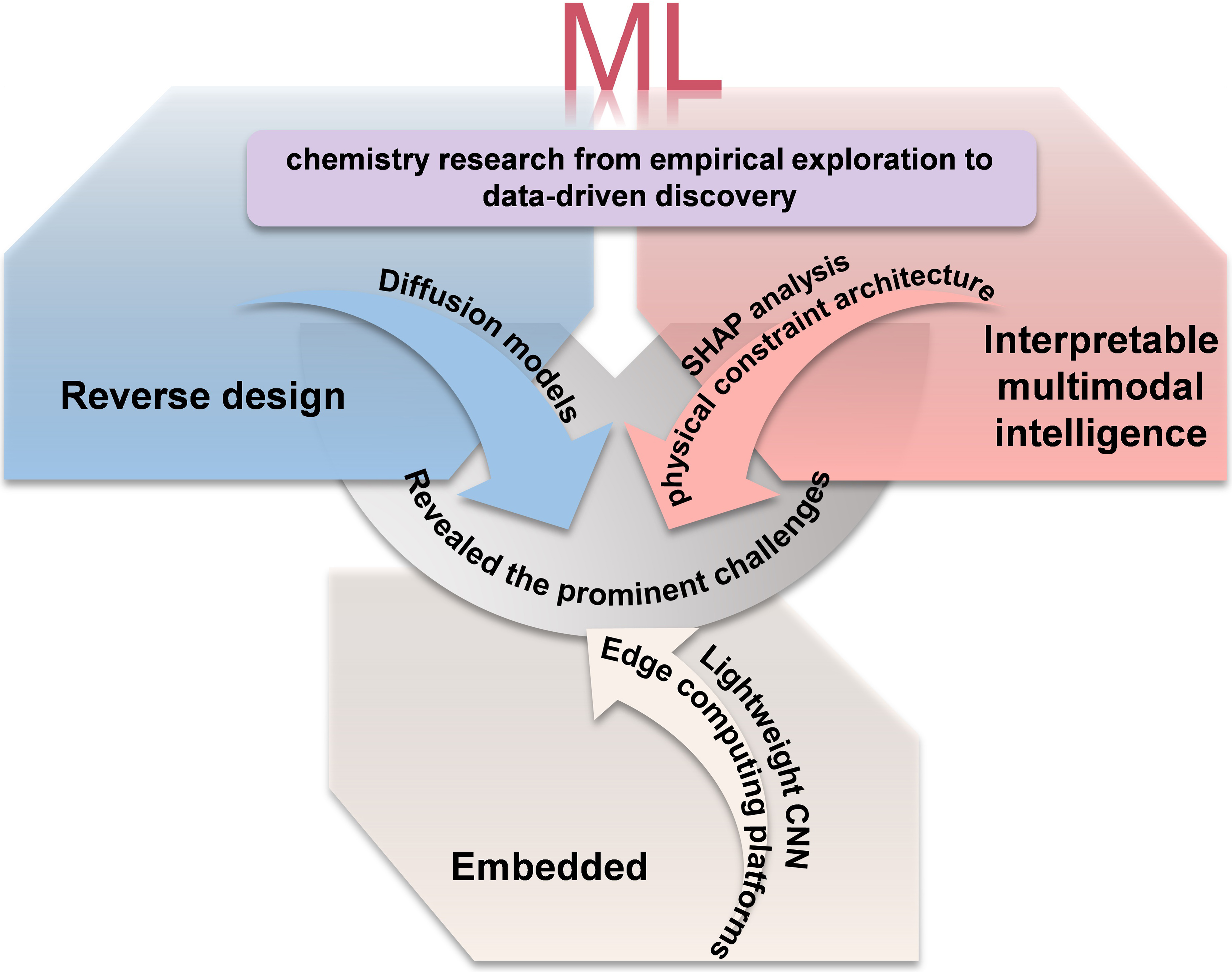

The fusion of machine learning is catalyzing a paradigm shift in chemistry research from empirical exploration to data-driven discovery. This review systematically summarizes the cutting-edge progress of machine learning algorithms in breaking through the limitations of traditional chemical research. In terms of reverse design, diffusion models have achieved a structural reconstruction accuracy of up to 93.4%, and closed-loop verification has been achieved through Rietveld refinement. Regarding the interpretable multimodal intelligence, by combining Shapley additive explanations (SHAP) analysis and physical constraint architecture, the structure-activity relationship across spectral, microscopic, and time series data has been successfully decoded through effective fusion of multimodal data and algorithms. For the embedded machine learning systems, the deployment of lightweight convolutional neural networks (CNN) and edge computing platforms provides real-time control capabilities for industrial synthesis and environmental monitoring via tight integration of algorithmic and system modalities. More importantly, we have revealed the existing challenges, including the generalization gap in low-symmetry systems, limitations in dynamic process modeling, and data heterogeneity in cross-modality integration. This study has drawn a development blueprint for the next generation of chemical intelligent systems, which integrates physical perception algorithms with automated experiments to ultimately achieve programmable material design.

- Open Access

- Review

Multimodal Intelligence in Chemical Discovery: Integrating Interpretable ML, Autonomous Robotics, and Edge Computing

- Huijie Zhou 1, 2,

- Wenjiang Zou 1,

- Shunyu Gu 2,

- Jiming Xu 1,

- Jing Zhang 1,

- Mohsen Shakouri 3,

- Jiang Xu 1,

- Lvzhou Li 1,

- Huan Pang 1, 2, *,

- Jianning Ding 1, *

Author Information

Received: 22 Aug 2025 | Revised: 10 Sep 2025 | Accepted: 28 Sep 2025 | Published: 16 Oct 2025

Abstract

Graphical Abstract

Keywords

chemical field | machine learning | reverse design | multimodal intelligence | application

References

- 1.Pihlajamäki, A.; Matus, M.F.; Malola, S.; et al. GraphBNC: Machine Learning-Aided Prediction of Interactions Between Metal Nanoclusters and Blood Proteins. Adv. Mater. 2024, 36, 2407046. https://doi.org/10.1002/adma.202407046.

- 2.Li, Q.; Zhang, Y.; Guo, X.; et al. Nucleation and Growth Mechanisms of Micro/Nano Structural Manganese-Trimesic Acid Coordinations for Aqueous Zinc-Ion Batteries. Angew. Chem. Int. Ed. 2025, 64, e202509741. https://doi.org/10.1002/anie.202509741.

- 3.Zhang, G.; Lu, Y.; Yang, Y.; et al. Dynamic Phase Transformations of Prussian Blue Analogue Crystals in Hydrotherms. J. Am. Chem. Soc. 2024, 146, 16659–16669. https://doi.org/10.1021/jacs.4c03827.

- 4.Zhang, G.; Feng, W.; Du, G.; et al. Thermodynamically-Driven Phase Engineering and Reconstruction Deduction of Medium-Entropy Prussian Blue Analogue Nanocrystals. Adv. Mater. 2025, 2503814. https://doi.org/10.1002/adma.202503814.

- 5.Dahl, J.C.; Niblett, S.; Cho, Y.; et al. Scientific Machine Learning of 2D Perovskite Nanosheet Formation. J. Am. Chem. Soc. 2023, 145, 23076–23087. https://doi.org/10.1021/jacs.3c05984.

- 6.Chen, L.; Yang, S.; Li, Y.; et al. Precursor Symmetry Triggered Modulation of Fluorescence Quantum Yield in Graphene Quantum Dots. Adv. Funct. Mater. 2024, 34, 2401246. https://doi.org/10.1002/adfm.202401246.

- 7.Le, T.C.; Yan, B.; Winkler, D.A. Robust Prediction of Personalized Cell Recognition from a Cancer Population by a Dual Targeting Nanoparticle Library. Adv. Funct. Mater. 2015, 25, 6927–6935. https://doi.org/10.1002/adfm.201502811.

- 8.Kenry. Machine Learning-Assisted Clustering of Nanoparticle-Binding Peptides and Prediction of Their Properties. Adv. Theory Simul. 2023, 6, 2300122. https://doi.org/10.1002/adts.202300122.

- 9.Dias, L.M.S.; Fu, L.; Pereira, R.F.P.; et al. Evolving Photonic Authentication with Sustainable Luminescent Smart E-tags. FlexMat 2024, 1, 116–126. https://doi.org/10.1002/flm2.16.

- 10.Baig, M.M.; Khan, S.A.; Ahmad, H.; et al. 3D Printing of Hydrogels for Flexible Micro-supercapacitors. FlexMat 2024, 1, 79–99. https://doi.org/10.1002/flm2.14.

- 11.Ahmad, F.; Mahmood, A.; Muhmood, T. Machine Learning-Integrated Omics for the Risk and Safety Assessment of Nanomaterials. Biomater. Sci. 2021, 9, 1598–1608. https://doi.org/10.1039/D0BM01672A.

- 12.Ji, Z.; Guo, W.; Wood, E.L.; et al. Machine Learning Models for Predicting Cytotoxicity of Nanomaterials. Chem. Res. Toxicol. 2022, 35, 125–139. https://doi.org/10.1021/acs.chemrestox.1c00310.

- 13.Suwardi, A.; Wang, F.; Xue, K.; et al. Machine Learning-Driven Biomaterials Evolution. Adv. Mater. 2022, 34, 2102703. https://doi.org/10.1002/adma.202102703.

- 14.Wang, L.; Wang, H.; Bai, M.; et al. A Comparative Review: Research in Safety and Sustainability of Carbon Nanomaterials Without and With Machine Learning Assistance. IEEE Access 2024, 12, 167120–167152. https://doi.org/10.1109/ACCESS.2024.3494549.

- 15.Dang, Y.; Wang, G.; Su, G.; et al. Rational Construction of a Ni/CoMoO4 Heterostructure with Strong Ni–O–Co Bonds for Improving Multifunctional Nanozyme Activity. ACS Nano 2022, 16, 4536–4550. https://doi.org/10.1021/acsnano.1c11012.

- 16.Fernandez, M.; Bilić, A.; Barnard, A.S. Machine Learning and Genetic Algorithm Prediction of Energy Differences between Electronic Calculations of Graphene Nanoflakes. Nanotechnology 2017, 28, 38LT03. https://doi.org/10.1088/1361-6528/aa82e5.

- 17.Gupta, N.; Jayaraman, A. Computational Approach for Structure Generation of Anisotropic Particles (CASGAP) with Targeted Distributions of Particle Design and Orientational Order. Nanoscale 2023, 15, 14958–14970. https://doi.org/10.1039/D3NR02425C.

- 18.Kløve, M.; Sommer, S.; Iversen, B.B.; et al. A Machine-Learning-Based Approach for Solving Atomic Structures of Nanomaterials Combining Pair Distribution Functions with Density Functional Theory. Adv. Mater. 2023, 35, 2208220. https://doi.org/10.1002/adma.202208220.

- 19.Konstantopoulos, G.; Koumoulos, E.P.; Charitidis, C.A. Digital Innovation Enabled Nanomaterial Manufacturing; Machine Learning Strategies and Green Perspectives. Nanomaterials 2022, 12, 2646. https://doi.org/10.3390/nano12152646.

- 20.Rangel DaCosta, L.; Sytwu, K.; Groschner, C.K.; et al. A Robust Synthetic Data Generation Framework for Machine Learning in High-Resolution Transmission Electron Microscopy (HRTEM). NPJ Comput. Mater. 2024, 10, 1–11. https://doi.org/10.1038/s41524-024-01336-0.

- 21.Wan, K.; He, J.; Shi, X. Construction of High Accuracy Machine Learning Interatomic Potential for Surface/Interface of Nanomaterials—A Review. Adv. Mater. 2024, 36, 2305758. https://doi.org/10.1002/adma.202305758.

- 22.Guerrero-Rivera, R.; Godínez-Garcia, F.J.; Hayashi, T.; et al. Machine-Learning Driven STM Images Prediction of Doped/Defective Graphene: towards Optimized Tools for 2D Nanomaterials Characterization. Comput. Mater. Sci. 2024, 242, 113076. https://doi.org/10.1016/j.commatsci.2024.113076.

- 23.Kuznetsova, V.; Coogan, Á.; Botov, D.; et al. Expanding the Horizons of Machine Learning in Nanomaterials to Chiral Nanostructures. Adv. Mater. 2024, 36, 2308912. https://doi.org/10.1002/adma.202308912.

- 24.Yang, L.; Wang, H.; Leng, D.; et al. Machine Learning Applications in Nanomaterials: Recent Advances and Future Perspectives. Chem. Eng. J. 2024, 500, 156687. https://doi.org/10.1016/j.cej.2024.156687.

- 25.Zhang, H.; Yang, M.; Wu, Q.; et al. Engineering Two-Dimensional Nanomaterials for Photothermal Therapy. Angew. Chem. Int. Ed. 2025, 64, e202424768. https://doi.org/10.1002/anie.202424768.

- 26.Cao, L.; Li, C.; Mueller, T. The Use of Cluster Expansions to Predict the Structures and Properties of Surfaces and Nanostructured Materials. J. Chem. Inf. Model. 2018, 58, 2401–2413. https://doi.org/10.1021/acs.jcim.8b00413.

- 27.Diao, S.; Wu, Q.; Li, S.; et al. From Synthesis to Properties: Expanding the Horizons of Machine Learning in Nanomaterials Research. Mater. Horiz. 2025, 12, 4133–4164. https://doi.org/10.1039/D4MH01909A.

- 28.Wang, M.; Wang, T.; Cai, P.; et al. Nanomaterials Discovery and Design through Machine Learning. Small Methods 2019, 3, 1900025. https://doi.org/10.1002/smtd.201900025.

- 29.Chen, R.; Liu, F.; Tang, Y.; et al. Combined First-Principles and Machine Learning Study of the Initial Growth of Carbon Nanomaterials on Metal Surfaces. Appl. Surf. Sci. 2022, 586, 152762. https://doi.org/10.1016/j.apsusc.2022.152762.

- 30.Alkharisi, M.K.; Dahish, H.A.; et al. Prediction Models for the Hybrid Effect of Nano Materials on Radiation Shielding Properties of Concrete Exposed to Elevated Temperatures. Case Stud. Constr. Mater. 2024, 21, e03750. https://doi.org/10.1016/j.cscm.2024.e03750.

- 31.Dhoble, S.; Wu, T.-H. Kenry Decoding Nanomaterial-Biosystem Interactions through Machine Learning. Angew. Chem. Int. Ed. 2024, 63, e202318380. https://doi.org/10.1002/anie.202318380.

- 32.Gao, X.J.; Yan, J.; Zheng, J.-J.; et al. Clear-Box Machine Learning for Virtual Screening of 2D Nanozymes to Target Tumor Hydrogen Peroxide. Adv. Healthc. Mater. 2023, 12, 2202925. https://doi.org/10.1002/adhm.202202925.

- 33.Zong, X.; Xu, X.; Pang, D.-W.; et al. Fine-Tuning Electron Transfer for Nanozyme Design. Adv. Healthc. Mater. 2025, 14, 2401836. https://doi.org/10.1002/adhm.202401836.

- 34.Ferdosi, S.; Stukalov, A.; Hasan, M.; et al. Enhanced Competition at the Nano–Bio Interface Enables Comprehensive Characterization of Protein Corona Dynamics and Deep Coverage of Proteomes. Adv. Mater. 2022, 34, 2206008. https://doi.org/10.1002/adma.202206008.

- 35.Winkler, D.A. Role of Artificial Intelligence and Machine Learning in Nanosafety. Small 2020, 16, 2001883. https://doi.org/10.1002/smll.202001883.

- 36.Firestein, K.L.; von Treifeldt, J.E.; Kvashnin, D.G.; et al. Young’s Modulus and Tensile Strength of Ti3C2 MXene Nanosheets As Revealed by In Situ TEM Probing, AFM Nanomechanical Mapping, and Theoretical Calculations. Nano Lett. 2020, 20, 5900–5908. https://doi.org/10.1021/acs.nanolett.0c01861.

- 37.Lanjan, A.; Moradi, Z.; Srinivasan, S. Computational Framework Combining Quantum Mechanics, Molecular Dynamics, and Deep Neural Networks to Evaluate the Intrinsic Properties of Materials. J. Phys. Chem. A 2023, 127, 6603–6613. https://doi.org/10.1021/acs.jpca.3c02887.

- 38.Mortazavi, B.; Rajabpour, A.; Zhuang, X.; et al. Exploring Thermal Expansion of Carbon-Based Nanosheets by Machine-Learning Interatomic Potentials. Carbon. 2022, 186, 501–508. https://doi.org/10.1016/j.carbon.2021.10.059.

- 39.Li, J.; Telychko, M.; Yin, J.; et al. Machine Vision Automated Chiral Molecule Detection and Classification in Molecular Imaging. J. Am. Chem. Soc. 2021, 143, 10177–10188. https://doi.org/10.1021/jacs.1c03091.

- 40.Fjodorova, N.; Novič, M.; Venko, K.; et al. Cheminformatics and Machine Learning Approaches to Assess Aquatic Toxicity Profiles of Fullerene Derivatives. IJMS 2023, 24, 14160. https://doi.org/10.3390/ijms241814160.

- 41.Gao, W.; Yu, C.; Chen, R. Artificial Intelligence Accelerators Based on Graphene Optoelectronic Devices. Adv. Photonics Res. 2021, 2, 2100048. https://doi.org/10.1002/adpr.202100048.

- 42.Jin, W.; Pei, J.; Xie, P.; et al. Machine Learning-Based Prediction of Mechanical Properties and Performance of Nickel–Graphene Nanocomposites Using Molecular Dynamics Simulation Data. ACS Appl. Nano Mater. 2023, 6, 12190–12199. https://doi.org/10.1021/acsanm.3c01919.

- 43.Khot, A.C.; Dongale, T.D.; Nirmal, K.A.; et al. Amorphous Boron Nitride Memristive Device for High-Density Memory and Neuromorphic Computing Applications. ACS Appl. Mater. Interfaces 2022, 14, 10546–10557. https://doi.org/10.1021/acsami.1c23268.

- 44.Zhang, C.; Yang, B.; Peng, Z.; et al. Machine Learning-Based Prediction of Mechanical Properties of N-Doped γ-Graphdiyne. Sci. China Mater. 2024, 67, 1129–1139. https://doi.org/10.1007/s40843-023-2733-7.

- 45.Du, D.; Zhang, Y.; Li, X.; et al. First-Principles Calculations, Machine Learning and Monte Carlo Simulations of the Magnetic Coercivity of FexCo1−x Bulks and Nanoclusters. Nanomaterials 2025, 15, 577. https://doi.org/10.3390/nano15080577.

- 46.Kang, J.; Noh, S.H.; Hwang, J.; et al. First-Principles Database Driven Computational Neural Network Approach to the Discovery of Active Ternary Nanocatalysts for Oxygen Reduction Reaction. Phys. Chem. Chem. Phys. 2018, 20, 24539–24544. https://doi.org/10.1039/C8CP03801E.

- 47.Zhou, P.; Wang, M.; Tang, F.; et al. Machine Learning Accelerates the Screening of Efficient Metal-Oxide Catalysts for Photocatalytic Water Splitting. Mater. Res. Bull. 2024, 179, 112956. https://doi.org/10.1016/j.materresbull.2024.112956.

- 48.Pinho, B.; Torrente-Murciano, L. Dial-A-Particle: Precise Manufacturing of Plasmonic Nanoparticles Based on Early Growth Information—Redefining Automation for Slow Material Synthesis. Adv. Energy Mater. 2021, 11, 2100918. https://doi.org/10.1002/aenm.202100918.

- 49.Guo, G.; Goldfeder, J.; Lan, L.; et al. Towards End-to-End Structure Determination from x-Ray Diffraction Data Using Deep Learning. NPJ Comput. Mater. 2024, 10, 1–12. https://doi.org/10.1038/s41524-024-01401-8.

- 50.Guo, G.; Saidi, T.L.; Terban, M.W.; et al. Ab Initio Structure Solutions from Nanocrystalline Powder Diffraction Data via Diffusion Models. Nat. Mater. 2025. https://doi.org/10.1038/s41563-025-02220-y.

- 51.Ma, K.; Gong, Y.; Aubert, T.; et al. Self-Assembly of Highly Symmetrical, Ultrasmall Inorganic Cages Directed by Surfactant Micelles. Nature 2018, 558, 577–580. https://doi.org/10.1038/s41586-018-0221-0.

- 52.Nishitsuji, R.; Nakashima, T.; Hisamoto, H.; et al. Simultaneous Recognition and Detection of Adenosine Phosphates by Machine Learning Analysis for Surface-Enhanced Raman Scattering Spectral Data. Sensors 2024, 24, 6648. https://doi.org/10.3390/s24206648.

- 53.Yu, Y.; Lu, W.; Yao, X.; et al. Machine Learning-Integrated Surface-Enhanced Raman Spectroscopy Analysis of Multicomponent Dye Mixtures. Spectrochim. Acta Part. A Mol. Biomol. Spectrosc. 2025, 332, 125806. https://doi.org/10.1016/j.saa.2025.125806.

- 54.Ieracitano, C.; Mammone, N.; Paviglianiti, A.; et al. A Conditional Generative Adversarial Network and Transfer Learning-Oriented Anomaly Classification System for Electrospun Nanofibers. Int. J. Neur. Syst. 2022, 32, 2250054. https://doi.org/10.1142/S012906572250054X.

- 55.Li, S.; Barnard, A.S. Safety-by-Design Using Forward and Inverse Multi-Target Machine Learning. Chemosphere 2022, 303, 135033. https://doi.org/10.1016/j.chemosphere.2022.135033.

- 56.Li, Y.; Liu, Y.; Miao, Y.; et al. Development of Heat-Resistant Tunnel Muck-Based Shotcrete for Geothermal Environments: Dual Drive of Combining Explainable Machine Learning and Microstructure Characterization. Constr. Build. Mater. 2025, 473, 140994. https://doi.org/10.1016/j.conbuildmat.2025.140994.

- 57.Tao, X. Compressive Strength Prediction of Nano-Modified Concrete: A Comparative Study of Advanced Machine Learning Techniques. AIP Adv. 2024, 14, 075017. https://doi.org/10.1063/5.0214890.

- 58.Ghorbani, K.; Mirchi, P.; Arabha, S.; et al. Lattice Thermal Conductivity and Young’s Modulus of XN4 (X = Be, Mg and Pt) 2D Materials Using Machine Learning Interatomic Potentials. Phys. Chem. Chem. Phys. 2023, 25, 12923–12933. https://doi.org/10.1039/D3CP00746D.

- 59.Lindsey, R.K.; Goldman, N.; Fried, L.E.; et al. Chemistry-Mediated Ostwald Ripening in Carbon-Rich C/O Systems at Extreme Conditions. Nat. Commun. 2022, 13, 1424. https://doi.org/10.1038/s41467-022-29024-x.

- 60.Isfeldt, G.; Lundell, F.; Wohlert, J. Interaction of Complex Particles: A Framework for the Rapid and Accurate Approximation of Pair Potentials Using Neural Networks. Phys. Rev. E 2024, 110, 055305. https://doi.org/10.1103/PhysRevE.110.055305.

- 61.Pradeepa, A.; Arathi, P. Computing Degree-Based Topological Descriptors of Certain Tessellations of Kekulenes Using M-Polynomial and Neighborhood M-Polynomial. Polycycl. Aromat. Compd. 2025, 45, 36–59. https://doi.org/10.1080/10406638.2024.2384901.

- 62.Harper, D.R.; Nandy, A.; Arunachalam, N.; et al. Representations and Strategies for Transferable Machine Learning Improve Model Performance in Chemical Discovery. J. Chem. Phys. 2022, 156, 074101. https://doi.org/10.1063/5.0082964.

- 63.Dong, W.; Huang, Y.; Lehane, B.; et al. Multi-Objective Design Optimization for Graphite-Based Nanomaterials Reinforced Cementitious Composites: A Data-Driven Method with Machine Learning and NSGA-Ⅱ. Constr. Build. Mater. 2022, 331, 127198. https://doi.org/10.1016/j.conbuildmat.2022.127198.

- 64.Gao, H.; Zhong, S.; Dangayach, R.; et al. Understanding and Designing a High-Performance Ultrafiltration Membrane Using Machine Learning. Environ. Sci. Technol. 2023, 57, 17831–17840. https://doi.org/10.1021/acs.est.2c05404.

- 65.Furxhi, I.; Roberts, S.; Cross, R.; et al. Bayesian Network Modelling for Predicting the Environmental Hazard of Silver Nanomaterials in Soils. NanoImpact 2025, 37, 100553. https://doi.org/10.1016/j.impact.2025.100553.

- 66.Kelkar, A.S.; Dallin, B.C.; Van Lehn, R.C. Identifying Nonadditive Contributions to the Hydrophobicity of Chemically Heterogeneous Surfaces via Dual-Loop Active Learning. J. Chem. Phys. 2022, 156, 024701. https://doi.org/10.1063/5.0072385.

- 67.Zhuang, Z.; Xu, Q.; Zeng, H.; et al. A Deep-Learning-Based Compact Method for Accelerating the Electrowetting Lattice Boltzmann Simulations. Phys. Fluids 2024, 36, 043323. https://doi.org/10.1063/5.0206608.

- 68.Wang, Z.; Ranasinghe, J.C.; Wu, W.; et al. Machine Learning Interpretation of Optical Spectroscopy Using Peak-Sensitive Logistic Regression. ACS Nano 2025, 19, 15457–15473. https://doi.org/10.1021/acsnano.4c16037.

- 69.Yu, H.; Zhou, G.-Y.; Liu, Y.-B.; et al. Deep Learning-Assisted Superhydrophobic LIG/MWCNT Wearable Sensor for Underwater Motion Detection. IEEE Sens. J. 2024, 24, 29392–29399. https://doi.org/10.1109/JSEN.2024.3434948.

- 70.Bruefach, A.; Ophus, C.; Scott, M.C. Analysis of Interpretable Data Representations for 4D-STEM Using Unsupervised Learning. Microsc. Microanal. 2022, 28, 1998–2008. https://doi.org/10.1017/S1431927622012259.

- 71.Ieracitano, C.; Paviglianiti, A.; Campolo, M.; et al. A Novel Automatic Classification System Based on Hybrid Unsupervised and Supervised Machine Learning for Electrospun Nanofibers. IEEE/CAA J. Autom. Sin. 2021, 8, 64–76. https://doi.org/10.1109/JAS.2020.1003387.

- 72.Sun, Z.; Shi, J.; Wang, J.; et al. A Deep Learning-Based Framework for Automatic Analysis of the Nanoparticle Morphology in SEM/TEM Images. Nanoscale 2022, 14, 10761–10772. https://doi.org/10.1039/D2NR01029A.

- 73.Kho, Z.; Bridger, A.; Butler, K.; et al. On the Use of Clustering Workflows for Automated Microstructure Segmentation of Analytical STEM Datasets. APL Mater. 2025, 13, 010901. https://doi.org/10.1063/5.0246329.

- 74.Li, Y.; Wang, Y.; Qi, S.; et al. Predicting Scattering from Complex Nano-Structures via Deep Learning. IEEE Access 2020, 8, 139983–139993. https://doi.org/10.1109/ACCESS.2020.3012132.

- 75.Boiko, D.A.; Kashin, A.S.; Sorokin, V.R.; et al. Analyzing Ionic Liquid Systems Using Real-Time Electron Microscopy and a Computational Framework Combining Deep Learning and Classic Computer Vision Techniques. J. Mol. Liq. 2023, 376, 121407. https://doi.org/10.1016/j.molliq.2023.121407.

- 76.Gu, Z.; Zhu, R.; Shen, T.; et al. Autonomous Nanorobots with Powerful Thrust under Dry Solid-Contact Conditions by Photothermal Shock. Nat. Commun. 2023, 14, 7663. https://doi.org/10.1038/s41467-023-43433-6.

- 77.Gandhi, A.M.; Shanmugan, S.; Gorjian, S.; et al. Performance Enhancement of Stepped Basin Solar Still Based on OSELM with Traversal Tree for Higher Energy Adaptive Control. Desalination 2021, 502, 114926. https://doi.org/10.1016/j.desal.2020.114926.

- 78.Jiang, T.; Gai, S.; Yin, Y.; et al. A Light/Thermal Cascaded-Driven Equipment for Machine Recognition Inspired by Water Lilies Using as Multifunctional Soft Actuator. Chem. Eng. J. 2024, 495, 153348. https://doi.org/10.1016/j.cej.2024.153348.

- 79.Guo, W.; Ma, Z.; Chen, Z.; et al. Thin and Soft Ti3C2Tx MXene Sponge Structure for Highly Sensitive Pressure Sensor Assisted by Deep Learning. Chem. Eng. J. 2024, 485, 149659. https://doi.org/10.1016/j.cej.2024.149659.

- 80.Zhang, J.; Perrin, M.L.; Barba, L.; et al. High-Speed Identification of Suspended Carbon Nanotubes Using Raman Spectroscopy and Deep Learning. Microsyst. Nanoeng. 2022, 8, 1–9. https://doi.org/10.1038/s41378-022-00350-w.

- 81.Zhao, Z.; Yang, X.; Wang, Y.; et al. Putting the Incoming/Outgoing Correlation (INOUTCO) Ion Imaging Surface Scattering Technique to the Test in O Atom Scattering from Graphite. J. Phys. Chem. C 2025, 129, 722–731. https://doi.org/10.1021/acs.jpcc.4c06578.

- 82.Hai, T.; Dahan, F.; Dhahad, H.A.; et al. Deep-Learning Optimization and Environmental Assessment of Nanomaterial’s Boosted Hydrogen and Power Generation System Combined with SOFC. Int. J. Hydrog. Energy 2024, 52, 202–215. https://doi.org/10.1016/j.ijhydene.2022.11.332.

- 83.Jia, P.; Cao, C.; Lu, X.; et al. Machine Learning-Integrated Numerical Simulation for Predicting Photothermal Conversion Performance of Metallic Nanofluids. Small 2025, 21, 2408984. https://doi.org/10.1002/smll.202408984.

- 84.Balraadjsing, S.; Peijnenburg, W.J.G.M.; Vijver, M.G. Exploring the Potential of in Silico Machine Learning Tools for the Prediction of Acute Daphnia Magna Nanotoxicity. Chemosphere 2022, 307, 135930. https://doi.org/10.1016/j.chemosphere.2022.135930.

- 85.Guo, H.; Lesani, P.; Zreiqat, H.; et al. A Fluorescent Sensor Array Based on Carbon Dots for the Accurate Determination of pH. Sens. Diagn. 2024, 3, 1923–1934. https://doi.org/10.1039/D4SD00275J.

- 86.Okeke, C.; Juma, I.; Cobarrubia, A.; et al. Probing Anharmonic Phonons in WS2 van Der Waals Crystal by Raman Spectroscopy and Machine Learning. iScience 2023, 26, 107174. https://doi.org/10.1016/j.isci.2023.107174.

- 87.Exner, T.E.; Papadiamantis, A.G.; Melagraki, G.; et al. Metadata Stewardship in Nanosafety Research: Learning from the Past, Preparing for an “on-the-Fly” FAIR Future. Front. Phys. 2023, 11, 1233879. https://doi.org/10.3389/fphy.2023.1233879.

- 88.He, S.; Nader, K.; Abarrategi, J.S.; et al. NANO.PTML Model for Read-across Prediction of Nanosystems in Neurosciences. Computational Model and Experimental Case of Study. J. Nanobiotechnol. 2024, 22, 435. https://doi.org/10.1186/s12951-024-02660-9.

- 89.Cruz, C.; Matatagui, D.; Ramírez, C.; et al. Carbon SH-SAW-Based Electronic Nose to Discriminate and Classify Sub-Ppm NO2. Sensors 2022, 22, 1261. https://doi.org/10.3390/s22031261.

- 90.Shao, S.; Xie, C.; Xia, Y.; et al. Highly Conjugated Three-Dimensional van Der Waals Heterostructure-Based Nanocomposite Films for Ultrahigh-Responsive TEA Gas Sensors at Room Temperature. J. Mater. Chem. A 2022, 10, 2995–3008. https://doi.org/10.1039/D1TA09749K.

- 91.Singh, S.; Saggu, I.S.; Singh, S.; et al. Detection of DMF and NH3 at Room Temperature Using a Sensor Based on a MoS2 /Single-Walled Carbon Nanotube Composite. ACS Appl. Nano Mater. 2023, 6, 10698–10712. https://doi.org/10.1021/acsanm.3c01638.

- 92.Jeindl, A.; Domke, J.; Hörmann, L.; et al. Nonintuitive Surface Self-Assembly of Functionalized Molecules on Ag(111). ACS Nano 2021, 15, 6723–6734. https://doi.org/10.1021/acsnano.0c10065.

- 93.Leppänen, E.; Aarva, A.; Sainio, S.; et al. Connection between the Physicochemical Characteristics of Amorphous Carbon Thin Films and Their Electrochemical Properties. J. Phys. Condens. Matter 2021, 33, 434002. https://doi.org/10.1088/1361-648X/ac1a2e.

- 94.Packwood, D.M. Bi-Functional On-Surface Molecular Assemblies Predicted from a Multifaceted Computational Approach. Adv. Phys. Res. 2022, 1, 2200019. https://doi.org/10.1002/apxr.202200019.

- 95.Khan, S.A.; Farooq, U.; Imran, M.; et al. Mathematical and Artificial Neural Network Modeling to Predict the Heat Transfer of Mixed Convective Electroosmotic Nanofluid Flow with Helmholtz-Smoluchowski Velocity and Multiple Slip Effects: An Application of Soft Computing. Case Stud. Therm. Eng. 2024, 61, 104950. https://doi.org/10.1016/j.csite.2024.104950.

- 96.Zhang, Y.; Li, Q.; Feng, W.; et al. Regulating Electron Transfer in Vanadium-Based Metal–Organic Frameworks via the Synergy of Linker Engineering and Machine Learning for Efficient and Reversible Aqueous Zinc Ion Batteries. Adv. Mater. 2025, 37, 2507609. https://doi.org/10.1002/adma.202507609.

- 97.Li, Q.; Zhang, Y.; Feng, W.; et al. Manganese–Based Metal–Organic Coordination for Aqueous Zinc–Ion Batteries with Varying Mechanical Adaptability and Machine Learning–Assisted Performance Decoding. Adv. Mater. 2025, 37, 2507951. https://doi.org/10.1002/adma.202507951.

- 98.Aytaç, E.; Khanzada, N.K.; Ibrahim, Y.; et al. Reverse Osmosis Membrane Engineering: Multidirectional Analysis Using Bibliometric, Machine Learning, Data, and Text Mining Approaches. Membranes 2024, 14, 259. https://doi.org/10.3390/membranes14120259.

- 99.Baig, N.; Usman, J.; Abba, S.I.; et al. Fractionation of Dyes/Salts Using Loose Nanofiltration Membranes: Insight from Machine Learning Prediction. J. Clean. Prod. 2023, 418, 138193. https://doi.org/10.1016/j.jclepro.2023.138193.

- 100.Li, J.; Meng, K.; Yu, X.; et al. Mechanistic Insight into a Graphene-like Stimulus-Responsive Desalination Membrane from Molecular Dynamics and First Principles. Diam. Relat. Mater. 2023, 136, 109910. https://doi.org/10.1016/j.diamond.2023.109910.

- 101.Madejski, G.R.; Ahmad, S.D.; Musgrave, J.; et al. Silicon Nanomembrane Filtration and Imaging for the Evaluation of Microplastic Entrainment along a Municipal Water Delivery Route. Sustainability 2020, 12, 10655. https://doi.org/10.3390/su122410655.

- 102.Zhang, M.; He, H.; Huang, Y.; et al. Machine Learning Integrated High Quantum Yield Blue Light Carbon Dots for Real-Time and on-Site Detection of Cr(VI) in Groundwater and Drinking Water. Sci. Total Environ. 2023, 904, 166822. https://doi.org/10.1016/j.scitotenv.2023.166822.

- 103.Ji, Y.; Ma, S.; Lv, S.; et al. Nanomaterials for Targeted Delivery of Agrochemicals by an All-in-One Combination Strategy and Deep Learning. ACS Appl. Mater. Interfaces 2021, 13, 43374–43386. https://doi.org/10.1021/acsami.1c11914.

- 104.Hao, T.; Zhou, H.; Gai, P.; et al. Deep Learning-Assisted Single-Atom Detection of Copper Ions by Combining Click Chemistry and Fast Scan Voltammetry. Nat. Commun. 2024, 15, 10292. https://doi.org/10.1038/s41467-024-54743-8.

- 105.Stuart, S.; Watchorn, J.; Gu, F.X. An Interpretable Machine Learning Framework for Modelling Macromolecular Interaction Mechanisms with Nuclear Magnetic Resonance. Digit. Discov. 2023, 2, 1697–1709. https://doi.org/10.1039/D3DD00009E.

- 106.Sun, H.; Amin, M.N.; Qadir, M.T.; et al. Investigating the Effectiveness of Carbon Nanotubes for the Compressive Strength of Concrete Using AI-Aided Tools. Case Stud. Constr. Mater. 2024, 20, e03083. https://doi.org/10.1016/j.cscm.2024.e03083.

- 107.Della Pia, F.; Zen, A.; Kapil, V.; et al. On the Increase of the Melting Temperature of Water Confined in One-Dimensional Nano-Cavities. J. Chem. Phys. 2024, 161, 224706. https://doi.org/10.1063/5.0239452.

- 108.Vakharia, V.; Castelli, I.E.; Bhavsar, K.; et al. Bandgap Prediction of Metal Halide Perovskites Using Regression Machine Learning Models. Phys. Lett. A 2022, 422, 127800. https://doi.org/10.1016/j.physleta.2021.127800.

- 109.Chen, K.; Li, N.; Luo, Y.; et al. High-Performance Hardware Primitives Based on Sub-10 Nm Nanodiodes for Cryptography Applications. J. Mater. Chem. C 2024, 12, 17878–17889. https://doi.org/10.1039/D4TC02206H.

- 110.Wang, S.; Zhu, J.; Blackwell, R.; et al. Automated Tip Conditioning for Scanning Tunneling Spectroscopy. J. Phys. Chem. A 2021, 125, 1384–1390. https://doi.org/10.1021/acs.jpca.0c10731.

- 111.Guccione, P.; Diacono, D.; Toso, S.; et al. Towards the Extraction of the Crystal Cell Parameters from Pair Distribution Function Profiles. IUCrJ 2023, 10, 610–623. https://doi.org/10.1107/S2052252523006887.

- 112.He, J.; Wang, C.; Tang, H.; et al. Prospective Research on the Tribological Behavior of Graphdiyne Nanofluid and Its Machine Learning Performance Prediction. Appl. Surf. Sci. 2025, 696, 162954. https://doi.org/10.1016/j.apsusc.2025.162954.

How to Cite

Zhou, H.; Zou, W.; Gu, S.; Xu, J.; Zhang, J.; Shakouri, M.; Xu, J.; Li, L.; Pang, H.; Ding, J. Multimodal Intelligence in Chemical Discovery: Integrating Interpretable ML, Autonomous Robotics, and Edge Computing. Sustainable Engineering Novit 2025, 1 (1), 4. https://doi.org/10.53941/sen.2025.100004.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References