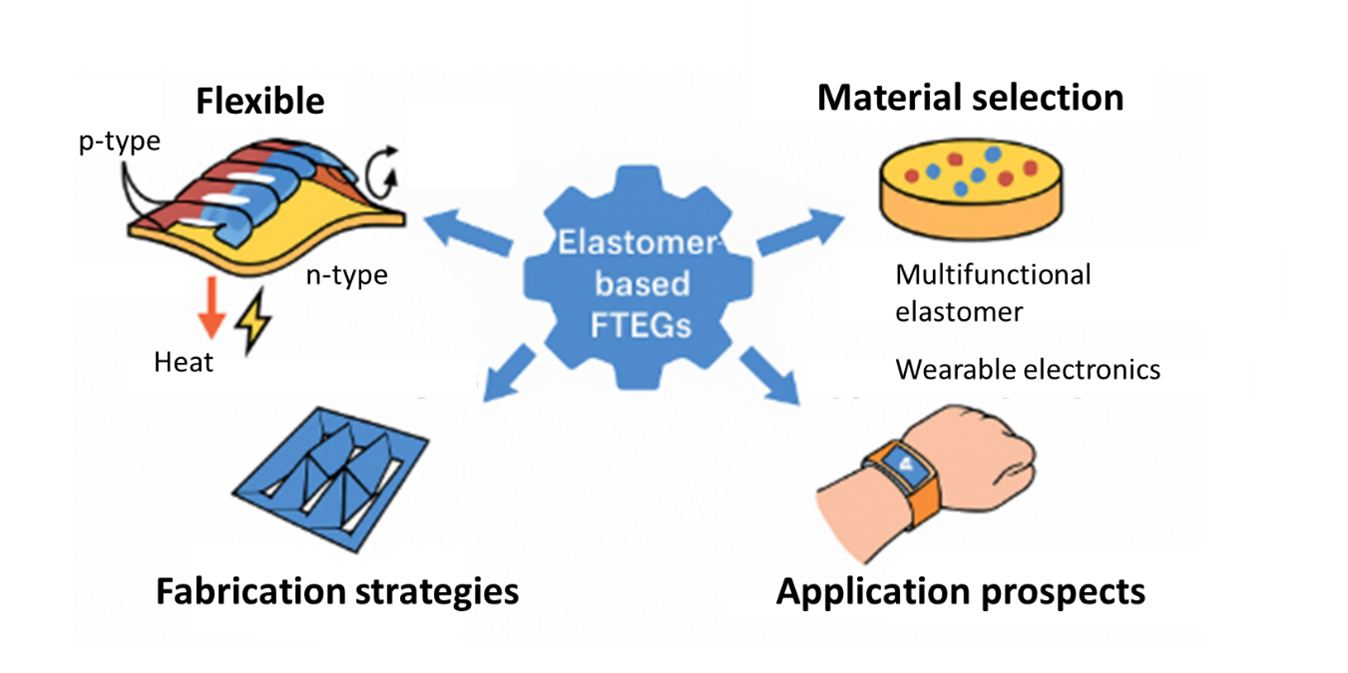

Flexible thermoelectric generators (FTEGs) are garnering significant attention for their ability to convert low-grade heat into electricity while maintaining mechanical flexibility, making them ideal for wearable electronics and soft robotics. This review outlines recent advances in elastomer-based FTEGs, with a focus on material selection, structural integration, and scalable fabrication. Emphasis is placed on the development of multifunctional elastomers with enhanced thermoelectric performance, the strategies for embedding fillers to maintain mechanical compliance, and the evolution of interfacial and module-level designs. Furthermore, emerging approaches, such as kirigami-inspired architectures, ionic interfaces, and liquid-metal grids, are explored for their role in improving device endurance and energy output. This review concludes by identifying key challenges, including long-term stability, biocompatibility, and sustainable manufacturing. It also proposes future directions that integrate geometry, chemistry, and computational tools to enable the next generation of deployable, eco-friendly FTEGs.

- Open Access

- Review

A Review of Elastomer-Based Flexible Thermoelectric Generators: Material Selection, Fabrication Strategies, and Application Prospects

- Wei-Hsin Chen 1, 2, 3, *,

- Sheng-Ting Lin 1

Author Information

Received: 05 Aug 2025 | Revised: 27 Sep 2025 | Accepted: 28 Sep 2025 | Published: 30 Sep 2025

Abstract

Graphical Abstract

Keywords

flexible thermoelectric generators (FTEGs) | elastomeric composites | stretchable energy harvesting | thermoelectric material integration | wearable electronics

References

- 1.Kim, S.J.; We, J.H.; Cho, B.J. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 2014, 7, 1959–1965.

- 2.Yang, T.; Pan, H.; Tian, G.; et al. Hierarchically structured PVDF/ZnO core-shell nanofibers for self-powered physiological monitoring electronics. Nano Energy 2020, 72, 104706.

- 3.Park, S.H.; Jo, S.; Kwon, B.; et al. High-performance shape-engineerable thermoelectric painting. Nat. Commun. 2016, 7, 13403.

- 4.Khatib, M.; Zohar, O.; Saliba, W.; et al. Highly Efficient and Water-Insensitive Self-Healing Elastomer for Wet and Underwater Electronics. Adv. Funct. Mater. 2020, 30, 1910196.

- 5.Liu, C.; Yin, X.; Chen, Z.; et al. Improving the thermoelectric performance of solution-processed polymer nanocomposites by introducing platinum acetylides with tailored intermolecular interactions. Chem. Eng. J. 2021, 419, 129624.

- 6.Mamur, H.; Dilmaç, Ö.F.; Begum, J.; et al. Thermoelectric generators act as renewable energy sources. Clean. Mater. 2021, 2, 100030.

- 7.Liu, K.; Ouyang, B.; Guo, X.; et al. Advances in flexible organic field-effect transistors and their applications for flexible electronics. NPJ Flex. Electron. 2022, 6, 1.

- 8.Lee, B.; Cho, H.; Park, K.T.; et al. High-performance compliant thermoelectric generators with magnetically self-assembled soft heat conductors for self-powered wearable electronics. Nat. Commun. 2020, 11, 5948.

- 9.Wang, Z.; Gao, Q.; Wang, W.; et al. High performance Ag2Se/Ag/PEDOT composite films for wearable thermoelectric power generators. Mater. Today Phys. 2021, 21, 100553.

- 10.Cao, T.; Shi, X.-L.; Li, M.; et al. Advances in bismuth-telluride-based thermoelectric devices: Progress and challenges. eScience 2023, 3, 100122.

- 11.Park, K.T.; Cho, Y.S.; Jeong, I.; et al. Highly Integrated, Wearable Carbon-Nanotube-Yarn-Based Thermoelectric Generators Achieved by Selective Inkjet-Printed Chemical Doping. Adv. Energy Mater. 2022, 12, 2200256.

- 12.Li, Y.; Zhang, H.; Chang, J.; et al. Solvent-Free MXene/Poly(ionic liquid) Composite Elastomers with Simultaneously Improved Mechanical and Electrical Properties for Sensing and Photothermal Applications. Nano Lett. 2025, 25, 9976–9984.

- 13.Zadan, M.; Malakooti, M.H.; Majidi, C. Soft and Stretchable Thermoelectric Generators Enabled by Liquid Metal Elastomer Composites. ACS Appl. Mater. Interfaces 2020, 12, 17921–17928.

- 14.Sun, X.; Hou, Y.; Zhu, Z.; et al. Modular assembly of self-healing flexible thermoelectric devices with integrated cooling and heating capabilities. Nat. Commun. 2025, 16, 4220.

- 15.Padmanabhan Ramesh, V.; Sargolzaeiaval, Y.; Neumann, T.; et al. Flexible thermoelectric generator with liquid metal interconnects and low thermal conductivity silicone filler. NPJ Flex. Electron. 2021, 5, 5.

- 16.Gobpant, J.; Klongratog, B.; Rudradawong, C.; et al. High-performance flexible thermoelectric generator based on silicone rubber and cover with graphite sheet. Appl. Therm. Eng. 2024, 236, 121656.

- 17.Panbude, A.; Veluswamy, P. Silicone Elastomer: Encapsulating Materials for Flexible Thermoelectric Generator. IEEE Sens. J. 2023, 23, 16608–16615.

- 18.Ding, W.; Shen, X.; Jin, M.; et al. Robust bendable thermoelectric generators enabled by elasticity strengthening. Nat. Commun. 2024, 15, 9767.

- 19.Li, Y.; Zeng, J.; Zhao, Y.; et al. Fabric-based flexible thermoelectric generators: Design methods and prospects. Front. Mater. 2022, 9, 1046883.

- 20.Zhu, S.; Fan, Z.; Feng, B.; et al. Review on Wearable Thermoelectric Generators: From Devices to Applications. Energies 2022, 15, 3375.

- 21.Du, Y.; Xu, J.; Paul, B.; et al. Flexible thermoelectric materials and devices. Appl. Mater. Today 2018, 12, 366–388.

- 22.Zhang, L.; Shi, X.-L.; Yang, Y.-L.; et al. Flexible thermoelectric materials and devices: From materials to applications. Mater. Today 2021, 46, 62–108.

- 23.Xia, T.; Wemyss, A.M.; Salehiyan, R.; et al. Effective and Fast-Screening Route to Evaluate Dynamic Elastomer-Filler Network Reversibility for Sustainable Rubber Composite Design. ACS Sustain. Chem. Eng. 2023, 11, 17857–17869.

- 24.Masoumi, S.; O’Shaughnessy, S.; Pakdel, A. Organic-based flexible thermoelectric generators: From materials to devices. Nano Energy 2022, 92, 106774.

- 25.Gokhale, P.; Loganathan, B.; Crowe, J.; et al. Development of Flexible Thermoelectric Cells and Performance Investigation of Thermoelectric Materials for Power Generation. Energy Procedia 2017, 110, 281–285.

- 26.Gong, S.; Schwalb, W.; Wang, Y.; et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132.

- 27.Kang, Y.H.; Bae, E.J.; Lee, M.H.; et al. Highly Flexible and Durable Thermoelectric Power Generator Using CNT/PDMS Foam by Rapid Solvent Evaporation. Small 2022, 18, e2106108.

- 28.Liu, Z.; Chen, G. Advancing Flexible Thermoelectric Devices with Polymer Composites. Adv. Mater. Technol. 2020, 5, 2000049.

- 29.Choi, J.; Jung, Y.; Dun, C.; et al. High-Performance, Wearable Thermoelectric Generator Based on a Highly Aligned Carbon Nanotube Sheet. ACS Appl. Energy Mater. 2020, 3, 1199–1206.

- 30.Cui, X.; Ruan, Q.; Zhuo, X.; et al. Photothermal Nanomaterials: A Powerful Light-to-Heat Converter. Chem. Rev. 2023, 123, 6891–6952.

- 31.Xu, Y.; Wu, B.; Hou, C.; et al. Reconfigurable flexible thermoelectric generators based on all-inorganic MXene/Bi2Te3 composite films. FlexMat 2024, 1, 248–257.

- 32.Dong, X.; Xiong, S.; Luo, B.; et al. Flexible and Transparent Organic-Inorganic Hybrid Thermoelectric Modules. ACS Appl. Mater. Interfaces 2018, 10, 26687–26693.

- 33.Ren, W.; Sun, Y.; Zhao, D.; et al. High-performance wearable thermoelectric generator with self-healing, recycling, and Lego-like reconfiguring capabilities. Sci. Adv. 2021, 7, eabe0586.

- 34.Huo, B.; Guo, C.-Y. Advances in Thermoelectric Composites Consisting of Conductive Polymers and Fillers with Different Architectures. Molecules 2022, 27, 6932.

- 35.Wang, Y.; Yang, L.; Shi, X.L.; et al. Flexible Thermoelectric Materials and Generators: Challenges and Innovations. Adv. Mater. 2019, 31, e1807916.

- 36.Nathan, A.; Ahnood, A.; Cole, M.T.; et al. Flexible Electronics: The Next Ubiquitous Platform. Proc. IEEE 2012, 100, 1486–1517.

- 37.Chen, J.; Zheng, J.; Gao, Q.; et al. Polydimethylsiloxane (PDMS)-Based Flexible Resistive Strain Sensors for Wearable Applications. Appl. Sci. 2018, 8, 345.

- 38.He, X.; Shi, J.; Yunna, H.; et al. Highly stretchable, durable, and breathable thermoelectric fabrics for human body energy harvesting and sensing. Carbon Energy 2022, 4, 621–632.

- 39.Liu, J.; Liu, Q.; Shuping, L.; et al. Wearable Thermoelectric Generators: Materials, Structures, Fabrications, and Applications. Rapid Res. Lett. 2023, 17, 2200502.

- 40.Won, D.; Bang, J.; Choi, S.H.; et al. Transparent Electronics for Wearable Electronics Application. Chem. Rev. 2023, 123, 9982–10078.

- 41.Wu, Q.; Hu, J. Waterborne polyurethane based thermoelectric composites and their application potential in wearable thermoelectric textiles. Compos. Part B Eng. 2016, 107, 59–66.

- 42.Cao, Z.; Koukharenko, E.; Tudor, M.J.; et al. Flexible screen printed thermoelectric generator with enhanced processes and materials. Sens. Actuators A Phys. 2016, 238, 196–206.

- 43.Jian, Z.; Wang, H.; Liu, M.; et al. Polyurethane-modified graphene oxide composite bilayer wound dressing with long-lasting antibacterial effect. Mater. Sci. Eng. C 2020, 111, 110833.

- 44.Lavazza, J.; Contino, M.; Marano, C. Strain rate, temperature and deformation state effect on Ecoflex 00-50 silicone mechanical behaviour. Mech. Mater. 2023, 178, 104560.

- 45.Patil, N.A.; Joshi, K.; Lee, J.; et al. Additive manufacturing of thermoplastic elastomer structures using dual material core-shell filaments. Addit. Manuf. 2024, 82, 104044.

- 46.He, H.; Ouyang, J. Enhancements in the mechanical stretchability and thermoelectric properties of PEDOT: PSS for flexible electronics applications. Acc. Mater. Res. 2020, 1, 146–157.

- 47.Chang, Y.; Huang, Y.-H.; Lin, P.-S.; et al. Enhanced Electrical Conductivity and Mechanical Properties of Stretchable Thermoelectric Generators Formed by Doped Semiconducting Polymer/Elastomer Blends. ACS Appl. Mater. Interfaces 2024, 16, 3764–3777.

- 48.Jeong, Y.J.; Jung, J.; Suh, E.H.; et al. Self-healable and stretchable organic thermoelectric materials: Electrically percolated polymer nanowires embedded in thermoplastic elastomer matrix. Adv. Funct. Mater. 2020, 30, 1905809.

- 49.Yang, S.; Qiu, P.; Chen, L.; et al. Recent developments in flexible thermoelectric devices. Small Sci. 2021, 1, 2100005.

- 50.Tzounis, L.; Petousis, M.; Grammatikos, S.; et al. 3D printed thermoelectric polyurethane/multiwalled carbon nanotube nanocomposites: A novel approach towards the fabrication of flexible and stretchable organic thermoelectrics. Materials 2020, 13, 2879.

- 51.Guo, R.; Shi, W.; Guo, R.; et al. A Novel PDMS-Based Flexible Thermoelectric Generator Fabricated by Ag2Se and PEDOT:PSS/Multi-Walled Carbon Nanotubes with High Output Performance Optimized by Embedded Eutectic Gallium–Indium Electrodes. Nanomaterials 2024, 14, 542.

- 52.Wang, S.; Han, L.; Liu, H.; et al. Ionic Gelatin-Based Flexible Thermoelectric Generator with Scalability for Human Body Heat Harvesting. Energies 2022, 15, 3441.

- 53.He, M.; Lin, Y.-J.; Chiu, C.-M.; et al. A flexible photo-thermoelectric nanogenerator based on MoS2/PU photothermal layer for infrared light harvesting. Nano Energy 2018, 49, 588–595.

- 54.Yu, Z.-D.; Lu, Y.; Wang, Z.-Y.; et al. High n-type and p-type conductivities and power factors achieved in a single conjugated polymer. Sci. Adv. 2023, 9, eadf3495.

- 55.Zhang, C.; Huang, H.; Han, S.; et al. Layer-by-Layer flexible organic thermoelectric devices based on PEDOT: PSS and PBFDO Energy Material Advances 2024, 5, 0104.

- 56.Kim, J.H.; Hwang, J.-Y.; Hwang, H.R.; et al. Simple and cost-effective method of highly conductive and elastic carbon nanotube/polydimethylsiloxane composite for wearable electronics. Sci. Rep. 2018, 8, 1375.

- 57.Wei, Y.; Zhou, H.; Deng, H.; et al. “Toolbox” for the Processing of Functional Polymer Composites. Nano-Micro Lett. 2021, 14, 35.

- 58.Park, S.J.; Cho, K.S. Filler-elastomer interactions: Influence of silane coupling agent on crosslink density and thermal stability of silica/rubber composites. J. Colloid Interface Sci. 2003, 267, 86–91.

- 59.Kim, S.-U.; Kim, J.-Y. Dynamic Statistical Mechanics Modeling of Percolation Networks in Conductive Polymer Composites for Smart Sensor Applications. Materials 2025, 18, 3097.

- 60.Bai, X.; Zhang, C.; Zeng, X.; et al. Recent progress in thermally conductive polymer/boron nitride composites by constructing three-dimensional networks. Compos. Commun. 2021, 24, 100650.

- 61.Saglik, K.; Yahyaoglu, M.; Candolfi, C.; et al. Enhancing Thermoelectric and Mechanical Properties of p-Type (Bi, Sb)2Te3 through Rickardite Mineral (Cu2.9Te2) Incorporation. Chem. Mater. 2023, 35, 3603–3613.

- 62.Aboughaly, M.; Babaei-Ghazvini, A.; Dhar, P.; et al. Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review. Polymers 2023, 15, 3981.

- 63.Choi, H.; Kim, Y.J.; Kim, C.S.; et al. Enhancement of reproducibility and reliability in a high-performance flexible thermoelectric generator using screen-printed materials. Nano Energy 2018, 46, 39–44.

- 64.Yang, Y.; Dias, M.A.; Holmes, D.P. Multistable kirigami for tunable architected materials. Phys. Rev. Mater. 2018, 2, 110601.

- 65.Song, J.; Park, K.; Kim, Y.; et al. Self-Healing Stretchable Thermoelectric Polymer Composite with Bismuth Antimony Telluride and Single-Walled Carbon Nanotubes for Thermoreceptor-Inspired Modular Systems. ACS Appl. Mater. Interfaces 2025, 17, 36922–36933.

- 66.Claumarchirant, J.F.; Nasiri, M.A.; Cho, C.; et al. Textile-based Thermoelectric Generator Produced Via Electrochemical Polymerization. Adv. Mater. Interfaces 2023, 10, 2202105.

- 67.Lin, Z.; Li, T.; Yang, S.; et al. Revolutionizing flexible electronics with liquid metal innovations. Device. 2024, 2, 100331.

- 68.Shukla, D.; Wang, H.; Awartani, O.; et al. Surface Embedded Metal Nanowire-Liquid Metal-Elastomer Hybrid Composites for Stretchable Electronics. ACS Appl. Mater. Interfaces 2024, 16, 14183–14197.

- 69.Zhang, P.; Deng, B.; Sun, W.; et al. Fiber-Based Thermoelectric Materials and Devices for Wearable Electronics. Micromachines 2021, 12, 869.

- 70.Chen, S.; Wu, Z.; Chu, C.; et al. Biodegradable Elastomers and Gels for Elastic Electronics. Adv. Sci. 2022, 9, e2105146.

- 71.Song, Y.; Zeng, W.; Rong, M.; et al. Flexible thermoelectric composite materials with self-healing ability for harvesting low-grade thermal energy. Compos. Sci. Technol. 2023, 242, 110179.

- 72.Kim, M.J.; Hwang, M.; Kim, J.-H.; et al. Biodegradable and Elastomeric Poly(glycerol sebacate) as a Coating Material for Nitinol Bare Stent. BioMed Res. Int. 2014, 2014, 956952.

- 73.Ali, Z.; Yaqoob, S.; Yu, J.; et al. Unveiling the Influential Factors and Heavy Industrial Applications of Graphene Hybrid Polymer Composites. J. Compos. Sci. 2024, 8, 183.

- 74.Liu, Y.; Wang, X.; Hou, S.; et al. Scalable-produced 3D elastic thermoelectric network for body heat harvesting. Nat. Commun. 2023, 14, 3058.

- 75.Shahil, K.M.F.; Balandin, A.A. Graphene–Multilayer Graphene Nanocomposites as Highly Efficient Thermal Interface Materials. Nano Lett. 2012, 12, 861–867.

- 76.Wu, Y.; An, C.; Guo, Y.; et al. Highly Aligned Graphene Aerogels for Multifunctional Composites. Nano-Micro Lett. 2024, 16, 118.

- 77.Zadan, M.; Patel, D.; Sabelhaus, A.; et al. Liquid Crystal Elastomer with Integrated Soft Thermoelectrics for Shape Memory Actuation and Energy Harvesting. Adv. Mater. 2022, 34, 2200857.

- 78.Park, T.H.; Kim, B.; Yu, S.; et al. Ionoelastomer electrolytes for stretchable ionic thermoelectric supercapacitors. Nano Energy 2023, 114, 108643.

- 79.Feng, C.; Hemantha Rajapaksha, C.P.; Jákli, A. Ionic Elastomers for Electric Actuators and Sensors. Engineering 2021, 7, 581–602.

- 80.Li, P.; Zhao, Y.; Li, H.; et al. Facile green strategy for improving thermoelectric performance of carbon nanotube/polyaniline composites by ethanol treatment. Compos. Sci. Technol. 2020, 189, 108023.

- 81.Xie, F. Natural polymer starch-based materials for flexible electronic sensor development: A review of recent progress. Carbohydr. Polym. 2024, 337, 122116.

- 82.Jeong, M.; Bae, E.; Park, B.; et al. High-performance and flexible thermoelectric generator based on a robust carbon nanotube/BiSbTe foam. Carbon Energy 2024, 7, e650.

- 83.Lv, H.; Liang, L.; Zhang, Y.; et al. A flexible spring-shaped architecture with optimized thermal design for wearable thermoelectric energy harvesting. Nano Energy 2021, 88, 106260.

- 84.Wang, H.; Lee, J.; Kim, J.H.; et al. Revealing the origin of the thermal conductivity improvement of the silane@polydopamine modified graphene/epoxy nanocomposites: A multiscale study. Compos. Sci. Technol. 2025, 261, 111009.

- 85.Romero-Gilbert, S.; Castro-García, M.; Díaz-Chamorro, H.; et al. Synthesis, Characterization and Catechol-Based Bioinspired Adhesive Properties in Wet Medium of Poly(2-Hydroxyethyl Methacrylate-co-Acrylamide) Hydrogels. Polymers 2024, 16, 187.

- 86.Chen, X.; Sun, P.; Tian, H.; et al. Self-healing and stretchable conductor based on embedded liquid metal patterns within imprintable dynamic covalent elastomer. J. Mater. Chem. C 2021, 10, 1039–1047.

- 87.Sargolzaeiaval, Y.; Padmanabhan Ramesh, V.; Neumann, T.; et al. Flexible thermoelectric generators for body heat harvesting–Enhanced device performance using high thermal conductivity elastomer encapsulation on liquid metal interconnects. Appl. Energy 2020, 262, 114370.

- 88.Liang, L.; Liu, X.; Li, P.; et al. A wearable multimodal health monitoring bracelet powered by high-power-density flexible thermoelectric generators. Device 2025, 3, 100748.

- 89.Liu, T.; Xie, L.; Zeng, J.; et al. Interfacial Superassembly of Light-Responsive Mechanism-Switchable Nanomotors with Tunable Mobility and Directionality. ACS Appl. Mater. Interfaces 2022, 14, 15517–15528.

- 90.Tuyen, N.T.; Kim, D.M.; Lee, J.-W.; et al. Innovative Hybrid Nanocomposites in 3D Printing for Functional Applications: A Review. Molecules 2024, 29, 5159.

- 91.Jamil, U.; Holden, N.M. Systematic review of life cycle assessment of thermoelectric materials and devices to identify knowledge gaps and sustainability perspectives. Environ. Impact Assess. Rev. 2025, 115, 108060.

- 92.Tang, Q.; Jiang, B.; Wang, K.; et al. High-entropy thermoelectric materials. Joule 2024, 8, 1641–1666.

- 93.Liu, J.; Wu, S.; Zhang, L.; et al. Molecular dynamics simulation for insight into microscopic mechanism of polymer reinforcement. Phys. Chem. Chem. Phys. 2011, 13, 518–529.

- 94.Tan, P.; Wang, H.; Xiao, F.; et al. Solution-processable, soft, self-adhesive, and conductive polymer composites for soft electronics. Nat. Commun. 2022, 13, 358.

- 95.Min, H.; Shuai, S.; Wanyu, L.; et al. Advances in printing techniques for thermoelectric materials and devices. Soft Sci. 2023, 3, 29.

- 96.Lin, H.; Peng, S.; Guo, S.; et al. 2D Materials and Primary Human Dendritic Cells: A Comparative Cytotoxicity Study. Small 2022, 18, 2107652.

How to Cite

Chen, W.-H.; Lin, S.-T. A Review of Elastomer-Based Flexible Thermoelectric Generators: Material Selection, Fabrication Strategies, and Application Prospects. Green Energy and Fuel Research 2025, 2 (3), 239–253. https://doi.org/10.53941/gefr.2025.100017.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References