Hydrogen evolution reaction (HER) catalysts are essential for renewable hydrogen production, but conventional screening through density functional theory (DFT) remains computationally demanding. Here, we present a proof-of-concept machine learning (ML) framework that predicts hydrogen adsorption energies on Au-based alloys using a curated dataset and nine chemically interpretable descriptors. Tree-based ensemble models achieve quantitative accuracy (mean absolute error ≈ 0.13 eV), sufficient to resolve weak, optimal, and strong adsorption regimes. Feature attribution highlights generalized coordination number and site-specific electronic descriptors as dominant factors, consistent with established chemisorption principles. Guided by these insights, the trained model was applied to a library of Au–M alloys, with targeted DFT validation identifying Au–Mo, Au–W, Au–Ta, Au–Hf, and Au–Tc as promising candidates that couple favorable adsorption with alloy stability. Beyond specific predictions, this work introduces an accessible, reproducible workflow that connects ML predictions to catalytic intuition. The framework serves as a reference for experimental chemists, lowering the barrier for integrating data-driven approaches into catalyst discovery.

- Open Access

- Article

Chemically Interpretable Machine Learning for Predicting HER Activity in Au-Based Alloys

Author Information

Received: 10 Oct 2025 | Revised: 13 Nov 2025 | Accepted: 17 Nov 2025 | Published: 24 Nov 2025

Abstract

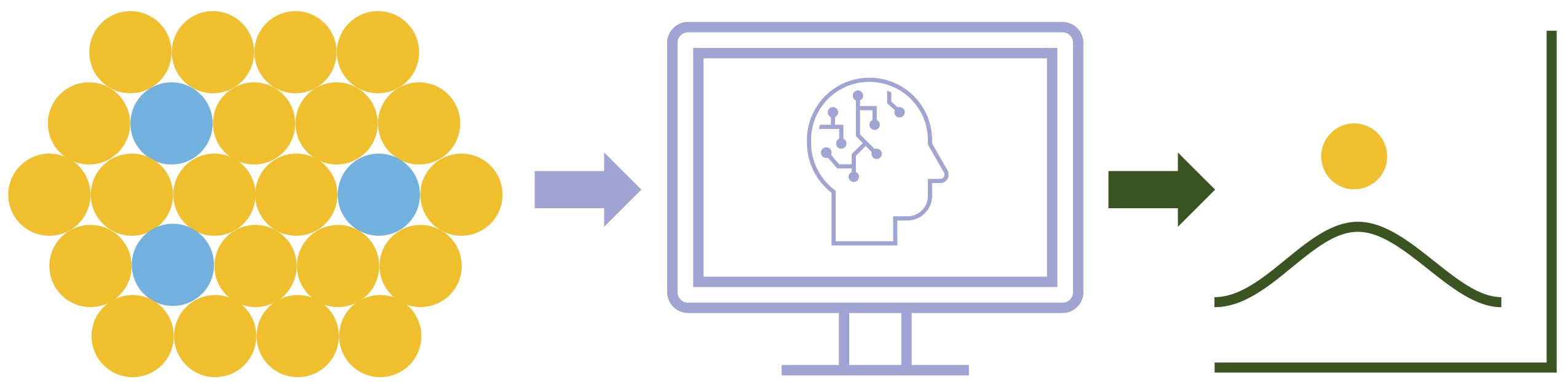

Graphical Abstract

Keywords

hydrogen evolution reaction (HER) | machine learning in catalysis | Au-based alloys | adsorption energy prediction | interpretable descriptors

References

- 1.Gao, Y.; Xu, Y.; Guo, H.; Li, J.; Ding, L.; Wang, T.; He, J.; Chang, K.; Wu, Z. A 17.73% Solar‐To‐Hydrogen Efficiency with Durably Active Catalyst in Stable Photovoltaic‐Electrolysis Seawater System. Angew. Chem. Int. Ed. 2025, 64, e202420814. https://doi.org/10.1002/anie.202420814.

- 2.Nsanzimana, J.M.V.; Cai, L.; Djire, A.; Pagot, G.; Mattana, P.; Vezzù, K.; Negro, E.; Xia, B.Y.; Di Noto, V. Tailoring Chemical Microenvironment of Iron‐Triad Electrocatalysts for Hydrogen Production by Water Electrolysis. Adv. Energy Mater. 2025, 15, 2501686. https://doi.org/10.1002/aenm.202501686.

- 3.Tang, J.; Guo, K.; Guan, D.; Hao, Y.; Shao, Z. A Semi-Vapor Electrolysis Technology for Hydrogen Generation from Wide Water Resources. Energy Environ. Sci. 2024, 17, 7394–7402. https://doi.org/10.1039/D4EE02722A.

- 4.Zhang, X.; Cao, C.; Ling, T.; Ye, C.; Lu, J.; Shan, J. Developing Practical Catalysts for High‐Current‐Density Water Electrolysis. Adv. Energy Mater. 2024, 14, 2402633. https://doi.org/10.1002/aenm.202402633.

- 5.Liu, Z.; Zhang, L.; Zheng, C.J.; Zhang, Y.; Chen, B.; Shao, Z.; Ge, J. Advanced Electrode Materials for Efficient Hydrogen Production in Protonic Ceramic Electrolysis Cells. Adv. Mater. 2025, 2503609. https://doi.org/10.1002/adma.202503609.

- 6.Brunin, G.; Ricci, F.; Ha, V.-A.; Rignanese, G.-M.; Hautier, G. Transparent Conducting Materials Discovery Using High-Throughput Computing. NPJ Comput. Mater. 2019, 5, 63. https://doi.org/10.1038/s41524-019-0200-5.

- 7.Wang, C.; Wang, B.; Wang, C.; Chang, Z.; Yang, M.; Wang, R. Efficient Machine Learning Model Focusing on Active Sites for the Discovery of Bifunctional Oxygen Electrocatalysts in Binary Alloys. ACS Appl. Mater. Interfaces 2024, 16, 16050–16061. https://doi.org/10.1021/acsami.3c17377.

- 8.Mai, H.; Le, T.C.; Chen, D.; Winkler, D.A.; Caruso, R.A. Machine Learning for Electrocatalyst and Photocatalyst Design and Discovery. Chem. Rev. 2022, 122, 13478–13515. https://doi.org/10.1021/acs.chemrev.2c00061.

- 9.Jeong, I.; Shim, Y.; Oh, S.; Yuk, J.M.; Roh, K.; Lee, C.; Lee, K.T. A Machine Learning‐Enhanced Framework for the Accelerated Development of Spinel Oxide Electrocatalysts. Adv. Energy Mater. 2024, 14, 2402342. https://doi.org/10.1002/aenm.202402342.

- 10.Chen, L.; Tian, Y.; Hu, X.; Yao, S.; Lu, Z.; Chen, S.; Zhang, X.; Zhou, Z. A Universal Machine Learning Framework for Electrocatalyst Innovation: A Case Study of Discovering Alloys for Hydrogen Evolution Reaction. Adv. Funct. Mater. 2022, 32, 2208418. https://doi.org/10.1002/adfm.202208418.

- 11.Liu, J.; Luo, W.; Wang, L.; Zhang, J.; Fu, X.; Luo, J. Toward Excellence of Electrocatalyst Design by Emerging Descriptor‐Oriented Machine Learning. Adv. Funct. Mater. 2022, 32, 2110748. https://doi.org/10.1002/adfm.202110748.

- 12.Jung, W.; Choi, J.; An, S.; Yun, S.; Chung, D.S.; Cha, H.; Lim, J.; Park, T. Photocatalytic Hydrogen Evolution with Conjugated Polymers: Structure–Property Insights and Design Strategies. Adv. Energy Mater. 2025, 15, 2501600. https://doi.org/10.1002/aenm.202501600.

- 13.Lee, W.J.; Kwak, H.S.; Lee, D.; Oh, C.; Yum, E.K.; An, Y.; Halls, M.D.; Lee, C.-W. Design and Synthesis of Novel Oxime Ester Photoinitiators Augmented by Automated Machine Learning. Chem. Mater. 2022, 34, 116–127. https://doi.org/10.1021/acs.chemmater.1c02871.

- 14.Nuñez, M. Exploring Materials Band Structure Space with Unsupervised Machine Learning. Comput. Mater. Sci. 2019, 158, 117–123. https://doi.org/10.1016/j.commatsci.2018.11.002.

- 15.Wang, C.; Wang, B.; Wang, C.; Li, A.; Chang, Z.; Wang, R. A Machine Learning Model with Minimize Feature Parameters for Multi-Type Hydrogen Evolution Catalyst Prediction. NPJ Comput. Mater. 2025, 11, 111. https://doi.org/10.1038/s41524-025-01607-4.

- 16.Wang, Z.; Yang, M.; Xie, X.; Yu, C.; Jiang, Q.; Huang, M.; Algadi, H.; Guo, Z.; Zhang, H. Applications of Machine Learning in Perovskite Materials. Adv. Compos. Hybrid. Mater. 2022, 5, 2700–2720. https://doi.org/10.1007/s42114-022-00560-w.

- 17.Mou, L.; Han, T.; Smith, P.E.S.; Sharman, E.; Jiang, J. Machine Learning Descriptors for Data‐Driven Catalysis Study. Adv. Sci. 2023, 10, 2301020. https://doi.org/10.1002/advs.202301020.

- 18.Zhang, N.; Yang, B.; Liu, K.; Li, H.; Chen, G.; Qiu, X.; Li, W.; Hu, J.; Fu, J.; Jiang, Y.; et al.Machine Learning in Screening High Performance Electrocatalysts for CO2 Reduction. Small Methods 2021, 5, 2100987. https://doi.org/10.1002/smtd.202100987.

- 19.Mamun, O.; Winther, K.T.; Boes, J.R.; Bligaard, T. High-Throughput Calculations of Catalytic Properties of Bimetallic Alloy Surfaces. Sci. Data 2019, 6, 76. https://doi.org/10.1038/s41597-019-0080-z.

- 20.Chen, X.; Zhou, T.; He, T.; Liu, Q. Vacancy Engineering in the First Coordination Shell of Single‐Atom Catalysts for Enhanced Hydrogen and Oxygen Evolution Reactions. Small 2025, 21, 2412000. https://doi.org/10.1002/smll.202412000.

- 21.Li, Y.; Zheng, S.; He, Y.; Yang, S.; Huang, W.-H.; Pao, C.-W.; Hu, Z.; Huang, X. Masked Second-Shell Sulfur Coordinating Atomically Dispersed Pd on Tin Oxide Boosts the Direct Synthesis of Hydrogen Peroxide. Chem. Eng. J. 2024, 500, 157297. https://doi.org/10.1016/j.cej.2024.157297.

- 22.Lv, Y.; Sun, W.; Luo, Q.; Gao, J.; Gu, G.; Ma, F. Fast Screening of High Anti-Corrosion Ta Ternary Alloys by Machine Learning and Electron-Level Descriptors. Mater. Chem. Phys. 2025, 339, 130820. https://doi.org/10.1016/j.matchemphys.2025.130820.

- 23.Tereshchenko, A.; Pashkov, D.; Guda, A.; Guda, S.; Rusalev, Y.; Soldatov, A. Adsorption Sites on Pd Nanoparticles Unraveled by Machine-Learning Potential with Adaptive Sampling. Molecules 2022, 27, 357. https://doi.org/10.3390/molecules27020357.

- 24.Shapera, E.P.; Bučar, D.-K.; Prasankumar, R.P.; Heil, C. Machine Learning Assisted Prediction of Organic Salt Structure Properties. NPJ Comput. Mater. 2024, 10, 176. https://doi.org/10.1038/s41524-024-01355-x.

- 25.Chen, K.; Kunkel, C.; Cheng, B.; Reuter, K.; Margraf, J.T. Physics-Inspired Machine Learning of Localized Intensive Properties. Chem. Sci. 2023, 14, 4913–4922. https://doi.org/10.1039/D3SC00841J.

- 26.Zou, Y.; Qian, J.; Wang, X.; Li, S.; Li, Y. Machine Learning-Assisted Prediction and Interpretation of Electrochemical Corrosion Behavior in High-Entropy Alloys. Comput. Mater. Sci. 2024, 244, 113259. https://doi.org/10.1016/j.commatsci.2024.113259.

- 27.Mishra, A.; Kompella, L.; Sanagavarapu, L.M.; Varam, S. Ensemble-Based Machine Learning Models for Phase Prediction in High Entropy Alloys. Comput. Mater. Sci. 2022, 210, 111025. https://doi.org/10.1016/j.commatsci.2021.111025.

- 28.Kapse, S.; Janwari, S.; Waghmare, U.V.; Thapa, R. Energy Parameter and Electronic Descriptor for Carbon Based Catalyst Predicted Using QM/ML. Appl. Catal. B: Environ. 2021, 286, 119866. https://doi.org/10.1016/j.apcatb.2020.119866.

- 29.Cerda, P.; Varoquaux, G.; Kégl, B. Similarity Encoding for Learning with Dirty Categorical Variables. Mach. Learn. 2018, 107, 1477–1494. https://doi.org/10.1007/s10994-018-5724-2.

- 30.Esterhuizen, J.A.; Goldsmith, B.R.; Linic, S. Uncovering Electronic and Geometric Descriptors of Chemical Activity for Metal Alloys and Oxides Using Unsupervised Machine Learning. Chem. Catal. 2021, 1, 923–940. https://doi.org/10.1016/j.checat.2021.07.014.

- 31.Lansford, J.L.; Vlachos, D.G. Spectroscopic Probe Molecule Selection Using Quantum Theory, First-Principles Calculations, and Machine Learning. ACS Nano 2020, 14, 17295–17307. https://doi.org/10.1021/acsnano.0c07408.

- 32.Chen, M.S.; Zuehlsdorff, T.J.; Morawietz, T.; Isborn, C.M.; Markland, T.E. Exploiting Machine Learning to Efficiently Predict Multidimensional Optical Spectra in Complex Environments. J. Phys. Chem. Lett. 2020, 11, 7559–7568. https://doi.org/10.1021/acs.jpclett.0c02168.

- 33.Wexler, R.B.; Martirez, J.M.P.; Rappe, A.M. Chemical Pressure-Driven Enhancement of the Hydrogen Evolving Activity of Ni2 P from Nonmetal Surface Doping Interpreted via Machine Learning. J. Am. Chem. Soc. 2018, 140, 4678–4683. https://doi.org/10.1021/jacs.8b00947.

- 34.Padama, A.A.B.; Palmero, M.A.; Shimizu, K.; Chookajorn, T.; Watanabe, S. Machine Learning and Density Functional Theory-Based Analysis of the Surface Reactivity of High Entropy Alloys: The Case of H Atom Adsorption on CoCuFeMnNi. Comput. Mater. Sci. 2025, 247, 113480. https://doi.org/10.1016/j.commatsci.2024.113480.

- 35.Pandit, N.K.; Roy, D.; Mandal, S.C.; Pathak, B. Rational Designing of Bimetallic/Trimetallic Hydrogen Evolution Reaction Catalysts Using Supervised Machine Learning. J. Phys. Chem. Lett. 2022, 13, 7583–7593. https://doi.org/10.1021/acs.jpclett.2c01401.

- 36.Dong, C.; Zhu, Y.; Qu, C.; Chen, Y.; Ma, Y.; Yu, Y.; Li, C. Coordination Chemistry-Driven Oxygen Vacancy Strategy for Rational Design of High-Performance Catalysts in BTX Oxidation. Coord. Chem. Rev. 2025, 545, 217007. https://doi.org/10.1016/j.ccr.2025.217007.

- 37.Chen, R.; Yang, J.; Yu, Y.; Liu, Z.; Wang, C.; Wen, Y.; Gao, Y.; Zhao, Y.; Sampara, C.S.; Li, W.; et al. Extra Trees Regression Assisted 1D Monolith Reactor Simulations Based on Microkinetic Analysis and Rate Transformation. Chem. Eng. Sci. 2025, 302, 120721. https://doi.org/10.1016/j.ces.2024.120721.

- 38.Da Costa, M.L.; Oviedo, L.R.; Franco, D.S.P.; Da Silva, W.L.; De Oliveira, J.S. Catalytic Ozonation for the Efficient Degradation of Tetracycline Using CoFe2O4@TiO2 Ceramic Nanocomposite: Kinetic, Thermodynamic and Machine Learning Study. Ceram. Int. 2025, 51, 7143–7158. https://doi.org/10.1016/j.ceramint.2024.12.149.

- 39.Naqvi, S.K.H.; Chong, K.T.; Tayara, H. Machine Learning-Enhanced Analysis of Catalyst Particle Size Effects and Performance Prediction of Platinum on Carbon Electrocatalysts. Comput. Mater. Sci. 2025, 259, 114105. https://doi.org/10.1016/j.commatsci.2025.114105.

- 40.Panapitiya, G.; Avendaño-Franco, G.; Ren, P.; Wen, X.; Li, Y.; Lewis, J.P. Machine-Learning Prediction of CO Adsorption in Thiolated, Ag-Alloyed Au Nanoclusters. J. Am. Chem. Soc. 2018, 140, 17508–17514. https://doi.org/10.1021/jacs.8b08800.

- 41.He, X.; Liu, J.; Yang, C.; Jiang, G. Predicting Thermodynamic Stability of Magnesium Alloys in Machine Learning. Comput. Mater. Sci. 2023, 223, 112111. https://doi.org/10.1016/j.commatsci.2023.112111.

- 42.Cheng, G.; Gong, X.-G.; Yin, W.-J. An Approach for Full Space Inverse Materials Design by Combining Universal Machine Learning Potential, Universal Property Model, and Optimization Algorithm. Sci. Bull. 2024, 69, 3066–3074. https://doi.org/10.1016/j.scib.2024.07.015.

- 43.Martínez-Alonso, C.; Vassilev-Galindo, V.; Comer, B.M.; Abild-Pedersen, F.; Winther, K.T.; LLorca, J. Application of machine learning to discover new intermetallic catalysts for the hydrogen evolution and the oxygen reduction reactions. Catal. Sci. Technol. 2024, 14, 3784–3799.

How to Cite

Kubik, M.; Wang, S.; Camargo, P. H. C. Chemically Interpretable Machine Learning for Predicting HER Activity in Au-Based Alloys. Materials and Interfaces 2025, 2 (4), 406–417. https://doi.org/10.53941/mi.2025.100032.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References