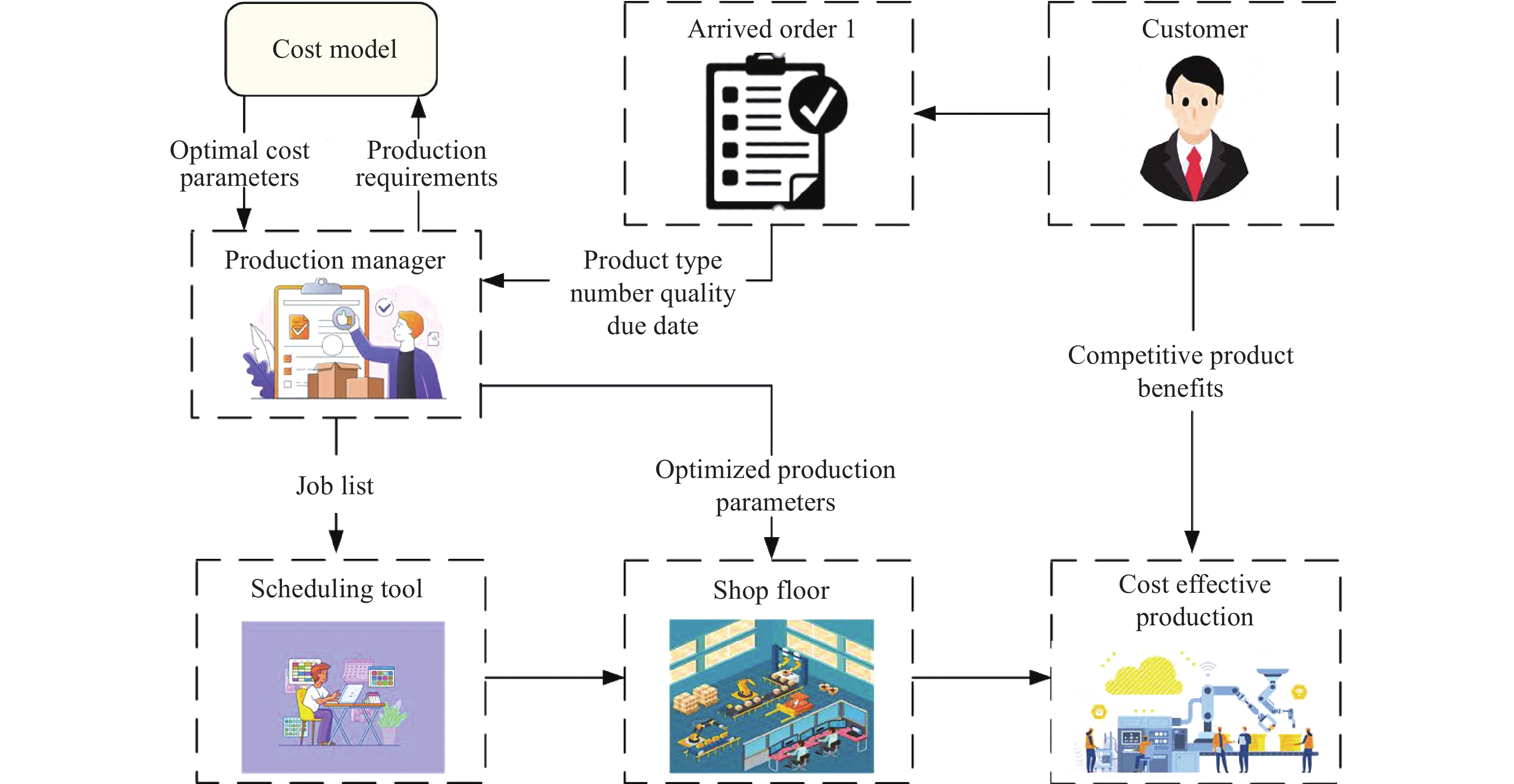

Intelligent manufacturing is facing significant challenges in adapting to the ever-changing equipment, instrumentation, process and economics. Such a trend together with the pressure to reliably control and contain production costs means that frequent adjusting decisions are required to adapt to incessant volatility imposed on manufacturing systems. Under this circumstance, cost-effective and quality-guaranteed manufacturing strategies would be the most logical route to reducing production costs. In this paper, a novel dynamical cost prediction and control (CPC) model is proposed to support collective decision-making in intelligent manufacturing, where the model output is the real-time prediction of possible manufacturing costs, while the inputs are generic manufacturing key performance indicators covering inventory, product quality, production efficiency, resource utilisation and environmental impact. This proposed CPC model distinguishes itself from existing ones for its capability to translate manufacturing data (at both the physical level and operation management level) into financial metrics that contribute to forming a common language between engineering, financial and administrative departments of an enterprise. The case study about the assembly line of optoelectronic devices demonstrates that, although different enterprise departments have different priorities, our CPC model helps them to achieve certain consensus on intended production that finally creates satisfactory profitability for the company at controlled manufacturing costs.

- Open Access

- Article

Reliable Cost Prediction and Control for Intelligent Manufacture: A Key Performance Indicator Perspective

- Hang Geng 1, *,

- Alireza Mousavi 2,

- Nikolaos Grigorios Markatos 2,

- Kai Chen 1,

- Xuan Gou 1

Author Information

Received: 10 Jul 2023 | Accepted: 11 Oct 2023 | Published: 26 Mar 2024

Abstract

Graphical Abstract

References

- 1.Abu Ebayyeh, A.A.R.M.; Danishvar, S.; Mousavi, A. An improved capsule network (WaferCaps) for wafer bin map classification based on DCGAN data upsampling. IEEE Trans. Semicond. Manuf., 2022, 35: 50−59. doi: 10.1109/TSM.2021.3134625

- 2.Adebanjo, D.; Teh, P.L.; Ahmed, P.K. The impact of external pressure and sustainable management practices on manufacturing performance and environmental outcomes. Int. J. Oper. Prod. Manage., 2016, 36: 995−1013. doi: 10.1108/IJOPM-11-2014-0543

- 3.Almeida, A.; Cunha, J. The implementation of an activity-based costing (ABC) system in a manufacturing company. Procedia Manuf., 2017, 13: 932−939. doi: 10.1016/j.promfg.2017.09.162

- 4.Amrina, E.; Vilsi, A.L. Key performance indicators for sustainable manufacturing evaluation in cement industry. Procedia CIRP, 2015, 26: 19−23. doi: 10.1016/j.procir.2014.07.173

- 5.Caballero-Águila, R.; Linares-Pérez, J. Distributed fusion filtering for uncertain systems with coupled noises, random delays and packet loss prediction compensation. Int. J. Syst. Sci., 2023, 54: 371−390. doi: 10.1080/00207721.2022.2122905

- 6.Cao, Q.D.; Yu, H.; Charisse, P.; et al. Is high-fidelity important for human-like virtual avatars in human computer interactions?. Int. J. Netw. Dyn. Intell., 2023, 2: 15−23. doi: 10.53941/ijndi0201008

- 7.Chen, H.W.; Chang, N.B. A comparative analysis of methods to represent uncertainty in estimating the cost of constructing wastewater treatment plants. J. Environ. Manage., 2002, 65: 383−409. doi: 10.1016/S0301-4797(01)90563-8

- 8.Cui, Y.; Liu, Y.R.; Zhang, W.B.; et al. Sampled-based consensus for nonlinear multiagent systems with deception attacks: The decoupled method. IEEE Trans. Syst. Man Cybern. Syst., 2021, 51: 561−573. doi: 10.1109/TSMC.2018.2876497

- 9.Danishvar, M.; Mousavi, A.; Broomhead, P. EventiC: A real-time unbiased event-based learning technique for complex systems. IEEE Trans. Syst. Man Cybern. Syst., 2020, 50: 1649−1662. doi: 10.1109/TSMC.2017.2775666

- 10.Dong, S.L.; Liu, M.Q.; Wu, Z.G. A survey on hidden Markov jump systems: Asynchronous control and filtering. Int. J. Syst. Sci., 2023, 54: 1360−1376. doi: 10.1080/00207721.2023.2171710

- 11.Fang, J.Z.; Liu, W.B.; Chen, L.W.; et al. A survey of algorithms, applications and trends for particle swarm optimization. Int. J. Netw. Dyn. Intell., 2023, 2: 24−50. doi: 10.53941/ijndi0201002

- 12.Fazli, E.; Rakhtala, S.M.; Mirrashid, N.; et al. Real-time implementation of a super twisting control algorithm for an upper limb wearable robot. Mechatronics, 2022, 84: 102808. doi: 10.1016/j.mechatronics.2022.102808

- 13.Gao, C.; Wang, Z.D.; Hu, J.; et al. Consensus-based distributed state estimation over sensor networks with encoding-decoding scheme: Accommodating bandwidth constraints. IEEE Trans. Netw. Sci. Eng., 2022, 9: 4051−4064. doi: 10.1109/TNSE.2022.3195283

- 14.Geng, H.; Liang, Y.; Cheng, Y.H. Target state and Markovian jump ionospheric height bias estimation for OTHR tracking systems. IEEE Trans. Syst. Man Cybern. Syst., 2020, 50: 2599−2611. doi: 10.1109/TSMC.2018.2822819

- 15.Geng, H.; Wang, Z.D.; Chen, Y.; et al. Multi-sensor filtering fusion with parametric uncertainties and measurement censoring: Monotonicity and boundedness. IEEE Trans. Signal Process., 2021, 69: 5875−5890. doi: 10.1109/TSP.2021.3118538

- 16.Geng, H.; Wang, Z.D.; Hu, J.; et al. Variance-constrained filter design with sensor resolution under round-robin communication protocol: An outlier-resistant mechanism. IEEE Trans. Syst. Man Cybern. Syst., 2023, 53: 3762−3773. doi: 10.1109/TSMC.2023.3234461

- 17.Geng, H.; Wang, Z.D.; Zou, L.; et al. Protocol-based Tobit Kalman filter under integral measurements and probabilistic sensor failures. IEEE Trans. Signal Process., 2021, 69: 546−559. doi: 10.1109/TSP.2020.3048245

- 18.Guo, X.W.; Bi, Z.L.; Wang, J.C.; et al. Reinforcement learning for disassembly system optimization problems: A Survey. Int. J. Netw. Dyn. Intell., 2023, 2: 1−14. doi: 10.53941/ijndi0201001

- 19.Han, F.; Liu, J.H.; Li, J.H.; et al. Consensus control for multi-rate multi-agent systems with fading measurements: The dynamic event-triggered case. Syst. Sci. Control Eng., 2023, 11: 2158959. doi: 10.1080/21642583.2022.2158959

- 20.Han, F.; Wang, Z.D.; Dong, H.L.; et al. Distributed H∞-consensus estimation for random parameter systems over binary sensor networks: A local performance analysis method. IEEE Trans. Netw. Sci. Eng., 2023, 10: 2334−2346. doi: 10.1109/TNSE.2023.3246427

- 21.Hou, Y.X.; Zhang, Y.; Lu, J.Y.; et al. Application of improved multi-strategy MPA-VMD in pipeline leakage detection. Syst. Sci. Control Eng., 2023, 11: 2177771. doi: 10.1080/21642583.2023.2177771

- 22.Ioannidis, S.; Xanthopoulos, A.S.; Sarantis, I.; et al. Joint production, inventory rationing, and order admission control of a stochastic manufacturing system with setups. Oper. Res., 2021, 21: 827−855. doi: 10.1007/s12351-019-00465-5

- 23.Juszczyk, M. The challenges of nonparametric cost estimation of construction works with the use of artificial intelligence tools. Procedia Eng., 2017, 196: 415−422. doi: 10.1016/j.proeng.2017.07.218

- 24.Kasie, F.M.; Bright, G. Integrating fuzzy case-based reasoning, parametric and feature-based cost estimation methods for machining process. J. Modell. Manage., 2021, 16: 825−847. doi: 10.1108/JM2-05-2020-0123

- 25.Lei, Y.X.; Karimi, H.R.; Chen, X.F. A novel self-supervised deep LSTM network for industrial temperature prediction in aluminum processes application. Neurocomputing, 2022, 502: 177−185. doi: 10.1016/j.neucom.2022.06.080

- 26.Li, X.; Li, M.L.; Yan, P.F.; et al. Deep learning attention mechanism in medical image analysis: Basics and beyonds. Int. J. Netw. Dyn. Intell., 2023, 2: 93−116. doi: 10.53941/ijndi0201006

- 27.Liang, S.; Liang, J.L.; Qiu, J.L. Finite-time input-to-state stability of discrete-time stochastic switched systems: A comparison principle-based method. Int. J. Syst. Sci., 2023, 54: 1−16. doi: 10.1080/00207721.2022.2093421

- 28.Luo, X.; Wu, H.; Wang, Z.; et al. A novel approach to large-scale dynamically weighted directed network representation. IEEE Trans. Pattern Anal. Mach. Intell., 2022, 44: 9756−9773. doi: 10.1109/TPAMI.2021.3132503

- 29.Luo, X.; Zhou, Y.; Liu, Z.G.; et al. Fast and accurate non-negative latent factor analysis of high-dimensional and sparse matrices in recommender systems. IEEE Trans. Knowl. Data Eng., 2023, 35: 3897−3911. doi: 10.1109/TKDE.2021.3125252

- 30.Ma, G.J.; Wang, Z.D.; Liu, W.B.; et al. Estimating the state of health for lithium-ion batteries: A particle swarm optimization-assisted deep domain adaptation approach. IEEE/CAA J. Autom. Sin., 2023, 10: 1530−1543. doi: 10.1109/JAS.2023.123531

- 31.Manesh, M.F.; Pellegrini, M.M.; Marzi, G.; et al. Knowledge management in the fourth industrial revolution: Mapping the literature and scoping future avenues. IEEE Trans. Eng. Manage., 2021, 68: 289−300. doi: 10.1109/tem.2019.2963489

- 32.Mourtzis, D.; Doukas, M.; Psarommatis, F. A toolbox for the design, planning and operation of manufacturing networks in a mass customisation environment. J. Manuf. Syst., 2015, 36: 274−286. doi: 10.1016/j.jmsy.2014.06.004

- 33.Mousavi, A.; Siervo, H.R.A. Automatic translation of plant data into management performance metrics: A case for real-time and predictive production control. Int. J. Prod. Res., 2017, 55: 4862−4877. doi: 10.1080/00207543.2016.1265682

- 34.Plinere, D.; Aleksejeva, L. Production scheduling in agent-based supply chain for manufacturing efficiency improvement. Procedia Comput. Sci., 2019, 149: 36−43. doi: 10.1016/j.procs.2019.01.104

- 35.Psarommatis, F.; Kiritsis, D. A hybrid Decision Support System for automating decision making in the event of defects in the era of Zero Defect Manufacturing. J. Ind. Inf. Integr., 2022, 26: 100263. doi: 10.1016/J.JII.2021.100263

- 36.Psarommatis, F.; May, G.; Dreyfus, P.A.; et al. Zero defect manufacturing: State-of-the-art review, shortcomings and future directions in research. Int. J. Prod. Res., 2020, 58: 1−17. doi: 10.1080/00207543.2019.1605228

- 37.Psarommatis, F.; Danishvar, M.; Mousavi, A.;

et al . Cost-based decision support system: A dynamic cost estimation of key performance indicators in manufacturing.IEEE Trans. Eng. Manage .2022 , in press. - 38.Psarommatis, F.; Prouvost, S.; May, G.; et al. Product quality improvement policies in industry 4.0: Characteristics, enabling factors, barriers, and evolution toward zero defect manufacturing. Front. Comput. Sci., 2020, 2: 26. doi: 10.3389/fcomp.2020.00026

- 39.Qu, B.G.; Wang, Z.D.; Shen, B.; et al. Decentralized dynamic state estimation for multi-machine power systems with non-Gaussian noises: Outlier detection and localization. Automatica, 2023, 153: 111010. doi: 10.1016/j.automatica.2023.111010

- 40.Shahi, K.; Li, Y.M. Background replacement in video conferencing. Int. J. Netw. Dyn. Intell., 2023, 2: 100004. doi: 10.53941/ijndi.2023.100004

- 41.Shen, Y.X.; Wang, Z.D.; Dong, H.L.; et al. Distributed recursive state estimation for a class of multi-rate nonlinear systems over wireless sensor networks under FlexRay protocols. IEEE Trans. Netw. Sci. Eng., 2023, 10: 1551−1563. doi: 10.1109/TNSE.2022.3229889

- 42.Stockton, D.J.; Khalil, R.A.; Mukhongo, L.M. Cost model development using virtual manufacturing and data mining: Part II–comparison of data mining algorithms. Int. J. Adv. Manuf. Technol., 2013, 66: 1389−1396. doi: 10.1007/s00170-012-4416-5

- 43.Stončiuvienė, N.; Ūsaitė-Duonielienė, R.; Zinkevičienė, D. Integration of activity-based costing modifications and LEAN accounting into full cost calculation. Inz. Ekon.–Eng. Econ., 2020, 31: 50−60. doi: 10.5755/j01.ee.31.1.23750

- 44.D’Urso, G.; Quarto, M.; Ravasio, C. A model to predict manufacturing cost for micro-EDM drilling. Int. J. Adv. Manuf. Technol., 2017, 91: 2843−2853. doi: 10.1007/s00170-016-9950-0

- 45.Wang, J.W.; Zhuang, Y.; Liu, Y.S. FSS-Net: A fast search structure for 3D point clouds in deep learning. Int. J. Netw. Dyn. Intell., 2023, 2: 100005. doi: 10.53941/ijndi.2023.100005

- 46.Wang, M.Y.; Wang, H.Y.; Zheng, H.R. A mini review of node centrality metrics in biological networks. Int. J. Netw. Dyn. Intell., 2022, 1: 99−110. doi: 10.53941/ijndi0101009

- 47.Wang, X.L.; Sun, Y.; Ding, D.R. Adaptive dynamic programming for networked control systems under communication constraints: A survey of trends and techniques. Int. J. Netw. Dyn. Intell., 2022, 1: 85−98. doi: 10.53941/ijndi0101008

- 48.Xiao, H.N.; Zhu, Q.X.; Karimi, H.R. Stability analysis of semi-Markov switching stochastic mode-dependent delay systems with unstable subsystems. Chaos Solitons Fractals, 2022, 165: 112791. doi: 10.1016/j.chaos.2022.112791

- 49.Wang, Y.M.; Liu, W.B.; Wang, C.; et al. A novel multi-objective optimization approach with flexible operation planning strategy for truck scheduling. Int. J. Netw. Dyn. Intell., 2023, 2: 100002. doi: 10.53941/ijndi.2023.100002

- 50.Wang, Y.A.; Shen, B.; Zou, L.; et al. A survey on recent advances in distributed filtering over sensor networks subject to communication constraints. Int. J. Netw. Dyn. Intell., 2023, 2: 100007. doi: 10.53941/ijndi0201007

- 51.Yi, X.J.; Yu, H.Y.; Fang, Z.Y.; et al. Probability-guaranteed state estimation for nonlinear delayed systems under mixed attacks. Int. J. Syst. Sci., 2023, 54: 2059−2071. doi: 10.1080/00207721.2023.2216274

- 52.Yu, H.C.; Wu, Z.T.; Jiang, B.P.; et al. Fault section location for distribution network based on linear integer programming. Int. J. Syst. Sci., 2023, 54: 391−404. doi: 10.1080/00207721.2022.2122906

- 53.Zhang, Y.H.; Zou, L.; Liu, Y.; et al. A brief survey on nonlinear control using adaptive dynamic programming under engineering-oriented complexities. Int. J. Syst. Sci., 2023, 54: 1855−1872. doi: 10.1080/00207721.2023.2209846

- 54.Zhao, Z.Y.; Wang, Z.D.; Zou, L.; et al. Zonotopic distributed fusion for nonlinear networked systems with bit rate constraint. Inf. Fusion, 2023, 90: 174−184. doi: 10.1016/j.inffus.2022.09.014

- 55.Zhao, Z.Y.; Wang, Z.D.; Zou, L.; et al. Zonotopic multi-sensor fusion estimation with mixed delays under try-once-discard protocol: A set-membership framework. Inf. Fusion, 2023, 91: 681−693. doi: 10.1016/j.inffus.2022.11.012

- 56.Zhu, K.Q.; Wang, Z.D.; Chen, Y.; et al. Event-triggered cost-guaranteed control for linear repetitive processes under probabilistic constraints. IEEE Trans. Autom. Control, 2023, 68: 424−431. doi: 10.1109/TAC.2022.3140384

- 57.Zou, L.; Wang, Z.D.; Han, Q.L.; et al. Tracking control under round-robin scheduling: Handling impulsive transmission outliers. IEEE Trans. Cybern., 2023, 53: 2288−2300. doi: 10.1109/TCYB.2021.3115459

- 58.Zou, L.; Wang, Z.D.; Shen, B.; et al. Moving horizon estimation over relay channels: Dealing with packet losses. Automatica, 2023, 155: 111079. doi: 10.1016/j.automatica.2023.111079

How to Cite

Geng, H.; Mousavi, A.; Markatos, N. G.; Chen, K.; Gou, X. Reliable Cost Prediction and Control for Intelligent Manufacture: A Key Performance Indicator Perspective. International Journal of Network Dynamics and Intelligence 2024, 3 (1), 100001. https://doi.org/10.53941/ijndi.2024.100001.

RIS

BibTex

Copyright & License

Copyright (c) 2024 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References