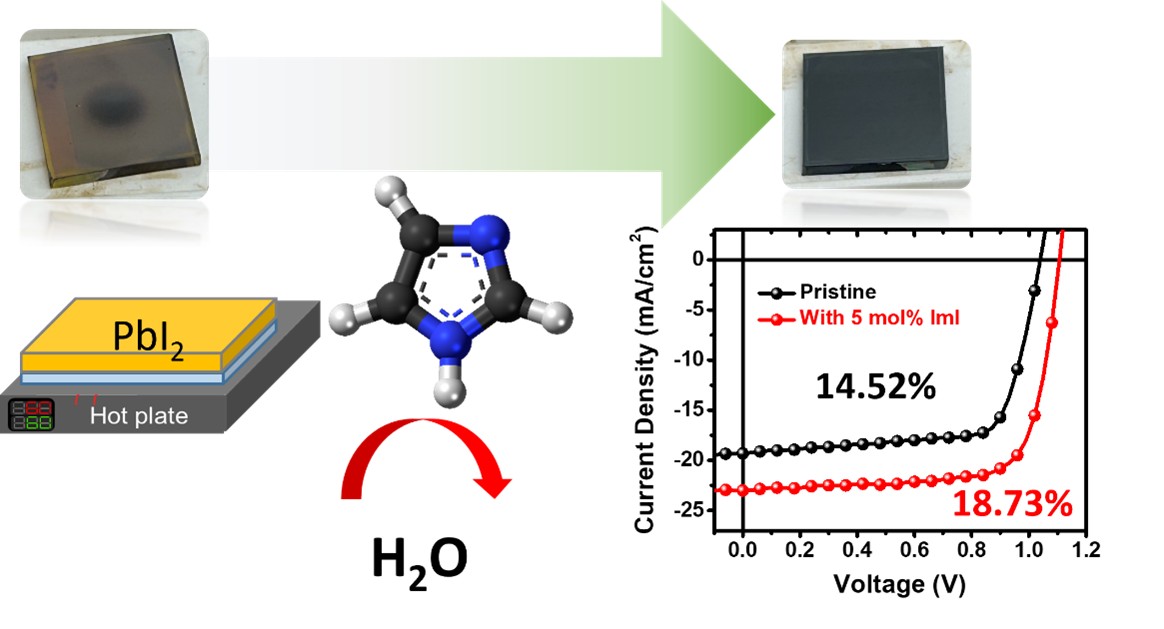

The development of efficient, scalable, and low-cost photovoltaic technologies is critical for advancing global energy sustainability. Perovskite solar cells (PSCs) have emerged as promising alternatives to traditional single-junction silicon-based solar cells due to their high power conversion efficiency (PCE) and solution-processable active materials. However, conventional fabrication methods typically require inert environments and complex anti-solvent processes, which increase production costs and limit scalability. Sequential deposition offers a promising solution by decoupling the solidification and crystallization steps, thereby eliminating the need for anti-solvent processes. Despite these advantages, fabricating high-quality mixed-cation perovskite layers in air remains a significant challenge, primarily due to the sensitivity of perovskite materials to moisture, which disrupts phase stability and perovskite phase formation. In this study, we addressed these challenges by developing an air-processable perovskite layer using a sequential deposition process. To overcome moisture-induced issues, pre-heating the substrate was employed to reduce surface tension and improve film coverage. Furthermore, imidazole iodide (ImI) was introduced into the PbI2 precursor to effectively cap Pb sites, preventing moisture interference and promoting a complete transition to the α-phase of formamidinium lead iodide (FAPbI3) without residual PbI2 in air. These strategies enabled the production of PSCs in air achieving a champion PCE of 18.73%. Stability testing further demonstrated that PSCs incorporating ImI exhibited a T80 device lifetime exceeding 500 hours. The finding demonstrates its role in moisture prevention and durability enhancement for the air-processable perovskite solar cells.

- Open Access

- Article

High-Efficiency Perovskite Solar Cell with an Air-Processable Active Layer via Sequential Deposition

- Shih-Han Huang 1, 2,

- Chien-Te Tsou 3,

- Yu-Hung Hsiao 2, 4,

- Chia-Feng Li 2, 5,

- You-Ren Chen 3,

- Wei-Fang Su 3, 5, *,

- Yu-Ching Huang 1, 2, 3, *

Author Information

Received: 04 Dec 2024 | Revised: 26 Dec 2024 | Accepted: 30 Dec 2024 | Published: 02 Jan 2025

Abstract

Graphical Abstract

Keywords

air-processable | mixed-cation | additive | sequential deposition | perovskite

References

- 1.Im, J.-H.; Lee, C.-R.; Lee, J.-W.; et al. 6.5% efficient perovskite quantum-dot-sensitized solar cell. Nanoscale 2011, 3, 4088–4093.

- 2.Huang, Z.; Bai, Y.; Huang, X.; et al. Anion–π interactions suppress phase impurities in FAPbI3 solar cells. Nature 2023, 623, 531–537.

- 3.Park, N.-G. Perovskite solar cells: An emerging photovoltaic technology. Mater. Today 2015, 18, 65–72.

- 4.Jeon, N.J.; Noh, J.H.; Kim, Y.C.; et al. Solvent engineering for high-performance inorganic–organic hybrid perovskite solar cells. Nat. Mater. 2014, 13, 897–903.

- 5.Yang, M.; Li, Z.; Reese, M.O.; et al. Perovskite ink with wide processing window for scalable high-efficiency solar cells. Nat. Energy 2017, 2, 17038.

- 6.Prasanna, R.; Gold-Parker, A.; Leijtens, T.; et al. Band Gap Tuning via Lattice Contraction and Octahedral Tilting in Perovskite Materials for Photovoltaics. J. Am. Chem. Soc. 2017, 139, 11117–11124.

- 7.Egger, D.A.; Kronik, L. Role of Dispersive Interactions in Determining Structural Properties of Organic–Inorganic Halide Perovskites: Insights from First-Principles Calculations. J. Phys. Chem. Lett. 2014, 5, 2728–2733.

- 8.Zhou, L.; Neukirch, A.J.; Vogel, D.J.; et al. Density of States Broadening in CH3NH3PbI3 Hybrid Perovskites Understood from ab Initio Molecular Dynamics Simulations. ACS Energy Lett. 2018, 3, 787–793.

- 9.Chen, J.; Kim, S.-G.; Park, N.-G. FA0.88Cs0.12PbI3−(PF6) Interlayer Formed by Ion Exchange Reaction between Perovskite and Hole Transporting Layer for Improving Photovoltaic Performance and Stability. Adv. Mater. 2018, 30, 1801948.

- 10.Jeong, J.; Kim, M.; Seo, J.; et al. Pseudo-halide anion engineering for α-FAPbI3 perovskite solar cells. Nature 2021, 592, 381–385.

- 11.Zhang, W.; Saliba, M.; Moore, D.T.; et al. Ultrasmooth organic–inorganic perovskite thin-film formation and crystallization for efficient planar heterojunction solar cells. Nat. Commun. 2015, 6, 6142.

- 12.Huang, S.-H.; Tian, K.-Y.; Huang, H.-C.; et al. Controlling the Morphology and Interface of the Perovskite Layer for Scalable High-Efficiency Solar Cells Fabricated Using Green Solvents and Blade Coating in an Ambient Environment. ACS Appl. Mater. Interfaces 2020, 12, 26041–26049.

- 13.Li, C.-F.; Huang, H.-C.; Huang, S.-H.; et al. High-Performance Perovskite Solar Cells and Modules Fabricated by SlotDie Coating with Nontoxic Solvents Nanomaterials [Online], 2023.

- 14.Huang, S.-H.; Guan, C.-K.; Lee, P.-H.; et al. Toward All Slot-Die Fabricated High Efficiency Large Area Perovskite Solar Cell Using Rapid Near Infrared Heating in Ambient Air. Adv. Energy Mater. 2020, 10, 2001567.

- 15.Kulkarni, S.A.; Baikie, T.; Boix, P.P.; et al. Band-gap tuning of lead halide perovskites using a sequential deposition process. J. Mater. Chem. A 2014, 2, 9221–9225.

- 16.Chen, H. Two-Step Sequential Deposition of Organometal Halide Perovskite for Photovoltaic Application. Adv. Funct. Mater. 2017, 27, 1605654.

- 17.Ummadisingu, A.; Grätzel, M. Revealing the detailed path of sequential deposition for metal halide perovskite formation. Sci. Adv. 2018, 4, e1701402.

- 18.Tai, Q.; You, P.; Sang, H.; et al. Efficient and stable perovskite solar cells prepared in ambient air irrespective of the humidity. Nat. Commun. 2016, 7, 11105.

- 19.Liu, K.; Luo, Y.; Jin, Y.; et al. Moisture-triggered fast crystallization enables efficient and stable perovskite solar cells. Nat. Commun. 2022, 13, 4891.

- 20.Glowienka, D.; Huang, S.-H.; Lee, P.-H.; et al. Understanding the Dominant Physics Mechanisms on the p-i-n Perovskite Solar Cells Fabricated by Scalable Slot-Die Coating Process in Ambient Air. Sol. RRL 2024, 8, 2300791.

- 21.Wang, H.; Ye, F.; Liang, J.; et al. Pre-annealing treatment for high-efficiency perovskite solar cells via sequential deposition. Joule 2022, 6, 2869–2884.

- 22.Xu, Q.; Shi, B.; Li, Y.; et al. Diffusible Capping Layer Enabled Homogeneous Crystallization and Component Distribution of Hybrid Sequential Deposited Perovskite. Adv. Mater. 2024, 36, 2308692.

- 23.Lin, D.; Gao, Y.; Zhang, T.; et al. Vapor Deposited Pure α-FAPbI3 Perovskite Solar Cell via Moisture-Induced Phase Transition Strategy. Adv. Funct. Mater. 2022, 32, 2208392.

- 24.Stoumpos, C.C.; Malliakas, C.D.; Kanatzidis, M.G. Semiconducting Tin and Lead Iodide Perovskites with Organic Cations: Phase Transitions, High Mobilities, and Near-Infrared Photoluminescent Properties. Inorganic Chem. 2013, 52, 9019–9038.

- 25.Montecucco, R.; Quadrivi, E.; Po, R.; et al. All-Inorganic Cesium-Based Hybrid Perovskites for Efficient and Stable Solar Cells and Modules. Adv. Energy Mater. 2021, 11, 2100672.

- 26.Li, Z.; Yang, M.; Park, J.-S.; et al. Stabilizing Perovskite Structures by Tuning Tolerance Factor: Formation of Formamidinium and Cesium Lead Iodide Solid-State Alloys. Chem. Mat. 2016, 28, 284–292.

- 27.Cheng, Y.; Xu, X.; Xie, Y.; et al. 18% High-Efficiency Air-Processed Perovskite Solar Cells Made in a Humid Atmosphere of 70% RH. Solar RRL 2017, 1, 1700097.

- 28.Yoon, S.J.; Kuno, M.; Kamat, P.V. Shift Happens. How Halide Ion Defects Influence Photoinduced Segregation in Mixed Halide Perovskites. ACS Energy Lett. 2017, 2, 1507–1514.

- 29.Philippe, B.; Park, B.-W.; Lindblad, R.; et al. Chemical and Electronic Structure Characterization of Lead Halide Perovskites and Stability Behavior under Different Exposures—A Photoelectron Spectroscopy Investigation. Chem. Mat. 2015, 27, 1720–1731.

- 30.Yu, X.; Qin, Y.; Peng, Q. Probe Decomposition of Methylammonium Lead Iodide Perovskite in N2 and O2 by in Situ Infrared Spectroscopy. J. Phys. Chem. A 2017, 121, 1169–1174.

- 31.Meng, K.; Wang, X.; Xu, Q.; et al. In Situ Observation of Crystallization Dynamics and Grain Orientation in Sequential Deposition of Metal Halide Perovskites. Adv. Funct. Mater. 2019, 29, 1902319.

- 32.Węcławik, M.; Gągor, A.; Piecha, A.; et al. Synthesis, crystal structure and phase transitions of a series of imidazolium iodides. CrystEngComm 2013, 15, 5633–5640.

- 33.Weber, O.J.; Marshall, K.L.; Dyson, L.M.; et al. Structural diversity in hybrid organic–inorganic lead iodide materials. Acta Crystallogr. Sect. B 2015, 71, 668–678.

How to Cite

Huang, S.-H.; Tsou, C.-T.; Hsiao, Y.-H.; Li, C.-F.; Chen, Y.-R.; Su, W.-F.; Huang, Y.-C. High-Efficiency Perovskite Solar Cell with an Air-Processable Active Layer via Sequential Deposition. Materials and Sustainability 2025, 1 (1), 3. https://doi.org/10.53941/matsus.2025.100003.

RIS

BibTex

Copyright & License

Copyright (c) 2025 by the authors.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Contents

References