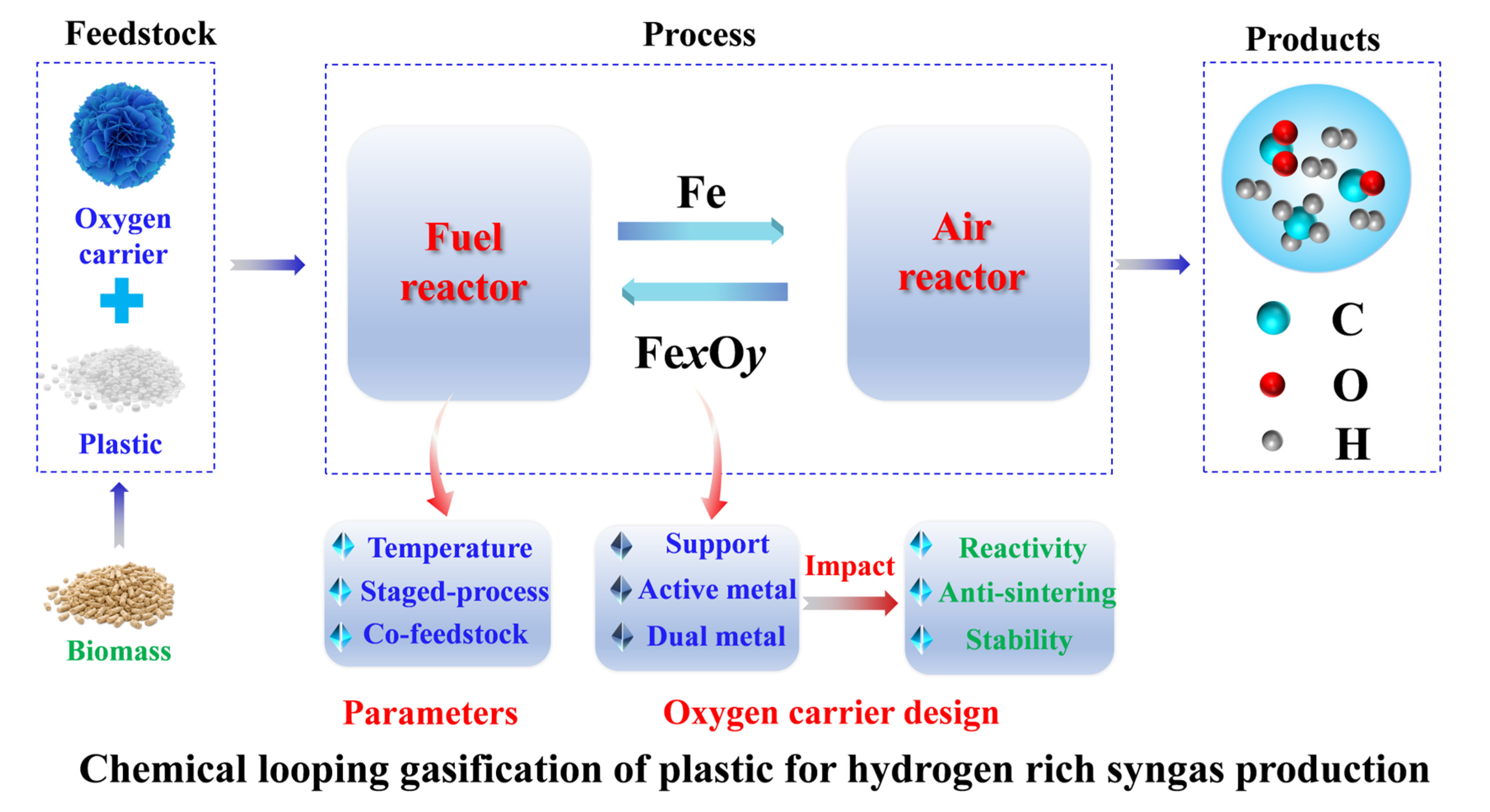

In the dual pursuit of achieving the global goal of carbon neutrality and curbing plastic pollution, chemical looping gasification (CLG) technology has emerged a key approach to integrate plastic waste recycling with H2-rich syngas production. This review systematically examines and compares the design strategy (support properties, active metal modification and bimetallic synergy) of oxygen carrier (OC) and the optimization progress of key process parameters (temperature, reactor staging and co-gasification of biomass) in the production of H2-rich syngas from plastic CLG. The findings demonstrate that support optimization and metal synergy can significantly regulate the syngas yield and its H2/CO ratio, while improving the cycle stability of OCs. Temperature and segmented CLG significantly improves the conversion rate and achieve flexible control of the H2/CO ratio. CLG of biomass and plastics can improve the yield and quality of H2-rich synthesis due to the complementary hydrocarbon and the coordinated conversion of tar. However, most studies at present use model plastics as fuel, which highlights the key shortcomings in understanding actual plastic waste, impurities, long-term CLG stability, and systematic economic evaluation. This review aims to provide guidance for the development of stable and selective OC systems and the optimization of CLG systems to achieve sustainable energy conversion of plastic waste.

- Open Access

- Review

Chemical Looping Gasification of Plastics toward Hydrogen-Rich Syngas: A Review of Oxygen Carrier Design and Process Optimization

- Jingmo Zhou 1,

- Yifan Wang 1,

- Fatma Abdelrhman 1,2,

- Wenke Zhao 1,

- Yaning Zhang 1,*

Author Information

Received: 15 Dec 2025 | Revised: 28 Dec 2025 | Accepted: 30 Dec 2025 | Published: 31 Dec 2025

Abstract

Graphical Abstract

Keywords

chemical looping gasification | plastic | oxygen carrier | process parameter | hydrogen-rich syngas

References

- 1.

Feng, J.X.; Zhu, Q.; Le, Q.Q.; et al. Source and performance of waste-derived porous carbon material as supercapacitor: Biomass, sludge and plastic waste as precursors. Renew. Sust. Energ. Rev. 2025, 211, 115178.

- 2.

Kumar, S.; Singh, E.; Mishra, R.; et al. Utilization of Plastic Wastes for Sustainable Environmental Management: A Review. Chem. Eur. J. 2021, 14, 3985–4006.

- 3.

Wang, Z.W.; Burra, K.G.; Lei, T.Z.; et al. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-A review. Prog. Energy Combust. Sci. 2021, 84, 100899.

- 4.

Lu, B.R.; Bai, B.; Zhang, R.H.; et al. Study on gasification characteristics and kinetics of polyformaldehyde plastics in supercritical water. J. Clean. Prod. 2023, 383, 135459.

- 5.

Dong, Q.; Lele, A.D.; Zhao, X.P.; et al. Depolymerization of plastics by means of electrified spatiotemporal heating. Nature 2023, 616, 488–494.

- 6.

Jin, Y.H.; Yang, H.M.; Guo, S.; et al. Carbon and H2 recoveries from plastic waste by using a metal-free porous biocarbon catalyst. J. Clean. Prod. 2023, 404, 136926.

- 7.

Zhang, P.; Liang, C.; Wu, M.D.; et al. Sustainable microwave-driven CO2 gasification of plastic waste for high-yield H2 and CO production. Appl. Catal. B J. 2024, 345, 123718.

- 8.

Ajorloo, M.; Ghodrat, M.; Scott, J.; et al. Modeling and experimental validation of the Co-gasification of plastic and biomass waste to estimate product yields. Energy 2025, 317, 134718.

- 9.

Gharibi, A.; Doniavi, E.; Hasanzadeh, R. A metaheuristic particle swarm optimization for enhancing energetic and exergetic performances of hydrogen energy production from plastic waste gasification. Energy Convers. Manag. 2024, 308, 118392.

- 10.

Lanjekar, P.R.; Panwar, N.L.; Agrawal, C. A comprehensive review on hydrogen production through thermochemical conversion of biomass for energy security. Bioresour. Technol. Rep. 2023, 21, 101293.

- 11.

Al-Qadri, A.A.; Ahmed, U.; Ahmad, N.; A review of hydrogen generation through gasification and pyrolysis of waste plastic and tires: Opportunities and challenges. Int. J. Hydrogen Energy 2024, 77, 1185–1204.

- 12.

Li, H.; Huang, Y.Q.; Zhang, Y.Y.; et al. Plastic photoreforming: Catalytic production of hydrogen and valuable chemicals. Green Chem. 2025, 27, 12050–12069.

- 13.

Wang, Y.C.; Liu, M.J.; Wu, C.N.; et al. Hollow Nanoboxes Cu2−xS@ZnIn2S4 Core-Shell S-Scheme Heterojunction with Broad-Spectrum Response and Enhanced Photothermal-Photocatalytic Performance. Small 2022, 18, 2202544.

- 14.

Zheng, Y.; Dong, J.; Huang, C.; et al. Co-doped Mo-Mo2C cocatalyst for enhanced g-C3N4 photocatalytic H2 evolution. Appl. Catal. B 2020, 260, 118220.

- 15.

Li, Y.R.; Nahil, M.A.; Williams, P.T. Pyrolysis-catalytic steam reforming of waste plastics for enhanced hydrogen/syngas yield using sacrificial tire pyrolysis char catalyst. Chem. Eng. J. 2023, 467, 143427.

- 16.

Liu, G.C.; Liao, Y.F.; Wu, Y.T.; et al. Enhancement of Ca2Fe2O5 oxygen carrier through Mg/Al/Zn oxide support for biomass chemical looping gasification. Energy Convers. Manag. 2019, 195, 262–273.

- 17.

Khani, Y.; Valizadeh, S.; Yim, H.; et al. Upgrading of plastic waste-derived wax through air gasification using promoted Ni/Al2O3 catalysts for H2 generation. Chem. Eng. J. 2023, 477, 147053.

- 18.

Li, W.J.; Li, C.G.; Liao, Y.F.; et al. Highly efficient and durable syngas production over one-step synthesized synergistic oxygen carriers in biomass chemical looping gasification. Bioresour. Technol. 2023, 386, 129553.

- 19.

Yan, J.C.; Lai, J.J.; Yin, K.H.; et al. Syngas production and gas-N evolution over heterogeneously doped La-Fe-O perovskite-type oxygen carriers in chemical looping gasification of microalgae. Bioresour. Technol. 2023, 369, 128507.

- 20.

Zhou, J.M.; Liu, C.Y.; Zhao, W.K.; et al. Modified Metal-Doped Fe-Al Catalysts for H2-Rich Syngas Production from Microwave-Assisted Gasification of HDPE Plastic. Catalysts 2025, 15, 111032.

- 21.

Ren, Z.Q.; Gao, Z.H.; Guo, Z.L.; et al. Sustainable hydrogen production from waste plastics via staged chemical looping gasification with iron-based oxygen carrier. Appl. Energy Combust. 2025, 23, 100362.

- 22.

Liu, B.J.; You, C.F.; Wang, H.M. Chemical looping gasification of waste plastics for syngas production using NiO/Al2O3 as dual functional material. Chem. Eng. J. 2024, 501, 157728.

- 23.

Fu, W.M.; Zhang, Y.N.; Cao, W.T.; et al. Microwave-assisted chemical looping gasification of plastics for H2-rich gas production. Chem. Eng. J. 2024, 499, 156225.

- 24.

Wang, L.; Xie, M.Y; Zhao, W.N; et al. Valorization of polyethylene waste via chemical looping gasification using high-entropy oxide oxygen carriers. J. Environ. Chem. Eng. 2025, 13, 118937.

- 25.

Zhao, T.M.; Wu, S.J; Lu, C.Q.; et al. Tuning oxygen activity via Ni doping in LaFeO3 for staged chemical looping gasification of plastic waste. Appl. Catal. B Environ. Energy 2026, 383, 126085.

- 26.

Du, X.D.; Lei, J.H.; Zhu, C.Z.; et al. Microwave-assisted gasification of plastics for tunable syngas production via bauxite residue-based catalytic oxygen carriers. Chem. Eng. J. 2025, 510, 161606.

- 27.

Zhang, W.J.; Tursun, Y.; Abduhani, H.; et al. Chemical looping co-gasification of cotton stalk and polyethylene over CuO/NiFe2O4 oxygen carrier. Chem. Eng. J. 2025, 525, 170378.

- 28.

Deng, J.; Meng, L.S.; Ma, D.; et al. High H2 selective performance of Ni-Fe-Ca/H-Al catalysts for steam reforming of biomass and plastic. J. Energy Chem. 2023, 80, 215–227.

- 29.

Liu, Q.Y.; Hu, C.S.; Peng, B.; et al. High H2/CO ratio syngas production from chemical looping co-gasification of biomass and polyethylene with CaO/Fe2O3 oxygen carrier. Energy Convers. Manag. 2019, 199, 111951.

- 30.

Al-Qadri, B.; Wang, X.J.; Chen, D.L. Experimental Study on Chemical Looping Co-gasification of Alfalfa and Polyethylene with Iron Ore as the Oxygen Carrier for High H2/CO Production. Energy Fuels 2022, 36, 6939–6948.

- 31.

Wu, S.J.; Ren, Z.Q.; Hu, Q.; et al. Upcycling plastic waste into syngas by staged chemical looping gasification with modified Fe-based oxygen carriers. Appl. Energy 2024, 353, 122105.

- 32.

Pérez-Vega, R.; Abad, A.; Gayán, P.; et al. Development of (Mn0.77Fe0.23)2O3 particles as an oxygen carrier for coal combustion with CO2 capture via in-situ gasification chemical looping combustion (iG-CLC) aided by oxygen uncoupling (CLOU). Fuel Proce. Technol. 2017, 164, 04.019.

- 33.

Dawa T, Martinez M.P., Sajjadi B. Enhanced Production of Hydrogen through Modified Brownmillerite Ca2Fe2-xMxO5 (M: Co, Cu, Ni) for Chemical Looping Gasification. Fuel 2025, 390, 134490.

- 34.

Domingos, Y.; Abad, A.; De Las Obras Loscertales, M.; et al. Chemical looping combustion and gasification of swine manure with a Cu-Based oxygen carrier. Chem. Eng. J. 2025, 503, 158503.

- 35.

Wang, P.L.; Zheng, C.H.; Li, Y.; et al. Exploring the regulation mechanism of Ca/Fe-based oxygen carrier in biomass chemical looping gasification. Chem. Eng. J. 2024, 498, 155488.

- 36.

Ji, J.Q.; Shen, L.H. Rational design of enhanced oxygen deficiency-enriched NiFe2O4 embedded in silica matrix as oxygen carriers for high-quality syngas production via biomass chemical looping gasification (BCLG). Energy 2024, 310, 133199.

- 37.

Xue, S.J.; Wang, X.D. Process simulation of chemical looping gasification of biomass using Fe-based oxygen carrier: Effect of coupled parameters. J. Clean. Prod. 2022, 356, 131839.

- 38.

Wang, Z.; Mu, L.; Miao, H.C.; et al. An innovative application of machine learning in prediction of the syngas properties of biomass chemical looping gasification based on extra trees regression algorithm. Energy 2023, 275, 127438.

- 39.

Liang, S.; Liao, Y.F.; Yang, H.L.; et al. Inhibition strategies for phase separation of iron-based oxygen carriers in chemical looping gasification- enhanced oxygen transport efficiency through oxide-support interactions. Sep. Purif. Technol. 2024, 343, 127173.

- 40.

Yan, J.C.; Sun, R.; Shen, L.H.; et al. Hydrogen-rich syngas production with tar elimination via biomass chemical looping gasification (BCLG) using BaFe2O4/Al2O3 as oxygen carrier. Chem. Eng. J. 2020, 387, 124107.

- 41.

Hu, J.J.; Li, C.; Guo, Q.H.; et al. Syngas production by chemical-looping gasification of wheat straw with Fe-based oxygen carrier. Bioresour. Technol. 2018, 263, 273–279.

- 42.

Cai, N.; Xia, S.W.; Li, X.Q.; et al. High-value products from ex-situ catalytic pyrolysis of polypropylene waste using iron-based catalysts: The influence of support materials. Waste Manag. 2021, 136, 47–56.

- 43.

Daneshmand-Jahromi, S.; Sedghkerdar, M.H.; Mahinpey, N. A review of chemical looping combustion technology: Fundamentals, and development of natural, industrial waste, and synthetic oxygen carriers. Fuel 2023, 341, 127626.

- 44.

Gao, Z.X.; Wu, D.; Barakat, M.; et al. Improving the Reactivity and Stability of Fe2O3/Al2O3 in Chemical Looping Process by Optimizing the Al2O3 Precursor. Ind. Eng. Chem. Res. 2024, 63, 3092–3103.

- 45.

Yao, D.D.; Yang, H.P.; Chen, H.P.; et al. Co-precipitation, impregnation and sol-gel preparation of Ni catalysts for pyrolysis-catalytic steam reforming of waste plastics. Appl. Catal. B 2018, 239, 565–577.

- 46.

Cai, N.; Xia, S.W.; Li, X.Q.; Sun, L.; et al. Influence of the ratio of Fe/Al2O3 on waste polypropylene pyrolysis for high value-added products. J. Clean. Prod. 2021, 315, 128240.

- 47.

Samprón, I.; García-Labiano, F.; Izquierdo, M.T.; et al. Understanding the structural changes on Fe2O3/Al2O3 oxygen carriers under chemical looping gasification conditions. Fuel 2024, 335, 129326.

- 48.

Liu, X.T.; Zhang, Y.S.; Nahil, M.A.; et al. Development of Ni- and Fe- based catalysts with different metal particle sizes for the production of carbon nanotubes and hydrogen from thermo-chemical conversion of waste plastics. J. Anal. Appl. Pyrolysis 2017, 125, 32–39.

- 49.

Habibi, R.; Mehrpooya, M. A novel integrated Ca-Cu cycle with coal/biomass gasification unit for clean hydrogen production. Energy Convers. Manag. 2021, 228, 113682.

- 50.

Yang, G.Y.; Xu, W.J.; Jia, J.B.; et al. Lattice oxygen activity regulation by alkaline earth metals in iron oxides for biomass chemical looping gasification. Carbon Capture Sci. Technol. 2025, 14, 100353.

- 51.

Mendiara, T.; Teresa Izquierdo, M.; Condori, Ó.; et al. Identification of oxygen carriers for chemical recycling of plastic waste using chemical looping technologies. Fuel 2025, 394, 135284.

- 52.

Huang, J.J.; Liu, W.; Yang, Y.H.; et al. High-Performance Ni-Fe Redox Catalysts for Selective CH4 to Syngas Conversion via Chemical Looping. ACS Catalysis 2018, 8, 1748–1756.

- 53.

Yao, D.D.; Wu, C.F.; Yang, H.P.; et al. Co-production of hydrogen and carbon nanotubes from catalytic pyrolysis of waste plastics on Ni-Fe bimetallic catalyst. Energy Convers. Manag. 2017, 148, 692–700.

- 54.

Falascino, E.; Joshi, R.K.; Kumar, S.; et al. Enabling plastic waste gasification by autothermal chemical looping with > 90% syngas purity for versatile feedstock handling. Appl. Energy Combust. Sci. 2024, 19, 100270.

- 55.

Xiao, J.Y.; Xu, T.T.; Shu, Z.M.; et al. Iron-based spinel for H2 production and CO2 separation from plastics via chemical looping. Appl. Therm. Eng. 2025, 274, 126633.

- 56.

Chen, L.Y.; Li, H.X.; Wang, H.F.; et al. Performance of red mud oxygen carriers in chemical-looping hydrogen production using different components of plastic waste pyrolytic gas. J. Clean. Prod. 2023, 409, 137213.

- 57.

Jiang, H.M; Huo, R.Q.; Zhang, Z.; et al. Dechlorination performance in chemical looping conversion of polyvinyl chloride plastic waste using K/Na/Ca-modified iron ore oxygen carriers. J. Environ. Chem. Eng. 2022, 10, 107314.

- 58.

Yang, H.L.; Liao, Y.F.; Liang, S.; et al. Enhanced syngas production via plastic rubber chemical looping gasification: Role of iron–nickel oxide oxygen carriers. Int. J. Hydrogen Energy 2024, 95, 362–376.

- 59.

Du, X.D.; Wang, J.; Song, J.X.; et al. Fuel gas production through waste polyethylene gasification using bauxite residue as the oxygen carrier. Fuel 2022, 321, 123878.

- 60.

Jagodzińska, K.; Jönsson, P.G.; Yang, W.J. Pyrolysis and in-line catalytic decomposition of excavated landfill waste to produce carbon nanotubes and hydrogen over Fe- and Ni-based catalysts—Investigation of the catalyst type and process temperature. Chem. Eng. J. 2022, 446, 136808.

- 61.

Huang, J.J.; Veksha, A.; Lisak, G.; et al. Consecutive coproduction of H2 and syngas from waste polyolefins derived pyrolysis gas via chemical looping cracking–gasification. Waste Manag. 2025, 203, 114855.

- 62.

Wang, P.L.; Zheng, C.H.; Zhao, H.B.; Modulating lattice oxygen activity of Ca2Fe2O5 for hydrogen-rich syngas production via chemical looping gasification of biomass/plastic. Fuel 2026, 408, 137651.

- 63.

Tian, W.D.; Zhang, S.M.; Wang, S.C.; et al. Biomass and waste plastics chemical looping co-gasification for hydrogen-electricity-DME conservation and recycling based on machine learning. Energy 2025, 318, 134868.

- 64.

Kudva, I.K.; Shinde, S.G.; Joshi, R.K.; et al. Low Carbon Formaldehyde Generation from Chemical Looping Gasification of Heterogeneous Solid Waste. Energy. Energy Fuels 2024, 38, 20839–20850.

This work is licensed under a Creative Commons Attribution 4.0 International License.