Downloads

Download

This work is licensed under a Creative Commons Attribution 4.0 International License.

Article

Online Big-Data Monitoring and Assessment Framework for Internal Combustion Engine with Various Biofuels

Ming Zhang 1,*, Vikas Sharma 2, Zezhong Wang 1, Yu Jia 1, Abul Kalam Hossain 1, and Yuchun Xu 1

1 College of Engineering and Physical Sciences, Aston University, Birmingham B4 7ET, UK

2 School of Architecture, Technology and Engineering, University of Brighton, Brighton BN2 4GJ, UK

* Correspondence: m.zhang21@aston.ac.uk

Received: 14 December 2022

Accepted: 26 April 2023

Published: 30 May 2023

Abstract: As the primary power source for automobiles, the internal combustion (IC) engines have been widely used and served millions of people worldwide. With increasingly stringent environmental regulations, biofuels have been obtained more attentions and are being used as alternative fuel to power IC engines. However, there are currently no standard solutions or well-established monitoring and assessment methods that can effectively evaluate the IC engine’s performance with biofuels. The expectation for biofuels is to keep the engine’s lifetime as long as the conventional fuels, or even longer. Otherwise, their usage would be unnecessary because they would reduce the lifecycle of the engine and also cause more waste and pollution. To address this challenge, we initially designed two biofuels: waste cooking oil biofuel (WCOB) and lamb fat biofuel (LFB). Then we proposed an online big-data monitoring and assessment framework for IC engines operating with various types of fuel. We conducted comprehensive experiments and comparisons based on the proposed framework. The results indicate that LFB performs best under all the performance indicators.

Keywords:

Industry 4.0 big-data analysis condition monitoring performance assessment internal combustion (IC) engine biofuels1. Introduction

Internal combustion engines (ICEs) are the core part of automobiles, which have mobilized humans and materials for over 150 years. As the symbol of the industrial revolution, the engine has been the topic of research ever since. Till now however, the brake thermal efficiency (BTE) of ICE is still not ideal, the optimal results are only 45% for gasoline light-duty engines, and 55% for heavy-duty diesel engines [1], which is relatively lower than the efficiency of electric motors. Among all sectors, transportation relies on fossil fuels the most, and accounts for 24% of global CO2 emissions in 2020 [2]. The increasingly stringent CO2 emissions and fuel consumption regulations have been raised in recent years. These policies have promoted researchers and engineers to study and design more environmentally friendly machines and fuels. However, for a large number of on service IC engines, it is not feasible to improve their mechanical structure. Therefore, developing alternative fuels would be a more reasonable way to reduce the pollutant in current automobiles [3]. Compared to gasoline engines, diesel engines have advantages such as high power, high BTE, and less CO2 emission. To improve the raw material usage in diesel fuel, more biodiesel fuels have been produced and studied. According to the latest review, the BTE of diesel engines with biodiesels has been increasing in the recent decade from 20% to 40% [4].

Biodiesel fuels are a relatively new-emerging technology for internal combustion engines. Compared to nonrenewable resources such as fossil fuels, biodiesels are generally made from vegetable oils or animal fats [5]. The various biodiesel fuels can be produced by recycling the waste and various natural materials, making them environmentally friendly and with fewer aromatic compounds and sulfur [6,7]. This kind of sustainable renewable fuel plays an important role in achieving world’s carbon neutrality goals by significantly reducing exhaust emissions including particulate matter, hydrocarbons and carbon monoxide [8]. However, the performance of biodiesel fuels is still challenging and being studied by researchers. The power performance, fuel consumption and emission performance have been studied [9,10]. But there is currently no specific solution to make an overall monitoring and evaluation of IC engines when they are powered by biodiesels. It is not sustainable if biofuel negatively affect the lifecycle of the IC engine [11]. Therefore, there is an urgent need to develop a set of assessment methods to select the best biofuels which could perform better and do not impact the lifetime of engines.

In recent years, with the development of the industrial 4.0 system, bigdata analysis techniques based on real-time condition monitoring have been widely applied [12,13]. The main goal is to continuously monitor and assess high-value equipment in real-time. As the most important machine for automotive applications, many advanced sensors, such as accelerometer, speed, torque, temperature, and pressure sensors have been installed on the IC engine to collect the original data and then obtain the machine’s performance [8,14,15]. Nowadays, the online condition monitoring techniques for IC engines include measuring temperature, pressure, rotation, oxygen, airflow, and utilizing methods of acoustic emission, vibration, oil and fuel analysis [16]. This results in the collection of large amount of data and monitoring challenges as the data for more than one machine cannot be all recorded and analyzed in timely manner by experts. Therefore, performance assessment frameworks have been proposed for making the effective measure indicators which could be calculated and represent the state of the engine [16,17]. However, the current assessment approaches have been proposed for the engines which are powered by common fuel, such as gasoline and diesel, and they were designed to evaluate the different engine states under the constant fuel type. The existing methods could not evaluate the engine with different types of fuel while biofuels could be more widely used for IC engines in the near future because of their environment-friendly properties. Therefore, it’s very important to develop the condition monitoring and assessment of IC engines to adopt to future biofuel requirements.

In recent years, the vibration characteristics have got attention in comparison with diesel and newly developed biodiesel [18‒20]. However, it is concluded that most of the research was conducted on diesel/biodiesel blends, and biodiesel/alcohol blends to analyze the relationship between fuel properties and engine vibration. When biodiesel was blended with diesel or alcohols, the viscosity and density were reduced, resulting in lower vibration. The novelty of the current research article is to analyze the effect of 100% biodiesels with different fuel properties. The newly developed biofuels include waste cooking oil biofuel (WCOB) and lamb fat biofuel (LFB) as the alternatives to diesel for IC engines, which have not been investigated yet. Meanwhile, we propose an online big-data monitoring and assessment framework based on a set of performance assessment indicators which include Root Mean Square (RMS), Peak to Peak, and Variance for mechanical vibration level, brake specific fuel consumption (BSFC), brake thermal efficiency (BTE) and friction power (FP). The overall performance of the engine under different fuels (diesel, WCOB, and LFB) has been compared comprehensively.

2. Methods

2.1. Material

Based on their availability on the local market, two alternative oil feedstocks, waste cooking oil (WCO) and lamb fat, were selected. While lamb fat was obtained from the butcher’s home, WCO was obtained from Aston University after the oil had been utilized. The components required to make biodiesel, such as sulfuric acid (H2SO4), potassium hydroxide (KOH), and methanol (CH3OH, 98% purity), were purchased from Sigma-Aldrich UK.

2.2. Biodiesel Production and Characterization

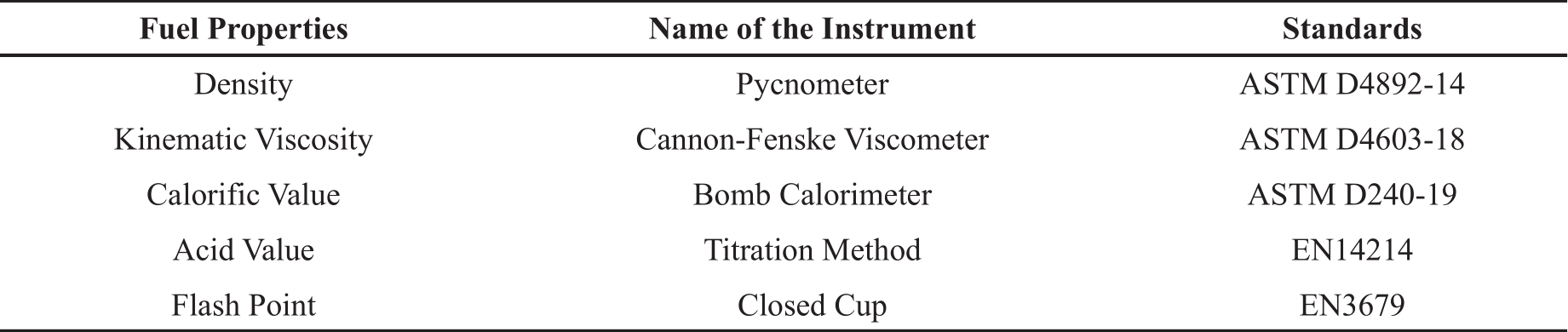

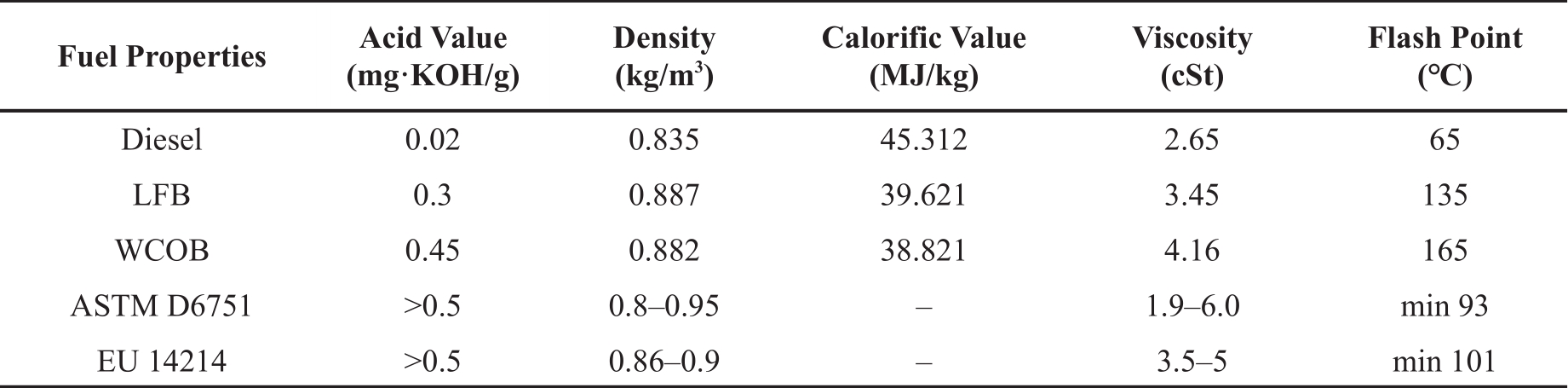

The large lamb skin was divided into smaller pieces and baked for one hour at 100 ℃. Later, the separated lamb fat (LF) was put into a jar for storage. Before the process, the WCO was filtered through a sock filter to get rid of sediments. Both feedstocks underwent transesterification to become biodiesel fuels [21]. The base catalyst, potassium hydroxide (KOH), is used with a 4:1 molar ratio of methanol to oil [21]. A mechanical stirrer was used to add the KOH-methanol combination to the heated oil at 60 ℃ and agitate it for an hour. After the procedure, the liquid was transferred to a separation device to separate the biodiesel and glycerol. In a procedure known as “biodiesel washing”, dissolved catalyst and soap produced during the chemical reaction were removed using hot distilled water (80 ℃). The biodiesel fuel sample was then left overnight to allow the water droplets to condense [21]. The sample was heated at a constant temperature of 100 ℃ for an hour to remove the moisture [21]. In the fuel characterization laboratory at Aston University UK, prepared biodiesel fuel was characterized. Table 1 displays the tools and benchmarks used for fuel characterization. The fuel qualities that were measured were compared to the biodiesel standards listed in Table 2.

Table 1. List of the instruments used for characterization.

Table 2. Physical characteristics of the tested fuels.

2.3. Online Monitoring Framework for Internal Combustion (IC) Engine

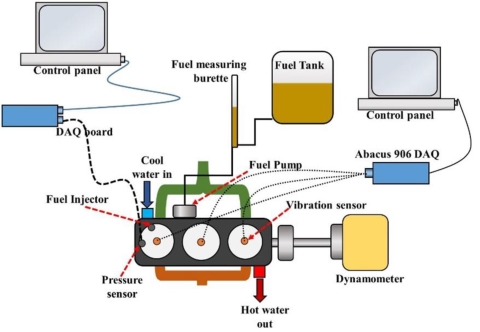

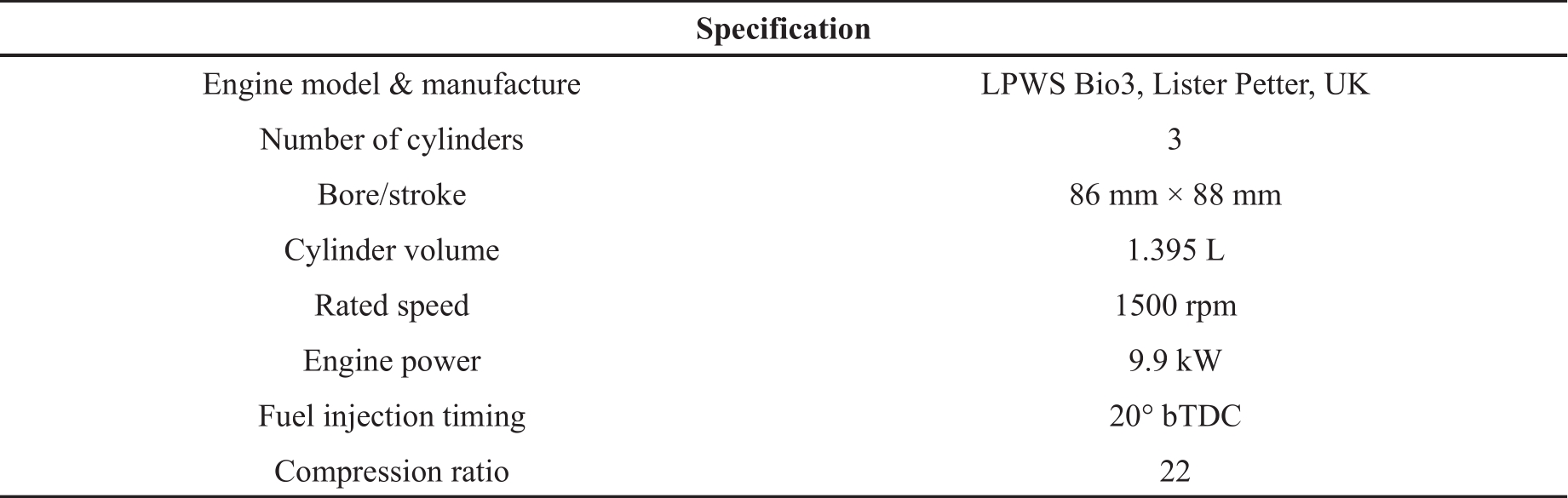

The online monitoring framework for an IC engine has been proposed and is shown in Figure 1. The Lister Petter Alpha series water-cooled, three-cylinder indirect injection (IDI) diesel engine, used in the combustion characterization tests, has been used in this system. Table 3 lists the test engine’s specifications. While the torque was changed, the engine’s speed was maintained at 1500 rpm. To alter the engine speed, a Froude Hofmann AG80HS eddy current dynameter was employed.

Figure 1. The workflow of dynamic maintenance scheduling.

Table 3. Engine specifications.

2.4. Vibration Measurement System

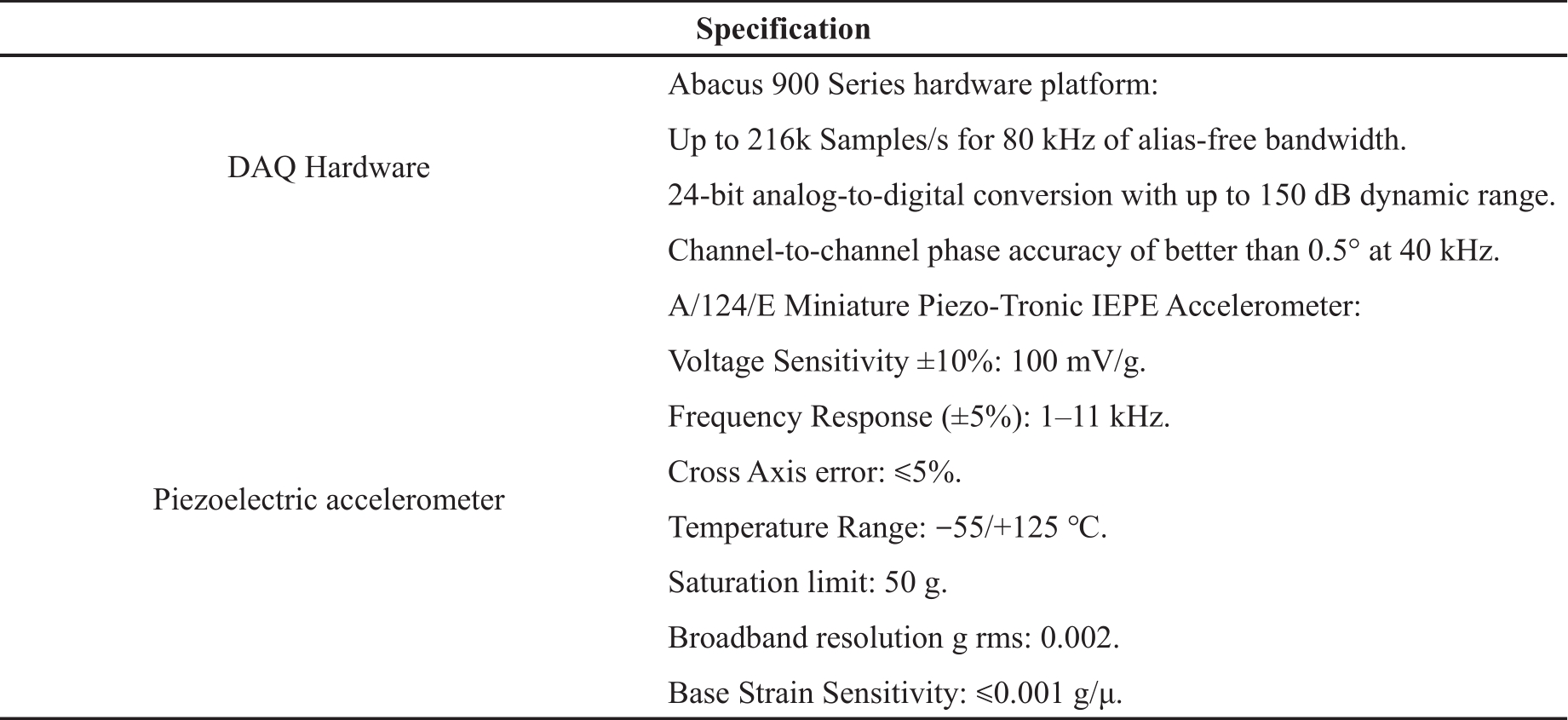

The vibration measurement system consists of an accelerometer, a Data Acquisition (DAQ) box (Abacus 900 Series hardware platform), and SignalCalc 900 Series software. The technical specifications of the DAQ box and Accelerometers used in this work are shown in Table 4. The vibration signals are collected by the DAQ box, then the SignalCalc 900 software records and shows the original signals.

Table 4. Technical specifications of DAQ Hardware and Piezoelectric accelerometer.

2.5. Data Collection and Processing

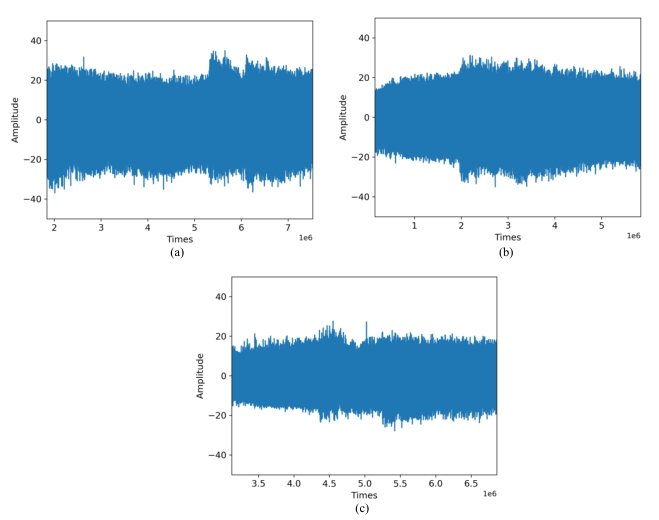

As shown in Figure 2, the vibration signal has been monitored continuously at a high sampling frequency 25.6 kHz throughout the entire experiment for different types of fuel with varying torque. Every minute, the DP900 system records 10 seconds of vibration data, equivalent to 256,000 points. The RMS, Peak to Peak (P2P) and Variance are calculated under different load conditions. The fuel consumption data was measured from the fuel test burette with a volume of 100 mL. The fuel consumption time for 100 mL was measured three times using a stopwatch at each engine load test with uncertainty ±2 ms. Later this data was used to calculate brake specific fuel consumption (BSFC), brake thermal efficiency and friction power.

Figure 2. Collected vibration data of different fuels: (a) diesel; (b) waste cooking oil biofuel (WCOB); (c) lamb fat biofuel (LFB).

2.6. Performance Assessment

In order to implement online assessment for IC engine powered with different kinds of fuel, we proposed to build feature indicators which represent the various performance aspects of the machine. First, three indicators to evaluate the mechanical vibration level including RMS, P2P and Variance have been designed. The equations have been defined as follows:

Brake-specific fuel consumption (BSFC), brake thermal efficiency (BTE) and friction power (FP) have been used as indicators for engine performance. The equations have been defined as follows:

where, N denotes engine speed (rpm), T denotes engine torque (Nm), mf denotes fuel mass flow rate (s), CV denotes calorific value of the fuel, pm denotes indicated mean effective pressure (bar), L denotes stroke length (m), A denotes cylinder area (m2) and K denotes the number of cylinders.

3. Results and Discussion

3.1. Mechanical Vibration Performance

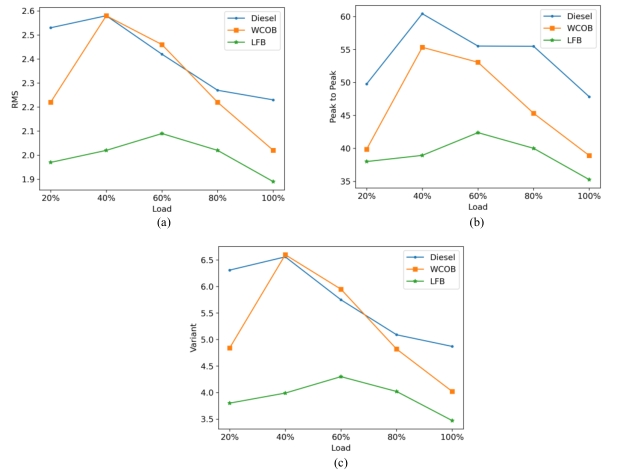

We analyzed the effects of load on vibration for three types of fuel (Diesel, WCOB and LFB) using three indictors (RMS, Peak to Peak and Variance). The results are shown in Figure 3. It is obvious that LFB obtains the best vibration performance on all indictors, WCOB takes second place, and diesel performs the worst. For the fuels of diesel and WCOB, the vibration performance acts worst under a load of 40% and best under a load of 100%. However, for the LFB, the vibration level performs best at a load of 60%.

Figure 3. Variation in mechanical vibration with engine load: (a) Root Mean Square (RMS); (b) Peak to Peak; (c) Variance.

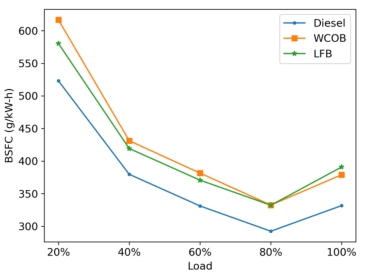

3.2. Brake Specific Fuel Consumption

At various engine loads, Figure 4 displays the brake specific fuel consumption (BSFC) for the tested fuels. BSFC gauges how efficiently an engine uses fuel to produce the required amount of power [22]. BSFC was calculated by using Equations (4) and (5) [23]. The BSFC is decreased when a combustion event or combustion phasing takes place close to the TDC [22]. The fuel’s ability to burn efficiently impacts BSFC as well. A fuel with a better ability to burn efficiently has a lower BSFC [22,24]. The BSFC values for LFB and WCOB were found to be greater than those for diesel fuel (Figure 4). It was due to biodiesel’s increased viscosity and lower heating properties [22,24]. BSFC for LFB and WCOB at increased load was found to be greater than diesel fuel by 13% and 15% at low engine load (20%), 16% and 13% at medium load (60%), and 17% and 12% at full engine load condition (100%) (Figure 4). Additionally, it was discovered that WCOB exhibits lower BSFC than LFB under both operating circumstances as a result of a higher heating value.

Figure 4. Variation in brake specific fuel consumption (BSFC) with engine load.

3.3. Brake Thermal Efficiency

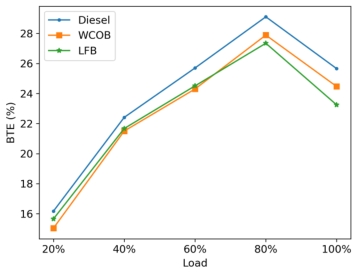

The BTE stands for fuel conversion efficiency and equates braking power to the fuel’s heat equivalent, and it was calculated from the Equation (6) [23]. Due to its lower energy content, biodiesel fuel often produces lower BTE than diesel fuel [25,26]. At operating conditions with varied loads, it was discovered that both the fuel samples, LFB and WCOB, displayed lower BTE (Figure 5). Additionally, it was noted that WCOB, which has a higher heating value, exhibited higher BTE than LFB under both operating conditions (Figure 5). In comparison to diesel fuel, the BTE values for LB and WCOB at varied load were found to be 4% and 8% lower at low load (20% load), 4.8% and 5.7% lower at medium load (60%), and 10% and 4.8% lower at maximum engine load (100%) respectively (Figure 5).

Figure 5. Variation in brake thermal efficiency (BTE) with engine load.

3.4. Friction Power

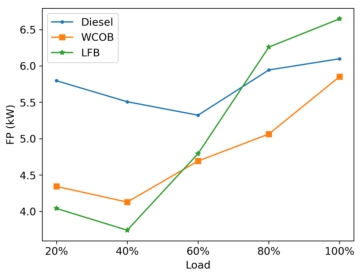

Forces acting between surfaces when they are in motion are commonly referred to as friction power (FP). The gap between stated horsepower and brake horsepower is known as total engine friction [27]. FP was calculated from the Equations (7) and (8) [23]. At operating conditions with variable loads, it was seen that FP for biodiesel fuel was found to be lower than that for diesel fuel (Figure 6). Due to the superior lubricity and viscosity, biodiesel fuels generally produce fewer friction losses when compared to fossil fuel [27]. As compared to diesel fuel, FP for LFB at variable load was found to be lower by 11–43% at engine load range of 20% to 60% and higher by 5–8% at 80% to 100% (Figure 6). FP for WCOB was discovered to be 4–33% lower than diesel fuel at engine loads of 20–100% (Figure 6).

Figure 6. Variation in friction power (FP) with engine load.

4. Discussion

In this paper, an online big-data monitoring and assessment framework has been proposed and used to evaluate and determine the best fuel among diesel and two developed biofuels (WCOB and LFB). Based on the performance indicators proposed in the framework, the overall engine performance with LFB and WCOB was found compatible with diesel fuel. The vibration characteristics have been evaluated by using the designed indicators including RMS, Peak to Peak, and Variance. The BSFC for biodiesel was found to be lower than that of diesel fuel with increases in the engine load due to its low heating value. The BTEs for LFB and WCOB were lower at variable loads. Additionally, both biofuels showed lower friction power as compared to diesel fuel. The results indicated that LFB performed best under all criteria for various loads.

Author Contributions: Conceptualization, M.Z. and V.S.; methodology, M.Z. and V.S.; validation, M.Z.; Y.Y. and Z.Z.; data curation, Y.J.; writing—original draft preparation, M.Z.; V.S. and Z.W.; writing—review and editing, Y.J.; A.K.H.; and Y.X.; supervision, A.K.H.; and Y.X.; project administration, A.K.H.; and Y.X.; funding acquisition, Y.X.

Data Availability Statement: The data presented in this study are available on request from the corresponding author.

Acknowledgments: The authors acknowledge the support by the RECLAIM project, named as “Remanufacturing and Refurbishment Large Industrial Equipment”, and received funding from the European Commission Horizon 2020 research and innovation programme No 869884; this research used SignalCalc software and Abacus 906 hardware from Data Physics Company.

Conflicts of Interest: The authors declare no conflict of interest.

References

- Joshi, A. Review of vehicle engine efficiency and emissions. SAE International Journal of Advances and Current Practices in Mobility 2020, 2, 2479–2507. DOI: https://doi.org/10.4271/2020-01-0352

- LiuZ.; CiaisP.; DengZ.; et al. Carbon monitor, a near-real-time daily dataset of global CO2 emission from fossil fuel and cement production. Scientific Data 2020, 7(1), 392. DOI: https://doi.org/10.1038/s41597-020-00708-7

- MurugesanA.; UmaraniC.; SubramanianR.; et al. Bio-diesel as an alternative fuel for diesel engines—a review. Renewable and Sustainable Energy Reviews 2009, 13(3), 653–662. DOI: https://doi.org/10.1016/j.rser.2007.10.007

- Anbarsooz, M. Combustion characteristics of nanofuels: A comprehensive review on diesel/biodiesel-based nanofuels. Fuel 2023, 337, 126834. DOI: https://doi.org/10.1016/j.fuel.2022.126834

- SaniM.S.; MamatR.; KhoerunnisaF.; et al. Vibration analysis of the engine using biofuel blends: A review. In MATEC Web of Conferences. EDP Sciences: Les Ulis, France, 2018, volume 225, page 01010. DOI: https://doi.org/10.1051/matecconf/201822501010

- HossainA.K.; RefahtalabP.; OmranA.; et al. An experimental study on performance and emission characteristics of an IDI diesel engine operating with neat oil-diesel blend emulsion. Renewable Energy 2020, 146, 1041–1050. DOI: https://doi.org/10.1016/j.renene.2019.06.162

- MaseraK.; HossainA.K.; DaviesP.A.; et al. Investigation of 2-butoxyethanol as biodiesel additive on fuel property and combustion characteristics of two neat biodiesels. Renewable Energy 2021, 164, 285–297. DOI: https://doi.org/10.1016/j.renene.2020.09.064

- SharmaV.; HossainA.K.; DuraisamyG. Experimental investigation of neat biodiesels’ saturation level on combustion and emission characteristics in a CI engine. Energies 2021, 14(16), 5203. DOI: https://doi.org/10.3390/en14165203

- GharehghaniA.; PourrahmaniH. Performance evaluation of diesel engines (PEDE) for a diesel-biodiesel fueled CI engine using nano-particles additive. Energy Conversion and Management 2019, 198, 111921. DOI: https://doi.org/10.1016/j.enconman.2019.111921

- SzabadosG.; BereczkyÁ. Experimental investigation of physicochemical properties of diesel, biodiesel and TBK-biodiesel fuels and combustion and emission analysis in CI internal combustion engine. Renewable Energy 2018, 121, 568–578. DOI: https://doi.org/10.1016/j.renene.2018.01.048

- AmaitikN.; ZhangM.; WangZ.; et al. Cost modelling to support optimum selection of life extension strategy for industrial equipment in smart manufacturing. Circular Economy and Sustainability 2022, 2, 1425–1444. DOI: https://doi.org/10.1007/s43615-022-00154-0

- MishraD.; PriyadarshiA.; DasS.M.; et al. Industry 4.0 application in manufacturing for real-time monitoring and control. Journal of Dynamics, Monitoring and Diagnostics 2022, 1, 176–187. DOI: https://doi.org/10.37965/jdmd.2022.118

- XuY.; TangX.; FengG.; et al. Orthogonal on-rotor sensing vibrations for condition monitoring of rotating machines. Journal of Dynamics, Monitoring and Diagnostics 2022, 1(1), 29–36. DOI: https://doi.org/10.37965/jdmd.v2i2.47

- ZhaoN.; ZhangJ.; MaW.; et al. Variational time-domain decomposition of reciprocating machine multi-impact vibration signals. Mechanical Systems and Signal Processing 2022, 172, 108977. DOI: https://doi.org/10.1016/j.ymssp.2022.108977

- ZhangM.; JiangZ.; FengK. Research on variational mode decomposition in rolling bearings fault diagnosis of the multistage centrifugal pump. Mechanical Systems and Signal Processing 2017, 93, 460–493. DOI: https://doi.org/10.1016/j.ymssp.2017.02.013

- Bingamil, A.; Alsyouf, I.; Cheaitou, A. Condition monitoring technologies, parameters and data processing techniques for fault detection of internal combustion engines: A literature review. In 2017 International Conference on Electrical and Computing Technologies and Applications (ICECTA), pp. 1–5. IEEE, 2017. DOI: https://doi.org/10.1109/ICECTA.2017.8252038

- ZhaoH.; ZhangJ.; JiangZ.; et al. A new fault diagnosis method for a diesel engine based on an optimized vibrationmel frequency undermultiple operation conditions. Sensors 2019, 19(11), 2590. DOI: https://doi.org/10.3390/s19112590

- YangT.; WangT.; LiG.; et al. Vibration characteristics of compression ignition engines fueled with blended petro-diesel and fischer-tropsch diesel fuel from coal fuels. Energies 2018, 11(8), 2043. DOI: https://doi.org/10.3390/en11082043

- JaikumarS.; BhattiS.K.; SrinivasV.; et al. Combustion and vibration characteristics of variable compression ratio direct injection diesel engine fuelled with diesel-biodiesel and alcohol blends. Engineering Reports 2020, 2(7), e12195. DOI: https://doi.org/10.1002/eng2.12195

- WrobelR.; SierzputowskiG.; SrokaZ.; et al. Comparison of diesel engine vibroacoustic properties powered by bio and standard fuel. Energies 2021, 14(5), 1478. DOI: https://doi.org/10.3390/en14051478

- SharmaV.; DuraisamyG.; ChoH.M.; et al. Production, combustion and emission impact of bio-mix methyl ester fuel on a stationary light duty diesel engine. Journal of Cleaner Production 2019, 233, 147–159. DOI: https://doi.org/10.1016/j.jclepro.2019.06.003

- GaurA.; DwivediG.; BaredarP.; et al. Influence of blending additives in biodiesel on physiochemical properties, engine performance, and emission characteristics. Fuel 2022, 321, 124072. DOI: https://doi.org/10.1016/j.fuel.2022.124072

- Heywood, J.B. Internal Combustion Engine Fundamentals. McGraw-Hill Education: New York City, NY, USA, 2018.

- AsokanM.A.; PrabuS.S.; AkhilV.S.; et al. Performance and emission behaviour of diesel and blends of watermelon seed oil biodiesel in direct injection diesel engine. Materials Today: Proceedings 2021, 45, 3274–3278. DOI: https://doi.org/10.1016/j.matpr.2020.12.469

- MouradM.; MahmoudK.R.; NourEldeenE.S.H. Improving diesel engine performance and emissions characteristics fuelled with biodiesel. Fuel 2021, 302, 121097. DOI: https://doi.org/10.1016/j.fuel.2021.121097

- YaliwalV.; GaddigoudarP.; AkkiS.; et al. Influence of piston bowl geometry on the performance and emission characteristics of a diesel engine operated on single fuel mode using dairy scum oil biodiesel. Materials Today: Proceedings 2022, 52, 1223–1227. DOI: https://doi.org/10.1016/j.matpr.2021.11.041

- SinghD.; GuF.; FieldhouseJ.D.; et al. Prediction and analysis of engine friction power of a diesel engine influenced by engine speed, load, and lubricant viscosity. Advances in Tribology 2014, 2014, 928015. DOI: https://doi.org/10.1155/2014/928015