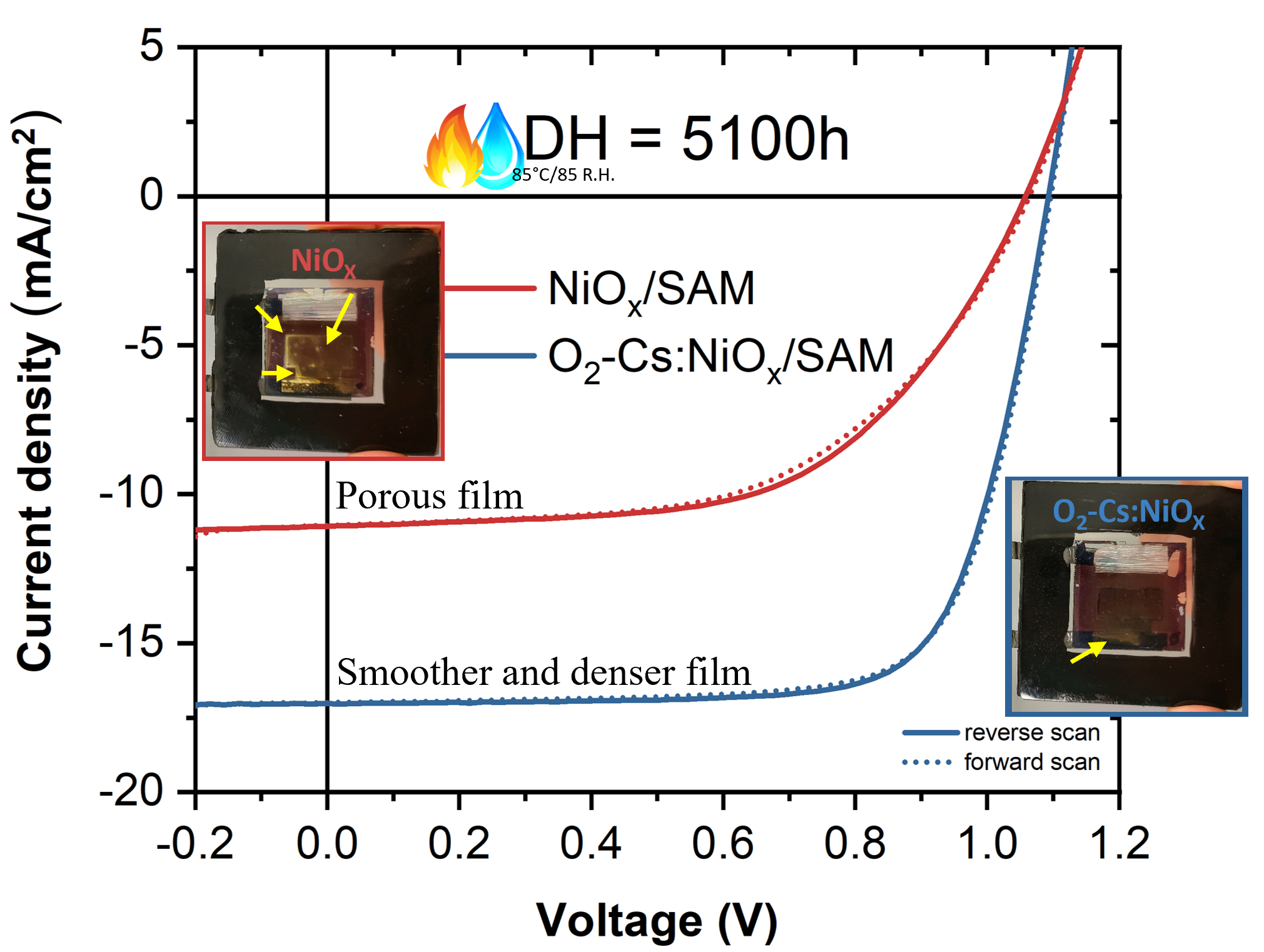

NiOx is widely used as a hole transport material in perovskite solar cells (PSCs). This wide band gap p-type material is conveniently deposited via high throughput RF-sputtering, making it suitable for the industrialization of PSCs. Nonetheless, for the cells to pass accelerated degradation tests such as the IEC 61215 damp heat (DH) test, the chemistry of the NiOx film should remain constant at elevated temperaturs to preserve its optoelectronic properties. This study emphasizes that structural defects resulting from Ni vacancies in NiOx lead to significant degradation of the PSCs after just a few hours of exposure to elevated temperatures (85 °C). We introduce here an approach to fine-tune the chemistry of the NiOx film by adjusting the gas flow during sputtering deposition and by incorporating Cs. Through this control on the chemistry of the layer, the optimized NiOx-based PSCs exhibit remarkable stability, with devices passing 5 times the IEC 61215 norm (<5% rel after 5000 h of DH testing) and also showing better stability under light soaking. XPS analysis reveals that the concentration of Ni3+ in the bulk of the standard NiOx film is twice that in the optimized NiOx. This suggests that the Ni3+ concentration, typically equal to the Ni vacancy concentration and beneficial for charge transport in NiOx, may actually compromise the stability of the PSCs. Additionally, the film density of the optimized NiOx film was significantly higher than that of the standard film.

- Open Access

- Article

Stabilizing the Chemistry of NiOx in Perovskite Solar Cells to Pass the Damp Heat Test

- Marion Dussouillez 1, 2, *, †,

- Mounir Mensi 3,

- Ivan Marozau 1,

- Quentin Jeangros 1,

- Sylvain Nicolay 1, ‡,

- Christophe Ballif 1, 2,

- Adriana Paracchino 1, *

Author Information

Received: 07 Jan 2025 | Revised: 10 Mar 2025 | Accepted: 13 Mar 2025 | Published: 18 Mar 2025

Abstract

Graphical Abstract

Keywords

doped-NiOx | perovskite solar cell | stability | industrialization

References

- 1.Cui, J.; Meng, F.; Zhang, H.; et al. CH3NH3PbI3-Based Planar Solar Cells with Magnetron-Sputtered Nickel Oxide. ACS Appl. Mater.s Interfaces 2014, 6, 22862.

- 2.Guziewicz, M.; Grochowski, J.; Borysiewicz, M.; et al. Electrical and optical properties of NiO films deposited by magnetron sputtering. Opt. Appl. 2011, 41, 431.

- 3.Xu, J.; Boyd, C.C.; Yu, Z.J.; et al. Triple-halide wide–band gap perovskites with suppressed phase segregation for efficient tandems. Science 2020, 367, 1097.

- 4.Hou, Y.; Aydin, E.; De Bastiani, M.; et al. Efficient tandem solar cells with solution-processed perovskite on textured crystalline silicon. Science 2020, 367, 1135.

- 5.De Bastiani, M.; Mirabelli, A.J.; Hou, Y.; et al. Efficient bifacial monolithic perovskite/silicon tandem solar cells via bandgap engineering. Nat. Energy 2021, 6, 167.

- 6.Kamino, B.A.; Paviet-Salomon, B.; Moon, S.J.; et al. Low-Temperature Screen-Printed Metallization for the Scale-Up of Two-Terminal Perovskite–Silicon Tandems. ACS Appl. Energy Mater. 2019, 2, 3815.

- 7.Dussouillez, M.; Moon, S.; Mensi, M.; et al. Understanding and Mitigating the Degradation of Perovskite Solar Cells Based on a Nickel Oxide Hole Transport Material during Damp Heat Testing. ACS Appl. Mater. Interfaces 2022, 15, 27941.

- 8.Karsthof, R.; Anton, A.M.; Kremer, F.; et al. Nickel vacancy acceptor in nickel oxide: Doping beyond thermodynamic equilibrium. Phys. Rev. Mater. 2020, 4, 034601.

- 9.Boyd, C.C.; Shallcross, R.C.; Moot, T.; et al. Overcoming Redox Reactions at Perovskite-Nickel Oxide Interfaces to Boost Voltages in Perovskite Solar Cells. Joule 2020, 4, 1759.

- 10.Itzhak, A.; He, X.; Kama, A.; et al. NiN-Passivated NiO Hole-Transport Layer Improves Halide Perovskite-Based Solar Cell. ACS Appl. Mater. Interfaces 2022, 14, 47587.

- 11.Peng, Z.; Zuo, Z.; Qi, Q.; et al. Managing the Double-Edged Sword of Ni3+ in Sputter-Deposited NiOx by Interfacial Redox Reactions for Efficient Perovskite Solar Cells. ACS Appl. Energy Mater. 2023, 6, 1396.

- 12.Guo, Y.; Ma, J.; Wang, H.; et al. Overcoming Ni3+-Induced Non-Radiative Recombination at Perovskite-Nickel Oxide Interfaces to Boost Voltages in Perovskite Solar Cells. Adv. Mater. Interfaces 2021, 8, 1.

- 13.Li, C.; Wang, X.; Bi, E.; et al. Rational design of Lewis base molecules for stable and efficient inverted perovskite solar cells. Science 2023, 379, 690.

- 14.Zhang, C.; Shen, X.; Chen, M.; et al. Constructing a Stable and Efficient Buried Heterojunction via Halogen Bonding for Inverted Perovskite Solar Cells. Adv. Energy Mater. 2023, 13, 2203250.

- 15.Lee, S.; Lee, J.; Park, H.; et al. Defect-Passivating Organic/Inorganic Bicomponent Hole-Transport Layer for High Efficiency Metal-Halide Perovskite Device. ACS Appl. Mater. Interfaces 2020, 12, 40310.

- 16.Phung, N.; Verheijen, M.; Todinova, A.; et al. Enhanced Self-Assembled Monolayer Surface Coverage by ALD NiO in p-i-n Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 2166.

- 17.Yu, X.; Wang, Y.; Li, L.; et al. Interfacial modification of NiOx by self-assembled monolayer for efficient and stable inverted perovskite solar cells. Chin. J. Chem. Phys. 2024, 37, 553.

- 18.Alghamdi, A.R.M.; Yanagida, M.; Shirai, Y.; et al. Surface Passivation of Sputtered NiOx Using a SAM Interface Layer to Enhance the Performance of Perovskite Solar Cells. ACS Omega 2022, 7, 12147.

- 19.Yan, X.; Zheng, J.; Zheng, L.L.; et al. Optimization of sputtering NiOx films for perovskite solar cell applications. Mater. Res. Bull. 2018, 103, 150.

- 20.Shi, J.; Lai, L.; Zhang, P.; et al. Aluminum doped nickel oxide thin film with improved electrochromic performance from layered double hydroxides precursor in situ pyrolytic route. J. Solid State Chem. 2016, 241, 1.

- 21.Chen, W.; Liu, F.Z.; Feng, X.Y.; et al. Cesium Doped NiOx as an Efficient Hole Extraction Layer for Inverted Planar Perovskite Solar Cells. Adv. Energy Mater. 2017, 7, 1700722.

- 22.Li, G.; Jiang, Y.; Deng, S.; et al. Overcoming the Limitations of Sputtered Nickel Oxide for High-Efficiency and Large-Area Perovskite Solar Cells. Adv. Sci. 2017, 4, 1700463.

- 23.Yao, Q.; Zhao, L.; Sun, X.; et al. Na2S decorated NiOx as effective hole transport layer for inverted planar perovskite solar cells. Mater. Sci. Semicond. Process 2023, 153, 107107.

- 24.Chen, W.; Wu, Y.; Yue, Y.; et al. Efficient and stable large-area perovskite solar cells with inorganic charge extraction layers. Science 2015, 350, 944.

- 25.Traore, B.; Pedesseau, L.; Blancon, J.C.; et al. Importance of Vacancies and Doping in the Hole-Transporting Nickel Oxide Interface with Halide Perovskites. ACS Appl. Mater. Interfaces 2020, 12, 6633.

- 26.Niu, G.; Wang, S.; Li, J.; et al. Oxygen doping in nickel oxide for highly efficient planar perovskite solar cells. J. Mater. Chem. A Mater. 2018, 6, 4721.

- 27.Biesinger, M.C.; Payne, B.P.; Lau, L.W.M.; et al. X-ray photoelectron spectroscopic chemical state quantification of mixed nickel metal, oxide and hydroxide systems. Surf. Interface Anal. 2009, 41, 324.

- 28.Biesinger, M.C.; Payne, B.P.; Grosvenor, A.P.; et al. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 2011, 257, 2717.

- 29.Islam, M.B.; Yanagida, M.; Shirai, Y.; et al. NiOx Hole Transport Layer for Perovskite Solar Cells with Improved Stability and Reproducibility. ACS Omega 2017, 2, 2291.

- 30.Predanocy, M.; Hotový, I.; Čaplovičová, M. Structural, optical and electrical properties of sputtered NiO thin films for gas detection. Appl. Surf. Sci. 2017, 395, 208.

- 31.Islam, R.; Chen, G.; Ramesh, P.; et al. Investigation of the Changes in Electronic Properties of Nickel Oxide (NiOx) Due to UV/Ozone Treatment. ACS Appl. Mater. Interfaces 2017, 9, 17201.

- 32.Fu, F.; Pisoni, S.; Jeangros, Q.; et al. I2 vapor-induced degradation of formamidinium lead iodide based perovskite solar cells under heat–light soaking conditions. Energy Environ. Sci. 2019, 12, 3074.

- 33.Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A 1976, 32, 751.

- 34.Bakar, W.A.W.A.; Othman, M.Y.; Ali, R.; et al. The Investigation of Active Sites on Nickel Oxide Base Catalysts towards the In-situ Reactions of Methanation and Desulfurization. Mod. Appl. Sci. 2009, 3, 35.

- 35.Uhlenbrock, S.; Scharfschwerdt, C.; Neumann, M.; et al. The influence of defects on the Ni 2p and O 1s XPS of NiO. J. Phys. Condens. Matter 1992, 4, 7973.

How to Cite

Dussouillez, M.; Mensi, M.; Marozau, I.; Jeangros, Q.; Nicolay, S.; Ballif, C.; Paracchino, A. Stabilizing the Chemistry of NiOx in Perovskite Solar Cells to Pass the Damp Heat Test. Materials and Sustainability 2025, 1 (1), 6. https://doi.org/10.53941/matsus.2025.100006.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References