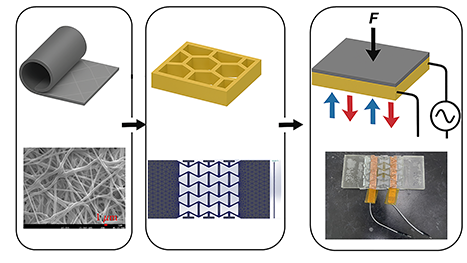

The development of efficient, flexible, and sustainable energy-harvesting technologies is critical for powering self-sufficient wearable electronics, biomedical sensors, and remote IoT systems. In this study, we present an advanced auxetic laminar composite architecture that integrates piezoelectric polymer films—specifically P(VDF-TrFE) and P(VDF-TrFE-CTFE)—with re-entrant honeycomb substrates fabricated using a UV-curable resin. The negative Poisson’s ratio (NPR) behavior of auxetic structures was strategically employed to amplify in-plane mechanical strain in the active piezoelectric layers, enhancing voltage output under uniaxial loading. The electrospun nanofibers exhibited uniform, bead-free morphologies with preferential β-phase crystallinity, confirmed via SEM and wide-angle X-ray diffraction (WAXD). Finite element simulations revealed strong stress concentration at re-entrant hinges and vertical struts, with the degree of auxetic deformation increasing at larger monomer angles (55–65°) and thicker substrates. Digital image correlation (DIC) analysis confirmed consistent deformation behavior and validated simulated strain fields. Composite structures incorporating 5 mm-thick auxetic substrates and P(VDF-TrFE) films demonstrated superior mechanical strength, enhanced interfacial stress transfer, and significantly improved voltage response compared to P(VDF-TrFE-CTFE)-based systems. Experimental results showed that induced piezoelectric voltage increased nonlinearly with applied force and excitation frequency, with P(VDF-TrFE) achieving up to ~250% output enhancement. Simulated voltage outputs were in close agreement with experimental trends, supporting the design rationale. This work demonstrates a scalable, low-toxicity, and recyclable design for flexible piezoelectric harvesters using mechanical metamaterials. The integration of auxetic geometries with optimized piezoelectric polymers enables high sensitivity and tunable mechanical-electrical coupling, aligning with sustainable development goals. These findings provide valuable insights for designing next-generation flexible power sources for green energy applications.

- Open Access

- Article

Auxetic Laminar Composites Based on P(VDF-TrFE) for Enhanced Piezoelectric Performance in Flexible Energy Devices

Author Information

Received: 09 Oct 2025 | Revised: 14 Nov 2025 | Accepted: 14 Nov 2025 | Published: 27 Nov 2025

Abstract

Graphical Abstract

Keywords

auxetic structures | piezoelectric polymers | flexible energy harvesting | P(VDF-TrFE) | digital image correlation

References

- 1.Hussain, S.Z.; Singh, V.P.; Sadeque, M.S.B.; et al. Piezoelectric-Triboelectric Hybrid Nanogenerator for Energy Harvesting and Self-Powered Sensing Applications. Small 2025, 21, 2504626.

- 2.

Wu, X.; Zhang, Y.; Li, Y.; et al. High-performance 2D NaNbO3/PVDF piezoelectric nanogenerators for energy harvesting and wearable electronics. J. Alloys Compd. 2025, 1038, 182747.

- 3.Pohanka, M. Piezoelectric Chemosensors and Biosensors in Medical Diagnostics. Biosensors 2025, 15, 197.

- 4.Yang, H.; Shao, N.; Wang, J.; et al. Experimental analysis of hybrid multiple-layer piezoelectric-solar energy harvester for self-powered wireless sensing. Sustain. Energy Technol. Assess. 2025, 73, 104157.

- 5.Xie, Z.; Ran, Y.; Fang, G.; et al. A novel variable potential energy well bistable piezoelectric rotational energy harvester. Mech. Syst. Signal Process. 2025, 239, 113312.

- 6.Alsaad, A.; Ahmad, I.; Aawan, A.; et al. Design, development and testing of a wearable hybrid energy harvester for sustainable gadgets. Adv. Sens. Energy Mater. 2025, 4, 100137.

- 7.Izyumskaya, N.; Alivov, Y.-I.; Cho, S.-J.; et al. Processing, structure, properties, and applications of PZT thin films. Crit. Rev. Solid State Mater. Sci. 2007, 32, 111–202.

- 8.Song, L.; Glinsek, S.; Alluri, N.R.; et al. Highly transparent lead-free piezoelectric haptic device. Commun. Mater. 2025, 6, 91.

- 9.Maxfield, M.; Christiani, B.; Sastri, V. Polymer nanocomposites comprising a polymer and an exfoliated particulate material derivatized with organo silanes, organo titanates, and organo zirconates dispersed therein and process of preparing same. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1115.

- 10.Zhang, J.; Wang, J.; Zhong, C.; et al. Flexible electronics: Advancements and applications of flexible piezoelectric composites in modern sensing technologies. Micromachines 2024, 15, 982.

- 11.Verma, A.; Dutta, P.; Awasthi, N.; et al. Investigation of the Different WO3 Nanofiller Morphology Influence on the Piezoelectric Properties of WO3-PVDF Nanocomposites for Self-Powered Biomedical Devices and Flexible Wearable Sensors. ACS Appl. Electron. Mater. 2025, 7, 7149–7159.

- 12.Revenant, C.; Toinet, S.; Lawrence Bright, E.; et al. The Longitudinal and Transverse Piezoelectric Effects of the Ferroelectric Polymer P (VDF-TrFE). Macromol. Mater. Eng. 2025, 310, 2400420.

- 13.Costa, C.M.; Diez, A.G.; Zarandona, A.; et al. Tailoring the piezoelectric and electrocaloric response of nanocomposites based on poly (vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) with barium strontium titanate ceramic particles. Polymer 2025, 325, 128305.

- 14.Afshar, H.; Kamran, F.; Shahi, F. Recent Progress in Energy Harvesting Technologies for Self-Powered Wearable Devices: The Significance of Polymers. Polym. Adv. Technol. 2025, 36, e70187.

- 15.Sherrell, P.C.; Šutka, A.; Timusk, M.; et al. Alternatives to Fluoropolymers for Motion-Based Energy Harvesting: Perspectives on Piezoelectricity, Triboelectricity, Ferroelectrets, and Flexoelectricity. Small 2024, 20, 2311570.

- 16.Halder, B.; Padwal, M.; Chandrasekhar, P.; et al. A Flame Retardant PVDF-HFP-Based Composite Electrolyte Enabled by Yttrium-Doped NASICON for Stable Lithium Metal Batteries. ACS Appl. Energy Mater. 2025, 8, 12815–12825.

- 17.Domalanta, M.R.B.; Caldona, E.B. Toward enhancing the surface adhesion of fluoropolymer-based coating materials. Polym. Rev. 2024, 64, 980–1030.

- 18.Zhou, X.; Xu, L.; Tang, L.; et al. Piezoelectric-pneumatic material jetting printing for non-contact conformal fabrication of high-temperature thick-film sensors. Addit. Manuf. 2024, 83, 104058.

- 19.Chen, B.; Jia, Y.; Narita, F.; et al. Screen-printed piezoelectric composites for vibrational energy harvesting in combination with structural composite laminates for powering a sensing node. Compos. Part B Eng. 2024, 273, 111274.

- 20.Ren, K.; Shen, Y.; Wang, Z.L. Piezoelectric properties of electrospun polymer nanofibers and related energy harvesting applications. Macromol. Mater. Eng. 2024, 309, 2300307.

- 21.Wood, C.D.; Cooper, A.I.; DeSimone, J.M. Green synthesis of polymers using supercritical carbon dioxide. Curr. Opin. Solid State Mater. Sci. 2004, 8, 325–331.

- 22.Wang, X.; Zhang, S.; Hu, Y.; et al. Piezoelectric polymers and their applications in antimicrobial fields. Mater. Chem. Front. 2025, 9, 754–771.

- 23.Chen, T.; Wang, K.; Chen, S.; et al. Nonlinear electromechanical coupling dynamics of a two-degree-of-freedom hybrid energy harvester. Appl. Math. Mech. 2025, 46, 989–1010.

- 24.

Lekha, C.C.; Purushothaman, S.M.; Begum, S.R.; et al. Flexible piezoelectric and hybrid nanogenerators based on single layered and stacked multilayered PVDF/CoFe2O4/KNaNbO3 composite electrospun nanofibers. Polymer 2025, 325, 128257.

- 25.Zhou, N.; Wang, N.; Wang, H.; et al. Optical 3D μ-printing of PVDF-based flexible microstructural auxetic metamaterials and 3D microgrid pyramid arrays for wearable electronics. Chem. Eng. J. 2025, 516, 163956.

- 26.Kang, J.; Shirzad, M.; Seok, J.M.; et al. Mechanical enhancement of porous scaffolds through integration of auxetic and conventional structures. Mater. Lett. 2025, 379, 137675.

- 27.Tahir, D.; Zhang, M.; Hu, H. Auxetic materials for personal protection: A review. Phys. Status Solidi 2022, 259, 2200324.

- 28.Lee, D.-C. Design of Auxetic Structures with Variable Stiffness for Electro-Active Soft Skin Sensor and Actuator. Nano Tech. Appl. 2025, 8, 1–7.

- 29.del Toro, S.F.; Crespo-Sanchez, J.; Ayllon, J.; et al. Mechanical performance of 3D-printed TPU auxetic structures for energy absorption applications. Polym. Test. 2025, 143, 108669.

- 30.Wang, D.; Chang, Y.; Cheng, P.; et al. Compressive deformation modes and properties of 3D printed continuous fiber reinforced composite auxetic honeycomb structures regulated by structural parameters. Structures 2025, 81, 110214.

- 31.

Fangachi, N.; Rguiti, M.; Yessari, M.; et al. Smart piezoelectric energy harvesting: How topology-optimized cavities boost performance in BaTiO3 multilayer structures. Smart Mater. Struct. 2025, 34, 085001.

- 32.de Souza Oliveira, H.; Khaanghah, N.S.; Elli, G.; et al. Mechanical metamaterial sensors: From design to applications. J. Phys. D Appl. Phys. 2025, 58, 133002.

- 33.Elsamanty, M.; Elshokrofy, H.; Ibrahim, A.; et al. Investigation and Tailoring of Rotating Squares’ and Rectangles’ Auxetic Structure Behavior through Computational Simulations of 6082T6 Aluminum Alloy Structures. Materials 2023, 16, 7597.

- 34.Zhan, X.; Wang, Q. Foldability-dependent thermomechanical analysis of metamaterial-reinforced plate. Acta Mech. 2025, 236, 6523–6548.

- 35.Alam, M.I.; Pandit, M.K.; Pradhan, A.K. In-plane load induced buckling behavior of laminated doubly curved shells based on a modified higher order zigzag theory. Mech. Based Des. Struct. Mach. 2025, 15, 9394.

- 36.Tang, Y.; Zong, H.; Huang, J.; et al. Iodine Stabilization in Perovskite Lattice for Internal Stress Relief. Small 2025, 21, 2410776.

- 37.Ghoddousi, S.; Mohammadnejad, M.; Safarabadi, M.; et al. Compression response of nature-inspired metamaterials based on Fibonacci spiral. Int. J. Mech. Sci. 2025, 285, 109853.

- 38.Zuo, H.E.; Heilmann, R.K.; Schattenburg, M.L. Analysis of stresses and shape changes in thin substrates with stressed film patterning using femtosecond laser micromachining. Opt. Laser Technol. 2023, 158, 108874.

- 39.Samal, S.; Vokoun, D.; Stachiv, I.; et al. Simulation of thermal stress predictions for NiTi coating on a stainless-steel substrate using thermal plasma spraying. Ceram. Int. 2025, 51, 12337–12345.

- 40.Tabak, A.; Safaei, B.; Memarzadeh, A.; et al. An extensive review of piezoelectric energy-harvesting structures utilizing auxetic materials. J. Vib. Eng. Technol. 2024, 12, 3155–3192.

- 41.Fatahi, M.H.; Hamedi, M.; Safarabadi, M. Experimental and numerical implementation of auxetic substrate for enhancing voltage of piezoelectric sandwich beam harvester. Mech. Adv. Mater. Struct. 2022, 29, 6107–6117.

- 42.Zhou, X.; Parida, K.; Chen, J.; et al. 3D printed auxetic structure-assisted piezoelectric energy harvesting and sensing. Adv. Energy Mater. 2023, 13, 2301159.

- 43.Chen, K.; Gao, Q.; Fang, S.; et al. An auxetic nonlinear piezoelectric energy harvester for enhancing efficiency and bandwidth. Appl. Energy 2021, 298, 117274.

- 44.Jana, S.; Garain, S.; Sen, S.; et al. The influence of hydrogen bonding on the dielectric constant and the piezoelectric energy harvesting performance of hydrated metal salt mediated PVDF films. Phys. Chem. Chem. Phys. 2015, 17, 17429–17436.

- 45.Garain, S.; Jana, S.; Sinha, T.K.; et al. Design of in situ poled Ce3+-doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Appl. Mater. Interfaces 2016, 8, 4532–4540.

- 46.Ye, Y.; Zhu, X.; Meng, N.; et al. Largely Promoted Mechano-Electrochemical Coupling Properties of Solid Polymer Electrolytes by Introducing Hydrogen Bonds-Rich Network. Adv. Funct. Mater. 2023, 33, 2307045.

- 47.Zhang, M.; Tan, S.; Xiong, J.; et al. Tailoring dielectric and energy storage performance of PVDF-based relaxor ferroelectrics with hydrogen bonds. ACS Appl. Energy Mater. 2021, 4, 8454–8464.

- 48.Garain, S.; He, D.; Monluc, H.; et al. Halide-Tunable Bond Engineering for High-Performance Multi-Responsive Piezoelectric Sensors via Enhanced Electrostatic Polarization in In Situ Perovskite-Embedded PVDF Nanofibers. Small 2025, 21, 2504787.

- 49.Garain, S.; Sinha, T.K.; Adhikary, P.; et al. Self-poled transparent and flexible UV light-emitting cerium complex–PVDF composite: A high-performance nanogenerator. ACS Appl. Mater. Interfaces 2015, 7, 1298–1307.

- 50.Choi, S.T.; Kwon, J.O.; Bauer, F. Multilayered relaxor ferroelectric polymer actuators for low-voltage operation fabricated with an adhesion-mediated film transfer technique. Sens. Actuators A Phys. 2013, 203, 282–290. https://doi.org/10.1016/j.sna.2013.08.049.

- 51.Turdakyn, N.; Bekezhankyzy, Z.; Araby, S.; et al. Investigation of electrospun piezoelectric P (VDF-TrFE) nanofiber-based nanogenerators for energy harvesting. Energy Rep. 2023, 10, 628–636.

- 52.Luo, H.; Wang, F.; Guo, R.; et al. Progress on polymer dielectrics for electrostatic capacitors application. Adv. Sci. 2022, 9, 2202438.

- 53.Liu, Q.; Yin, X.; Richard, C.; et al. Influence of the crystallization on the molecular mobility and ionic DC conductivity behaviors of relaxor ferroelectric P (VDF-TrFE-CTFE) terpolymers. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1645–1657.

- 54.Huang, Y.; Xu, J.-Z.; Soulestin, T.; et al. Can relaxor ferroelectric behavior be realized for poly (vinylidene fluoride-co-chlorotrifluoroethylene)[P (VDF–CTFE)] random copolymers by inclusion of CTFE units in PVDF crystals? Macromolecules 2018, 51, 5460–5472.

- 55.Pothier, A.M., M.; Brinson, H. Unit Cell Modelling of Auxetic Structure. J. Miner. Mater. Charact. Eng. 2022, 10, 360–369. https://doi.org/10.4236/jmmce.2022.104025.

- 56.Kornievsky, A.; Nasedkin, A. Numerical investigation of mechanical properties of foams modeled by regular Gibson–Ashby lattices with different internal structures. Materialia 2022, 26, 101563.

- 57.Dong, Z.; Li, Y.; Zhao, T.; et al. Experimental and numerical studies on the compressive mechanical properties of the metallic auxetic reentrant honeycomb. Mater. Des. 2019, 182, 108036.

- 58.

Alluri, N.R.; Saravanakumar, B.; Kim, S.-J. Flexible, hybrid piezoelectric film (BaTi(1−x)ZrxO3)/PVDF nanogenerator as a self-powered fluid velocity sensor. ACS Appl. Mater. Interfaces 2015, 7, 9831–9840.

This work is licensed under a Creative Commons Attribution 4.0 International License.