Downloads

Download

This work is licensed under a Creative Commons Attribution 4.0 International License.

Review

Artificial Intelligence and Its Roles in the R&D of Vehicle Powertrain Products

Quan Zhou *, Ji Li, and Hongming Xu *

Birmingham CASE Automotive Research and Education Centre, University of Birmingham, Birmingham, B15 2TT UK

* Correspondence: q.zhou@bham.ac.uk (Q.Z.); h.m.xu@bham.ac.uk (H.X.)

Received: 5 October 2022

Accepted: 20 November 2022

Published: 25 December 2022

Abstract: Decarbonization requires global actions, and the transport sector is the main battlefield since it contributes more than 20% of CO 2 emissions. Vehicle electrification is an effective routine to reduce vehicle carbon emissions, but it increases the complexity of the vehicle systems, especially the powertrain systems. The rapid development of artificial intelligence (AI) is promoting the development of new automation technologies that can benefit the automotive industry. This paper reviews the key milestones of AI technology development for vehicle research and development (R&D) and highlights the advantage of AI-based methods in powertrain design and control. An outlook of future research directions will be discussed, and conclusions will be summarized.

Keywords:

artificial intelligence powertrain design powertrain control product evolution1. Introduction

Rapid computer science and IT developments are reshaping the automotive industry, providing new solutions to the grand challenges that conventional technologies cannot address. Mitigation of carbon emissions is one of the great challenges, and the road transport sector must take action since it contributed to more than 20% of CO 2 emissions worldwide [ 1]. Since the introduction of electronic control units for vehicle powertrains in the 1970s, energy consumption and toxic emissions have been dramatically reduced. FIAT saved more than 3-5% of fuel by introducing an electronically controlled valve system [ 2]. Honda offers more than 24% fuel efficiency improvement in city and highway driving conditions through an electronically controlled hybrid powertrain [ 3]. Policymakers develop increasing rigor regulations to force the OEMs to improve the vehicle’s energy efficiency as well as emission performance. There is a trend that vehicles will involve more electronic controls, and the electric controllers need to be calibrated properly in their research and development (R&D) stage. According to the prediction of the UK Advanced Propulsion Centre (APC), the complexity of vehicle software systems will be increasing expressional, accounting for 10 8 times more than it is now in the 2040s [ 4]. Conventional human-driven design-of-experiment (DoE) methods are hard to chase the rapid development of vehicle E/E systems and artificial intelligence is therefore required to assist automotive engineers in developing more advanced vehicle products.

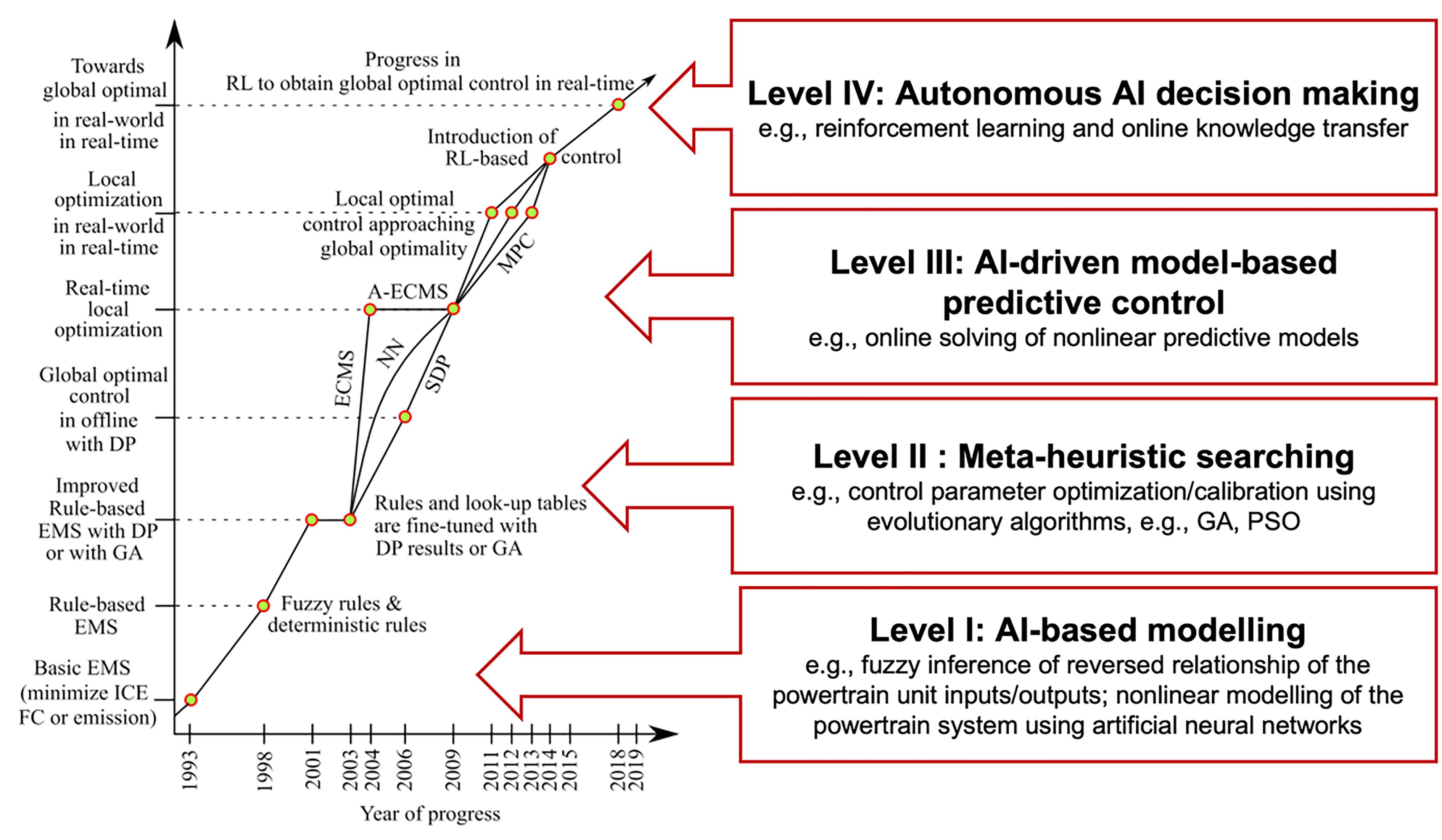

The formal research of artificial intelligence (AI) started in the 1940s and the first application of AI for vehicle powertrains was reported in the 1990s. In the 1990s, fuzzy inference systems (FIS), which emulate the way of human decision-making, are first developed to control the power flows in a hybrid vehicle. Followed by the first paper on FIS-based vehicle control reported at the 1993 International Symposium on Intelligent Control [ 5], Lee et al. proposed a fuzzy-logic-based torque control strategy for parallel hybrid vehicles in 1998 [ 6]. When people enter the 21st century, the increasing volume of storage and RAM for computers allows engineers to conduct global searching of design/control parameters. Dynamic programming is first introduced for the global optimization of HEV power management strategy in 2003 [ 7], and some sub-global methods, e.g., Genetic Algorithms (GA) [ 8], are developed to improve the computational efficiency. With the development of embedded systems in the 2010s, automotive controllers are capable to process complex model-based control in real-time conditions [ 9]. Artificial intelligence is developed to (1) build onboard control-oriented models [ 10] and (2) resolve nonlinear model-based control functions based on online optimizations [ 11]. The massive production of high-performance GPUs and the rapid development of Internet of Vehicle facilities in the later 2010s boosted the development and implementation of learning-based methods for automobiles. Deep learning, reinforcement learning, and transfer learning are developed for the perception [ 12], planning [ 13], and optimal control [ 14] of connected and autonomous vehicles (CAVs).

Based on the key milestones of AI applications in automotive systems, we can categorize the development of AI into four levels as shown in Figure 1. For Level I, AI models are used to model the nonlinearity of the vehicle systems, e.g., engine performances [ 15]. The AI models are expected to assist in some R&D tasks, e.g., component sizing [ 16] and control calibration [ 17] if they have the capability of offline optima searching (Level II). By incorporating AI-based modelling and AI-based optimization, the Level III AI models can deal with model predictive control tasks that allow the vehicle system to be optimized online [ 18, 19]. In Level IV, AI models would have the capability of self-learning and adaptive learning based on the recent development in the internet of vehicles and advanced algorithms, e.g., the reinforcement learning [ 20] and transfer learning [ 21].

Figure 1. Stages of AI development for automotive applications (reproduced based on Figure 3 in [ 22]).

The rest of this paper will provide a comprehensive review of how AI models contribute to the design and control tasks in automotive powertrain research and development. A research outlook will be discussed before summarizing the conclusions.

2. AI Methods for Powertrain Design

Powertrain design involves several offline optimization tasks, e.g., component sizing and control calibration. Modular design allows fast and low-cost development of new vehicular products. Volkswagen develops a modular platform for the flexible development of its new electric and hybrid powertrains [ 23]. CHANGAN motor unveiled its brand new ‘Blue Core’ high-efficiency internal combustion engine (ICE) series for hybrid vehicles on a modular platform [ 24]. Artificial intelligence has been deployed for hybrid vehicles to allow global optimization, and this motivates the research into intelligent modular design.

There are two typical methods for modular design: two-level optimization and simultaneous optimization. Two-level optimizations consider component sizing and control calibration as two separate tasks. For component sizing, Pourabdollah et al. optimized a hybrid vehicle based on varying levels of modelling details using the Convex Optimization (CO) [ 25]. The optimal component size of a hybrid system considering the cost and battery life has been developed using the Nondominated Sorting Genetic Algorithm (NSGA-II) [ 26]. For control parameters, Wang et al. optimized the control parameters for energy management to minimize the daily cost using the dynamic programming (DP) [ 27]. Simultaneous optimization deals with component sizing and control parameter optimization as integrity. Lv et al. found the optimal combination of component size and control parameters considering the vehicle dynamic performance, ride comfort and energy efficiency [ 28]. Zhou et al developed a modified accelerated particle swarm optimization (MAPSO) algorithm for modular design considering the design variables which are from discontinuously varying domains (e.g. integers) [ 29]. The results suggested that the proposed MAPSO can achieve global optimal results in a more computationally efficient manner compared to both Pareto methods (NSGA-II) and weighted-sum methods (PSO, APSO).

DoE-based models for vehicle product development are believed to be enhanced by the Digital Twin (DT) [ 30, 31] since DTs are not only digital models of the physical entities but also have AI functions embedded to enable self-understanding, learning, and reasoning for R&D tasks [ 32]. Currently, most DT research for vehicle applications mainly focuses on improving model accuracy [ 33] and data connection [ 34]. Li et al. incorporate an H-infinity filter with the PSO algorithm to improve the model accuracy of the digital counterpart of batteries for EVs [ 33]. Venkatesan et al. developed a DT based on the ANN algorithm for energy efficiency optimization of an EV motor system [ 35]. Liu et al. developed a DT of a transport system to help autonomous vehicle decision-making with a fused sensor data [ 36]. Zhou et al. developed a DT of an energy-harvesting shock absorber to optimize its design parameters using the PSO [ 37]. Zhou et al. proposed a human-knowledge-augmented Gaussian process regression method to build a battery DT for the state-of-health estimation [ 38]. It is essential for OEMs to attain robust and reliable design in the R&D stage harnessing DT because it is impossible for vehicle manufacturers to monitor and control all vehicles centrally through the centralized Cloud computing [ 30].

3. AI Methods for Powertrain Control

Offline optimization is capable to help OEMs pass the regulations defined by policymakers, but the driving environment is much more unpredictable and more dynamically varying in real-world driving, therefore, more adaptive online optimization methods are needed for the control of vehicle powertrains. The most used online technique is the model-based predictive control (MPC), which runs the online optimization in a rolling process based on a real-time model of the control targets [ 39]. Because the vehicle model is normally fixed with offline calibrated results, MPC is less adaptive in non-calibrated conditions, e.g., in real-world driving [ 40]. Therefore, advanced EMSs that have the capability of self-learning are in urgent demand to help automakers comply with legislation and improve their customer satisfaction.

Learning-based vehicle control techniques are significantly superior to conventional rule-based and model-based methods. Reinforcement learning (RL) is an emerging and promising technology for the online optimal control [ 41]. It is a plant-model-free method based on Bellman’s theory [ 42], which updates its knowledge base on reinforcement information to fulfil online optimization in unknown environments [ 43]. The effectiveness of RL has been demonstrated in various vehicle control applications [ 44]. Remarkable improvements in vehicle energy efficiency have been achieved by RL methods, e.g. Q-learning [ 45], double Q-learning [ 46], and multiple-step Q-learning [ 47]. Most research on RL-based power management control focuses on learning from scratch. This requires a long time to develop a proper control policy in real-world interactions.

In recent years, multi-mode PHEV has been developed as a new powertrain topology to allow the vehicle operates in pure battery mode, series hybrid mode, and parallel hybrid mode flexibility for maximum fuel economy [ 47]. This powertrain topology has been widely adopted by OEMs and T1 suppliers worldwide, e.g., Honda, BYD, and MAHLE [ 48]. Distinguished from the control of series or parallel HEVs, the control of the engine, generator, and traction motor cannot be coupled, and multi-inputs-multi-outputs (MIMO) control is required. This new requirement motivates the evolution from single-agent learning to multi-agent learning because the multi-agent system offers a feasible path for the MIMO control [ 50]. MADRL emphasizes the behaviors of multiple learning agents coexisting in a common environment with different collaboration modes. Typically, there are three working modes between the RL agents: (1) cooperative mode, (2) competitive mode, and (3) a mixture of the two [ 51]. In cooperative scenarios, agents work together to maximize a shared long-term return; in contrast, in competitive scenarios, agents’ returns typically add up to zero; in mixed scenarios, there are general sum returns in both cooperative and competitive agents [ 52]. Because the RL-based EMS for MIMO control of multi-mode PHEV is new, more research work is expected in recent years.

4. Research Outlook

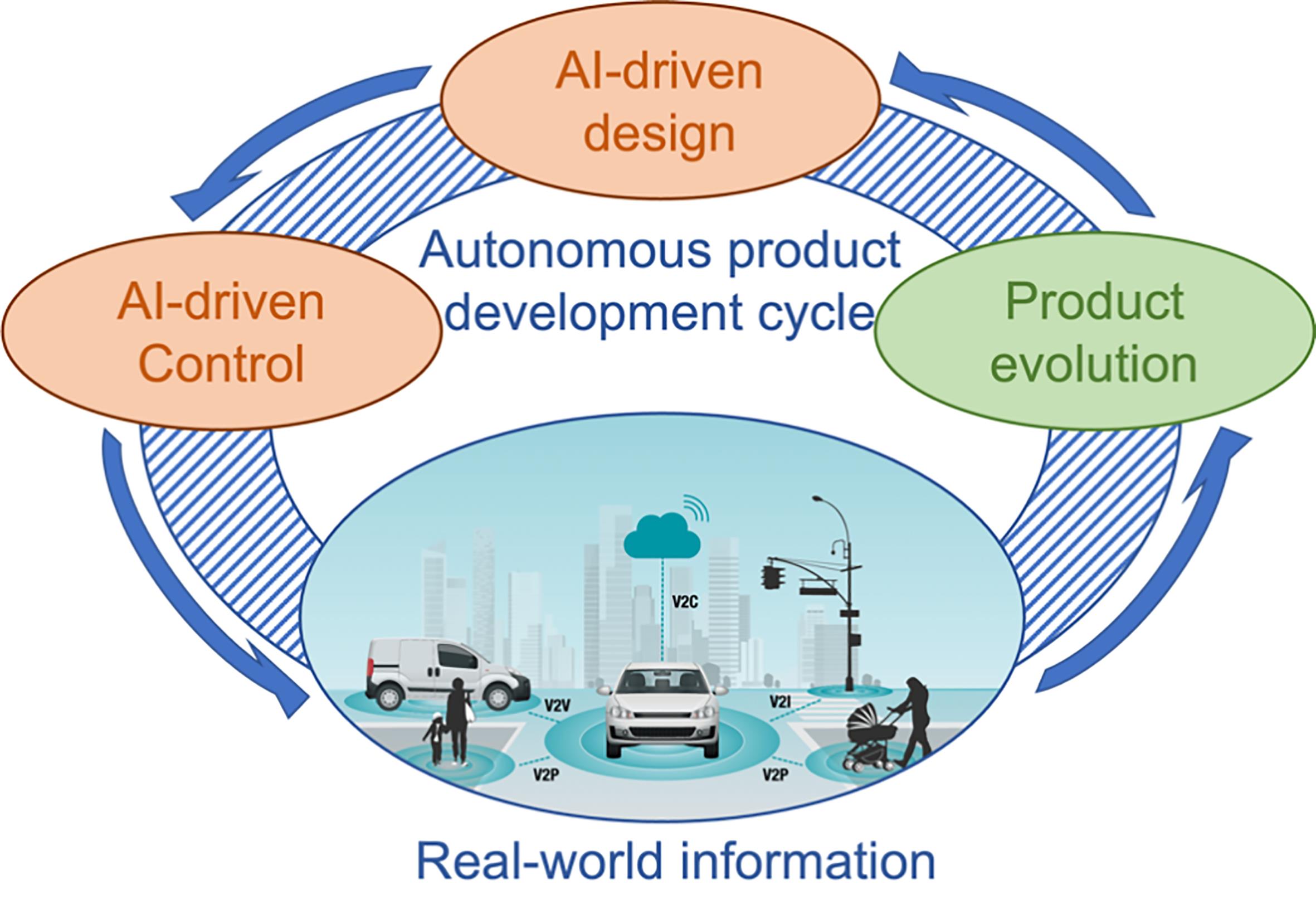

Vehicle connection, automation, electrification, and sharing (CASE) are the future of road mobility systems. The development of the Internet of Vehicles is promoting the new “living business” for automotive companies, which is built on a new product development cycle that is driven by artificial intelligence, Figure 2. Following the existing AI-driven design and control work, the key chain to close the autonomous product development loop would be AI-driven product development. The enabling technology for AI-driven product evolution is transfer learning based on highly generalized models.

Figure 2. Autonomous product development cycle.

Transfer learning is a paradigm which leverages the previously acquired knowledge (e.g., offline optimization) to improve the efficiency and accuracy of learning in another domain (e.g., real-world driving). This will allow the development of vehicle products with less R&D cost and time. The transferable knowledge in automotive product development can be the optimal design parameters or control strategies. It can be modelled by parametric or non-parametric methods. ANN [ 53] and fuzzy systems [ 54] are normally developed for parametric modelling. Zhou et al. proposed a transfer learning framework based adaptive fuzzy inference system (ANFIS) that enables online knowledge transfer by optimizing the control policy using the Deep Deterministic Policy Gradient (DDPG) [ 55]. With significantly superior representation capability to the parametric methods, the emerging Gaussian process regression (GPR) has been recognized as a promising non-parametric method [ 56]. Zhou et al. combine the GPR model with the ANFIS controller to enable transfer learning across worldwide driving cycles. An experimental study suggested that more than 27% control utility can be improved through the proposed method [ 21].

5. Conclusions

This paper reviews the recent work on AI-based vehicle design and control and provides a research outlook on the autonomous product development cycle based on the observation of the CASE revolution in the automotive industry. The conclusions drawn from the literature survey are as follows:

(1) Stages I and II AI methods have demonstrated strong capability to deal with offline optimization tasks in automotive product development, e.g., system integration, component sizing, and control parameter calibration. The technical readiness of Stages I and II AI methods are very close to commercialization.

(2) Stages III and IV AI methods show great potential to impact the current control of vehicle systems, providing the strong capability to deal with nonlinear optimal control and adaption to the dynamic environment. Further developments in hardware and IT communication are required to promote the commercialization of Stage III and IV AI methods.

(3) Transfer learning, a higher-level IV intelligence is a promising future direction which will act as an enabling technology to close the autonomous product development cycle. It will boost product evolution and reduce the R&D cost and time and thus impact the future of the automotive industry.

Author Contributions: Writing—original draft preparation, Q.Z.; Writing—review and editing, Q.Z., J.L., and H.X.

Funding: This research received no external funding

Data Availability Statement: Not applicable.

Acknowledgments: The authors acknowledge the support from Birmingham CASE automotive research and education centre, University of Birmingham.

Conflicts of Interest: The authors declare no conflict of interest.

References

- IEA, Global EV Outlook C. 2020. Available online: https://www.iea.org/reports/global-ev-outlook-2020 (Accessed on 5 October 2022). doi: 10.1787/d394399e-en. DOI: https://doi.org/10.1787/d394399e-en

- Atabani A.E. ; Badruddin I.A. ; Mekhilef S. ; et al . A review on global fuel economy standards, labels and technologies in the transportation sector. Renewable Sustainable Energy Rev. 2011, 15, 4586– 4610. doi: 10.1016/j.rser.2011.07.092 . DOI: https://doi.org/10.1016/j.rser.2011.07.092

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704– 718. doi: 10.1109/JPROC.2007.892489. DOI: https://doi.org/10.1109/JPROC.2007.892489

- Jackson, N. Virtual Product Engineering Roadmap. Available online: https://www.automotivecouncil.co.uk (Accessed on 5 October 2022).

- Farrall S.D. ; Jones R . P. Energy management in an automotive electric/heat engine hybrid powertrain using fuzzy decision making. In Proceedings of 8th IEEE International Symposium on Intelligent Control, Chicago, IL, USA, 25– 27 August 1993; IEEE: Piscataway, NJ, USA, 1993. doi: 10.1109/isic.1993.397669 . DOI: https://doi.org/10.1109/ISIC.1993.397669

- Lee H.D. ; Sul S . K. Fuzzy-logic-based torque control strategy for parallel-type hybrid electric vehicle. IEEE Trans. Ind. Electron. 1998, 45, 625– 632. doi: 10.1109/41.704891 . DOI: https://doi.org/10.1109/41.704891

- Lin C.C. ; Peng H. ; Grizzle J.W. ; et al . Power management strategy for a parallel hybrid electric truck. IEEE Trans. Control Syst. Technol. 2003, 11, 839– 849. doi: 10.1109/TCST.2003.815606 . DOI: https://doi.org/10.1109/TCST.2003.815606

- Piccolo A. ; Ippolito L. ; Zo Galdi V. ; et al . Optimisation of energy flow management in hybrid electric vehicles via genetic algorithms. In 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Proceedings (Cat. No.01TH8556), Como, Italy, 08– 12 July 2001; IEEE: Piscataway, NJ, USA, 2001. doi: 10.1109/aim.2001.936493 . DOI: https://doi.org/10.1109/AIM.2001.936493

- Borhan H. ; Vahidi A. ; Phillips A.M. ; et al . MPC-based energy management of a power-split hybrid electric vehicle. IEEE Trans. Control Syst. Technol. 2012, 20, 593– 603. doi: 10.1109/TCST.2011.2134852 . DOI: https://doi.org/10.1109/TCST.2011.2134852

- Xie S. ; Hu X. ; Qi S. ; et al . An artificial neural network-enhanced energy management strategy for plug-in hybrid electric vehicles. Energy 2018, 163, 837– 848. doi: 10.1016/j.energy.2018.08.139 . DOI: https://doi.org/10.1016/j.energy.2018.08.139

- Xu F. ; Chen H. ; Gong X. ; et al . Fast nonlinear model predictive control on FPGA using particle swarm optimization. IEEE Trans. Ind. Electron. 2016, 63, 310– 321. doi: 10.1109/TIE.2015.2464171 . DOI: https://doi.org/10.1109/TIE.2015.2464171

- Leng B. ; Jin D. ; Xiong L. ; et al . Estimation of tire-road peak adhesion coefficient for intelligent electric vehicles based on camera and tire dynamics information fusion. Mech. Syst. Signal Process. 2021, 150, 107275. doi: 10.1016/j.ymssp.2020.107275 . DOI: https://doi.org/10.1016/j.ymssp.2020.107275

- Li Y. ; He H. ; Peng J. ; et al . Deep Reinforcement Learning-Based Energy Management for a Series Hybrid Electric Vehicle Enabled by History Cumulative Trip Information. IEEE Trans. Veh. Technol. 2019, 68, 7416– 7430. doi: 10.1109/tvt.2019.2926472 . DOI: https://doi.org/10.1109/TVT.2019.2926472

- Han W. ; Xiong L. ; Yu Z . Analysis and optimization of minimum hydraulic brake-by-wire system for wheeled vehicles based on queueing theory. IEEE Trans. Veh. Technol. 2021, 70, 12491– 12505. doi: 10.1109/TVT.2021.3116760 . DOI: https://doi.org/10.1109/TVT.2021.3116760

- Li J. ; Zhou Q. ; Williams H. ; et al . Fuzzy-tree-constructed data-efficient modelling methodology for volumetric efficiency of dedicated hybrid engines. Appl. Energy 2022, 310, 118534. doi: 10.1016/j.apenergy.2022.118534 . DOI: https://doi.org/10.1016/j.apenergy.2022.118534

- Zhou Q. ; Zhang W. ; Cash S. ; et al . Intelligent sizing of a series hybrid electric power-train system based on Chaos-enhanced accelerated particle swarm optimization. Appl. Energy 2017, 189, 588– 601. doi: 10.1016/j.apenergy.2016.12.074 . DOI: https://doi.org/10.1016/j.apenergy.2016.12.074

- Li Z. ; Zhou Q. ; Zhang Y. ; et al . Enhanced intelligent proportional-integral-like fuzzy knowledge–based controller using chaos-enhanced accelerated particle swarm optimization algorithm for transient calibration of air–fuel ratio control system. Proc. Inst. Mech. Eng.; Part D 2019, 234, 39– 55. doi: 10.1177/0954407019862079 . DOI: https://doi.org/10.1177/0954407019862079

- Zhou Q. ; Zhang Y. ; Li Z. ; et al . Cyber-Physical Energy-Saving Control for Hybrid Aircraft-Towing Tractor based on Online Swarm Intelligent Programming. IEEE Trans. Ind. Inf. 2018, 14, 4149– 4158. doi: 10.1109/TII.2017.2781230 . DOI: https://doi.org/10.1109/TII.2017.2781230

- Li J. ; Zhou Q. ; He Y. ; et al . Dual-loop Online Intelligent Programming for Driver-oriented Predict Energy Management of Plug-in Hybrid Electric Vehicles. Appl. Energy 2019, 253, 113617. DOI: https://doi.org/10.1016/j.apenergy.2019.113617

- Liu T. ; Hu X. ; Hu W. ; et al . A Heuristic Planning Reinforcement Learning-Based Energy Management for Power-Split Plug-in Hybrid Electric Vehicles. IEEE Trans. Ind. Inf. 2019, 15, 6436– 6445. doi: 10.1109/TII.2019.2903098 . DOI: https://doi.org/10.1109/TII.2019.2903098

- Zhou Q. ; Li Y. ; Zhao D. ; et al . Transferable representation modelling for real-time energy management of the plug-in hybrid vehicle based on k-fold fuzzy learning and Gaussian process regression. Appl. Energy 2022, 305, 117853. doi: 10.1016/j.apenergy.2021.117853 . DOI: https://doi.org/10.1016/j.apenergy.2021.117853

- Biswas A. ; Emadi A . Energy Management Systems for Electrified Powertrains: State-of-The-Art Review and Future Trends. IEEE Trans. Veh. Technol. 2019, 68, 6453– 6467. doi: 10.1109/tvt.2019.2914457 . DOI: https://doi.org/10.1109/TVT.2019.2914457

- Volkswagen AG , Modular electric drive matrix (MEB) . Available online: https://www.volkswagen-newsroom.com/en/images/detail/volkswagen-showcar-id-crozz-3165 (Accessed on 5 October 2022).

- Changan UK R&D Centre Ltd . Changan Open a New Test Centre and Unveil Blue Core 1.5T Engine. Available online: http://www.changanuk.com/News/changan-open-new-test-centre-and-unveil-blue-core-15t-engine (Accessed on 5 October 2022).

- Pourabdollah M. ; Egardt B. ; Murgovski N. ; et al . Convex Optimization Methods for Powertrain Sizing of Electrified Vehicles by Using Different Levels of Modeling Details. IEEE Trans. Veh. Technol. 2018, 67, 1881– 1893. doi: 10.1109/TVT.2017.2767201 . DOI: https://doi.org/10.1109/TVT.2017.2767201

- Zhang L. ; Hu X. ; Wang Z. ; et al . Multiobjective Optimal Sizing of Hybrid Energy Storage System for Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 1027– 1035. doi: 10.1109/TVT.2017.2762368 . DOI: https://doi.org/10.1109/TVT.2017.2762368

- Wang X. ; Liang Q . Energy management strategy for plug-in hybrid electric vehicles via bidirectional vehicle-to-grid. IEEE Syst. J. 2015, 11, 1789– 1798. doi: 10.1109/JSYST.2015.2391284 . DOI: https://doi.org/10.1109/JSYST.2015.2391284

- Lv C. ; Hu X. ; Sangiovanni-Vincentelli A. ; et al . Driving-Style-Based Codesign Optimization of an Automated Electric Vehicle: A Cyber-Physical System Approach. IEEE Trans. Ind. Electron. 2018, 66, 2965– 2975. doi: 10.1109/TIE.2018.2850031 . DOI: https://doi.org/10.1109/TIE.2018.2850031

- Zhou Q. ; He Y. ; Zhao D. ; et al . Modified Particle Swarm Optimization with Chaotic Attraction Strategy for Modular Design of Hybrid Powertrains. IEEE Trans. Transp. Electrif. 2020, 7, 616– 625. doi: 10.1109/TTE.2020.3014688 . DOI: https://doi.org/10.1109/TTE.2020.3014688

- Liu M. ; Fang S. ; Dong H. ; et al . Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346– 361. doi: 10.1016/j.jmsy.2020.06.017 . DOI: https://doi.org/10.1016/j.jmsy.2020.06.017

- Zhou Q. ; Zhang C. ; Li Y. ; et al . Robust optimization of energy management strategy in hybrid vehicles based on digital twin and PSO algorithm (in Chinese). J. Automot. Saf. Energy 2022, 13, 517– 525. doi: 10.3969/j.issn.1674-8484.2022.03.013 .

- Bolton R.N. ; McColl-Kennedy J.R. ; Cheung L. ; et al . Customer experience challenges: bringing together digital, physical and social realms. J. Serv. Manag. 2018, 29, 776– 808. doi: 10.1108/JOSM-04-2018-0113 . DOI: https://doi.org/10.1108/JOSM-04-2018-0113

- Li W. ; Rentemeister M. ; Badeda J. ; et al . Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. doi: 10.1016/j.est.2020.101557 . DOI: https://doi.org/10.1016/j.est.2020.101557

- Bhatti G. ; Mohan H. ; Singh R . R. Towards the future of ssmart electric vehicles: Digital twin technology. Renewable Sustainable Energy Rev. 2021, 141, 110801. doi: 10.1016/j.rser.2021.110801 . DOI: https://doi.org/10.1016/j.rser.2021.110801

- Venkatesan S. ; Manickavasagam K. ; Tengenkai N. ; et al . Health monitoring and prognosis of electric vehicle motor using intelligent-digital twin. IET Electr. Power Appl. 2019, 13, 1328– 1335. doi: 10.1049/iet-epa.2018.5732 . DOI: https://doi.org/10.1049/iet-epa.2018.5732

- Liu Y. ; Wang Z. ; Han K. ; et al . Sensor Fusion of Camera and Cloud Digital Twin Information for Intelligent Vehicles. In 2020 IEEE Intelligent Vehicles Symposium (IV), Las Vegas, NV, USA, 19 October–13 November 2020; IEEE: Piscataway, NJ, USA, 2020. doi: 10.1109/IV47402.2020.9304643 . DOI: https://doi.org/10.1109/IV47402.2020.9304643

- Zhou Q. ; Guo S. ; Xu L. ; et al . Global Optimization of the Hydraulic-electromagnetic Energy-harvesting Shock Absorber for Road Vehicles with Human-knowledge-integrated Particle Swarm Optimization Scheme. IEEE/ASME Trans. Mechatron. 2021, 26, 1225– 1235. doi: 10.1109/tmech.2021.3055815 . DOI: https://doi.org/10.1109/TMECH.2021.3055815

- Zhou Q. ; Wang C. ; Sun Z. ; et al . Human-knowledge-augmented Gaussian Process Regression for State-of-Health Prediction of Lithium-ion Batteries with Charging Curves. J. Electrochem. Energy Convers. Storage 2021, 18, 030907. doi: 10.1115/1.4050798 . DOI: https://doi.org/10.1115/1.4050798

- Wang H. ; Huang Y. ; Soltani A. ; et al . Cyber-Physical Predictive Energy Management for Through-The-Road Hybrid Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 3246– 3256. doi: 10.1109/TVT.2019.2902485 . DOI: https://doi.org/10.1109/TVT.2019.2902485

- Martínez, C.M.; Cao, D. Integrated energy management for electrified vehicles. In Ihorizon-Enabled Energy Management for Electrified Vehicles; Butterworth-Heinemann: Oxford, UK, 2019; pp. 15– 75. doi: 10.1016/B978-0-12-815010-8.00002-8. DOI: https://doi.org/10.1016/B978-0-12-815010-8.00002-8

- Silver D. ; Huang A. ; Maddison C.J. ; et al . Mastering the game of Go with deep neural networks and tree search. Nature 2016, 529, 484– 489. doi: 10.1038/nature16961 . DOI: https://doi.org/10.1038/nature16961

- Bellman, R. Dynamic Programming and a New Formalism in the Calculus of Variations. Proc. Natl. Acad. Sci. 1954, 40, 231– 235. doi: 10.1073/pnas.40.4.231. DOI: https://doi.org/10.1073/pnas.40.4.231

- Hu Y. ; Wang W. ; Liu H. ; et al . Reinforcement Learning Tracking Control for Robotic Manipulator with Kernel-Based Dynamic Model. IEEE Trans. Neural Networks Learn. Syst. 2019, 31, 3570– 3578. doi: 10.1109/tnnls.2019.2945019 . DOI: https://doi.org/10.1109/TNNLS.2019.2945019

- Radac M.B. ; Precup R . E. Data-driven model-free slip control of anti-lock braking systems using reinforcement Q-learning. Neurocomputing 2018, 275, 317– 329. doi: 10.1016/j.neucom.2017.08.036 . DOI: https://doi.org/10.1016/j.neucom.2017.08.036

- Liu T. ; Zou Y. ; Liu D. ; et al . Reinforcement Learning of Adaptive Energy Management with Transition Probability for a Hybrid Electric Tracked Vehicle. IEEE Trans. Ind. Electron. 2015, 62, 7837– 7846. DOI: https://doi.org/10.1109/TIE.2015.2475419

- Shuai B. ; Zhou Q. ; Li J. ; et al . Heuristic action execution for energy efficient charge-sustaining control of connected hybrid vehicles with model-free double Q-learning. Appl. Energy 2020, 267, 114900. DOI: https://doi.org/10.1016/j.apenergy.2020.114900

- Zhou Q. ; Li J. ; Shuai B. ; et al . Multi-step Reinforcement Learning for Model-Free Predictive Energy Management of an Electrified Off-highway Vehicle. Appl. Energy 2019, 255, 113755. doi: 10.1016/j.apenergy.2019.113755 . DOI: https://doi.org/10.1016/j.apenergy.2019.113755

- Pei H. ; Hu X. ; Yang Y. ; et al . Designing Multi-Mode Power Split Hybrid Electric Vehicles Using the Hierarchical Topological Graph Theory. IEEE Trans. Veh. Technol. 2020, 69, 7159– 7171. doi: 10.1109/TVT.2020.2993019 . DOI: https://doi.org/10.1109/TVT.2020.2993019

- Xu R. ; Li J. ; Dong X. ; et al . Bridging the Domain Gap for Multi-Agent Perception. arXiv preprint Unpublished work, 2022. doi: arXiv: 2210.08451. DOI: https://doi.org/10.1109/ICRA48891.2023.10160871

- Chen W. ; Xu R. ; Xiang H. ; et al . Model-Agnostic Multi-Agent Perception Framework. arXiv preprint Unpublished work, 2022. doi: arXiv: 2203.13168.

- Schmidt L.M. ; Brosig J. ; Plinge A. ; et al . An Introduction to Multi-Agent Reinforcement Learning and Review of its Application to Autonomous Mobility. arXiv preprint Unpublished work, 2022. doi: arXiv: 2203.07676. DOI: https://doi.org/10.1109/ITSC55140.2022.9922205

- Lowe R. ; Wu Y.I. ; Tamar A. ; et al . Multi-agent actor-critic for mixed cooperative-competitive environments. In Advances in Neural Information Processing Systems 30 (NIPS 2017), Proceedings of the Annual Conference on Neural Information Processing Systems 2017, Long Beach, CA, USA, 4– 9 December 2017; pp. 6380– 6391.

- Zhao Z.Q. ; Zheng P. ; Xu S.T. ; et al . Object Detection with Deep Learning: A Review. IEEE Trans. Neural Networks Learn. Syst. 2019, 30, 3212– 3232. doi: 10.1109/TNNLS.2018.2876865 . DOI: https://doi.org/10.1109/TNNLS.2018.2876865

- Ashok Kumar P.M. ; Vaidehi V . A transfer learning framework for traffic video using neuro-fuzzy approach. Sādhanā 2017, 42, 1431– 1442. doi: 10.1007/s12046-017-0705-x . DOI: https://doi.org/10.1007/s12046-017-0705-x

- Zhou Q. ; Zhao D. ; Shuai B. ; et al . Knowledge Implementation and Transfer With an Adaptive Learning Network for Real-Time Power Management of the Plug-in Hybrid Vehicle. IEEE Trans. Neural Networks Learn. Syst. 2021, 32, 5298– 5308. DOI: https://doi.org/10.1109/TNNLS.2021.3093429

- Williams C.K. ; Rasmussen C . E. Gaussian Processes for Machine Learning. MIT Press: Cambridge, MA, USA, 2006. DOI: https://doi.org/10.7551/mitpress/3206.001.0001