Downloads

Download

This work is licensed under a Creative Commons Attribution 4.0 International License.

Review

Industry 4.0 in Metal Forming Industry Towards Automotive Applications: A Review

Heli Liu 1,2, Saksham Dhawan 1,2, Merrill Shen 1, Kangan Chen 1, Vincent Wu 3, and Liliang Wang 1,2,*

1 Department of Mechanical Engineering, Imperial College London, London, SW7 2AZ, UK

2 SmartForming Research Base, Imperial College London, London, SW7 2AZ, UK

3 School of Informatics, The University of Edinburgh, Edinburgh, EH8 9LE, UK

* Correspondence: liliang.wang@imperial.ac.uk

Received: 23 September 2022

Accepted: 18 November 2022

Published: 18 December 2022

Abstract: Industry 4.0 is shaping the metal forming industry. The ongoing key Industry 4.0 technologies, including the industrial cyber-physical system (I-CPS), industrial internet of things (I-IoT), digital twin (DT), big data (BD) and cloud computing (CC), are expected to improve every stage during the metal forming processes, including the supply chains, raw material provision, tool design and manufacture, forming operations, energy consumption, cost, quality control and customer services. Here, we review the development and implementations of these key Industry 4.0 technologies in the metal forming industry. Based on the discussion of the opportunities and challenges of Industry 4.0 technologies in metal forming, this review provides some perspectives of future metal forming research directions towards automotive applications.

Keywords:

Industry 4.0 metal forming automotive industrial cyber-physical system (I-CPS) industrial internet of things (I-IoT) digital twin (DT) big data (BD) cloud computing (CC)1.Introduction

Metal forming has long been an important sector during the technology evolution, and is one of the most popular manufacturing crafts [1]. The metal forming industry accounts for nearly 20% of the national GDP of the modern industrialised nations [2]. In addition, 90% [3] and 67% [4] of steel and aluminium products respectively, especially those used in automotive, aircraft, naval and domestic appliance industries, are manufactured by at least one metal forming process. Advanced metal forming technologies enable the efficient manufacturing of complex-shaped components with remarkable reduction in raw material usage, high formability and high post-form material strengths. The corresponding technologies have been successfully integrated in manufacturing plants, especially in automotive and aircraft plants over the past decades [5–9], together with the development of other theoretical and experimental metal forming related technologies including coating [10–12], lubrication [13–17] and tool design [18,19].

Empowered by the Fourth Industrial Revolution, namely the Industry 4.0 [20], a concept initiated in 2011 and popularised in 2015, the business models for the entire manufacturing industry are being digitally transformed and revitalised towards mechanical automation by key enabling technologies covering communication, controlling and intelligence, that enhance the manufacturing productivity and flexibility [21–23]. However, according to a survey carried out in 2020 for global manufacturers, approximately 52% of the participating manufacturers indicated that their companies lack the expertise and culture to explore and use Industry 4.0 technologies. This can be further proved by the fact that only 28% of these responders have tried to integrate any Industry 4.0 technology to optimise their manufacturing processes [24]. The subdued inclination for uptake of these Industry 4.0 technologies leads to significant challenges when achieving the industry-scale transformation of digital manufacturing [24].

In the present work, we review 102 peer-reviewed articles and recent manufacturing reports focusing on the metal forming technologies, key Industry 4.0 technologies including the industrial cyber-physical system (I-CPS), industrial internet of things (I-IoT), digital twin (DT), big data (BD) and cloud computing (CC), and their recent developments and implementations in metal forming field towards automotive applications. Of these, over 90 items were published over the last decade (2013 to present), and over 40 items were published since 2020. In addition, we open a discussion focusing on the ongoing efforts and potential opportunities and challenges based upon the recent research findings that emphasise the implementation, interaction, integration, and innovation of the introduced Industry 4.0 technologies.

2.Industrial Cyber-Physical System

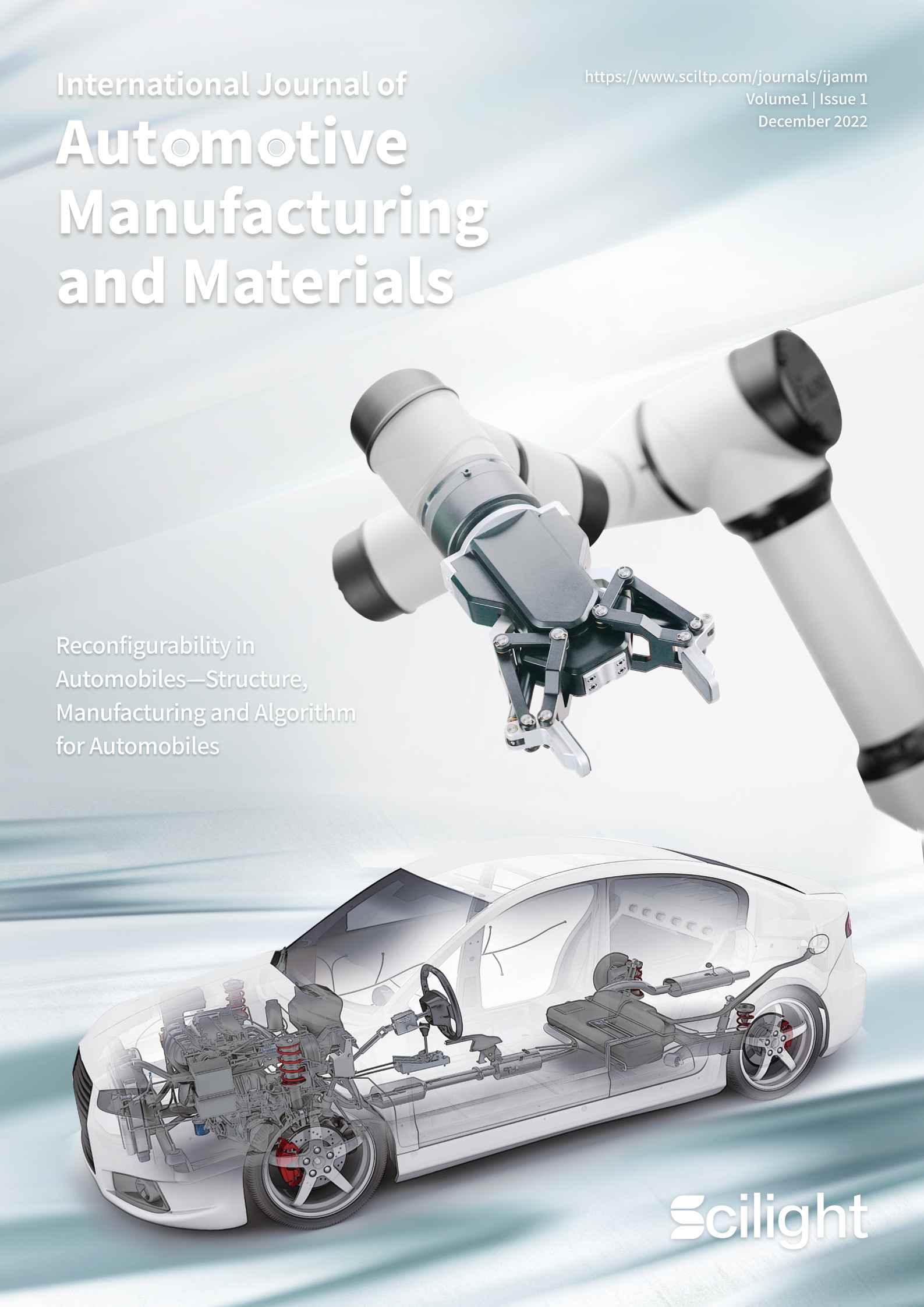

A rapid growth has been witnessed in the development of diverse cyber-physical systems (CPS). Of these, as shown in Figure 1, the industrial cyber-physical system (I-CPS) can be defined as a combination of the industrial cyber and physical systems that synergistically enable precise and efficient manufacturing production applications [22,25]. The I-CPS is expected to strengthen the operation stages throughout the metal forming plant, including the supply chains [26], raw blanks or billets production [27,28], forming operation and quality prediction [29], energy saving [30], cost reduction and customer services [31]. The implementation of I-CPS in metal forming industry requires sophisticated interactions among different digital technologies. Taking the digital transformation of a rolling mill as an example, the full integration of I-CPS in the rolling mill incorporates the sensing technology for collecting real-time big data, big data processing technology, and data visualisation technology for mapping the effects of milling parameters [32].

Figure 1. The configuration of I-CPS. Reprinted/adapted with permission from [22].

An I-CPS was designed for the automotive hot stamping factories [33]. The key processing parameters, production efficiency and energy consumption were monitored and optimised remotely for hot stamping factories. The hot stamping I-CPS configuration towards automotive applications consists of five key layers, (1) the sensing and input layer for information or data requisition, (2) the edge computing layer for data processing and transferring, (3) the metadata storage layer for large-scale metadata online storage requirements, (4) the intelligent analysis layer for model establishment on the production efficiency analysis, energy consumption analysis, process optimisation, etc., and (5) the application layer for digital applications such as the data visualisation, production report generation and permission distribution.

3.Industrial Internet of Things

First introduced in 1999, the idea of internet of things (IoT) enables the inter-connection of ‘Anything’ in ‘Anywhere’ at ‘Anytime’. Specifically, it is described as a smart system incorporating the physical world into a digital ecosystem [31]. Therein, the ‘things’ indicates the unprecedented amounts of electronic devices including wireless sensing networks, external recorders and other subsystems [34]. The IoT has attracted increasing attention, and the total value of global IoT technologies is projected to reach $6.2 trillion by 2025 [35].

The industrial IoT (I-IoT) is the application of IoT in industrial activities, which is dedicated to improve the productivity, efficiency, safety, flexibility, scalability, customer service and enhancing intelligence of the manufacturing and industrial systems [22,36]. I-IoT offers seamless interoperability and connectivity among industrial devices, systems, services, networks, and in particular the control systems. I-IoT can be defined in three tiers from the industrial perspective [22], i.e., Tier 1: physical layer (or Edge [36]), consisting of various hardware devices like sensors and external recorders; Tier 2: communication layer (or Platform [36]), providing shared manufacturing big data and connecting the physical layer to the Tier 3, the application layer (or Enterprise [36]), which is represented by the smart factory, smart plant and smart supply chain.

Advanced sensing technology is one of the key factors for realising the I-IoT in metal forming industry via connecting the physical layer with the application layer [37]. Figure 2 shows a typical sensing network in metal forming workshops operated in I-IoT [38], where the protection of security, IT environment, power system and facilities around the factory are monitored. The sensing technology for metal forming can be divided into four types [37], i.e., the direct metrology (e.g., directly measuring the contact pressure in stamping process [39]), the indirect metrology (e.g., incorporating a sensor into a bolt [40]), the die-embedded metrology (e.g., die embedded micro-sensors [41]) and the intelligent metrology. Of these, the intelligent metrology equipped with a visualisation system incorporating sensors (hard sensing), process simulation (soft sensing) and data (knowledge), was proposed for precisely monitoring the metal forming processes [37].

Figure 2. Typical sensing network of metal forming workshops in I-IoT. Reprinted/adapted with permission from [38].

In automotive industry, the integration of I-IoT and automated supply chain was proposed for optimising the metal forming productivity, forming process, product quality and economic feasibility [1,42]. The I-IoT is getting more importance and visibility in metal forming industry because it led to better formability and precision of the formed products [41]. For instance, the metal additive manufacturing (AM) can be regarded as an essential ingredient in the intelligent production systems, and can be intelligently driven by integrating the Industry 4.0 technologies in CNC machines, especially the I-IoT technology [43]. Challenges in traditional metal AM, such as the poor repeatability, improper material property, interlayer imperfection, data management and low efficiency, can be improved by associating I-IoT [44]. The I-IoT technology has been implemented in servo presses in metal forming processes for improving the tool life [45], in which the artificial intelligence (AI) is expected to be integrated to predict the future maintenance requirements. With overall monitoring of the metal forming workshop, including die casting [46] and forming processes [30], the I-IoT technology can improve the energy efficiency and management of the metal forming enterprises.

4.Digital Twin

Introduced in 2003 via a course named ‘product lifecycle management’ by Grieves [47], digital twin (DT) has become one of the most promising technologies for realising Industry 4.0. DT can be defined as the seamless integration between the cyber and physical spaces [48]. Specifically, in industrial applications, it integrates the physical manufacturing entities to their respective cyber entities and includes diverse decision-making algorithms, modules or platforms for industrial activties [49,50]. Using the real-time data collected from embedded sensors, sophisticated high-fidelity models (virtual entity) are established to reflect the real-time state (such as information model and functional elements) by almost mirroring the entire life-cycle of the manufactured products (physical entity) [50].

The implementation of DT in metal forming industry has been widely considered to improve the metal forming process from various perspectives, including the real-time component geometrical precision and tolerance [51], tools or forming machines [52], energy consumption [47], and design roadmap of the metal forming process [53]. For instance, a DT-driven modelling method was proposed for reflecting real-time state of sheet metal forming process focusing on the die wear conditions [47]. The updating coefficient of friction, blank holder force, punch force, and punch displacement were monitored and captured by the force and displacement sensors. The optimisation results demonstrate that a 14.35% reduction was achieved in the maximum thinning region of the stamped part, as well as 8.9% reduction in the energy consumption through the forming process.

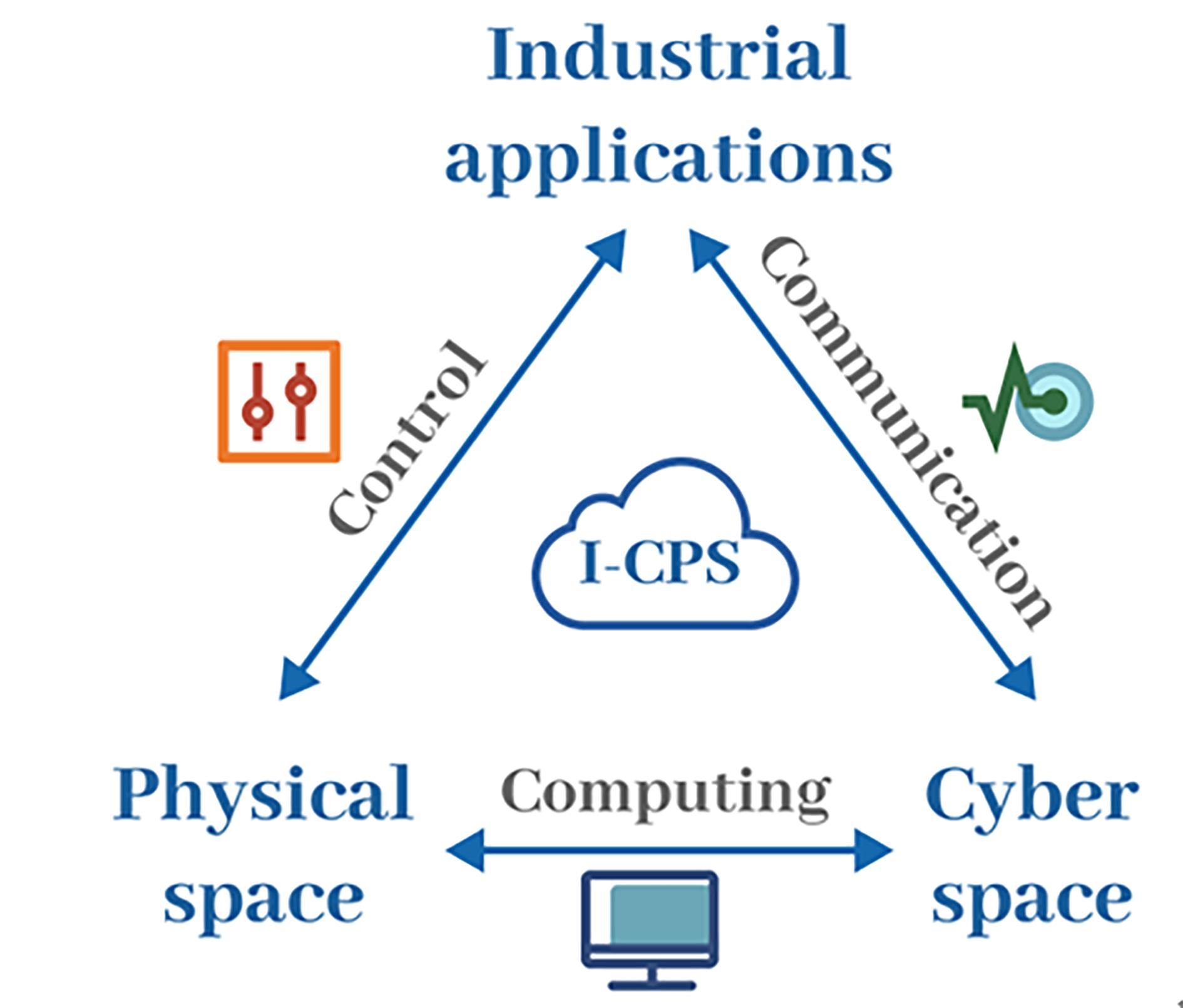

The DT technology is now being actively considered as a supervisory role in metal AM process through real-time monitoring and control [54-60]. A DT hierarchy consisting of four distinct tiers for the metal AM DT was proposed [57]. As show in Figure 3, Tier 1 represents the Implicit DT, which mirrors a specific metal AM machine. In this Tier, the prediction via high-fidelity physical models is made to avoid multi-trials [61]. Tier 2 represents the Instantiated DT that relies on the sensing technology to connect the physical and virtual entities. Tier 3 represents the Interfaced DT that enables the real-time monitoring, controlling and optimising. The DT closed-loop (real-time in-situ monitoring and control system [60]) is established to allow the feedback to the physical space following the instantiated updating of the virtual space. Finally, Tier 4 represents the Intelligent DT that can realise the sophisticated real-time decision making through the application of AI. This releases the potential of forming the tailored products since correction could be made via intelligent predictions when or before the defects occur [62]. Although the effectiveness of each Tier, especially Tier 4, in this metal DT hierarchy requires more investigations and conclusive validations, they are still referable to all the metal forming processes.

Figure 3. The metal AM digital twin hierarchy. Reprinted/adapted with permission from [57].

A DT-based CPS was proposed to predict whether a product can be formed in abnormal scenarios involving automotive body production lines [63]. The information models of the product, process, plant, etc., were established for the automotive body production lines. Experimental results demonstrate that an average prediction accuracy of over 96% was achieved in the actual production line. In addition, a hybrid data-driven and model-based framework for establishing a combined monitoring and control system was proposed in the complicated automotive sheet metal forming processes [42]. This framework used the retrieved data (such as the material information and coatings) and the captured real-time metal forming data (such as temperature, sheet thickness and tribology behaviours) as an input for the process models to predict the product/process settings as the output, then this would be utilised for optimising the product properties or process settings. However, the computational cost of the process model needs to be reduced to provide faster response, and further lab-scale validation is required on this framework.

5.Big Data

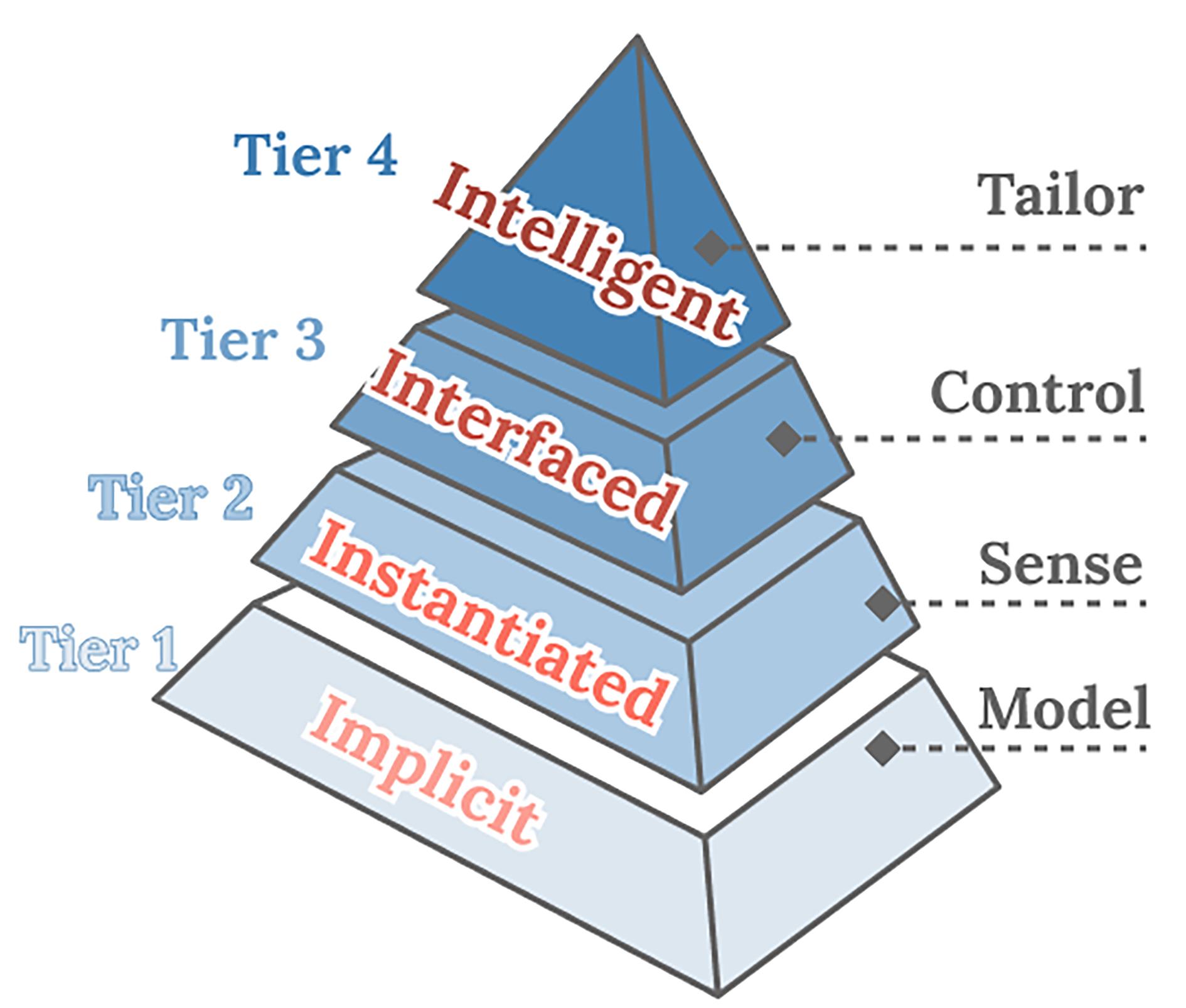

Big data (BD) refers to the datasets that are too large or complex to be tackled by traditional data-processing methods, thus requires new technologies to mine insightful information from it. BD can be characterised in five well-accepted dimensions, namely the ‘5Vs’ representing ‘Volume, Velocity, Value, Veracity and Variety’ [64] (Figure 4a). Moreover, the well-known FAIR (Findable, Accessible, Interoperable and Reusable) data principles (Figure 4b) provide a foundational guideline for researchers to generate, store, utilise and manage scientific big data [65]. The FAIR data principles act as valuable guidebook since volumes of data are being generated and captured during daily manufacturing and academic activities. In the manufacturing sector, the total value of the global big data market was $3.22 billion in 2018, and it is expected to exceed $9 billion by 2026 [66]. As one of the key subsectors of manufacturing industry [67], the metal forming industry increasingly generates big data which desires effective processing and characterisation for mining more insightful information. Thus, the big data (BD) technology has been extensively studied and implemented in almost all stages of metal forming process, ranging from customer services to supply chains [31], from material preparation [68,69] to failure prediction and quality analysis [70,71].

Figure 4. (a) The ‘5Vs’ property of big data; (b) The FAIR principles; (c) Mapping the dataset from a specific metal forming process: hot stamping process, for automotive components production.

Big data generated during the metal forming processes are mainly captured by the sensing networks [72,73]. In addition, the metal forming data can also be collected from the experimentally verified finite element analysis (FEA) simulations [74,75]. Fig. 4c shows the data mapping of the hot stamping datasets collected from the experimentally verified FEA models containing the thermo-mechanical information (e.g., temperature data, contact pressure data, strain rate data) of the stamping and quenching operations [5–7,76]. These FEA models simulated the hot stamping of representative automotive components such as side beams, B-pillars and door inners. This data collection method can be proactive by providing optimisation suggestions through data processing and analysis before the actual forming process commences.

The AI technology leads the investigations on big data processing in metal forming, spanning the material design [78], forming force prediction [77], tribological characteristics [78,79] and product surface quality [80], geometrical accuracy [81], process formability [82], tool path design and generation [83] (especially for incremental sheet metal forming [84]), product [85] and die designs [86], in-process defect monitoring [87], etc. Therein, various AI methods, especially machine learning (ML) algorithms, including the artificial neural network (ANN) algorithm [85], support vector machine (SVM) [78], quantum-behaved particle swarm optimisation (QPSO) algorithm [80], multilayer perceptron (MLP) algorithm [88] and convolutional neural networks (CNNs) [83], are widely utilised. In terms of the applications of AI in sheet metal forming, supervised ML is still the predominant AI method [77]. However, one of the limitations of ML algorithms is that the generalisation of the prediction is required to draw conclusions on a different metal forming process, if the dataset of that process is not included in the training data [83].

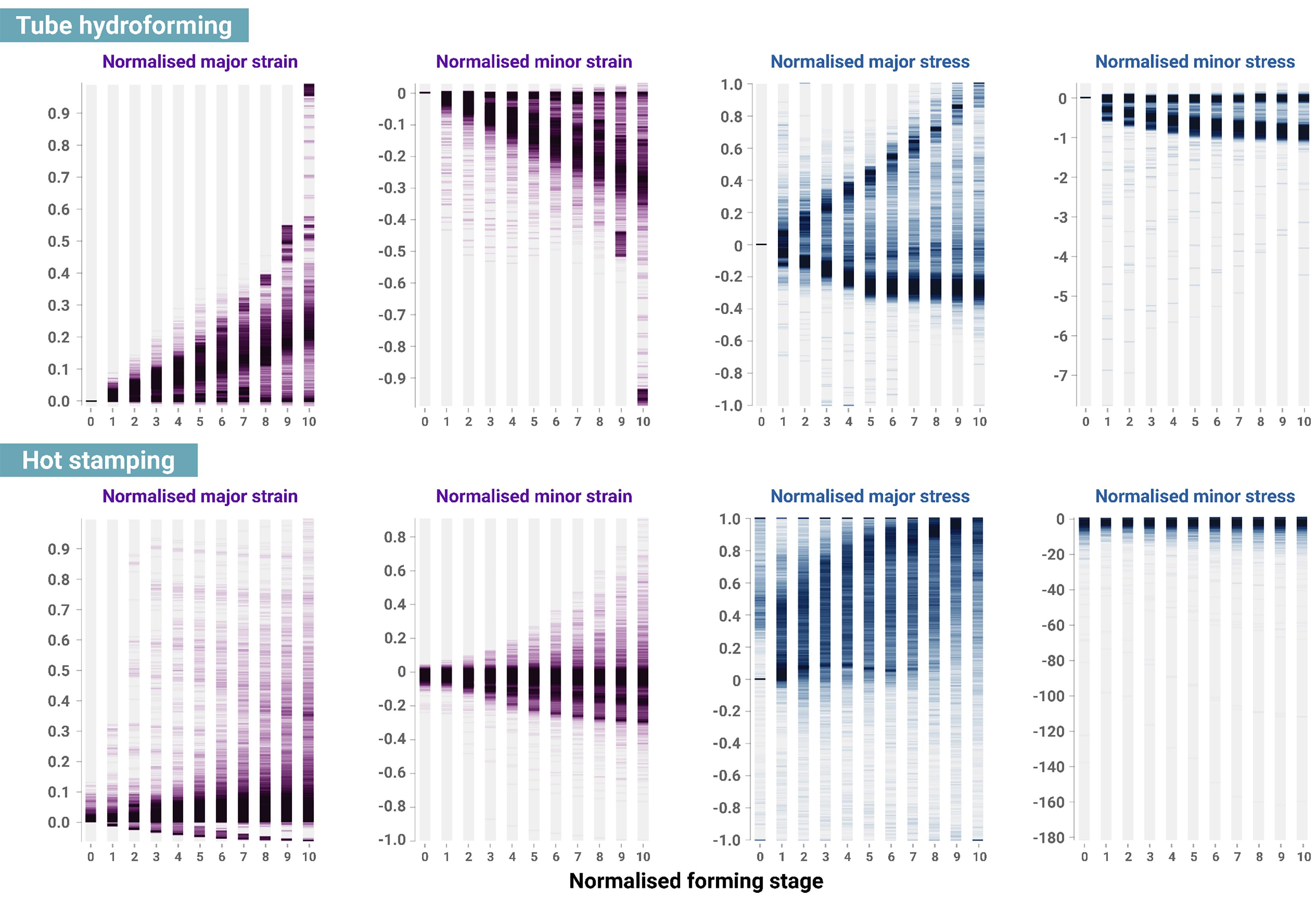

Data visualisation can provide intuitive digital information. The global flow of steels [3] and aluminium [4] were mapped based on big data, which provides intuitive and comprehensive image on the entire material supply chain cycle from the raw materials to end-use goods. Big data was collected from the manufacturing processes enabling the development of Digital Characteristics (DCs) to map the manufacturing processes from the perspective of metadata [89], where our understanding remains incomplete. The DCs incorporate essential information spanning the design, manufacturing and application stages of the manufactured products [89]. Figure 5 shows the DCs developed based on the datasets from the tube hydroforming and hot stamping process by characterising the thermo-mechanical evolutions during forming, including the normalised major and minor strains, and normalised major and minor stresses. Distinct discrepancies can be clearly observed by comparing the DCs of the two metal forming processes, indicating the potential for using DCs to identify different metal forming (or manufacturing) processes if essential information of the data is absent.

Figure 5. The DCs of the tube hydroforming process and hot stamping process by mapping the evolutionary normalised thermo-mechanical data as a function of normalised forming stages 0–10.

6.Cloud Computing

Cloud-based computing resources, enabling distributed and dynamic collaborative manufacturing operations, have drawn increasing interests. Cloud computing (CC) is a model for enabling convenient, on-demand network access to a shared pool of configurable computing resources that can be rapidly provisioned and released with minimal management effort or service provider interaction [90]. The key for CC is to provide geographically distributed manufacturers with centralised computation services. For sheet metal forming technology, a CC service was scheduled for establishing the cloud-based production system [91]. Therein, a genetic algorithm-based planning and scheduling application was developed to provide cost-efficiency, flexibility and scalability solutions. The application case demonstrates that the proposed scheduling system utilised the CC technology to provide ‘close to real-time’ analysis and planning according to the dynamic requirements and inputs for multiple factories. In addition, the incremental sheet forming process was adapted into CC for providing flexible manufacturing service to production networks for three selected industries (case study) [92]. The tool path control was also optimised by developing an adaptive control algorithm with variable forming depth at a process level for bypassing the fracturing of sheets due to the localised thinning. The potential of selecting incremental sheet forming service providers was highlighted based on the material database.

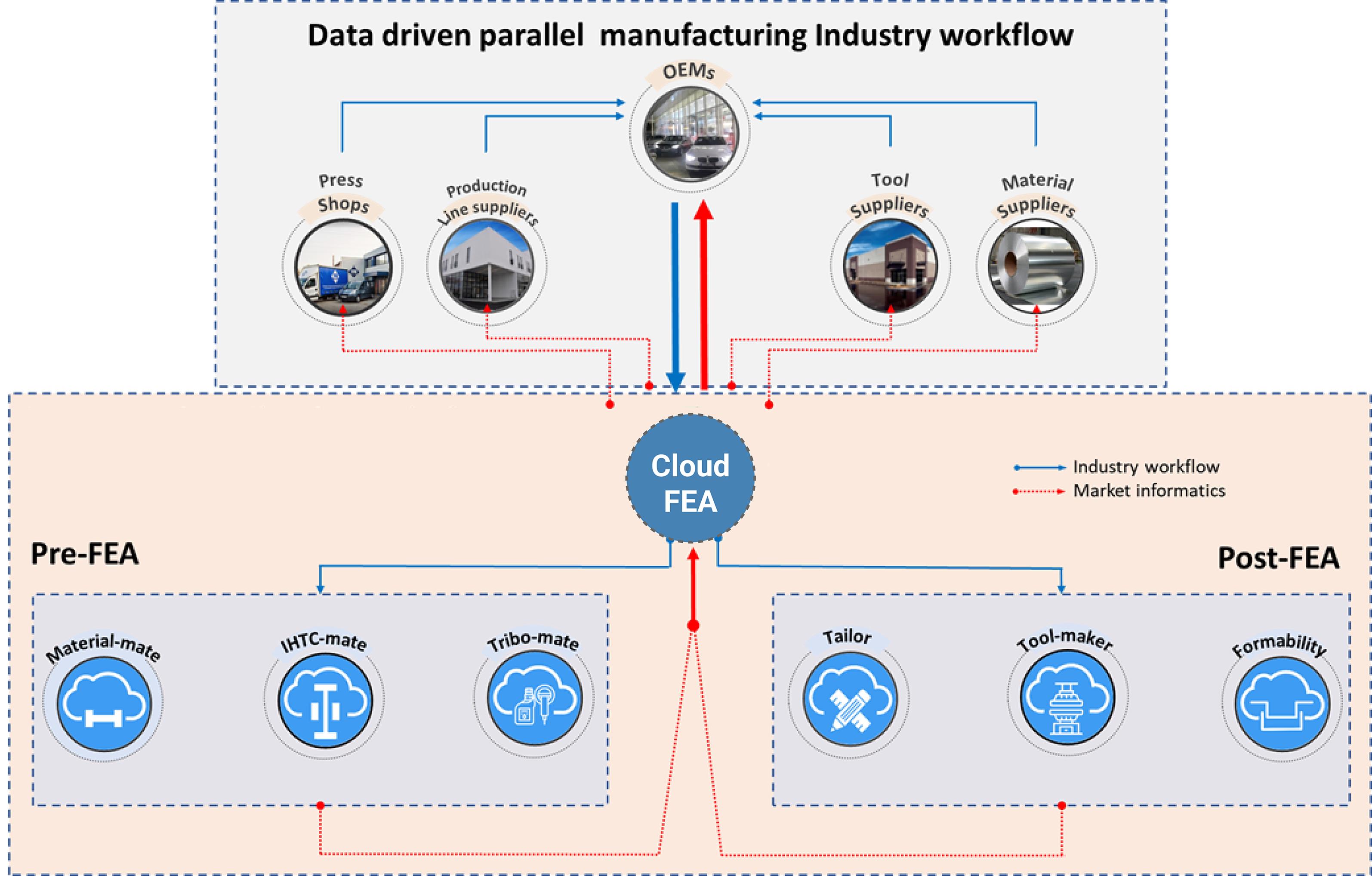

Innovations are being made on configuring the CC system for enhancing metal forming processes [93]. A group of researchers have pioneered the cloud-based FEA technologies enabling advanced multi-objective FEA of metal forming processes, in addition, commercial cloud based services such as the ESI cloud and AutoForm cloud, were developed to enhance the computational efficiency [74,94,95]. This cloud-based FEA platform contains verified scientific data repository, pre-FEA modules, post-FEA modules, etc [74,94]. Figure 6 shows the configuration of this novel platform, where the stored data can be used for data sharing and analysis, leading to digitally enhanced research and development [94]. The pre-FEA modules contains the ‘Material-mate’ module for enabling the generation of material cards to be used in forming tests, the ‘IHTC-mate’ module for creating interfacial heat transfer coefficient (IHTC) computing plug-ins for heat transfer models, and the ‘Tribo-mate’ module for enabling interactive friction models to be used and validated by forming tests. The post-FEA modules contains the ‘Tailor’ module for enabling the prediction of post-form strength, the ‘Tool-maker’ module for enabling the prediction of cold die quenching efficiency, and the ‘Formability’ module for enabling the prediction of formability. The effectiveness of these functional modules was successfully validated in peer-reviewed studies towards automotive applications [74,75,94-99]. The cloud FEA can be further characterised into 3 layers, namely the resource layer, cloud platform layer and application layer. The resource providers and users can be world-wide academic institutions, material suppliers, and equipment, brand and design manufacturers.

Figure 6. The configuration of the cloud FEA platform. Reprinted/adapted with permission from [94].

7.Discussion

The Industry 4.0 technologies are not isolated. The increasingly sophisticated metal forming operations require the emergent I-CPS, I-IoT, DT, BD and CC technologies. For instance, the DTs and BD are mutually reinforcing technologies in the era of digital manufacturing [48]. The sensing technology is one of the most important enablers in I-IoT, I-CPS, DT, etc. [37]. Advance in the fields of mechanical engineering, material engineering, communication engineering, electronic and information engineering, computer science, control science and engineering, data science, etc., also supports to widen the scope of these technologies. These are highly expected to boost the creation of new Industry 4.0 technologies and new emerging subjects focusing on the digital metal forming transformation. Meanwhile, the key Industry 4.0 technologies are creating exponential growth in metal forming big data, which brings boundless potentials for mining more comprehensive and insightful information through data processing, analysing and visualisation [100], and further data application on digitally enhancing and optimising the metal forming processes. As a result, more comprehensive online data repository can be established, more intelligent metal forming processes can be developed, and more tailored products are expected to be manufactured based on the big data analysis.

Despite the research and development progress, challenges also need to be addressed when promoting Industry 4.0 technologies. Taking I-CPS and I-IoT as examples, the main challenges of their applications can be summarised in the capabilities, management, engineering, ecosystems, infrastructures and information systems [25]. The main challenge of DT includes big data processing, and the privacy and security issues [101]. As for CC, the main challenge of CC includes security, performance, availability and low integrity with in-house IT resources [90].

The never-before-seen surge in the big data availability brings promising opportunities, while at the same time, brings tremendous challenges in data management and data processing as well [102], not to mention manage such a huge volume of data following the FAIR data principles. In addition, since the data privacy or protection policies are regarded as the top priority in manufacturing sector [72], the collaborations, such as big data sharing and exchange within I-CPS or I-IoT systems, among different factories or institutions can be hindered. To process these metal forming big data, the AI methods, especially the ML algorithms, are widely used nowadays. However, big challenges of achieving generalised prediction and high interpretability, and applying appropriate data pre-processing methods before using the ML algorithms still remain. Moreover, due to the restrictions on the data collection methods and data privacy in automotive industry, most of the collected metal forming data would lack critical information of the formed products and metal forming process itself. This leads to unstable and inaccurate predictions while applying the ML algorithms since the available training data is insufficient.

In terms of automotive industry, the Industry 4.0 technologies can improve the metal forming processes on almost all the stages including the supply and purchasing chains, raw material and tool manufacture, forming operations, energy consumption, quality control and customer services. The cost during the entire metal forming operation cycle can be reduced, and the efficiency can be increased. However, the lack of expertise, familiarity and culture of using Industry 4.0 technologies in some traditional automotive industries is a long-standing challenge [24], such as lacking the training of managing, processing or analysing the metal forming big data. To improve this, guidance of applying the key Industry 4.0 technologies in world leading automotive institutions and industries, as well as policy makers is encouraged to show the advances of digital manufacturing.

Author Contributions: Conceptualization, L.W. and H.L.; investigation, H.L., M.S., K.C., S.D., and V.W.; writing—original draft preparation, H.L., M.S., and K.C.; writing—review and editing, L.W. and S.D.; visualization, H.L.; supervision, L.W. All authors have read and agreed to the published version of the manuscript.

Funding: This research received no external funding.

Data Availability Statement: Not applicable.

Acknowledgments: This research was supported by the China Scholarship Council (Grant CSC No. 201906050181): A

non-profit institution enabling talented Chinese students to undertake a PhD programme overseas.

Conflicts of Interest: The authors declare no conflict of interest.

References

- Awasthi A. ; Saxena K.K. ; Arun V . Sustainable and smart metal forming manufacturing process. Materials Today. Proceedings, 2021, 44, Part 1: 2069-2079. DOI: https://doi.org/10.1016/j.matpr.2020.12.177

- Cao J. ; Banu M . Opportunities and challenges in metal forming for lightweighting: review and future work. Journal of Manufacturing Science and Engineering, 2020, 142(11): 110813. DOI: https://doi.org/10.1115/1.4047732

- Cullen J.M. ; Allwood J.M. ; Bambach M .D. Mapping the global flow of steel: from steelmaking to end-use goods. Environmental Science & Technology, 2012, 46(24): 13048-13055. DOI: https://doi.org/10.1021/es302433p

- Cullen J.M. ; Allwood J .M. Mapping the global flow of aluminum: from liquid aluminum to end-use goods. Environmental Science & Technology, 2013, 47(7): 3057-3064. DOI: https://doi.org/10.1021/es304256s

- El Fakir O. ; Wang L.L. ; Balint D. ; et al . Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754. International Journal of Machine Tools and Manufacture, 2014, 87: 39-48. DOI: https://doi.org/10.1016/j.ijmachtools.2014.07.008

- Zheng K.L. ; Dong Y.C. ; Zheng J.H. ; et al . The effect of hot form quench (HFQ®) conditions on precipitation and mechanical properties of aluminium alloys. Materials Science and Engineering: A, 2019, 761: 138017. DOI: https://doi.org/10.1016/j.msea.2019.06.027

- Zhang Q.L. ; Luan X. ; Dhawan S. ; et al . Development of the post-form strength prediction model for a high-strength 6xxx aluminium alloy with pre-existing precipitates and residual dislocations. International Journal of Plasticity, 2019, 119: 230-248. DOI: https://doi.org/10.1016/j.ijplas.2019.03.013

- Sun Y.H. ; Wang K.H. ; Politis D.J. ; et al . An experimental investigation on the ductility and post-form strength of a martensitic steel in a novel warm stamping process. Journal of Materials Processing Technology, 2020, 275: 116387. DOI: https://doi.org/10.1016/j.jmatprotec.2019.116387

- Liu X.C. ; Di B.Z. ; Yu X.N. ; et al . Development of a formability prediction model for aluminium sandwich panels with polymer core. Materials, 2022, 15(12): 4140. DOI: https://doi.org/10.3390/ma15124140

- Ma G.J. ; Wang L.L. ; Gao H.X. ; et al . The friction coefficient evolution of a TiN coated contact during sliding wear. Applied Surface Science, 2015, 345: 109-115. DOI: https://doi.org/10.1016/j.apsusc.2015.03.156

- Elmkhah H. ; Mahboubi F. ; Abdollah-zadeh A. ; et al . A new approach to improve the surface properties of H13 steel for metal forming applications by applying the TiAlN multi-layer coating. Journal of Manufacturing Processes, 2018, 32: 873-877. DOI: https://doi.org/10.1016/j.jmapro.2018.04.010

- Lugscheider E. ; Bobzin K. ; Piñero C. ; et al . Development of a superlattice (Ti,Hf,Cr)N coating for cold metal forming applications. Surface and Coatings Technology, 2004, 177/178: 616-622. DOI: https://doi.org/10.1016/S0257-8972(03)00935-6

- Wang L.L. ; Zhou J. ; Duszczyk J. ; et al . Friction in aluminium extrusion—part 1: a review of friction testing techniques for aluminium extrusion. Tribology International, 2012, 56: 89-98. DOI: https://doi.org/10.1016/j.triboint.2012.01.012

- Wang L.L. ; Yang H .L. Friction in aluminium extrusion—part 2: a review of friction models for aluminium extrusion. Tribology International, 2012, 56: 99-106. DOI: https://doi.org/10.1016/j.triboint.2012.06.006

- Yang X. ; Liu X.C. ; Liu H. ; et al . Experimental and modelling study of friction evolution and lubricant breakdown behaviour under varying contact conditions in warm aluminium forming processes. Tribology International, 2021, 158: 106934. DOI: https://doi.org/10.1016/j.triboint.2021.106934

- Liu H.L. ; Yang X. ; Zheng Y. ; et al . Experimental study on galling behavior in aluminum stamping processes. Physical Sciences Forum, 2022, 4(1): 10. DOI: https://doi.org/10.3390/psf2022004010

- Hu Y. ; Wang L. ; Politis D.J. ; et al . Development of an interactive friction model for the prediction of lubricant breakdown behaviour during sliding wear. Tribology International, 2017, 110: 370-377. DOI: https://doi.org/10.1016/j.triboint.2016.11.005

- Hu Y.R. ; Yuan X. ; Ma G.J. ; et al . Tool-life prediction under multi-cycle loading during metal forming: a feasibility study. Manufacturing Review, 2015, 2: 28. DOI: https://doi.org/10.1051/mfreview/2015031

- Li Z.X. ; Rezaei S. ; Wang T. ; et al . Recent advances and trends in roll bonding process and bonding model: a review. Chinese Journal of Aeronautics, 2022, in press. DOI: https://doi.org/10.1016/j.cja.2022.07.004

- Bai C.G. ; Dallasega P. ; Orzes G. ; et al . Industry 4.0 technologies assessment: a sustainability perspective. International Journal of Production Economics, 2020, 229: 107776. DOI: https://doi.org/10.1016/j.ijpe.2020.107776

- Ibarra D. ; Ganzarain J. ; Igartua J .I. Business model innovation through industry 4.0: a review. Procedia Manufacturing, 2018, 22: 4-10. DOI: https://doi.org/10.1016/j.promfg.2018.03.002

- Xu H.S. ; Yu W. ; Griffith D. ; et al . A survey on industrial internet of things: a cyber-physical systems perspective. IEEE Access, 2018, 6: 78238-78259. DOI: https://doi.org/10.1109/ACCESS.2018.2884906

- Majeed A. ; Zhang Y.F. ; Ren S. ; et al . A big data-driven framework for sustainable and smart additive manufacturing. Robotics and Computer-integrated Manufacturing, 2021, 67: 102026. DOI: https://doi.org/10.1016/j.rcim.2020.102026

- Wilson, G. PwC: digital factories shaping the future of manufacturing. Available Online: https://manufacturingdigital.com/technology/pwc-digital-factories-shaping-future-manufacturing (Accessed on 23 September 2022).

- Leitão P. ; Colombo A.W. ; Karnouskos S . Industrial automation based on cyber-physical systems technologies: prototype implementations and challenges. Computers in Industry, 2016, 81: 11-25. DOI: https://doi.org/10.1016/j.compind.2015.08.004

- Gupta N. ; Tiwari A. ; Bukkapatnam S .T.S.; et al. Additive manufacturing cyber-physical system: supply chain cybersecurity and risks. IEEE Access, 2020, 8: 47322-47333. DOI: https://doi.org/10.1109/ACCESS.2020.2978815

- Chen B. ; Chang J .Y.J. Dynamic analysis of intelligent coil leveling machine for cyber-physical systems implementation. Procedia CIRP, 2017, 63: 390-395. DOI: https://doi.org/10.1016/j.procir.2017.03.115

- Sun J. ; Peng W. ; Ding J.G. ; et al . Key intelligent technology of steel strip production through process. Metals, 2018, 8(8): 597. DOI: https://doi.org/10.3390/met8080597

- Lee J. ; Noh S.D. ; Kim H.J. ; et al . Implementation of cyber-physical production systems for quality prediction and operation control in metal casting. Sensors, 2018, 18(5): 1428. DOI: https://doi.org/10.3390/s18051428

- Gan L. ; Huang H.H. ; Li L. ; et al . IoT-enabled energy efficiency monitoring and analysis method for energy saving in sheet metal forming workshop. Journal of Central South University, 2022, 29(1): 239-258. DOI: https://doi.org/10.1007/s11771-022-4933-9

- Witkowski K . Internet of things, big data, industry 4.0—innovative solutions in logistics and supply chains managemen. Procedia Engineering, 2017, 182: 763-769. DOI: https://doi.org/10.1016/j.proeng.2017.03.197

- Ralph B.J. ; Sorger M. ; Hartl K. ; et al . Transformation of a rolling mill aggregate to a cyber physical production system: from sensor retrofitting to machine learning. Journal of Intelligent Manufacturing, 2022, 33(2): 493-518. DOI: https://doi.org/10.1007/s10845-021-01856-2

- Wang L. ; Zhu B. ; Liu Y. ; et al . Design and application of CPS for hot stamping based on cloud computing. Advanced High Strength Steel and Press Hardening, Proceedings of the 5th International Conference (ICHSU2020), Shanghai, China: ICHUS, 2021: 423-429.

- Oruganti S.K. ; Khosla A. ; Thundat T .G. Wireless power-data transmission for industrial internet of things: simulations and experiments. IEEE Accesss, 2020, 8: 187965-187974. DOI: https://doi.org/10.1109/ACCESS.2020.3030658

- PwC . Annual manufacturing report 2020. Available Online: https://www.pwc.co.uk/industries/manufacturing/insights/annual-manufacturing-report.html (Accessed on 23 September 2022).

- Sisinni E. ; Saifullah A. ; Han S. ; et al . Industrial internet of things: challenges, opportunities, and directions. IEEE Transactions on Industrial Informatics, 2018, 14(11): 4724-4734. DOI: https://doi.org/10.1109/TII.2018.2852491

- Yang M . Sensing technologies for metal forming. Sensors and Materials, 2019, 31(10): 3121-3128. DOI: https://doi.org/10.18494/SAM.2019.2399

- Suresh A. ; Udendhran R. ; Yamini G . Internet of things and additive manufacturing: toward intelligent production systems in industry 4.0. Kanagachidambaresan, G.; Anand, R.; Balasubramanian, E.; et al. Internet of things for industry 4.0: designchallenges and solutions. Cham: Springer, 2020: 73-89. DOI: https://doi.org/10.1007/978-3-030-32530-5_5

- Mahayotsanun N. ; Sah S. ; Cao J. ; et al . Tooling-integrated sensing systems for stamping process monitoring. International Journal of Machine Tools & Manufacture, 2009, 49(7/8): 634-644. DOI: https://doi.org/10.1016/j.ijmachtools.2009.01.009

- Groche P. ; Brenneis M . Manufacturing and use of novel sensoric fasteners for monitoring forming processes. Measurement, 2014, 53: 136-144. DOI: https://doi.org/10.1016/j.measurement.2014.03.042

- Yang M . Smart metal forming with digital process and IoT. International Journal of Lightweight Materials and Manufacture, 2018, 1(4): 207-214. DOI: https://doi.org/10.1016/j.ijlmm.2018.10.001

- Tatipala S. ; Wall J. ; Johansson C. ; et al . A hybrid data-based and model-based approach to process monitoring and control in sheet metal forming. Processes, 2020, 8(1): 89. DOI: https://doi.org/10.3390/pr8010089

- Dilberoglu U.M. ; Gharehpapagh B. ; Yaman U. ; et al . The role of additive manufacturing in the era of industry 4.0. Procedia Manufacturing, 2017, 11: 545-554. DOI: https://doi.org/10.1016/j.promfg.2017.07.148

- Ashima R. ; Haleem B. ; Bahl S. ; et al . Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Materials Today: Proceedings, 2021, 45(6): 5081-5088. DOI: https://doi.org/10.1016/j.matpr.2021.01.583

- Kawamoto K. ; Ando H. ; Yamamichi K . Application of servo presses to metal forming processes. Procedia Manufacturing, 2018, 15: 31-38. DOI: https://doi.org/10.1016/j.promfg.2018.07.166

- Chen E.H. ; Cao H.J. ; He Q.Y. ; et al . An IoT based framework for energy monitoring and analysis of die casting workshop. Procedia CIRP, 2019, 80: 693-698. DOI: https://doi.org/10.1016/j.procir.2018.12.002

- Gan L. ; Li L. ; Huang H .H. Digital twin-driven sheet metal forming: modeling and application for stamping considering mold wear. Journal of Manufacturing Science and Engineering, 2022, 144(12): 121003. DOI: https://doi.org/10.1115/1.4054902

- Tao F. ; Zhang H. ; Liu A. ; et al . Digital twin in industry: state-of-the-art. IEEE Transactions on Industrial Informatics, 2019, 15(4): 2405-2415. DOI: https://doi.org/10.1109/TII.2018.2873186

- Uhlemann T .H.J.; Lehmann C.; Steinhilper R. The digital twin: realizing the cyber-physical production system for industry 4.0. Procedia CIRP, 2017, 61: 335-340. DOI: https://doi.org/10.1016/j.procir.2016.11.152

- Tao F. ; Qi Q .L. Make more digital twins. Nature, 2019, 573(7775): 490-491. DOI: https://doi.org/10.1038/d41586-019-02849-1

- Söderberg R. ; Wärmefjord K. ; Carlson J.S. ; et al . Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Annals, 2017, 66(1): 137-140. DOI: https://doi.org/10.1016/j.cirp.2017.04.038

- Moreno A. ; Velez G. ; Ardanza A. ; et al . Virtualisation process of a sheet metal punching machine within the industry 4.0 vision. International Journal on Interactive Design and Manufacturing (IJIDeM), 2017, 11(2): 365-373. DOI: https://doi.org/10.1007/s12008-016-0319-2

- Ralph B.J. ; Schwarz A. ; Stockinger M . An implementation approach for an academic learning factory for the metal forming industry with special focus on digital twins and finite element analysis. Procedia Manufacturing, 2020, 45: 253-258. DOI: https://doi.org/10.1016/j.promfg.2020.04.103

- Gaikwad A. ; Yavari R. ; Montazeri M. ; et al . Toward the digital twin of additive manufacturing: integrating thermal simulations, sensing, and analytics to detect process faults. IISE Transactions, 2020, 52(11): 1204-1217. DOI: https://doi.org/10.1080/24725854.2019.1701753

- Gunasegaram D.R. ; Murphy A.B. ; Matthews M.J. ; et al . The case for digital twins in metal additive manufacturing. JPhys Materials, 2021, 4(4): 040401. DOI: https://doi.org/10.1088/2515-7639/ac09fb

- Stavropoulos P. ; Papacharalampopoulos A. ; Michail C.K. ; et al . Robust additive manufacturing performance through a control oriented digital twin. Metals, 2021, 11(5): 708. DOI: https://doi.org/10.3390/met11050708

- Phua A. ; Davies C .H.J.; Delaney G.W. A digital twin hierarchy for metal additive manufacturing. Computers in Industry, 2022, 140: 103667. DOI: https://doi.org/10.1016/j.compind.2022.103667

- Liu C. ; Roux L.L. ; Körner C. ; et al . Digital twin-enabled collaborative data management for metal additive manufacturing systems. Journal of Manufacturing Systems, 2022, 62: 857-874. DOI: https://doi.org/10.1016/j.jmsy.2020.05.010

- Mandolla C. ; Petruzzelli A.M. ; Percoco G. ; et al . Building a digital twin for additive manufacturing through the exploitation of blockchain: a case analysis of the aircraft industry. Computers in Industry, 2019, 109: 134-152. DOI: https://doi.org/10.1016/j.compind.2019.04.011

- Everton S.K. ; Hirsch M. ; Stravroulakis P. ; et al . Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Materials & Design, 2016, 95: 431-445. DOI: https://doi.org/10.1016/j.matdes.2016.01.099

- Mukherjee T. ; DebRoy T . A digital twin for rapid qualification of 3D printed metallic components. Applied Materials Today, 2019, 14: 59-65. DOI: https://doi.org/10.1016/j.apmt.2018.11.003

- Yao B. ; Imani F. ; Yang H . Markov decision process for image-guided additive manufacturing. IEEE Robotics and Automation Letters, 2018, 3(4): 2792-2798. DOI: https://doi.org/10.1109/LRA.2018.2839973

- Son Y.H. ; Park K.T. ; Lee D. ; et al . Digital twin–based cyber-physical system for automotive body production lines. The International Journal of Advanced Manufacturing Technology, 2021, 115(1): 291-310. DOI: https://doi.org/10.1007/s00170-021-07183-3

- Zhong R.Y. ; Newman S.T. ; Huang G.Q. ; et al . Big data for supply chain management in the service and manufacturing sectors: challenges, opportunities, and future perspectives. Computers & Industrial Engineering, 2016, 101: 572-591. DOI: https://doi.org/10.1016/j.cie.2016.07.013

- Wilkinson M.D. ; Dumontier M. ; Aalbersberg I .J.J.; et al. The FAIR guiding principles for scientific data management and stewardship. Scientific Data, 2016, 3: 160018.

- Fortune Business Insights. Big data in manufacturing industry size, share & industry analysis, by offering (solution and services), by development (on premise, cloud-based and hybrid), by application (customer analytics, quality assessment, supply chain management, production management, and others) and regional forecast . Available Online: https://www.fortunebusinessinsights.com/big-data-in-manufacturing-industry-102366 (Accessed on 23 September 2022).

- Cao J. ; Brinksmeier E. ; Fu M.W. ; et al . Manufacturing of advanced smart tooling for metal forming. CIRP Annals, 2019, 68(2): 605-628. DOI: https://doi.org/10.1016/j.cirp.2019.05.001

- Bonatti C. ; Mohr D . One for all: universal material model based on minimal state-space neural networks. Science Advances, 2021, 7(26): eabf3658. DOI: https://doi.org/10.1126/sciadv.abf3658

- Feng S. ; Zhou H.Y. ; Dong H .B. Using deep neural network with small dataset to predict material defects. Materials & Design, 2019, 162: 300-310. DOI: https://doi.org/10.1016/j.matdes.2018.11.060

- Bustillo A. ; Pimenov D.Y. ; Mia M. ; et al . Machine-learning for automatic prediction of flatness deviation considering the wear of the face mill teeth. Journal of Intelligent Manufacturing, 2021, 32(3): 895-912. DOI: https://doi.org/10.1007/s10845-020-01645-3

- Li X. ; Jia X.D. ; Yang Q.B. ; et al . Quality analysis in metal additive manufacturing with deep learning. Journal of Intelligent Manufacturing, 2020, 31(8): 2003-2017. DOI: https://doi.org/10.1007/s10845-020-01549-2

- Kusiak A . Smart manufacturing must embrace big data. Nature, 2017, 544(7648): 23-25. DOI: https://doi.org/10.1038/544023a

- Kang H.S. ; Lee J.Y. ; Choi S.S. ; et al . Smart manufacturing: past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing-Green Technology, 2016, 3(1): 111-128. DOI: https://doi.org/10.1007/s40684-016-0015-5

- Wang A.L. ; Liu J. ; Gao H.X. ; et al . Hot stamping of AA6082 tailor welded blanks: experiments and knowledge-based cloud–finite element (KBC-FE) simulation. Journal of Materials Processing Technology, 2017, 250: 228-238. DOI: https://doi.org/10.1016/j.jmatprotec.2017.07.025

- Zhu M.Q. ; Lim Y.C. ; Cai Z.J. ; et al . Cloud FEA of hot stamping processes using a software agnostic platform. The International Journal of Advanced Manufacturing Technology, 2021, 112(11): 3445-3458. DOI: https://doi.org/10.1007/s00170-020-06533-x

- Wang K.H. ; Kopec M. ; Chang S.P. ; et al . Enhanced formability and forming efficiency for two-phase Titanium alloys by Fast light Alloys Stamping Technology (FAST) Materials & Design, 2020, 194: 108948. DOI: https://doi.org/10.1016/j.matdes.2020.108948

- Alsamhan A. ; Ragab A.E. ; Dabwan A. ; et al . Prediction of formation force during single-point incremental sheet metal forming using artificial intelligence techniques. PLoS One, 2019, 14(8): e0221341. DOI: https://doi.org/10.1371/journal.pone.0221341

- Kubik C. ; Knauer S.M. ; Groche P . Smart sheet metal forming: importance of data acquisition, preprocessing and transformation on the performance of a multiclass support vector machine for predicting wear states during blanking. Journal of Intelligent Manufacturing, 2022, 33(1): 259-282. DOI: https://doi.org/10.1007/s10845-021-01789-w

- Merayo D. ; Rodríguez-Prieto A. ; Camacho A . M. Topological optimization of artificial neural networks to estimate mechanical properties in metal forming using machine learning. Metals, 2021, 11(8): 1289. DOI: https://doi.org/10.3390/met11081289

- Li W. ; Zhang L.C. ; Chen X.P. ; et al . Predicting the evolution of sheet metal surface scratching by the technique of artificial intelligence. The International Journal of Advanced Manufacturing Technology, 2021, 112(3): 853-865. DOI: https://doi.org/10.1007/s00170-020-06394-4

- Taherkhani A. ; Basti A. ; Nariman-Zadeh N. ; et al . Achieving maximum dimensional accuracy and surface quality at the shortest possible time in single-point incremental forming via multi-objective optimization. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2019, 233(3): 900-913. DOI: https://doi.org/10.1177/0954405418755822

- Ambrogio G. ; Filice L. ; Guerriero F. ; et al . Prediction of incremental sheet forming process performance by using a neural network approach. The International Journal of Advanced Manufacturing Technology, 2011, 54(9): 921-930. DOI: https://doi.org/10.1007/s00170-010-3011-x

- Liu S.M. ; Xia Y.F. ; Liu Y.H. ; et al . Tool path planning of consecutive free-form sheet metal stamping with deep learning. Journal of Materials Processing Technology, 2022, 303: 117530. DOI: https://doi.org/10.1016/j.jmatprotec.2022.117530

- Opritescu D. ; Volk W . Automated driving for individualized sheet metal part production—A neural network approach. Robotics and Computer-Integrated Manufacturing, 2015, 35: 144-150. DOI: https://doi.org/10.1016/j.rcim.2015.03.006

- Chan W.L. ; Fu M.W. ; Lu J . An integrated FEM and ANN methodology for metal-formed product design. Engineering Applications of Artificial Intelligence, 2008, 21(8): 1170-1181. DOI: https://doi.org/10.1016/j.engappai.2008.04.001

- Pilani R. ; Narasimhan K. ; Maiti S.K. ; et al . A hybrid intelligent systems approach for die design in sheet metal forming. The International Journal of Advanced Manufacturing Technology, 2000, 16(5): 370-375. DOI: https://doi.org/10.1007/s001700050168

- Zhang M. ; Sun C.N. ; Zhang X. ; et al . High cycle fatigue life prediction of laser additive manufactured stainless steel: a machine learning approach. International Journal of Fatigue, 2019, 128: 105194. DOI: https://doi.org/10.1016/j.ijfatigue.2019.105194

- Zhou H.S. ; Xu Q.F. ; Nie Z.G. ; et al . A study on using image-based machine learning methods to develop surrogate models of stamp forming simulations. Journal of Manufacturing Science and Engineering, 2022, 144(2): 021012. DOI: https://doi.org/10.1115/1.4051604

- Yang X. ; Liu H.L. ; Dhawan S. ; et al . Digitally-enhanced lubricant evaluation scheme for hot stamping applications. Nature Communications, 2022, 13(1): 5748. DOI: https://doi.org/10.1038/s41467-022-33532-1

- Dillon T. ; Wu C. ; Chang E . Cloud computing: issues and challenges. 2010 24th IEEE International Conference on Advanced Information Networking and Applications, Perth, WA, Australia: IEEE, 2010: 27-33. DOI: https://doi.org/10.1109/AINA.2010.187

- Helo P. ; Phuong D. ; Hao Y . Cloud manufacturing – scheduling as a service for sheet metal manufacturing. Computers & Operations Research, 2019, 110: 208-219. DOI: https://doi.org/10.1016/j.cor.2018.06.002

- Paniti I . Adaptation of incremental sheet forming into cloud manufacturing. CIRP Journal of Manufacturing Science and Technology, 2014, 7(3): 185-190. DOI: https://doi.org/10.1016/j.cirpj.2014.04.003

- Kao Y.C. ; Liu Y.P. ; Wei C.L. ; et al . Application of a cyber-physical system and machine-to-machine communication for metal processes. 2018 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Houston, TX, USA: IEEE, 2018: 1-6. DOI: https://doi.org/10.1109/I2MTC.2018.8409810

- Dhawan S . Development of a cloud FEA platform for advanced FE simulations of metal forming processes. (Imperial College London, 2022).

- Wang A.L. ; El Fakir O. ; Liu J. ; et al . Multi-objective finite element simulations of a sheet metal-forming process via a cloud-based platform. The International Journal of Advanced Manufacturing Technology, 2019, 100(9): 2753-2765. DOI: https://doi.org/10.1007/s00170-018-2877-x

- Wang A.L. ; Zheng Y. ; Liu J. ; et al . Knowledge based cloud FE simulation–data-driven material characterization guidelines for the hot stamping of aluminium alloys. Journal of Physics: Conference Series, 2016, 734: 032042. DOI: https://doi.org/10.1088/1742-6596/734/3/032042

- Yang, Lubricant X. 4.0: Digitally enhanced lubricant development for metal forming applications. (Imperial College London, 2021.

- Luan X. ; Zhang Q.L. ; Fakir O.E. ; et al . Uni-Form: a pilot production line for hot/warm sheet metal forming integrated in a cloud based SMARTFORMING platform. Zhang, Y.S.; Ma, M.T. Advanced high strength steel and press hardening. Singapore: World Scientific, 2016: 492-497. DOI: https://doi.org/10.1142/9789813207301_0067

- Fakir O. ; Wang A. ; Zhang Q. ; et al . Multi-objective sheet metal forming simulations using a software agnostic platform. IOP Conference Series: Materials Science and Engineering, 2018, 418: 012122. DOI: https://doi.org/10.1088/1757-899X/418/1/012122

- Jain N. ; Choudhary S . Overview of virtualization in cloud computing. 2016 Symposium on Colossal Data Analysis and Networking (CDAN), Indore, India: IEEE, 2016: 1-4. DOI: https://doi.org/10.1109/CDAN.2016.7570950

- Fuller A. ; Fan Z. ; Day C. ; et al . Digital twin: enabling technologies, challenges and open research. IEEE Access, 2020, 8: 108952-108971. DOI: https://doi.org/10.1109/ACCESS.2020.2998358

- Hagenah H. ; Schulte R. ; Vogel M. ; et al . 4.0 in metal forming–questions and challenges. Procedia CIRP, 2019, 79: 649-654. DOI: https://doi.org/10.1016/j.procir.2019.02.055