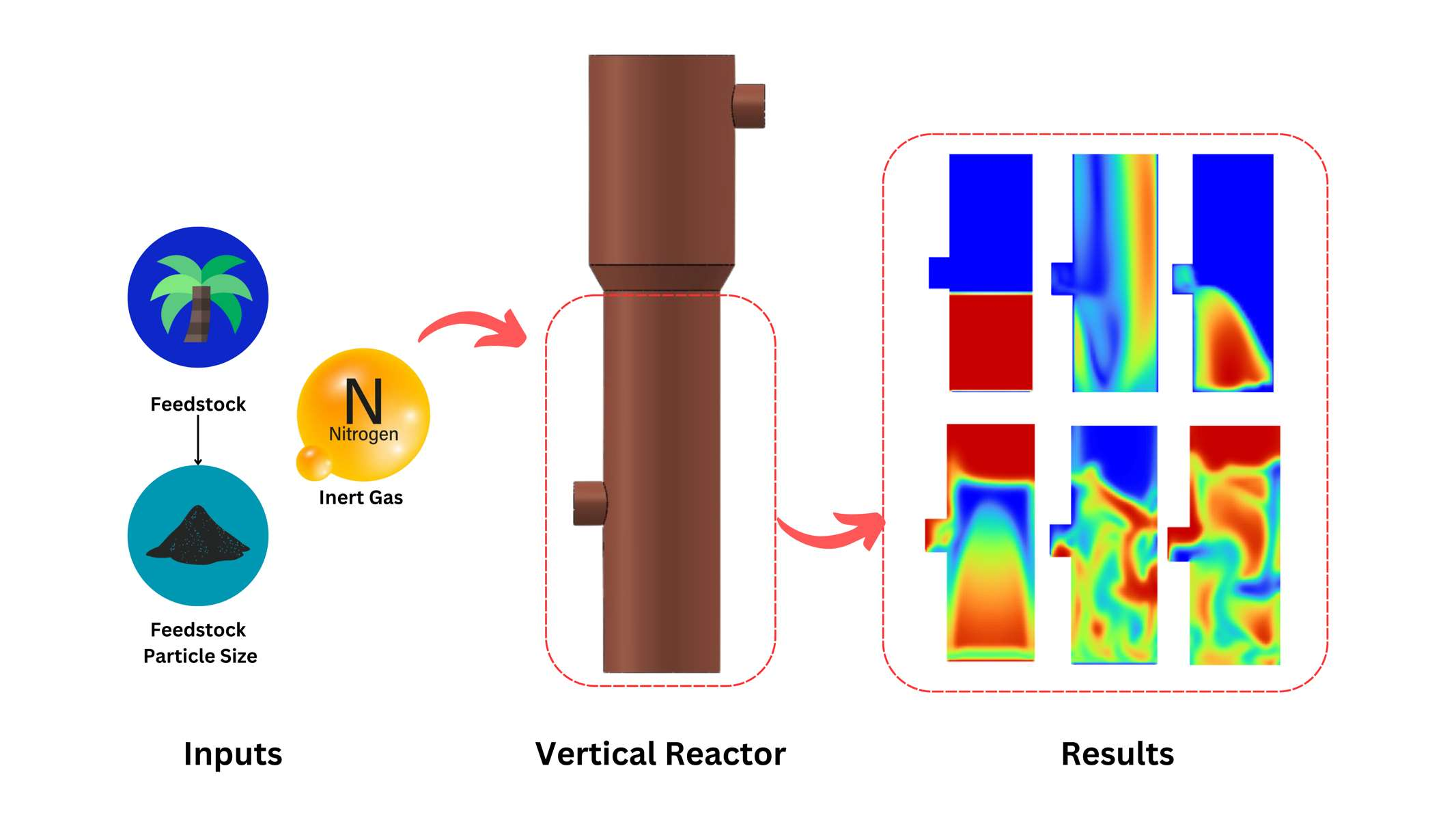

This study employs Computational Fluid Dynamics (CFD) to investigate the nitrogen gas flow patterns, feedstock particle size, turbulence zones, and the distribution of the solid volume fraction in a vertical pyrolysis reactor. By employing the Eulerian multiphase model and a transient solver, the analysis allows the investigation of whether the feedstock particle size is appropriate for maintaining good mixing and identifying potential turbulence zones during the feedstock loading stage. The results highlighted the critical importance of feedstock particle size and nitrogen gas velocity in maintaining adequate mixing. Using a time-averaged profile, feedstock with a 0.55 mm diameter and a bulk density of 536 kg/m3, combined with a continuous nitrogen gas supply at 0.485 m/s, resulted in significant bed expansion, twice the initial height. This ensures that the biomass feedstock particles do not settle at the bottom of the reactor, thus facilitating uniform heat transfer, which affects yield efficiency. The velocity of the feedstock with nitrogen gas peaked at 0.98 m/s. At 25% loading capacity, the solid-phase volume fraction decreases from 0.6 to a range of 0.1 to 0.3, indicating efficient mixing and heat transfer. It was observed that the proper nitrogen gas velocity also promotes uniform heating, enhancing the process’s overall performance.

- Open Access

- Article

Multiphase Fluid Dynamics in a Vertical Pyrolysis Reactor Using Computational Fluid Dynamics

Author Information

Received: 10 Sep 2025 | Revised: 29 Oct 2025 | Accepted: 03 Nov 2025 | Published: 13 Nov 2025

Abstract

Graphical Abstract

Keywords

biomass | computational fluid dynamics | fluid flow, pyrolysis | multiphase | vertical reactor

References

- 1.

IEA. CO2 Emissions in 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 8 August 2025).

- 2.Kurniawan, T.A.; Ali, S.; Mohyuddin, A.; et al. Cultivating sustainability: Harnessing biochar-derived composites for carbon-neutral wastewater treatment. Process Saf. Environ. Prot. 2024, 187, 665–697. https://doi.org/10.1016/j.psep.2024.04.040.

- 3.

Hanson, E.; Nwakile, C.; Hammed, V.O. Carbon capture, utilization, and storage (CCUS) technologies: Evaluating the effectiveness of advanced CCUS solutions for reducing CO2 emissions. Results Surf. Interfaces 2025, 18, 100381. https://doi.org/10.1016/j.rsurfi.2024.100381.

- 4.Biswal, B.K.; Balasubramanian, R. Use of biomass-derived biochar as a sustainable material for carbon sequestration in soil: Recent advancements and future perspectives. NPJ Mater. Sustain. 2025, 3, 26. https://doi.org/10.1038/s44296-025-00066-8.

- 5.Ubando, A.T.; Rivera, D.R.T.; Chen, W.-H.; et al. A comprehensive review of life cycle assessment (LCA) of microalgal and lignocellulosic bioenergy products from thermochemical processes. Bioresour. Technol. 2019, 291, 121837. https://doi.org/10.1016/j.biortech.2019.121837.

- 6.Rivera, D.R.T.; Culaba, A.B.; Ubando, A.T.; et al. The Environmental Performance of Torrefied Microalgae Biomass using Torrefaction Severity Factor. In Proceedings of the 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November 2019–1 December 2019; pp. 1–5.

- 7.Khodaei, H.; Álvarez-Bermúdez, C.; Chapela, S.; et al. Eulerian CFD simulation of biomass thermal conversion in an indirect slow pyrolysis rotary kiln unit to produce biochar from recycled waste wood. Energy 2024, 288, 129895. https://doi.org/10.1016/j.energy.2023.129895.

- 8.Escalante, J.; Chen, W.-H.; Tabatabaei, M.; et al. Pyrolysis of lignocellulosic, algal, plastic, and other biomass wastes for biofuel production and circular bioeconomy: A review of thermogravimetric analysis (TGA) approach. Renew. Sustain. Energy Rev. 2022, 169, 112914. https://doi.org/10.1016/j.rser.2022.112914.

- 9.Sangaré, D.; Moscosa-Santillan, M.; Bostyn, S.; et al. Multi-step kinetic mechanism coupled with CFD modeling of slow pyrolysis of biomass at different heating rates. Chem. Eng. J. 2024, 479, 147791. https://doi.org/10.1016/j.cej.2023.147791.

- 10.Lu, L.; Gao, X.; Dietiker, J.-F.; et al. MFiX based multi-scale CFD simulations of biomass fast pyrolysis: A review. Chem. Eng. Sci. 2022, 248, 117131. https://doi.org/10.1016/j.ces.2021.117131.

- 11.Guran, S. Chapter 8—Sustainable Waste-to-Energy Technologies: Gasification and Pyrolysis. In Sustainable Food Waste-to-Energy Systems; Trabold, T.A., Babbitt, C.W., Eds.; Academic Press: San Diego, CA, USA, 2018; pp. 141–158.

- 12.Zawawi, M.H.; Saleha, A.; Salwa, A.; et al. A review: Fundamentals of computational fluid dynamics (CFD). In Proceedings of the Green Design and Manufacture: Advanced and Emerging Applications: Proceedings of the 4th International Conference on Green Design and Manufacture, Ho Chi Minh, Vietnam, 29–30 April 2018; p. 020252.

- 13.Sumner, J.; Watters, C.S.; Masson, C. CFD in Wind Energy: The Virtual, Multiscale Wind Tunnel. Energies 2010, 3, 989–1013. https://doi.org/10.3390/en3050989.

- 14.Tian, W.; Han, X.; Zuo, W.; et al. Building energy simulation coupled with CFD for indoor environment: A critical review and recent applications. Energy Build. 2018, 165, 184–199. https://doi.org/10.1016/j.enbuild.2018.01.046.

- 15.Al-abidi, A.A.; Bin Mat, S.; Sopian, K.; et al. CFD applications for latent heat thermal energy storage: A review. Renew. Sustain. Energy Rev. 2013, 20, 353–363. https://doi.org/10.1016/j.rser.2012.11.079.

- 16.Mohamed, M.H.; Ali, A.M.; Hafiz, A.A. CFD analysis for H-rotor Darrieus turbine as a low speed wind energy converter. Eng. Sci. Technol. Int. J. 2015, 18, 1–13. https://doi.org/10.1016/j.jestch.2014.08.002.

- 17.Chen, J.; Xu, F.; Tan, D.; et al. A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl. Energy 2015, 141, 106–118. https://doi.org/10.1016/j.apenergy.2014.12.026.

- 18.Singh, R.I.; Brink, A.; Hupa, M. CFD modeling to study fluidized bed combustion and gasification. Appl. Therm. Eng. 2013, 52, 585–614. https://doi.org/10.1016/j.applthermaleng.2012.12.017.

- 19.Tobo, Y.; Lotfi, A.; Virla, L.D.; et al. Fast pyrolysis multiphase CFD-kinetics model in a drop tube reactor. Fuel 2023, 340, 127524. https://doi.org/10.1016/j.fuel.2023.127524.

- 20.Hartge, E.-U.; Ratschow, L.; Wischnewski, R.; et al. CFD-simulation of a circulating fluidized bed riser. Particuology 2009, 7, 283–296. https://doi.org/10.1016/j.partic.2009.04.005.

- 21.Kaczor, Z.; Buliński, Z.; Werle, S. Modelling approaches to waste biomass pyrolysis: A review. Renew. Energy 2020, 159, 427–443. https://doi.org/10.1016/j.renene.2020.05.110.

- 22.Janajreh, I.; Raza, S.S. Numerical simulation of waste tyres gasification. Waste Manag. Res. 2015, 33, 460–468. https://doi.org/10.1177/0734242X15573656.

- 23.Pourhoseinian, M.; Asasian-Kolur, N.; Sharifian, S. Comparative computational fluid dynamics analysis of fast pyrolysis of agricultural feedstocks across different biomass categories. Biomass Bioenergy 2024, 180, 107026. https://doi.org/10.1016/j.biombioe.2023.107026.

- 24.Wang, M.; Jia, T.; Song, X.; et al. CFD–DEM Simulation of Heat Transfer and Reaction Characteristics of Pyrolysis Process of MSW Heated by High-Temperature Flue Gas. Processes 2024, 12, 390. https://doi.org/10.3390/pr12020390.

- 25.Kamila, B.; Sadhukhan, A.K.; Gupta, P. 2D CFD modeling for pyrolysis of a large biomass particle: Effect of L/D ratio, internal convection and shrinkage. Chem. Eng. Res. Des. 2024, 208, 921–933. https://doi.org/10.1016/j.cherd.2024.07.002.

- 26.Wang, L.; Deng, J.; Yang, X.; et al. Role of biochar toward carbon neutrality. Carbon Res. 2023, 2, 2. https://doi.org/10.1007/s44246-023-00035-7.

- 27.Aniza, R.; Chen, W.-H.; Yang, F.-C.; et al. Integrating Taguchi method and artificial neural network for predicting and maximizing biofuel production via torrefaction and pyrolysis. Bioresour. Technol. 2022, 343, 126140. https://doi.org/10.1016/j.biortech.2021.126140.

- 28.Makkawi, Y.; Mohamed, B. CFD modeling of date palm (Phoenix dactylifera) waste fast pyrolysis in a fluidized bed-including experimental kinetics, validation, and remarks on the modeling approach. Renew. Energy 2024, 224, 120175. https://doi.org/10.1016/j.renene.2024.120175.

- 29.Gidaspow, D.; Bezburuah, R.; Ding, J. Hydrodynamics of Circulating Fluidized Beds: Kinetic Theory Approach; Illinois Institute of Technology: Chicago, IL, USA, 1991.

- 30.Lun, C.K.K.; Savage, S.B.; Jeffrey, D.J.; et al. Kinetic theories for granular flow: Inelastic particles in Couette flow and slightly inelastic particles in a general flowfield. J. Fluid Mech. 1984, 140, 223–256. https://doi.org/10.1017/S0022112084000586.

- 31.Syamlal, M. The Particle-Particle Drag Term in a Multiparticle Model of Fluidization; EG and G Washington Analytical Services Center, Inc.: Morgantown, WV, US, 1987.

- 32.Gunn, D.J. Transfer of heat or mass to particles in fixed and fluidised beds. Int. J. Heat Mass Transf. 1978, 21, 467–476. https://doi.org/10.1016/0017-9310(78)90080-7.

- 33.El may, Y.; Jeguirim, M.; Dorge, S.; et al. Study on the thermal behavior of different date palm residues: Characterization and devolatilization kinetics under inert and oxidative atmospheres. Energy 2012, 44, 702–709. https://doi.org/10.1016/j.energy.2012.05.022.

- 34.Luo, H.; Wang, X.; Liu, X.; et al. A review on CFD simulation of biomass pyrolysis in fluidized bed reactors with emphasis on particle-scale models. J. Anal. Appl. Pyrolysis 2022, 162, 105433. https://doi.org/10.1016/j.jaap.2022.105433.

This work is licensed under a Creative Commons Attribution 4.0 International License.