Downloads

Download

This work is licensed under a Creative Commons Attribution 4.0 International License.

Review

Reconfigurability in Automobiles—Structure, Manufacturing and Algorithm for Automobiles

Zheming Zhuang 1, Yuntao Guan 1, Shuangjia Xu 2,4, and Jian S. Dai 3,4, *

1 Key Laboratory of Mechanism Theory and Equipment Design of the Ministry of Education, Centre for Advanced Mechanisms and Robotics, Tianjin University, Tianjin, 300072, China; zhuangzheming@tju.edu.cn (Z.Z.); guanyuntao_018@tju.edu.cn (Y.G.)

2 DH Robotics Ltd, Shenzhen, China; Shuangjia.xu@dh-robotics.com

3 Institute for Robotics, Southern University of Science and Technology, Shenzhen, China

4 Centre for Robotics Research, King’s College London, London, UK

* Correspondence: jian.dai@kcl.ac.uk

Received: 9 November 2022

Accepted: 10 November 2022

Published: 18 December 2022

Abstract: For the automobile design and manufacturing, as a typical representative of the industry, the development and upgrading represent the application of the state-of-the-art technology in the industry. With a period of development, the related technology of traditional manufacturing factories for automobiles are found with some common issues while improving. As such, the reconfigurable intelligent manufacturing factory of the automobiles is fast developed with focus on reconfigurability in structures, manufactures and algorithms, thus advancing the level of the reconfigurable intelligent manufacturing continuously. With a sufficient reconfigurable manufacturing technology as the basis, reconfigurability can be better introduced to the structure design and the driving algorithms of the automobiles. Reconfigurability provides a new bridge for transforming the traditional automobile to the reconfigurable automobile, and a new driving force for the upgrading of the reconfigurable driving algorithms.

Keywords:

reconfigurability automobile structure manufacturing factory algorithm1.Introduction

With the rapid development of industrial technology, manufacturing enterprises are entering a critical period of transformation and upgrading. For the original industrial model, it is urgent to solve some core problems like the long production cycle, high labor cost and large production pollution [1,2]. If these problems can be solved effectively, the enterprises will become more adaptable to change of the market environment, thus seizing the opportunity for a new round of the industrial transformation and leap.

The development scale and technological level of automobile manufacturing industry is an important symbol of a comprehensive national strength for a country. This industry involves cross amalgamation of several fields like machinery, materials, logistics, management etc., as one of the first industries that introduce robotics into the manufacturing process [3–7]. In the field of automobile manufacturing, traditional labor-intensive industries are being replaced by technology-intensive industries gradually. Thus, the construction of intelligent manufacturing factories relying on automated production will become the mainstream, and the robots will become more and more important in relevant production activities [2–4,7], meaning that optimization of robot’s performance is the key to improvement of production efficiency.

The technology upgrade will bring intelligent manufacturing factories with sufficient production capacity [1,2,5], sophisticated assembly [3,7] and flexible switching [1,4,6]. With the support of the above advantages, it will better promote the upgrading and reform of the automobile industry. Traditional automobile design and driving algorithms do not get rid of the limitations of traditional automobile structure and size, but reconfigurable theory can develop the structure of traditional automobile, and can promote the creation of innovative driving algorithms. This allows automobiles to be produced more efficiently and driven more freely, providing better driving experience and improving the quality of the automotive industry’s service to humanity on all fronts.

2.Reconfigurable Structure for Automobiles

The intelligent manufacturing factory may own an ability to manufacture complex automobile structures through introducing reconfigurable theory. As one of the most important structures for automobile, chassis determines the motor performance and user experience of automobile [8,9]. Scholars and engineers have paid attention to the structural design of chassis for many years. However, limited by the overall structure of automobile [10], the chassis may influence the automobile performance greatly for even a small change [8,11], and so, it is very difficult to modify the chassis [12]. At present, the structure of automobile chassis is relatively uniform [9,12,13], that is, for the chassis, there are few breakthrough innovations and the manufacturing mode is relatively simple. Due to the simplified structure of chassis, the advantages of intelligent manufacturing factory cannot be maximized, and the environment for use of automobiles has been limited. Currently, most commercially available cars can only be driven on wide and flat roads. However, the concept of amphibious automobile has been proposed and applied in real life since 1920s [14]. In 1961, the world's first mass produced amphibious automobile was marketed. Based on a chassis equipped with a variety of drives, the amphibious automobile owned complete functions, but its performance at work was not so stable, and thus, it failed to gain the trust of consumers due to poor safety. This amphibious automobile was eventually eliminated by the market, for only 4000 units were sold in the 7 years after launch [15]. In the following decades, the value of amphibious automobile in the military field was gradually developed, and globally, several military powers carried out studies on amphibious automobile successively. They developed various powerful amphibious automobiles, e.g., WaterCar Panther and Dobbertin Hydrocar, but their moving speed was slow [16] for heavy chassis [15,16]. Also, it was very difficult to maintain the amphibious automobiles due to their complex chassis structures [16]. The cost for research and development, manufacturing and maintenance of the amphibious automobiles was very high because they were designed for military use. Thus, they are not applicable for use in our daily life. It was not until 2004 that an amphibious automobile tore across the English Channel in 100 minutes, demonstrating the application value of amphibious automobile to consumers again. Similarly, this amphibious automobile failed to be marketed due to its high production cost and low work efficiency [17,18]. By now, amphibious automobile has not been popularized in the civil field although its structure has been continuously improved and developed by scholars and engineers, and has even been well applied in the military field. There are two reasons for this:

(1) Amphibious automobile needs to adapt to various environments, and so, the requirement for its structure is very high [10,14,17].

(2) In driving, the amphibious automobile needs a computer [15–17] to guarantee the speed of movement as well as the safety of the driver.

For both reasons, there has been no new breakthrough in the development of automobile.

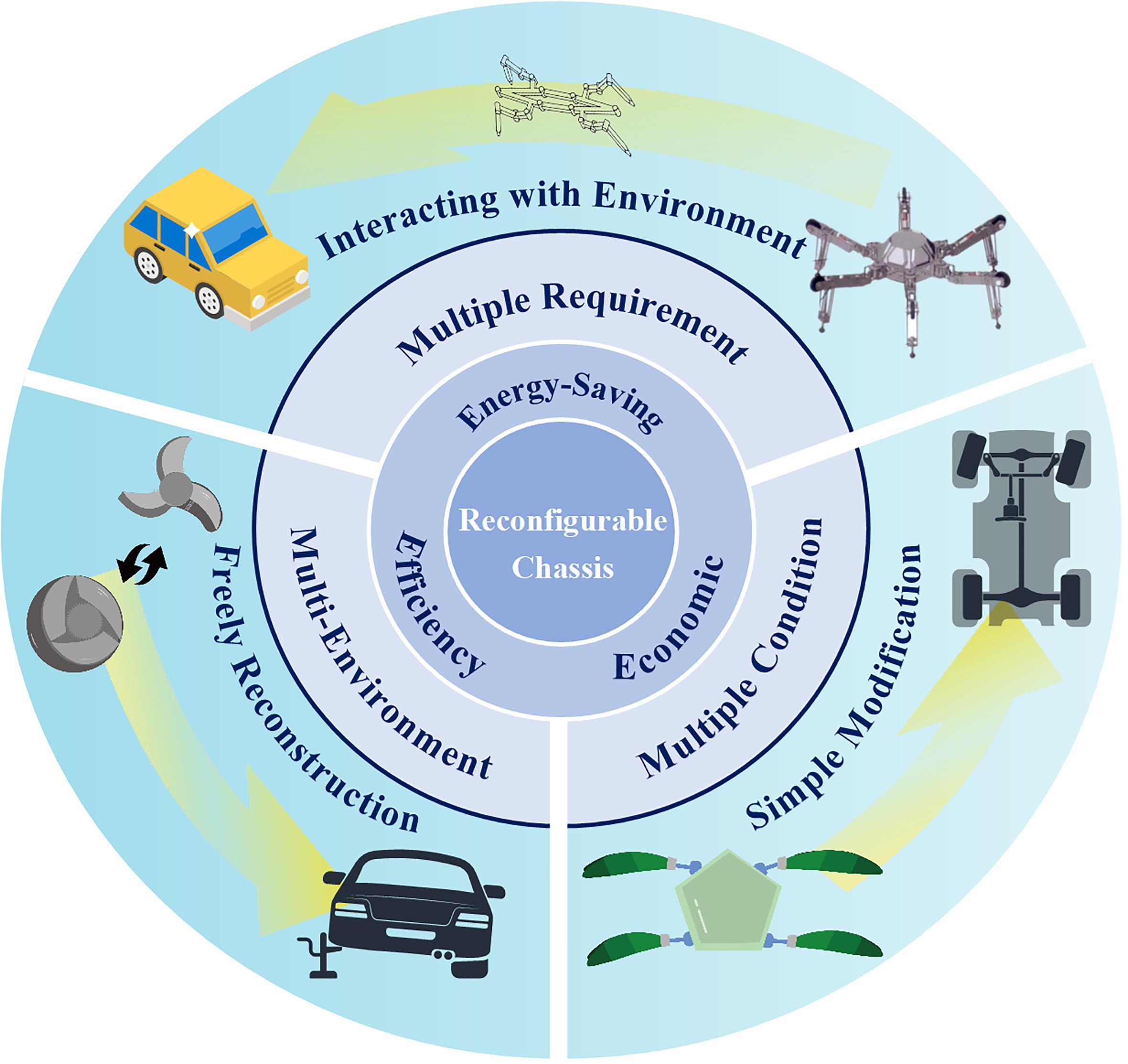

The concept of reconfigurable structure provides a new solution for the promotion of amphibious automobile, as shown in Figure 1. As a typical case, the metamorphic wheel-legs rover proposed by Dai and Ding [19] integrated the advantages of legged robot and wheeled car. In the case, a variable body structure was designed so that metamorphic rover could adapt to complex environments well, and thus, it might even be used in extreme environments like Mars. When switched to the legged form, it had a high terrain adaptability. The amphibious automobile of similar structure may move on uneven mountain roads or soft swamps smoothly [20–22], and therefore, it can assist humans in field exploration [23], rescue and disaster relief [24,25]. However, the legged form of automobile moves slowly [20,23]. Furthermore, it is difficult for the users to manipulate [21,24], and the overall motion stability is poor [20,25]. Thus, the amphibious automobile may be switched to the wheeled form on a flat surface for fast moving speed and good stability [21,23–25], and to the legged form again as driving into a complex terrain. To sum up, similar structures can be widely applied in modification of automobile chassis, allowing amphibious automobile more adaptable to complicated environments. For example, for the front of automobile, the structure may be reconfigured into different shapes [26] to reduce the resistance from a small water current or wind, thus improving the speed of movement, and saving the fuel. Energy-saving is achieved by interacting with environment. Wheels can be reconfigured into a shape like propeller [26,27] for changing the propulsion mode and adapting to an environment like underwater. Efficient work is achieved through freely reconstruction. Amphibious automobile can also be used for entertainment in daily life. For this, the requirement in speed of car is generally low, and the chassis may be designed into a reconfigurable structure like flippers of an animal [28] so that the car may move on water surface, and thus, the fun of driving may be enhanced, and possible contingencies may be handled. Cost-effective product is designed through simple modification. Overall, the reconfigurable structure has enhanced the environmental adaptability and expanded the application scenarios for automobiles, which will bring more surprises to production and life of human in the future.

Figure 1. Structures inspired by reconfigurable theory.

3.Traditional Manufacturing Factory for Automobiles

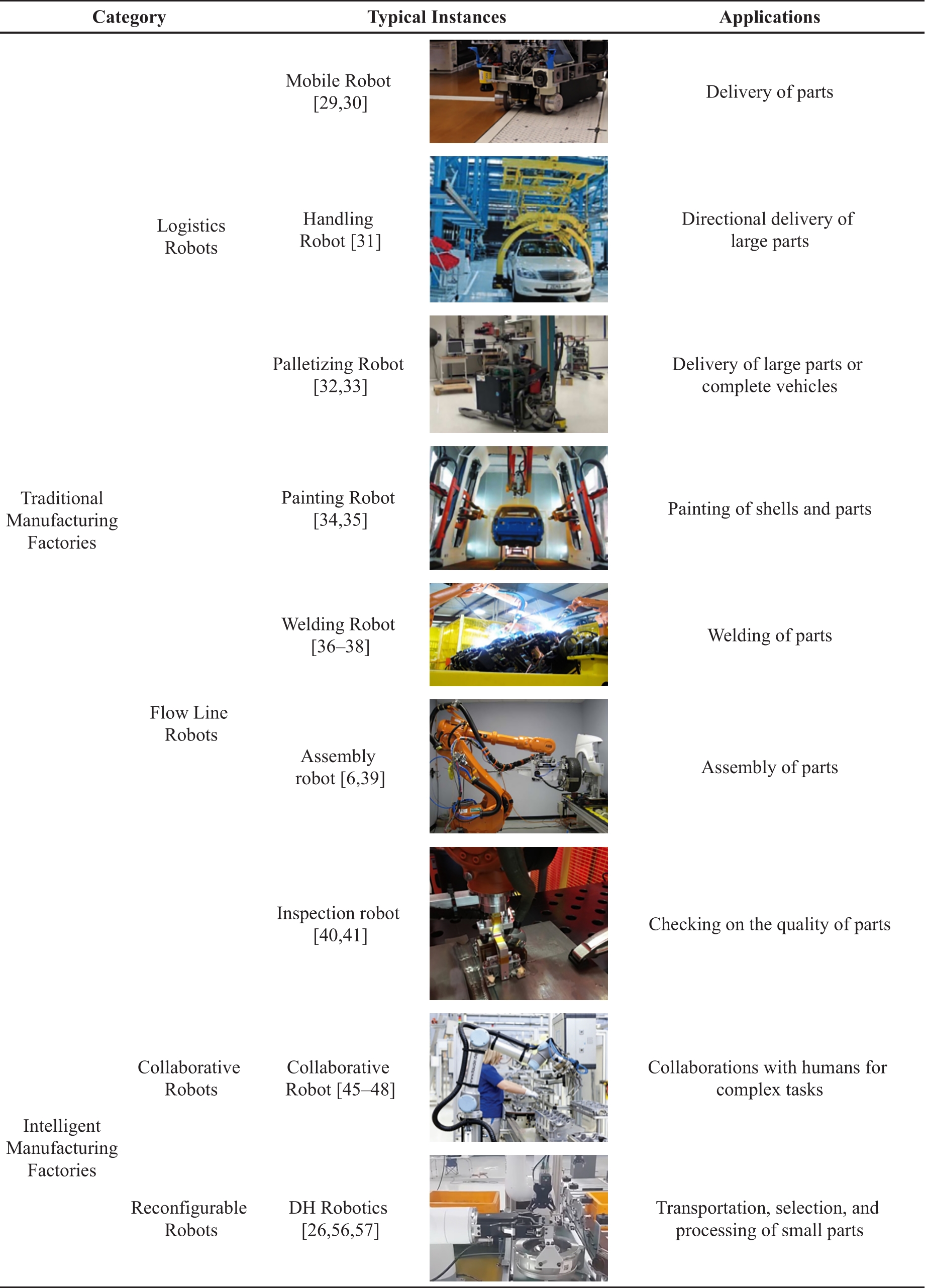

The complexity of automobile structure puts forward new requirements for automobile manufacturing factory. At present, automobile factories may be divided into traditional manufacturing factories and intelligent manufacturing factories, and the robots in traditional manufacturing factories may be divided into logistics robots and flow line robots according to the application scenarios. The logistics robots, e.g., transportation robots [29–31], palletizing robots [32,33], and etc., which are the most common almost throughout the manufacturing process of automobiles, are used for spatial orientation of auto parts. Their tasks are generally simple, and so, the requirement for precision is relatively low, but the requirements for efficiency and service life are high, especially for factories with limited production sites that often cannot establish a whole process for the production line, where logistics robots are very critical for the manufacturing process because the manufacturing process needs to be completed by crossing over production line and dispatching equipment. Flow line robots are used for the production line manufacturing process of automobiles. They play a key role in the manufacturing process as the main automobile workers from parts to final products, e.g., painting robots [34,35], welding robots [36–38], assembly robot [6,39] and inspection robot [40,41]. They are usually of large size and high precision, and also, with a high degree of automation, they are easy to operate and maintain. Meanwhile, they have a clear division of labor and fixed workstations and thus are only oriented toward a certain part of the production, lacking interaction with staffs. If one of them fails, the production schedule of the entire manufacturing factory would be affected.

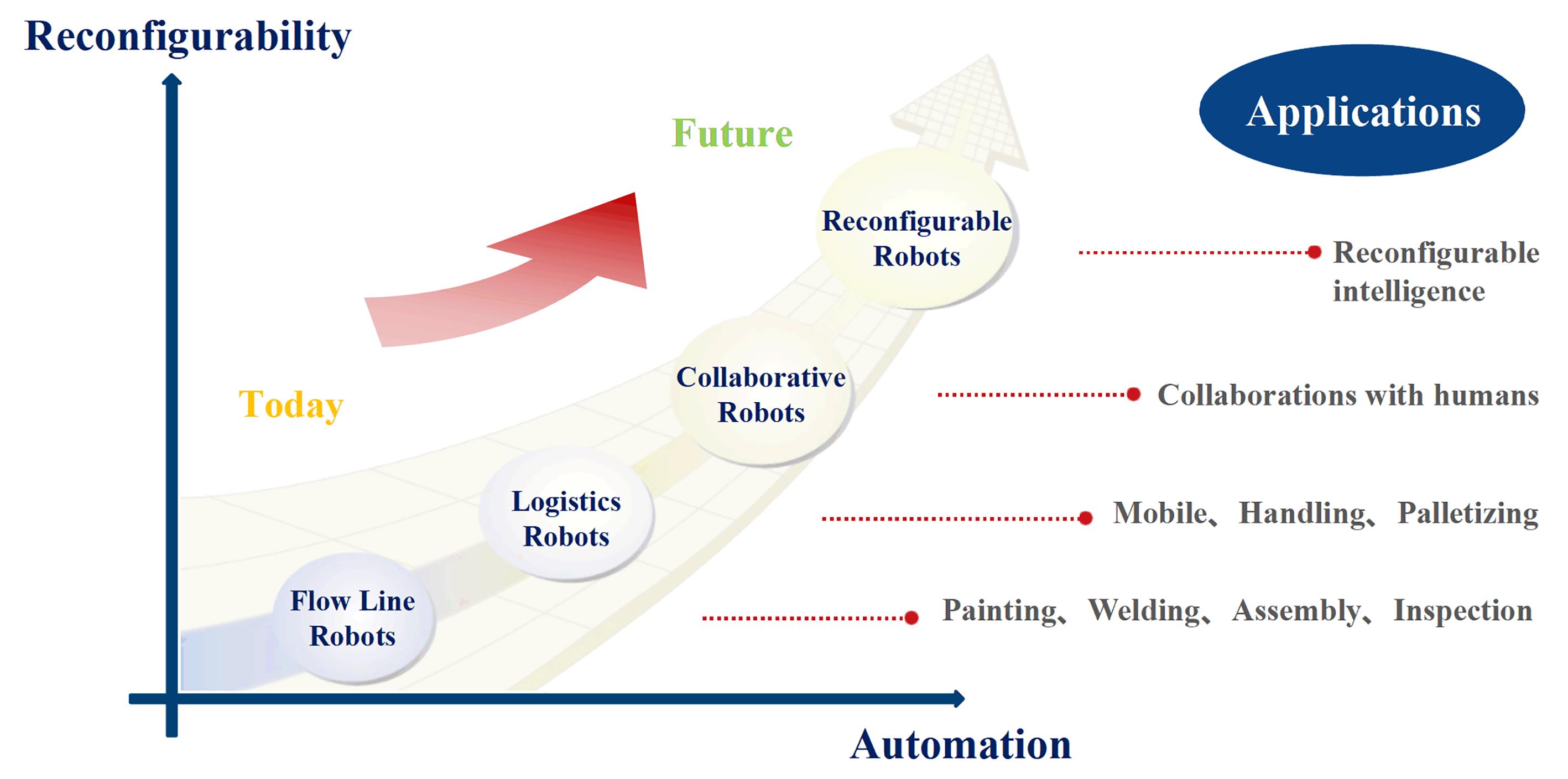

In recent years, the automobile factories have developed rapidly due to investment in robots. The robots have advanced the automation degree, reduced the production cost, and balanced the product quality for the factories. However, during the rapid growth of robots, relevant techniques for robots in automobile factories are being faced with many challenges, e.g., lack of generality [6,29,32,34,39,40], large space demand [32,35,38], high cost for investing [30,33,34,37,41] and etc., which set limitations to the benefits of the manufacturing factory and optimization and upgrade of factories’ production mode. Also, these problems could lead to the bankruptcy of automobile enterprises by causing a great impact on the capital chain during the factory optimization and upgrading phase, making classic brands vanish and staffs suffer unemployment. Therefore, the application of robots in manufacturing factory of automobiles needs more advanced solutions. The intelligent manufacturing factory of the future should not only be enabled a high level of automation, but also need to improve the versatility and coordination of robots in the factory to enhance its ability to adapt to different production needs, as shown in Figure 2. The intelligent manufacturing factory [42,43] that can realize small batch size or multi-batch production for high efficiency and flexible deployment is one of the optimal solutions for these challenges.

Figure 2. Prospect for the intelligent manufacturing factory.

4.Intelligent Manufacturing Factory for Automobiles

Intelligent manufacturing automobile factory is a new future-oriented production factory [42]. Compared to traditional manufacturing factories, it emphasizes informatization, integration, systematization, and standardization. As a large number of intelligent robots are put into use, the efficiency for production of automobiles is improved, and the production cost is lowered. Thus, it has become an important solution for upgrading traditional manufacturing factory. At present, the existing applications include cooperative robots and reconfigurable robots. The solution of cooperative robot takes human factors into account in the operation of robots, relies on both workers and robots as completing the tasks for automobile manufacturing, and combines the unique capabilities of human beings with the advantages of intelligent robots [44]. The design of cooperative robot pays more attention to the interaction with humans because with the help of humans, the robots can complete more complicated tasks and respond to unexpected situations more effectively. Generally, the cooperative robots are small in size, and so, their mobility is good, while traditional robots are mostly limited to a preconfigured path, that is, with higher flexibility and wider application range [45–47], the cooperative robots make the manufacturing process more reasonable and safer by information interaction with humans [45,48]. However, the requirements for the workers in operation technique, professional quality and related technical training are also advanced [49,50]. At the same time, intelligent manufacturing factories have reconfigurable robots with higher imagination and openness. The core of reconfigurable robot is not hardware, but platform. Compared with traditional robots of poor adjustability, tight spatial layout and high manufacturing cost, configurable robots can integrate most functions in a small number of stations. Inspired by the evolution of human beings as well as the division and reorganization of cells [51,52], reconfigurable robots allow the machine to “transform and reconfigure” according to the actual needs, realize “dynamic evolution”, flexibly adapt to the changing working environment and functional requirement, and thus realize multiple functions by one machine [53–55].

Table 1. Manufacturing factory of automobiles.

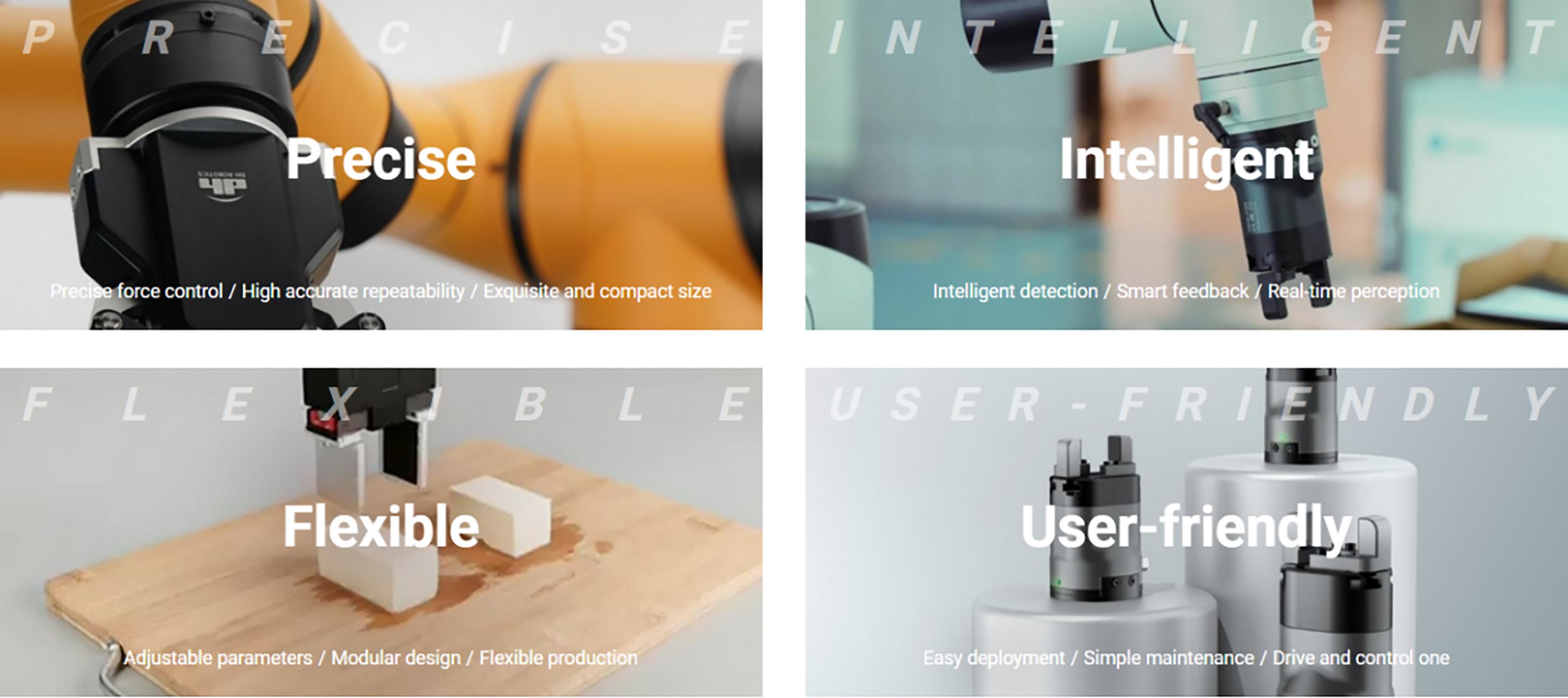

The concept of reconfigurable robot was first proposed by Dai in 1998 [51], and relevant theory has become a mainstream trend in current and future mechanics. As a typical case of application in automobile production, the robot gripper produced by DH-Robotics Company with reconfigurable mechanism as the core technology has significant advantages, e.g., compact structure, good dynamic performance, high precision in force control, simple operation, good environmental adaptability and wide application range [26,56], as shown in Figure 3. By now, it has been applied in many automobile enterprises such as BYD, FAW-Volkswagen, SAIC-Volkswagen, TOYOTA, NISSAN, Hyundai and so on [57]. Intelligent manufacturing factories with reconfigurable robots can fully meet the customers’ demand for customization, thus further adapting to larger production batch size and more frequent model change, and realizing the reconfiguration of intelligent manufacturing factory. However, the current development of application scenarios for reconfigurable robots is still to be further improved, and relevant market share is still small. Therefore, there is a large space for the research on reconfigurable robots of very high application value, which needs the active participation of scholars and engineers.

Figure 3. Core advantages of reconfigurable robots.

5.Reconfigurable Algorithm for Automobiles

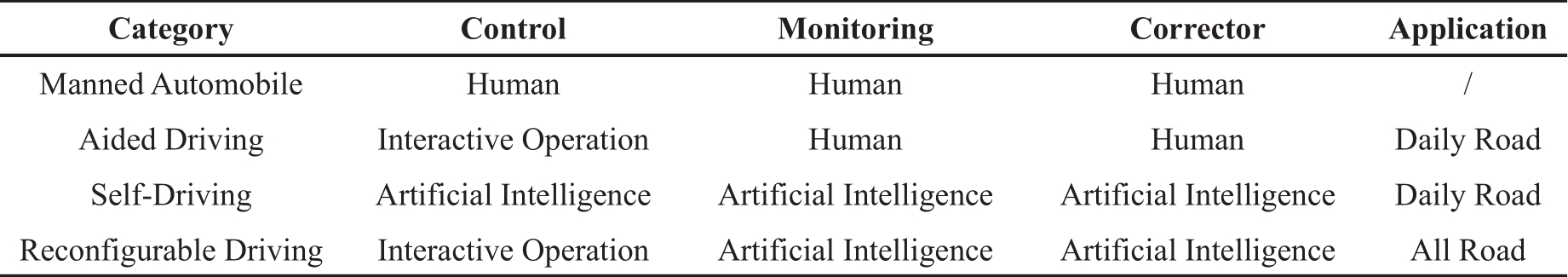

It is well known that the popularization and application of reconfigurable automobile cannot be accomplished without supporting algorithms [15–17]. With the rapid development of computer technology and the standardization of daily road design, automobile manufacturers have begun to develop intelligent automobiles, for which some progress has been made, as shown in Table 2, where aided driving automobile is the most common one. However, the algorithms for aided driving are mostly used for some basic auxiliary functions, e.g., automatic parking [58–60], cruise control [61,62], collision warning [63,64], and etc. In most cases, the drivers are still required to control the automobiles, which means there’s still a long way to free the drivers’ hands completely. Therefore, the current difficult point or hotspot is still how to realize the transformation from aided driving mode to self-driving mode and guarantee the safety and comfort of driving process. The main existing algorithms for unmanned driving include longitudinal motion control [65,66], path following [67–69] and trajectory tracking control [70–72]. However, a large-scale application of self-driving automobile is still limited by the uncertainty of driving environment, and more sensing information is to be integrated into the algorithm.

Table 2. Comparison of automobile driving algorithms.

The transformation from aided driving mode to self-driving mode is a progress. However, the transformation from aided driving mode to reconfigurable driving mode is a brand new development. The proposed reconfigurable driving mode may solve some key problems in automobile driving process. For totally different environments, e.g., gentle road surface and obstacles like steps, an algorithm is required to solve the problem that automobile structure cannot satisfy the requirements for actual conditions of roads. With the support of reconfigurable driving algorithm, the automobiles can adapt to different road environments through a change in configuration. For example, the automobile chassis can be reconfigured into a form of legs or flippers to cross a river or even venture into space [26,19–22,27]. It is even possible to reconfigure the entire automobile chassis [73,74] for true all-terrain applications, and thus, more automobile products may be developed. However, all of the above intelligent algorithms rely on the data transmission of on-board sensors to realize the interactions of human with automobile and automobile with environment. Therefore, the precision, transmission speed and cost of on-board sensors are also one of the factors influencing the reconfigurable driving [75,76].

6.Intelligent Reconfigurable Factory for Automobiles

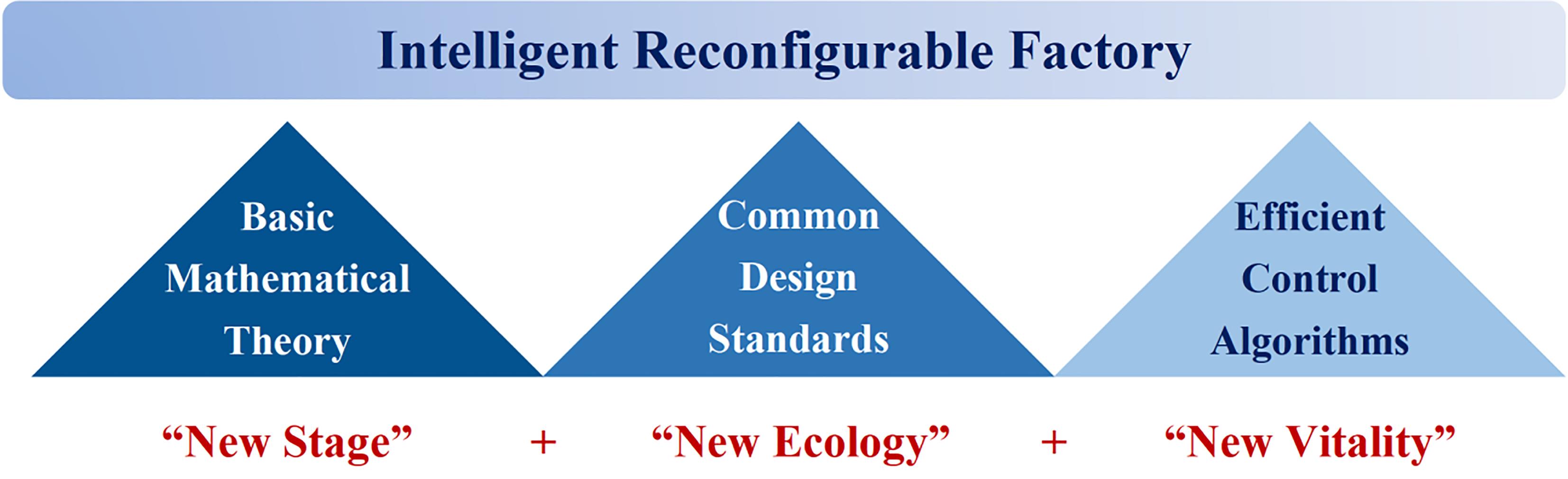

In recent years, many cases of integrating reconfigurable theory with intelligent factory of automobiles has emerged in the industry, and has also achieved initial results, and thus, the reconfigurable theory of automobiles and intelligent factory of automobiles have reached a new climax. However, technology related to intelligent reconfigurable factory still needs to be further developed, since the main obstacle at present is the lack of basic mathematical theory, common design standards and efficient control algorithms, as shown in Figure 4.

Figure 4. Technology of intelligent reconfigurable factory.

The diversification of application scenarios and customization needs has led to increasing requirements for reconfigurability and variable structure efficiency of automobile structure and robots in the factory. While control and mathematical theory are closely related, the research of reconfigurable automobile structure and robots needs to adopt the cutting-edge results of mathematical disciplines. Geometrical Foundations and Screw Algebra for Mechanisms and Robotics [77] discussed the relevant theoretical issues and provided theoretical support to advance the application and development of reconfigurable automobile structure and robots. For example, both design and algorithms need to use Euler's formula, but the differences between the two domains are so great that different versions of mathematical theory have to be integrated to be applied in an intelligent reconfigurable factory, which can be done through Lie groups and Lie algebras to connect the two domains.

The development of intelligent reconfigurable factory requires the construction of digital standards common to all disciplines to provide the necessary environment for the design and research of reconfigurable automobile structure and robots. All scholars and engineers have to take the responsibility for the application and development of intelligent reconfigurable factory. The integration of multiple disciplines, the requirement for high efficiency, and diverse applications will eventually lead to the 4th Industrial Revolution, and we will usher in the era of intelligent reconfigurable factory [78–80]. Only by forming a common design standard can more reconfigurable automobile structure and robots be born that can adapt to a variety of working environments and meet a variety of processing needs, and only then can intelligent reconfigurable factory be rapidly promoted.

So far, there are sensing [19,23,55,81–83], interactive [20–22,84,85], autonomous [25,83,86,87] and other types of reconfigurable automobiles and robots. However, there is still much room for improvement of intelligent reconfigurable factory to be capable of interacting with humans, “thinking” by themselves, and being completely unmanned. We must pay more attention to the development of software-based automobiles and robots, especially the development of knowledge robots and virtual-real interaction technologies. Also, we should attach much importance to the organic integration of humans, automobiles and robots.

7.Conclusion

Usually, traditional automobiles and robots in the factory can only complete a single job, while reconfigurable automobiles and robots can change their own structures and forms as faced with complex environments, thus completing more work efficiently. As the theoretical basis of reconfigurable structure, reconfigurable mechanics needs to be further explored by scholars. As the core technology of reconfigurable theory, reconfigurable structure needs to be further developed and applied by engineers. As an important means of intelligent reconfigurable factory, reconfigurable theory is to be further promoted and optimized by the entire automobile industry.

In the future, the application scenarios of reconfigurable theory in intelligent factories of automobiles will be greatly expanded. This will enable the automotive industry to continue to take on new life, bring innovation to transportation, and contribute to technological development, bringing greater convenience to mankind. The development trend of future automobile intelligent factory can be summarized as three fusions: the fusion of software and hardware, the fusion of virtual and reality, and the fusion of human and machine. Machine refers to the reconfigurable theory, while human plays the role of “intelligence”. The combination of the reconfigurable theory and the “intelligence” will open up a new avenue for innovation of intelligent reconfigurable factory of automobiles.

Author Contributions: The individual contributions of authors: conceptualization, J.S.D. and Z.Z.; methodology, Z.Z.; software, Y.G.; validation, J.S.D., Z.Z. and S.X.; formal analysis, Z.Z.; investigation, Y.G.; resources, S.X.; data curation, Z.Z.; writing—original draft preparation, Z.Z. and Y.G.; writing—review and editing, J.S.D.; visualization, Z.Z.; supervision, J.S.D.; project administration, Z.Z.; funding acquisition, J.S.D.

Funding: This research was funded by the Natural Science Foundation of China (Project No. 51535008, 51721003) and the Programme of International Collaboration (“111 Program”) under Grant No. B16034.

Data Availability Statement: Not applicable.

Acknowledgments: The authors are grateful to the Centre for Advanced Mechanisms and Robotics of Tianjin University, for providing research opportunity and financial support.

Conflicts of Interest: The authors declare no conflict of interest.

References

- Kang H.S. ; Lee J.Y. ; Choi S.S. ; et al . Smart manufacturing: past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing-Green Technology, 2016, 3(1): 111-128. DOI: https://doi.org/10.1007/s40684-016-0015-5

- Oztemel E. ; Gursev S . Literature review of Industry 4.0 and related technologies. Journal of Intelligent Manufacturing, 2020, 31(1): 127-182. DOI: https://doi.org/10.1007/s10845-018-1433-8

- Bartoš M. ; Bulej V. ; Bohušík M. ; et al . An overview of robot applications in automotive industry. Transportation Research Procedia, 2021, 55: 837-844. DOI: https://doi.org/10.1016/j.trpro.2021.07.052

- Anzolin G. ; Andreoni A. ; Zanfei A . Robot adoption and FDI driven transformation in the automotive industry. International Journal of Automotive Technology and Management, 2020, 20(2): 215-237. DOI: https://doi.org/10.1504/IJATM.2020.10030508

- Bogue R . Robotic vision boosts automotive industry quality and productivity. Industrial Robot, 2013, 40(5): 415-419. DOI: https://doi.org/10.1108/IR-04-2013-342

- Brogårdh T . Present and future robot control development-an industrial perspective. Annual Reviews in Control, 2007, 31(1): 69-79. DOI: https://doi.org/10.1016/j.arcontrol.2007.01.002

- Tsarouchi P. ; Makris S. ; Michalos G. ; et al . Robotized assembly process using dual arm robot. Procedia CIRP, 2014, 23: 47-52. DOI: https://doi.org/10.1016/j.procir.2014.10.078

- Cavazzuti M. ; Baldini A. ; Bertocchi E. ; et al . High performance automotive chassis design: a topology optimization based approach. Structural and Multidisciplinary Optimization, 2011, 44(1): 45-56. DOI: https://doi.org/10.1007/s00158-010-0578-7

- Gobbi M. ; Mastinu G. ; Doniselli C . Optimising a car chassis. Vehicle System Dynamics, 1999, 32(2/3): 149-170. DOI: https://doi.org/10.1076/vesd.32.2.149.2085

- Sun W.C. ; Pan H.H. ; Gao H .J. Filter-based adaptive vibration control for active vehicle suspensions with electrohydraulic actuators. IEEE Transactions on Vehicular Technology, 2016, 65(6): 4619-4626. DOI: https://doi.org/10.1109/TVT.2015.2437455

- Wennberg D . Light-weighting methodology in rail vehicle design through introduction of load carrying sandwich panels. Stockholm: KTH Royal Institute of Technology, 2011.

- Kuzyshyn A.Y. ; Batig V .V. Construction of mechanical model of the diesel-train DTKr-2 car and its features. Science and Transport Progress, 2017, 6(72): 20-29. DOI: https://doi.org/10.15802/stp2017/117936

- Ning D.H. ; Sun S.S. ; Li H.Y. ; et al . Active control of an innovative seat suspension system with acceleration measurement based friction estimation. Journal of Sound and Vibration, 2016, 384: 28-44. DOI: https://doi.org/10.1016/j.jsv.2016.08.010

- Cherry S . That sinking feeling. IEEE Spectrum, 2009, 46(1): 49-50. DOI: https://doi.org/10.1109/MSPEC.2009.4734315

- Mathijsen D . This is the age of amphibious vehicles. Reinforced Plastics, 2004, 48(9): 32-35. DOI: https://doi.org/10.1016/S0034-3617(04)00434-5

- Schmenn S. ; Heupel T . Evaluation alternativer automotive-innovationen. Barsch, T.; Heupel, T.; Trautmann, H. Die blue-ocean-strategie in theorie und praxis: diskurs und 16 beispiele erfolgreicher anwendung. Wiesbaden: Springer Fachmedien Wiesbaden, 2019: 213-225. DOI: https://doi.org/10.1007/978-3-658-15480-6_15

- Huang E. ; Davison K. ; Shreve S. ; et al . Bridging newsrooms and classrooms: preparing the next generation of journalists for converged media. Journalism & Communication Monographs, 2006, 8(3): 221-262. DOI: https://doi.org/10.1177/152263790600800302

- Shirsath P.S. ; Hajare M.S. ; Sonawane G.D. ; et al . A review on design and analysis of amphibious vehicle. International Journal of Science, Technology & Management, 2015, 4(1): 43-56.

- Ding X.L. ; Xu K . Design and analysis of a novel metamorphic wheel-legged rover mechanism. Journal of Central South University (Science and Technology), 2009, 40(S1): 91-101.

- Li M.X. ; Guo S.X. ; Hirata H. ; et al . A roller-skating/walking mode-based amphibious robot. Robotics and Computer-Integrated Manufacturing, 2017, 44: 17-29. DOI: https://doi.org/10.1016/j.rcim.2016.06.005

- Zhai Y. ; Gao P. ; Sun Y. ; et al . Gait planning for a multi-motion mode wheel-legged hexapod robot. 2016 IEEE International Conference on Robotics and Biomimetics (ROBIO), Qingdao, China: IEEE, 2016: 449-454. DOI: https://doi.org/10.1109/ROBIO.2016.7866363

- Jehanno J.M. ; Cully A. ; Grand C. ; et al . Design of a wheel-legged hexapod robot for creative adaptation. Kozłowski, K.; Tokhi, M.O.; Virk, G.S. Mobile Service Robotics. Singapore: World Scientific, 2014: 267-276. DOI: https://doi.org/10.1142/9789814623353_0032

- Guo F. ; Wang S.K. ; Yue B.K. ; et al . A deformable configuration planning framework for a parallel wheel-legged robot equipped with lidar. Sensors, 2020, 20(19): 5614. DOI: https://doi.org/10.3390/s20195614

- Chen Z.H. ; Wang S.K. ; Wang J .Z,;et al. Control strategy of stable walking for a hexapod wheel-legged robot. ISA Transactions, 2021, 108: 367-380. DOI: https://doi.org/10.1016/j.isatra.2020.08.033

- Zhang H.L. ; Zhuang Z.M. ; Wei W. ; et al . Structure design and motion control of a hybrid quadruped robot with wheels and Legs. 2022 8th International Conference on Mechatronics and Robotics Engineering (ICMRE), Munich, Germany: IEEE, 2022: 122-128. DOI: https://doi.org/10.1109/ICMRE54455.2022.9734076

- Jiansheng D . Reconfigurable mechanisms and robots. Beijing: Higher Education Press, 2020.

- Rohmer E. ; Reina G. ; Yoshida K . Dynamic simulation-based action planner for a reconfigurable hybrid leg–wheel planetary exploration rover. Advanced Robotics, 2010, 24(8/9): 1219-1238. DOI: https://doi.org/10.1163/016918610X501499

- Baines R. ; Patiballa S .K; Booth J.;et al. Multi-environment robotic transitions through adaptive morphogenesis. Nature, 2022, 610(7931): 283-289. DOI: https://doi.org/10.1038/s41586-022-05188-w

- Unhelkar V.V. ; Dörr S. ; Bubeck A. ; et al . Introducing mobile robots to moving-floor assembly lines: design, evaluation, and deployment. IEEE Robotics & Automation Magazine, 2018, 25(2): 72-81. DOI: https://doi.org/10.1109/MRA.2018.2815639

- Čech M. ; Wicher P. ; Lenort R. ; et al . Autonomous Mobile robot technology for supplying assembly lines in the automotive industry. Acta logistica, 2020, 7(2): 103-109. DOI: https://doi.org/10.22306/al.v7i2.164

- Blatnický M. ; Dižo J. ; Gerlici J. ; et al . Design of a robotic manipulator for handling products of automotive industry. International Journal of Advanced Robotic Systems, 2020, 17(1): 1729881420906290. DOI: https://doi.org/10.1177/1729881420906290

- Krug R. ; Stoyanov T. ; Tincani V. ; et al . The next step in robot commissioning: autonomous picking and palletizing. IEEE Robotics and Automation Letters, 2016, 1(1): 546-553. DOI: https://doi.org/10.1109/LRA.2016.2519944

- Semeniuta O. ; Dransfeld S. ; Falkman P . Vision-based robotic system for picking and inspection of small automotive components. 2016 IEEE International Conference on Automation Science and Engineering (CASE), Fort Worth, TX, USA: IEEE, 2016: 549-554. DOI: https://doi.org/10.1109/COASE.2016.7743452

- Xie F.G. ; Liu X.J. ; Wu C. ; et al . A novel spray painting robotic device for the coating process in automotive industry. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2015, 229(11): 2081-2093. DOI: https://doi.org/10.1177/0954406214553018

- Ahmad B. ; Iqbal A. ; Saqib R. ; et al . Design and implementation of bluetooth controlled painting robot for auto industry. Intelligent Computing, Cham: Springer International Publishing, 2019: 359-367. DOI: https://doi.org/10.1007/978-3-030-01177-2_26

- IDRIS A .A.M. Improvement of painting and welding in automotive industry using robots. IOSR Journal of Mechanical and Civil Engineering, 2020, 17(5):18-28.

- Božek P . Robot path optimization for spot welding applications in automotive industry. Tehnički vjesnik, 2013, 20(5): 913-917.

- Toai T.T. ; Chu D.H. ; My C .A. Development of a new 6 DOFs welding robotic system for a specialized application. BalasV.E.; SolankiV.K.; KumarR. Further advances in internet of things in biomedical and cyber physical systems. Cham: Springer International Publishing, 2021: 135-150. DOI: https://doi.org/10.1007/978-3-030-57835-0_11

- Chen H.P. ; Eakins W. ; Wang J.J. ; et al . Robotic wheel loading process in automotive manufacturing automation. 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Loui, MO, USA: IEEE, 2009: 3814-3819. DOI: https://doi.org/10.1109/IROS.2009.5354048

- Brito T. ; Queiroz J. ; Piardi L. ; et al . A machine learning approach for collaborative robot smart manufacturing inspection for quality control systems. Procedia Manufacturing, 2020, 51: 11-18. DOI: https://doi.org/10.1016/j.promfg.2020.10.003

- Javadi Y. ; Mohseni E. ; MacLeod C.N. ; et al . Continuous monitoring of an intentionally-manufactured crack using an automated welding and in-process inspection system. Materials & Design, 2020, 191: 108655. DOI: https://doi.org/10.1016/j.matdes.2020.108655

- Zheng M.K. ; Ming X .G. Construction of cyber-physical system–integrated smart manufacturing workshops: a case study in automobile industry. Advances in Mechanical Engineering, 2017, 9(10): 1687814017733246. DOI: https://doi.org/10.1177/1687814017733246

- Qu Y.J. ; Ming X.G. ; Liu Z.W. ; et al . Smart manufacturing systems: state of the art and future trends. The International Journal of Advanced Manufacturing Technology, 2019, 103(9): 3751-3768. DOI: https://doi.org/10.1007/s00170-019-03754-7

- Vysocky A. ; Novak P . Human – robot collaboration in industry. MM Science Journal, 2016, 2016(2): 903-906. DOI: https://doi.org/10.17973/MMSJ.2016_06_201611

- Müller R. ; Vette M. ; Scholer M . Robot workmate: a trustworthy coworker for the continuous automotive assembly line and its implementation. Procedia CIRP, 2016, 44: 263-268. DOI: https://doi.org/10.1016/j.procir.2016.02.077

- Inkulu A.K. ; Bahubalendruni M .V.A.R.; Dara A.; et al. Challenges and opportunities in human robot collaboration context of Industry 4.0 - a state of the art review. Industrial Robot, 2021, 49(2): 226-239. DOI: https://doi.org/10.1108/IR-04-2021-0077

- Asadi E. ; Li B.B. ; Chen I .M. Pictobot: a cooperative painting robot for interior finishing of industrial developments. IEEE Robotics & Automation Magazine, 2018, 25(2): 82-94. DOI: https://doi.org/10.1109/MRA.2018.2816972

- Michalos G. ; Kousi N. ; Karagiannis, P,; et al . Seamless human robot collaborative assembly – an automotive case study. Mechatronics, 2018, 55: 194-211. DOI: https://doi.org/10.1016/j.mechatronics.2018.08.006

- di Marino C. ; Tarallo A. ; Vitali A. ; et al . Collaborative robotics and ergonomics: a scientific review. Proceedings of the ASME 2021 International Mechanical Engineering Congress and Exposition, Virtual, Online: ASME, 2021: V006T06A020. DOI: https://doi.org/10.1115/IMECE2021-72919

- Boy G .A. Design for flexibility: a human systems integration approach. Cham: Springer, 2021. DOI: https://doi.org/10.1007/978-3-030-76391-6

- Dai J.S. ; Rees Jones J . Mobility in metamorphic mechanisms of foldable/erectable kinds. Journal of Mechanical Design, 1999, 121(3): 375-382. DOI: https://doi.org/10.1115/1.2829470

- Dai J .S. Metamorphic mechanisms and their configuration models. Chinese Journal of Mechanical Engineering (English Edition), 2000, 13(3): 212. DOI: https://doi.org/10.3901/CJME.2000.03.212

- Yan H.S. ; Liu N .T. Joint-codes representations for mechanisms and chains with variable topologies. Transactions of the Canadian Society for Mechanical Engineering, 2003, 27(1/2): 131-143. DOI: https://doi.org/10.1139/tcsme-2003-0007

- Aimedee F. ; Gogu G. ; Dai J.S. ; et al . Systematization of morphing in reconfigurable mechanisms. Mechanism and Machine Theory, 2016, 96, Part 2: 215-224. DOI: https://doi.org/10.1016/j.mechmachtheory.2015.07.009

- Zhuang Z.M. ; Zhang Z. ; Guan Y.T. ; et al . Design and control of SLPM-based extensible continuum arm. Journal of Mechanisms and Robotics, 2022, 14(6): 061011. DOI: https://doi.org/10.1115/1.4054996

- Kang X. ; Zhang X.S. ; Dai J .S. First- and second-order kinematics-based constraint system analysis and reconfiguration identification for the queer-square mechanism. Journal of Mechanisms and Robotics, 2019, 11(1): 011004. DOI: https://doi.org/10.1115/1.4041486

- DH-Robotics . Industrial applications: auto parts. Available online: https://www.dh-robotics.com/applications/industry/automotive (accessed on 5 November 2022).

- Neven D. ; de Brabandere D. ; Georgoulis S. ; et al . Towards End-to-End lane detection: an instance segmentation approach. 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China: IEEE, 2018: 286-291. DOI: https://doi.org/10.1109/IVS.2018.8500547

- Chai R.Q. ; Tsourdos A. ; Savvaris A. ; et al . Design and implementation of deep neural Network-Based control for automatic parking maneuver process. IEEE Transactions on Neural Networks and Learning Systems, 2022, 33(4): 1400-1413. DOI: https://doi.org/10.1109/TNNLS.2020.3042120

- Gao H.B. ; Zhu J.P. ; Li X.D. ; et al . Automatic parking control of unmanned vehicle based on switching control algorithm and backstepping. IEEE/ASME Transactions on Mechatronics, 2022, 27(3): 1233-1243. DOI: https://doi.org/10.1109/TMECH.2020.3037215

- Wang Q. ; Gao J.Y. ; Yuan Y . Embedding structured contour and location prior in siamesed fully convolutional networks for road detection. IEEE Transactions on Intelligent Transportation Systems, 2018, 19(1): 230-241. DOI: https://doi.org/10.1109/TITS.2017.2749964

- Chen L.C. ; Papandreou G. ; Kokkinos I. ; et al . DeepLab: semantic image segmentation with deep convolutional nets, atrous convolution, and fully connected CRFs. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2018, 40(4): 834-848. DOI: https://doi.org/10.1109/TPAMI.2017.2699184

- Choi W . Near-online multi-target tracking with aggregated local flow descriptor. 2015 IEEE International Conference on Computer Vision (ICCV), Santiago, Chile: IEEE, 2015: 3029- 3037. DOI: https://doi.org/10.1109/ICCV.2015.347

- Lin T.Y. ; Dollár P. ; Girshick R. ; et al . Feature pyramid networks for object detection. 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA: IEEE, 2017: 936-944. DOI: https://doi.org/10.1109/CVPR.2017.106

- Xu S.B. ; Peng H. ; Song Z.Y. ; et al . Accurate and smooth speed control for an autonomous vehicle. 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China: IEEE, 2018: 1976-1982. DOI: https://doi.org/10.1109/IVS.2018.8500519

- Kim H. ; Kim D. ; Shu I. ; et al . Time-varying parameter adaptive vehicle speed control IEEE Transactions on Vehicular Technology, 2016, 65(2): 581-588. DOI: https://doi.org/10.1109/TVT.2015.2402756

- Chatzikomis C. ; Sorniotti A. ; Gruber P. ; et al . Comparison of path tracking and torque-vectoring controllers for autonomous electric vehicles. IEEE Transactions on Intelligent Vehicles, 2018, 3(4): 559-570. DOI: https://doi.org/10.1109/TIV.2018.2874529

- Guo J.H. ; Luo Y.G. ; Li K .Q. An adaptive hierarchical trajectory following control approach of autonomous four-wheel independent drive electric vehicles. IEEE Transactions on Intelligent Transportation Systems, 2018, 19(8): 2482-2492. DOI: https://doi.org/10.1109/TITS.2017.2749416

- Nam H. ; Choi W. ; Ahn C . Model predictive control for evasive steering of an autonomous vehicle International Journal of Automotive Technology, 2019, 20(5): 1033-1042. DOI: https://doi.org/10.1007/s12239-019-0097-5

- Brown M. ; Funke J. ; Erlien S. ; et al . Safe driving envelopes for path tracking in autonomous vehicles. Control Engineering Practice, 2017, 61: 307-316. DOI: https://doi.org/10.1016/j.conengprac.2016.04.013

- Wei H. ; Mu X.X. ; Zhang L. ; et al . Modeling and trajectory tracking control for flapping-wing micro aerial vehicles. IEEE/CAA Journal of Automatica Sinica, 2021, 8(1): 148-156. DOI: https://doi.org/10.1109/JAS.2020.1003417

- Alcala E. ; Puig V. ; Quevedo J. ; et al . Autonomous vehicle control using a kinematic Lyapunov-based technique with LQR-LMI tuning. Control Engineering Practice, 2018, 73: 1-12. DOI: https://doi.org/10.1016/j.conengprac.2017.12.004

- Niu S. ; Ye L.Q. ; Liu H.D. ; et al . Ant3DBot: a modular self-reconfigurable robot with multiple configurations. Intelligent Robotics and Applications, Cham: Springer International Publishing, 2022: 552-563. DOI: https://doi.org/10.1007/978-3-031-13844-7_52

- Tu Y.X. ; Liang G.Q. ; Lam T .L. FreeSN: a freeform strut-node structured modular self-reconfigurable robot - design and implementation. 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA: IEEE, 2022: 4239- 4245. DOI: https://doi.org/10.1109/ICRA46639.2022.9811583

- Pallottino F. ; Antonucci F. ; Costa C. ; et al . Optoelectronic proximal sensing vehicle-mounted technologies in precision agriculture: a review. Computers and Electronics in Agriculture, 2019, 162: 859-873. DOI: https://doi.org/10.1016/j.compag.2019.05.034

- Lynch L. ; Newe T. ; Clifford J. ; et al . Automated ground vehicle (AGV) and sensor technologies- a review. 2018 12th International Conference on Sensing Technology (ICST), Limerick, Ireland: IEEE, 2018: 347-352. DOI: https://doi.org/10.1109/ICSensT.2018.8603640

- Jiansheng D . Geometrical foundations and screw algebra for mechanisms and robotics. Beijing: Higher Education Press, 2014.

- Bortolini,M; Galizia,G.G; Mora,C. Reconfigurable manufacturing systems: Literature review and research trend. Journal of Manufacturing Systems, 2018, 49: 93-106. DOI: https://doi.org/10.1016/j.jmsy.2018.09.005

- Andersen A.L. ; Larsen J.K. ; Brunoe T.D. ; et al . Critical enablers of changeable and reconfigurable manufacturing and their industrial implementation. Journal of Manufacturing Technology Management, 2018, 29(6): 983-1002. DOI: https://doi.org/10.1108/JMTM-04-2017-0073

- Pansare R. ; Yadav G. ; Nagare M .R. Reconfigurable manufacturing system: a systematic review,meta-analysis and future research directions. Journal of Engineering, Design and Technology, 2021, submitted. DOI: https://doi.org/10.1108/JEDT-05-2021-0231

- Liu G.J. ; Abdul S. ; Goldenberg A .A. Distributed control of modular and reconfigurable robot with torque sensing. Robotica, 2008, 26(1): 75-84. DOI: https://doi.org/10.1017/S0263574707003608

- Li Y. ; Lu Z.P. ; Zhou F. ; et al . Decentralized trajectory tracking control for modular and reconfigurable robots with torque sensor: adaptive terminal sliding control-based approach. Journal of Dynamic Systems, Measurement, and Control, 2019, 141(6): 061003. DOI: https://doi.org/10.1115/1.4042550

- Le A.V. ; Kyaw P.T. ; Mohan R.E. ; et al . Autonomous floor and staircase cleaning framework by reconfigurable sTetro robot with perception sensors. Journal of Intelligent & Robotic Systems, 2020, 101(1): 17. DOI: https://doi.org/10.1007/s10846-020-01281-2

- Huang J.L. ; Zhakypov Z. ; Sonar H. ; et al . A reconfigurable interactive interface for controlling robotic origami in virtual environments. The International Journal of Robotics Research, 2018, 37(6): 629-647. DOI: https://doi.org/10.1177/0278364918769157

- Huang J .L. Development and control of interactive reconfigurable robotic systems. Lausanne: École Polytechnique Fédérale de Lausanne, 2021.

- Yi L. ; Le A.V. ; Hayat A.A. ; et al . Anti-collision static rotation local planner for four independent steering drive self-reconfigurable robot. 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA: IEEE, 2022: 5835-5841. DOI: https://doi.org/10.1109/ICRA46639.2022.9812445

- Thalamy P. ; Piranda B. ; Bourgeois J . A survey of autonomous self-reconfiguration methods for robot-based programmable matter. Robotics and Autonomous Systems, 2019, 120: 103242. DOI: https://doi.org/10.1016/j.robot.2019.07.012