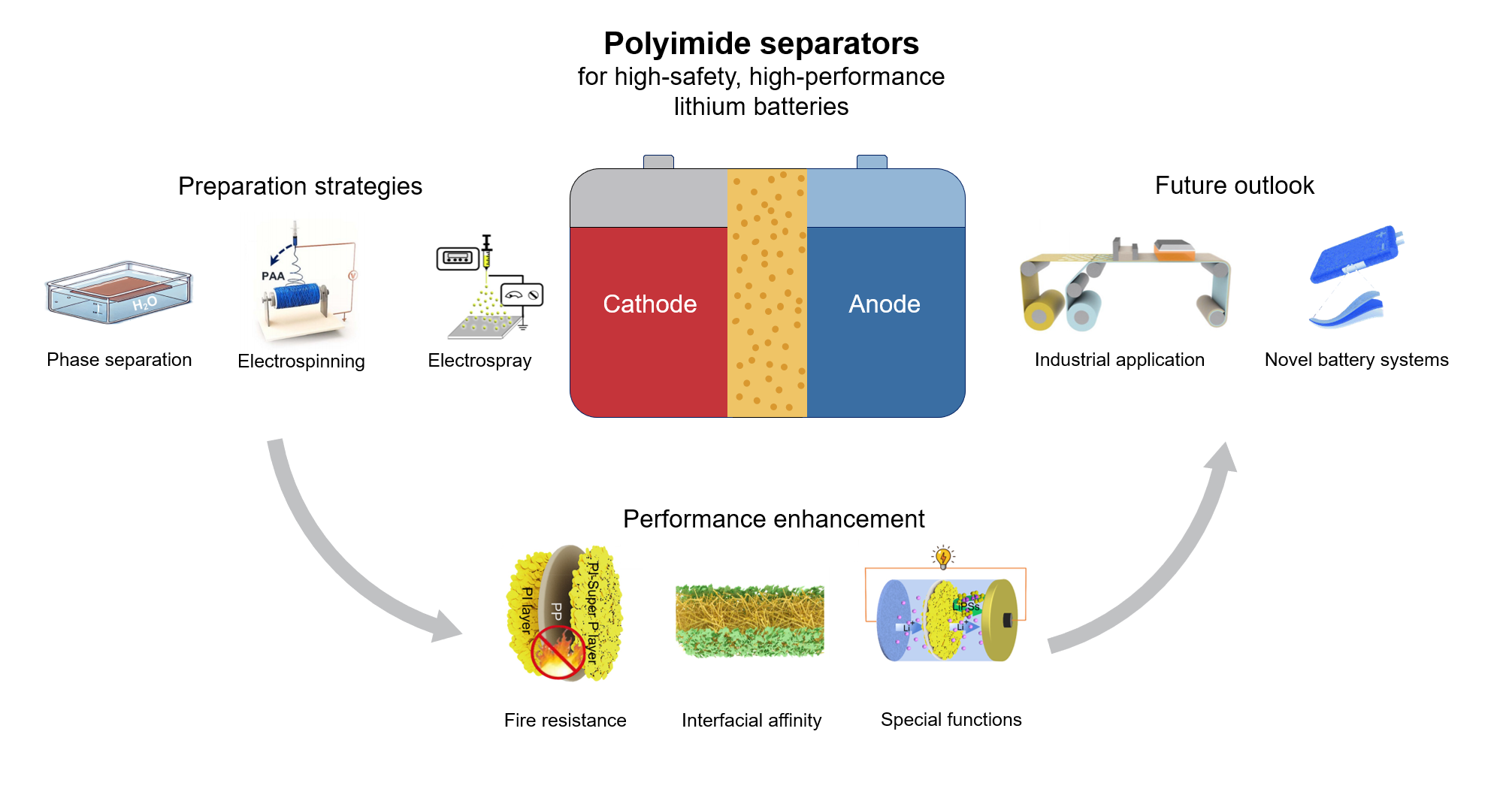

The development of lithium-ion batteries towards higher energy density and enhanced safety is hindered by the performance limitations of their core component: the separator. The inherent drawbacks of traditional polyolefin separators, namely poor thermal stability (pronounced melting and shrinkage at elevated temperatures) and insufficient electrolyte affinity (leading to high interfacial impedance), represent critical obstacles that must be overcome. Polyimide (PI), renowned for its exceptional thermal resistance, mechanical strength, and chemical stability, emerges as an ideal alternative material. However, transforming dense PI polymers into high-performance porous separators faces three major challenges: (i) achieving precise construction of high porosity and interconnected pore channels while maintaining excellent thermal stability; (ii) balancing high porosity with high mechanical strength and further optimizing the electrochemical interface; and (iii) overcoming the bottlenecks of high cost and scalable manufacturing to meet industrial demands. This review systematically summarizes strategies and progress in addressing these challenges. First, we analyze preparation strategies for porous structures, discussing breakthroughs achieved by nonsolvent-induced phase separation (NIPS), thermally induced phase separation (TIPS), and electrospinning methods and electrospinning methods in constructing fine structures such as nanofiber networks and vertical channels. Subsequently, we focus on performance optimization and functionalization: enhancing mechanical and thermal stability through inorganic compositing and surface armoring; optimizing ion transport and interfacial compatibility via polar modification and wettable coatings; and imparting advanced functionalities like smart responsiveness and catalytic conversion to adapt to emerging battery systems such as lithium-sulfur and lithium-metal batteries. The discussion consistently centers on the transition from laboratory research to industrial application, evaluating the practical potential of various strategies. Finally, we outline future directions, emphasizing the need to bridge the gap from material innovation to commercial application through rational design and engineering innovation, aiming to provide a clear roadmap for developing next-generation, safe, high-performance lithium battery separator solutions.

- Open Access

- Review

Polyimide Separators Navigating Challenges and Opportunities in Next-Generation Lithium Batteries

- Shijie Zhong 1,†,

- Haodong Xie 1,†,

- Quan Li 2,

- Yunfa Dong 1,

- Shengyu Zhou 1,

- Zhihao Zhu 1,

- Jiecai Han 1,

- Jipeng Liu 3,

- Yuhui He 1,*,

- Yupei Han 4,*

Author Information

Received: 29 Nov 2025 | Revised: 29 Dec 2025 | Accepted: 08 Jan 2026 | Published: 28 Jan 2026

Abstract

Graphical Abstract

Keywords

polyimide separators | lithium batteries | high safety | interfacial engineering | functionalized separators

References

- 1.

Du, L.Y.; Zhang, Y.M.; Xiao, Y.Y.; et al. A defect-rich carbon induced built-in interfacial electric field accelerating ion-conduction towards superior-stable solid-state batteries. Energy Environ. Sci. 2025, 18, 2949–2961.

- 2.

Du, L.L.; Zhang, B.; Deng, W.; et al. Hierarchically self-assembled MOF network enables continuous ion transport and high mechanical strength. Adv. Energy Mater. 2022, 12, 202200501.

- 3.

Shen, J.; Zhang, B.; Huang, W.; et al. Achieving thermodynamic stability of single-crystal Co-free Ni-rich cathode material for high voltage lithium-ion batteries. Adv. Funct. Mater. 2023, 33, 2300081.

- 4.

Lagadec, M.F.; Zahn, R.; Wood, V. Characterization and performance evaluation of lithium-ion battery separators. Nat. Energy 2019, 4, 16–25.

- 5.

Dai, J.H.; Shi, C.; Li, C.; et al. A rational design of separator with substantially enhanced thermal features for lithium-ion batteries by the polydopamine-ceramic composite modification of polyolefin membranes. Energy Environ. Sci. 2016, 9, 3252–3261.

- 6.

Li, H.; Wu, D.B.; Wu, J.; et al. Flexible, high-wettability and fire-resistant separators based on hydroxyapatite nanowires for advanced lithium-ion batteries. Adv. Mater. 2017, 29, 201703548.

- 7.

Huang, X.S.; Hitt, J. Lithium ion battery separators: Development and performance characterization of a composite membrane. J. Membr. Sci. 2013, 425, 163–168.

- 8.

Xiang, Y.Y.; Li, J.S.; Lei, J.H.; et al. Advanced separators for lithium-ion and lithium-sulfur batteries: A review of recent progress. ChemSusChem 2016, 9, 3023–3039.

- 9.

Chen, H.D.; Liu, X.H.; Zhang, S.Q.; et al. Full recovery of polyimide wastes into high-value products through break and reconstruction of imide ring. Adv. Sci. 2025, 12, 2414416.

- 10.

Chen, L.; Yang, D.D.; Xin, J.H.; et al. High dielectric sulfonyl-containing polyimide binders optimize the long-term stability and safety of NCM811 lithium-ion batteries at high voltages. Chem. Eng. J. 2025, 503, 158670.

- 11.

Deng, Y.R.; Pan, Y.L.; Zhang, Z.X.; et al. Novel thermotolerant and flexible polyimide aerogel separator achieving advanced lithium-ion batteries. Adv. Funct. Mater. 2022, 32, 2106176.

- 12.

Zhang, Y.L.; Ruan, K.P.; Zhou, K.; et al. Controlled distributed Ti3C2Tx hollow microspheres on thermally conductive polyimide composite films for excellent electromagnetic interference shielding. Adv. Mater. 2023, 35, 202211642.

- 13.

Liu, X.J.; Zheng, M.S.; Chen, G.; et al. High-temperature polyimide dielectric materials for energy storage: Theory, design, preparation and properties. Energy Environ. Sci. 2022, 15, 56–81.

- 14.

Han, B.; Ding, X.; Yu, B.Q.; et al. Two-dimensional covalent organic frameworks with Cobalt(II)-phthalocyanine sites for efficient electrocatalytic carbon dioxide reduction. J. Am. Chem. Soc. 2021, 143, 7104–7113.

- 15.

Liaw, D.J.; Wang, K.L.; Huang, Y.C.; et al. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974.

- 16.

Luo, X.X.; Li, W.H.; Liang, H.J.; et al. Covalent organic framework with highly accessible carbonyls and π-cation effect for advanced potassium-ion batteries. Angew. Chem. Int. Ed. 2022, 61, 202117661.

- 17.

Yao, L.Y.; Ma, C.; Sun, L.B.; et al. Highly crystalline polyimide covalent organic framework as dual-active-center cathode for high-performance lithium-ion batteries. J. Am. Chem. Soc. 2022, 144, 23534–23542.

- 18.

Yu, J.F.; Dong, N.X.; Liu, B.X.; et al. A newly-developed heat-resistance polyimide microsphere coating to enhance the thermal stability of commercial polyolefin separators for advanced lithium-ion battery. Chem. Eng. J. 2022, 442, 136314.

- 19.

Wan, J.Y.; Xie, J.; Kong, X.; et al. Ultrathin, flexible, solid polymer composite electrolyte enabled with aligned nanoporous host for lithium batteries. Nat. Nanotechnol. 2019, 14, 705–711.

- 20.

Huang, H.T.; Chen, K.J.; Li, C.Y.; et al. Zwitterion grafted polyimide separator for improving lithium-ion transport and its application in LiCoO2 batteries. Chem. Eng. J. 2024, 481, 148577.

- 21.

Jeong, T.Y.; Lee, Y.D.; Ban, Y.; et al. Polyimide composite separator containing surface-modified hollow mesoporous silica nanospheres for lithium-ion battery application. Polymer 2021, 212, 123288.

- 22.

Li, X.G.; Liu, K.F.; Yan, Y.; et al. Thermostable and nonflammable polyimide/zirconia compound separator for lithium-ion batteries with superior electrochemical and safe properties. J. Colloid Interface Sci. 2022, 625, 936–945.

- 23.

Zhao, H.J.; Deng, N.P.; Wang, G.; et al. A core@sheath nanofiber separator with combined hardness and softness for lithium-metal batteries. Chem. Eng. J. 2021, 404, 126542.

- 24.

Feng, X.J.; Wang, H.Y.; Yan, L.X.; et al. Composite separator based on a polyimide nanofiber membrane for advanced lithium-ion batteries. Acs Appl. Polym. Mater. 2024, 6, 11028–11038.

- 25.

Wang, Z.Y.; Liu, F.Z.; Li, X.G.; et al. Dual-functional separators regulating ion transport enabled by 3D-reinforced polyimide microspheres protective layer for dendrite-free and high-temperature lithium metal batteries. Acs Appl. Mater. Interfaces 2024, 16, 23826–23837.

- 26.

Song, C.Y.; Gao, C.; Peng, Q.G.; et al. A novel high-performance electrospun of polyimide/lignin nanofibers with unique electrochemical properties and its application as lithium-ion batteries separators. Int. J. Biol. Macromol. 2023, 246, 125668.

- 27.

Duan, H.Y.; Li, K.; Xie, M.; et al. Scalable synthesis of ultrathin polyimide covalent organic framework nanosheets for high-performance lithium-sulfur batteries. J. Am. Chem. Soc. 2021, 143, 19446–19453.

- 28.

Xu, Z.X.; Li, M.; Sun, W.Y.; et al. An ultrafast, durable, and high-loading polymer anode for aqueous Zinc-ion batteries and supercapacitors. Adv. Mater. 2022, 34, 2200077.

- 29.

Zong, Y.; He, H.W.; Wang, Y.Z.; et al. Functionalized separator strategies toward advanced aqueous zinc-ion batteries. Adv. Energy Mater. 2023, 13, 202300403.

- 30.

Li, C.; Liu, R.; Xiao, Y.; et al. Recent progress of separators in lithium-sulfur batteries. Energy Storage Mater. 2021, 40, 439–460.

- 31.

Ren, D.S.; Feng, X.N.; Liu, L.S.; et al. Investigating the relationship between internal short circuit and thermal runaway of lithium-ion batteries under thermal abuse condition. Energy Storage Mater. 2021, 34, 563–573.

- 32.

Zhang, L.P.; Li, X.L.; Yang, M.R.; et al. High-safety separators for lithium-ion batteries and sodium-ion batteries: Advances and perspective. Energy Storage Mater. 2021, 41, 522–545.

- 33.

Versaci, D.; Canale, I.; Goswami, S.; et al. Molybdenum disulfide/polyaniline interlayer for lithium polysulphide trapping in lithium-sulphur batteries. J. Power Sources 2022, 521, 230945.

- 34.

Wen, C.; Ding, H.B.; Yang, Y. Numerical simulation of nanodroplet generation of water vapour in high-pressure supersonic flows for the potential of clean natural gas dehydration. Energy Convers. Manag. 2021, 231, 113853.

- 35.

Wang, Y.; Liu, X.; Sheng, J.; et al. Nanoporous regenerated cellulose separator for high-performance lithium ion batteries prepared by nonsolvent-induced phase separation. Acs Sustain. Chem. Eng. 2021, 9, 14756–14765.

- 36.

Hussain, A.; Raza, W.; Mehmood, A.; et al. Ionic potency regulation of coagulation bath induced by saline solution to control over the pore structure of PBI membrane for high-performance lithium metal batteries. J. Energy Chem. 2024, 94, 288–298.

- 37.

Ho, C.C.; Su, J.F. Boosting permeation and separation characteristics of polyethersulfone ultrafiltration membranes by structure modification via dual-PVP pore formers. Polymer 2022, 241, 124560.

- 38.

Tsai, C.Y.; Liu, Y.L. Crosslinked polyimide asymmetric membranes as thermally-stable separators with self-protective layers and inhibition of lithium dendrite growth for lithium metal battery. J. Membr. Sci. 2021, 640, 119816.

- 39.

Li, Y.J.; Yang, H.C.; Ahmadi, A.; et al. A thermal resistant and flame retardant separator reinforced by attapulgite for lithium-ion batteries via multilayer coextrusion. Polymer 2022, 253, 125027.

- 40.

Arundati, A.H.; Ratri, C.R.; Chalid, M.; et al. A combination of nonsolvent and thermally induced phase separation (N-TIPS) technique for the preparation of highly porous cellulose acetate membrane as lithium-ion battery separators. Ionics 2024, 30, 123–133.

- 41.

Enchinton, A.; Martinez, A.C.; Gonzalez, K.R.; et al. 3D printing of highly porous polypropylene separators for lithium-ion batteries using fused deposition modeling and thermally induced phase separation. Adv. Mater. Technol. 2025, 10, 202500912.

- 42.

Mohammadzad, M.K.; Pircheraghi, G.; Sharifi, H. Fabrication, characterization, and electrochemical performance of the HDPE/sepiolite nanocomposite as a novel separator for Li-ion batteries. Express Polym. Lett. 2021, 15, 1063–1080.

- 43.

Bai, Y.T.; Yan, C.Q.; Li, Z.; et al. Preparation of high-strength polyimide porous films with thermally closed pore property by in situ pore formation method. Acta Phys. Chim. Sin. 2024, 40, 2306010.

- 44.

Deng, Y.; Pan, Y.; Li, C.; et al. Advanced polyimide separator via co-precursor method for lithium-ion batteries with low thermal runaway risks. J. Energy Storage 2022, 56, 106100.

- 45.

Gu, J.P.; Zhang, K.Y.; Li, X.T.; et al. Construction of safety and non-flammable polyimide separator containing carboxyl groups for advanced fast charing lithium-ion batteries. Chin. J. Polym. Sci. 2022, 40, 345–354.

- 46.

Lin, Y.-H.; Huang, W.-M.; Li, J.-Y.; et al. Nonsolvent-induced phase separation polyimide/polymeric ionic liquid separators for high-performance and safe lithium metal-based batteries. J. Membr. Sci. 2025, 728, 124125.

- 47.

Wen, G.; Cai, W.; Lv, S.; et al. A microfluid-on-microfluid phase separation strategy fabricates high-throughout porous polyimide separator for lithium-ion batteries. Polymer 2024, 303, 127102.

- 48.

Zhang, Q.; Chen, L.; Li, X.; et al. Robust, high-temperature-resistant polyimide separators with vertically aligned uniform nanochannels for high-performance lithium-ion batteries. ACS Nano 2024, 18, 32162–32174.

- 49.

Huang, X.; Cheng, S.; Huang, C.; et al. Superspreading-based fabrication of thermostable nanoporous polyimide membranes for high safety separators of lithium-ion batteries. Small 2024, 20, 2311219.

- 50.

Jalees, S.; Hussain, A.; Iqbal, R.; et al. Functional PBI membrane based on polyimide covalent organic framework for durable lithium metal battery. J. Energy Storage 2024, 101, 113985.

- 51.

Zhang, Y.S.; Zhang, X.L.; Silva, S.R.P.; et al. Lithium-sulfur batteries meet electrospinning: Recent advances and the key parameters for high gravimetric and volume energy density. Adv. Sci. 2022, 9, 202103879.

- 52.

Liu, Z.Z.; Li, G.J.; Qin, Q.; et al. Electrospun PVDF/PAN membrane for pressure sensor and sodium-ion battery separator. Adv. Compos. Hybrid Mater. 2021, 4, 1215–1225.

- 53.

Liu, Y.Y.; Lin, D.C.; Liang, Z.; et al. Lithium-coated polymeric matrix as a minimum volume-change and dendrite-free lithium metal anode. Nat. Commun. 2016, 7, 10992.

- 54.

Deng, J.H.; Cao, D.Q.; Yang, X.Q.; et al. Cross-linked cellulose/carboxylated polyimide nanofiber separator for lithium-ion battery application. Chem. Eng. J. 2022, 433, 133934.

- 55.

Yang, Q.; Deng, N.P.; Chen, J.Y.; et al. The recent research progress and prospect of gel polymer electrolytes in lithium-sulfur batteries. Chem. Eng. J. 2021, 413, 127427.

- 56.

Yang, K.; Liu, Z.; Chai, J.; et al. High performance polyimide-based separator for 4.5V high voltage LiCoO2 battery with superior safety. Mater. Chem. Phys. 2022, 282, 125975.

- 57.

Wang, Y.; Guo, M.; Fu, H.; et al. Thermotolerant separator of cross-linked polyimide fibers with narrowed pore size for lithium-ion batteries. J. Membr. Sci. 2022, 662, 121004.

- 58.

Sun, G.; Feng, X.; Zhang, X.; et al. In-situ reinforced polyimide nanofiber membranes for highly efficient and safe lithium-ion batteries. J. Membr. Sci. 2024, 697, 122549.

- 59.

Liu, K.; Lin, D.; Dong, N.; et al. In-situ ScOOH coaxially armored polyimide nanofibrous separator with high electrolyte wettability and thermostability for high-safety and high-rate capability lithium-ion batteries. J. Membr. Sci. 2025, 736, 124722.

- 60.

Wang, J.; He, C.; Jia, Y.; et al. Fire-proofing, mechanic-reinforcing, electrostatic-spinning strategies toward fabricating porous separator for superior and safer lithium-ion batteries. ACS Appl. Polym. Mater. 2025, 7, 4725–4738.

- 61.

Pan, C.; Wei, X.; Feng, Y.T.; et al. WO3-composited polyimide nanofibrous separator with superior mechanical properties and high capacity for lithium-ion batteries. J. Mater. Sci. 2023, 58, 10686–10698.

- 62.

Song, C.; Luo, J.; Gao, C.; et al. Halloysite nanotubes enhanced polyimide/oxidized-lignin nanofiber separators for long-cycling lithium metal batteries. Int. J. Biol. Macromol. 2024, 273, 132640.

- 63.

Qian, Y.S.; Chen, K.; Feng, Z.X.; et al. A Fluorinated-polyimide-based composite nanofibrous separator with homogenized pore size for wide-temperature lithium metal batteries. Small Struct. 2023, 4, 202200383.

- 64.

Shimbori, Y.; Ooga, S.; Kajihara, K.; et al. Effect of polybenzimidazole addition to three-dimensionally ordered macroporous polyimide separators on mechanical properties and electrochemical performances. Electrochemistry 2024, 92, 23–00145.

- 65.

Wang, Z.; Li, X.; Dong, N.; et al. Novel ZrO2@Polyimde nano-microspheres-coated polyethylene separators for high energy density and high safety Li-ion battery. Mater. Today Energy 2022, 30, 101155.

- 66.

Green-Warren, R.A.; Fassler, A.L.; Juhl, A.; et al. Self-limiting electrospray deposition (SLED) of porous polyimide coatings as effective lithium-ion battery separator membranes. Rsc Appl. Polym. 2024, 2, 1074–1081.

- 67.

Kang, S.H.; Lee, H.; Hong, Y.J.; et al. High-performance, roll-to-roll fabricated scaffold-supported solid electrolyte separator for practical all-solid-state batteries. Small 2025, 21, 202502996.

- 68.

Chen, Y.; Liu, H.; Luo, J.; et al. In situ aluminide armored polyimide nanofiber separators with ultrahigh strength and high wettability for advanced lithium-ion batteries. Ceram. Int. 2023, 49, 31953–31964.

- 69.

Sun, G.; Jiang, S.; Feng, X.; et al. Ultra-robust polyimide nanofiber separators with shutdown function for advanced lithium-ion batteries. J. Membr. Sci. 2022, 645, 120208.

- 70.

Jia, S.; Yang, S.; Pan, Y.; et al. Boehmite-PVDF-CTFE/F-PI composite separator irradiated by electron beam for high-rate lithium-ion batteries. J. Membr. Sci. 2024, 704, 122827.

- 71.

Chen, H.H.; Yu, L.; Cao, X.; et al. The multicomponent synergistic effect of a hierarchical Li0.485La0.505TiO3 solid-state electrolyte for dendrite-free lithium-metal batteries. Nanoscale 2022, 14, 7768–7777.

- 72.

Cheon, J.; Park, S.H.; Kim, Y.; et al. Aluminum oxide and ethylene bis(diphenylphosphine)-incorporated poly(imide) separators for lithium-ion batteries. Bull. Korean Chem. Soc. 2022, 43, 1103–1110.

- 73.

Palanisamy, M.; Lin, K.-W.; Lo, C.-T.; et al. In situ thermal safety aspect of the electrospun polyimide-Al2O3 separator reveals less exothermic heat energies than polypropylene at the thermal runaway event of lithium-ion batteries. ACS Appl. Mater. Interfaces 2022, 14, 28310–28320.

- 74.

Wu, D.; Dong, N.; Wang, R.; et al. In situ construction of High-safety and Non-flammable polyimide “Ceramic” Lithium-ion battery separator via SiO2 Nano-Encapsulation. Chem. Eng. J. 2021, 420, 129992.

- 75.

Li, X.; Liu, K.; Dong, N.; et al. A dendrite-blocking polyimide-meta-aramid separator with ultrahigh strength and thermostability for high-security lithium-ion battery. Chem. Eng. J. 2024, 481, 148525.

- 76.

Sun, G.H.; Cui, J.Q.; Zhang, Q.S.; et al. Polybenzimidazolium-reinforced polyimide separators to inhibit dendrites for high-security lithium-ion batteries. Sci. China-Chem. 2025, 68, 3221–3229.

- 77.

Li, M.; Wang, K.; Shen, F.; et al. An electrolyte-locked thermally stable composite separator for safe lithium ion batteries. J. Alloys Compd. 2023, 938, 168543.

- 78.

Liao, C.; Wang, W.; Wang, J.; et al. Magnetron sputtering deposition of silicon nitride on polyimide separator for high-temperature lithium-ion batteries. J. Energy Chem. 2021, 56, 1–10.

- 79.

Zhong, S.; Dong, L.; Yuan, B.; et al. Stabilizing high-nickel cathodes via interfacial hydrogen bonding effects using a hydrofluoric acid-scavenging separator. Engineering 2024, 39, 117–126.

- 80.

Chen, Y.; Luo, J.; Xu, H.; et al. Core-Shell structured polyimide@γ-Al2O3 nanofiber separators for lithium-ion batteries. ACS Appl. Energy Mater. 2023, 6, 1692–1701.

- 81.

Jiang, W.; Chen, Y.; Zhang, J.; et al. Alkali etching enhanced polyimide-based three-layer composite separator for lithium-ion batteries. Ionics 2024, 30, 3209–3221.

- 82.

Yan, L.X.; Feng, X.J.; Wang, H.Y.; et al. Preparation of PEI-modified PI separators for advanced lithium ion batteries. Ionics 2025, 31, 453–465.

- 83.

Seong Heo, J.; Yim, T. Lithium p-toluenesulfinate-coated poly(imide) separators for enhanced safety and electrochemical performances of lithium-ion batteries. J. Ind. Eng. Chem. 2025, 144, 746–753.

- 84.

Wang, Y.; Yang, W.; Zhao, D.; et al. Design and fabrication of a multifunctional Co2Mo3O8-modified separator for enhanced performance and safety in lithium–sulfur batteries. Mater. Chem. Phys. 2025, 344, 131170.

- 85.

Lei, T.; Chen, W.; Hu, Y.; et al. A nonflammable and thermotolerant separator suppresses polysulfide dissolution for safe and long-cycle lithium-sulfur batteries. Adv. Energy Mater. 2018, 8, 1802441.

- 86.

Chen, H.; Wei, Y.; Cao, X.; et al. Boosting polysulfide capture and redox conversion by functional separator combined with porous hosts for advanced Li-S batteries. J. Electroanal. Chem. 2022, 918, 116483.

- 87.

Lee, Y.D.; Yuenyongsuwan, J.; Nanthananon, P.; et al. Polyimide hybrid membranes with graphene oxide for lithium–sulfur battery separator applications. Polymer 2022, 255, 125110.

- 88.

Zhu, Y.; Zhang, Y.; Jin, S.; et al. Toward safe and high-performance lithium–sulfur batteries via polyimide nanosheets-modified separator. ACS Sustain. Chem. Eng. 2023, 11, 1434–1447.

- 89.

He, Y.; Guo, J.; Bi, C.; et al. Sandwich-like polyimide nanofiber membrane of PEO-based solid-state electrolytes to promote mechanical properties and security for lithium metal batteries. Int. J. Hydrogen Energy 2025, 109, 1266–1273.

- 90.

Li, M.; Wang, K.; Liu, J.; et al. Synergistically reinforced poly(ethylene oxide)-based composite electrolyte for high-temperature lithium metal batteries. J. Colloid Interface Sci. 2022, 622, 1029–1036.

- 91.

Hu, W.; Zhu, G.; Chi, F.; et al. Searching for thermal shutdown separators in lithium-ion batteries: Paradigm and practice. Int. J. Heat Mass Transf. 2025, 236, 126248.

- 92.

Yin, Y.; Wang, K.; Shen, F.; et al. Dendrite-suppressing separator with high thermal stability modified by beaded-chain-like polyimide coating for a Li metal anode. Energy Fuels 2021, 35, 8417–8422.

- 93.

Sun, B.; Zhang, Z.; Xu, J.; et al. Composite separator based on PI film for advanced lithium metal batteries. J. Mater. Sci. Technol. 2022, 102, 264–271.

This work is licensed under a Creative Commons Attribution 4.0 International License.