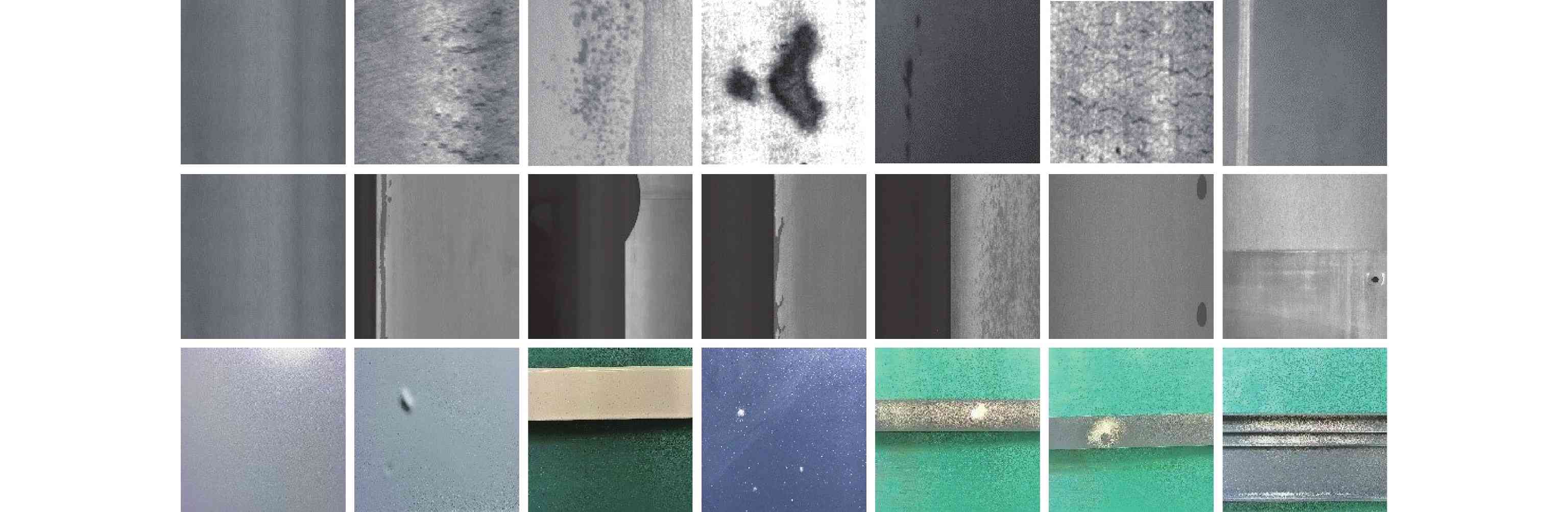

Due to the limitations of manufacture technologies, working environments and other conditions, metals (such as steel and aluminum) are susceptible to surface defects during the production process. Therefore, defect detection is an indispensable part of metal manufacturing. This paper innovatively proposes a one-stage defect detection model named Metal-YOLOX. Metal-YOLOX addresses the limitations in existing models posed by large variances in defect features and inadequate balance between detection accuracy and efficiency. Firstly, the composite convolution module of Metal-YOLOX integrates texture, dilated and deformable convolutions to filter out irrelevant features and extract effective feature information. Secondly, the feature cross-fusion module (HCNet) alleviates the problem of large dimensional differences in defects. HCNet uses skip connections to establish the connection between the original multi-scale features and the output nodes, and reduces the addition of redundant information. Thirdly, Metal-YOLOX adopts the deep separable convolution and global channel reduction. This lightweight design helps reduce computational complexity. Finally, detailed experiments demonstrate that, in terms of mean average precision, Metal-YOLOX achieves 79.83, 69.14, and 81.22 on the NEU-DET, GC-10 and Aluminum datasets, respectively. Furthermore, Metal-YOLOX dramatically reduces parameter number and computational complexity. The experiments validate that the Metal-YOLOX model improves the detection performance, maintains the detection speed, and meets the real-time requirements.

- Open Access

- Article

Metal Surface Defect Detection Based on Metal-YOLOX

- Xiaoli Yue,

- Jiandong Chen,

- Guoqiang Zhong *

Author Information

Received: 14 Jun 2023 | Accepted: 13 Sep 2023 | Published: 21 Dec 2023

Abstract

Graphical Abstract

References

- 1.Nussbaumer, H.J. Fast Fourier Transform and Convolution Algorithms, 2nd ed.; Springer: Berlin, Heidelberg, 1982. doi: 10.1007/978-3-642-81897-4

- 2.Honarkhah, M.; Caers, J. Stochastic simulation of patterns using distance-based pattern modeling. Math. Geosci., 2010, 42:487−517. doi: 10.1007/s11004-010-9276-7

- 3.Prasitmeeboon, P.; Yau, H. Defect detection of particleboards by visual analysis and machine learning. In Proceedings of the 5th International Conference on Engineering, Applied Sciences and Technology (ICEAST), Luang Prabang, Laos, 2–5 July 2019; IEEE: New York, 2019; pp. 1–4. doi: 10.1109/ICEAST.2019.8802526

- 4.Li, J.H.; Quan, X.X.; Wang, Y.L. Research on defect detection algorithm of ceramic tile surface with multi-feature fusion. Comput. Eng. Appl., 2020, 56: 191−198. doi: 10.3778/j.issn.1002-8331.1907-0130

- 5.Persoon, E.; Fu, K.S. Shape discrimination using Fourier descriptors. IEEE Trans. Pattern Anal. Mach. Intell. 1986, PAMI-8, 388–397. doi: 10.1109/TPAMI.1986.4767799

- 6.Nieniewski, M. Morphological detection and extraction of rail surface defects. IEEE Trans. Instrum. Meas., 2020, 69: 6870−6879. doi: 10.1109/TIM.2020.2975454

- 7.Chen, Y.J.; Ding, Y.Y.; Zhao, F.; et al. Surface defect detection methods for industrial products: A review. Appl. Sci., 2021, 11: 7657. doi: 10.3390/app11167657

- 8.Wang, C.; Wang, Z.D.; Ma, L.F.; et al. Subdomain-alignment data augmentation for pipeline fault diagnosis: An adversarial self-attention network. IEEE Trans. Ind. Inform. 2023, in press. doi: 10.1109/TII.2023.3275701

- 9.Wang, C.; Wang, Z.D.; Ma, L.F.; et al. A novel contrastive adversarial network for minor-class data augmentation: Applications to pipeline fault diagnosis. Knowl.-Based Syst., 2023, 271: 110516. doi: 10.1016/j.knosys.2023.110516

- 10.Ni, H.X.; Wang, M.Z.; Zhao, L.Y. An improved faster R-CNN for defect recognition of key components of transmission line. Math. Biosci. Eng., 2021, 18: 4679−4695. doi: 10.3934/mbe.2021237

- 11.Ding, R.W.; Dai, L.H.; Li, G.P.; et al. TDD-net: a tiny defect detection network for printed circuit boards. CAAI Trans. Intell. Tech-nol., 2019, 4: 110−116. doi: 10.1049/trit.2019.0019

- 12.Tang, J.H.; Mao, Y.C.; Wang, J.; et al. Multi-task enhanced dam crack image detection based on faster R-CNN. In Proceedings of the 4th International Conference on Image, Vision and Computing (ICIVC), Xiamen, China, 5–7 July 2019; IEEE: New York, 2019; pp. 336–340. doi: 10.1109/ICIVC47709.2019.8981093

- 13.Liu, Z.G.; Liu, K.; Zhong, J.P.; et al. A high-precision positioning approach for catenary support components with multiscale difference. IEEE Trans. Instrum. Meas., 2020, 69: 700−711. doi: 10.1109/TIM.2019.2905905

- 14.Alzubaidi, L.; Zhang, J.L.; Humaidi, A.J.; et al. Review of deep learning: Concepts, CNN architectures, challenges, applications, future directions. J. Big Data, 2021, 8: 53. doi: 10.1186/s40537-021-00444-8

- 15.Redmon, J.; Divvala, S.; Girshick, R.; et al. You only look once: Unified, real-time object detection. In Proceedings of 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; IEEE: New York, 2016; pp. 779–788. doi: 10.1109/CVPR.2016.91

- 16.Lin, T.Y.; Goyal, P.; Girshick, R.; et al. Focal loss for dense object detection. In Proceedings of 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017; IEEE: New York, 2017; pp. 2999–3007. doi: 10.1109/ICCV.2017.324

- 17.Liu, W.; Anguelov, D.; Erhan, D.; et al. SSD: Single shot MultiBox detector. In Proceedings of the 14th European Conference on Computer Vision, Amsterdam, The Netherlands, 11–14 October 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 21–37. doi: 10.1007/978-3-319-46448-0_2

- 18.Ren, S.Q; He, K.M; Girshick, R.; et al. Faster R-CNN: Towards real-time object detection with region proposal networks. IEEE Trans. Pattern Anal. Mach. Intell., 2017, 39: 1137−1149. doi: 10.1109/TPAMI.2016.2577031

- 19.Wang, T.; Su, J.H.; Xu, C.; et al. An intelligent method for detecting surface defects in aluminium profiles based on the improved YOLOv5 algorithm. Electronics, 2022, 11: 2304. doi: 10.3390/electronics11152304

- 20.Wang, Q.L.; Wu, B.G.; Zhu, P.F.; et al. ECA-net: Efficient channel attention for deep convolutional neural networks. In Proceedings of 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; IEEE: New York, 2020; pp. 11531–11539. doi: 10.1109/CVPR42600.2020.01155

- 21.Song, K.C.; Yan, Y.H. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci., 2013, 285: 858−864. doi: 10.1016/j.apsusc.2013.09.002

- 22.Lv, X.M.; Duan, F.J.; Jiang, J.J.; et al. Deep metallic surface defect detection: The new benchmark and detection network. Sensors, 2020, 20: 1562. doi: 10.3390/s20061562

- 23.Dataset for Identifying Surface Defects in Aluminium Profiles. Available online: https://tianchi.aliyun.com/dataset/140666 (accessed on 17 September 2018). (In Chinese).

- 24.Song, G.L.; Liu, Y.; Wang, X.G. Revisiting the sibling head in object detector. In Proceedings of 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; IEEE: New York, 2020; pp. 11560–11569. doi: 10.1109/CVPR42600.2020.01158

- 25.Wu, Y.; Chen, Y.P.; Yuan, L.; et al. Rethinking classification and localization for object detection. In Proceedings of 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; IEEE: New York, 2020; pp. 10183–10192. doi: 10.1109/CVPR42600.2020.01020

- 26.Liu, S.; Qi, L.; Qin, H.F.; et al. Path aggregation network for instance segmentation. In Proceedings of 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; IEEE: New York, 2018; pp. 8759–8768. doi: 10.1109/CVPR.2018.00913

- 27.Bochkovskiy, A.; Wang, C.Y.; Liao, H.Y.M. YOLOv4: Optimal speed and accuracy of object detection. arXiv preprint arXiv:2004.10934, 2020.

- 28.Yu, F.; Koltun, V.; Funkhouser, T. Dilated residual networks. In Proceedings of 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; IEEE: New York, 2017; pp. 636–644. doi: 10.1109/CVPR.2017.75

- 29.Dai, J.F.; Qi, H.Z.; Xiong, Y.W.; et al. Deformable convolutional networks. In Proceedings of 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017; IEEE: New York, 2017; pp. 764–773. doi: 10.1109/ICCV.2017.89

- 30.Tan, M.X.; Pang, R.M.; Le, Q.V. EfficientDet: Scalable and efficient object detection. In Proceedings of 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; IEEE: New York, 2020; pp.10778–10787. doi: 10.1109/CVPR42600.2020.01079

- 31.Sifre, L.; Mallat, S. Rigid-motion scattering for texture classification. arXiv preprint arXiv: 1403.1687, 2014.

- 32.Redmon, J.; Farhadi, A. YOLOv3: An incremental improvement. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, 2018.

- 33.Jocher, G.; Stoken, A.; Borovec, J.; et al. Ultralytics/yolov5: v3.0 (Version v3.0). Zenodo, 2020.

- 34.Ge, Z.; Liu, S.T.; Wang, F.; et al. YOLOX: Exceeding YOLO series in 2021. arXiv preprint arXiv: 2107.08430, 2021.

- 35.Wang, C.Y.; Bochkovskiy, A.; Liao, H.Y.M. YOLOv7: Trainable bag-of-freebies sets new state-of-the-art for real-time object detectors. In Proceedings of 2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Vancouver, Canada, 17–24 June 2023; IEEE: Vancouver, Canada, 2023; pp. 7464–7475. doi: 10.1109/CVPR52729.2023.00721

- 36.Selvaraju, R.R.; Cogswell, M.; Das, A.; et al. Grad-CAM: Visual explanations from deep networks via gradient-based localization. Int. J Comput. Vis., 2020, 128: 336−359. doi: 10.1007/s11263-019-01228-7

How to Cite

Yue, X.; Chen, J.; Zhong, G. Metal Surface Defect Detection Based on Metal-YOLOX. International Journal of Network Dynamics and Intelligence 2023, 2 (4), 100020. https://doi.org/10.53941/ijndi.2023.100020.

RIS

BibTex

Copyright & License

Copyright (c) 2023 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References